Pool wall prefabricated block splicing structure suitable for static pressure assembled pool and construction method thereof

A prefabricated block and prefabricated technology, applied in large-capacity bulk material storage, building types, buildings, etc., can solve the problems of easy bending of prefabricated block steel bars on the pool wall, so as to ensure the tensile and flexural properties and increase splicing Strength, the effect of ensuring the quality of the butt joint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

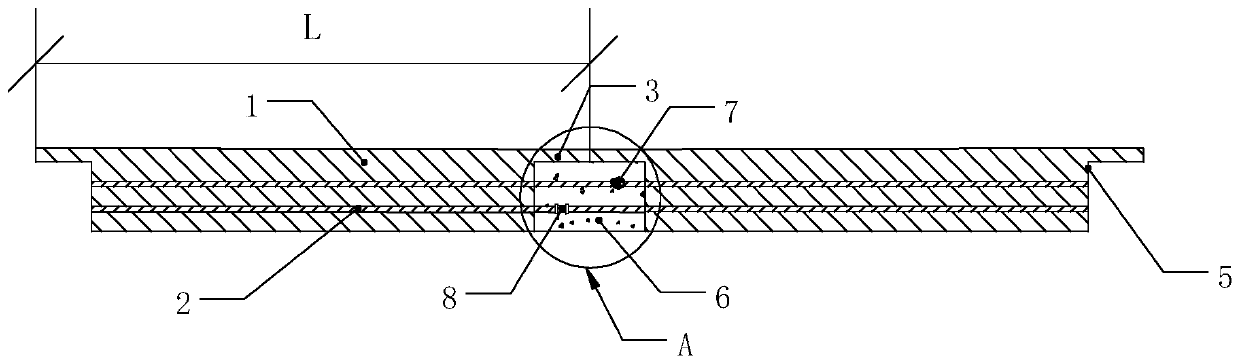

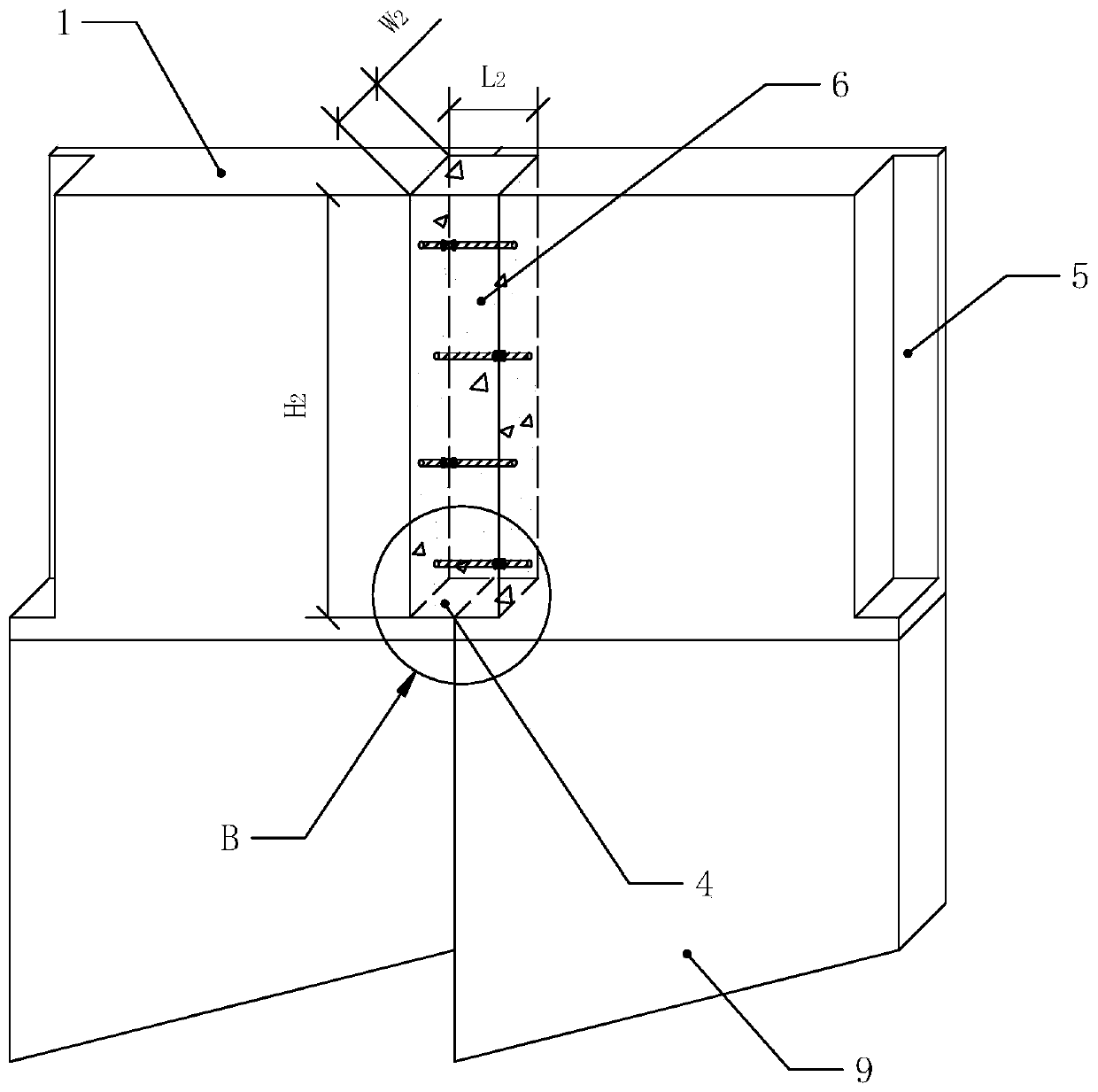

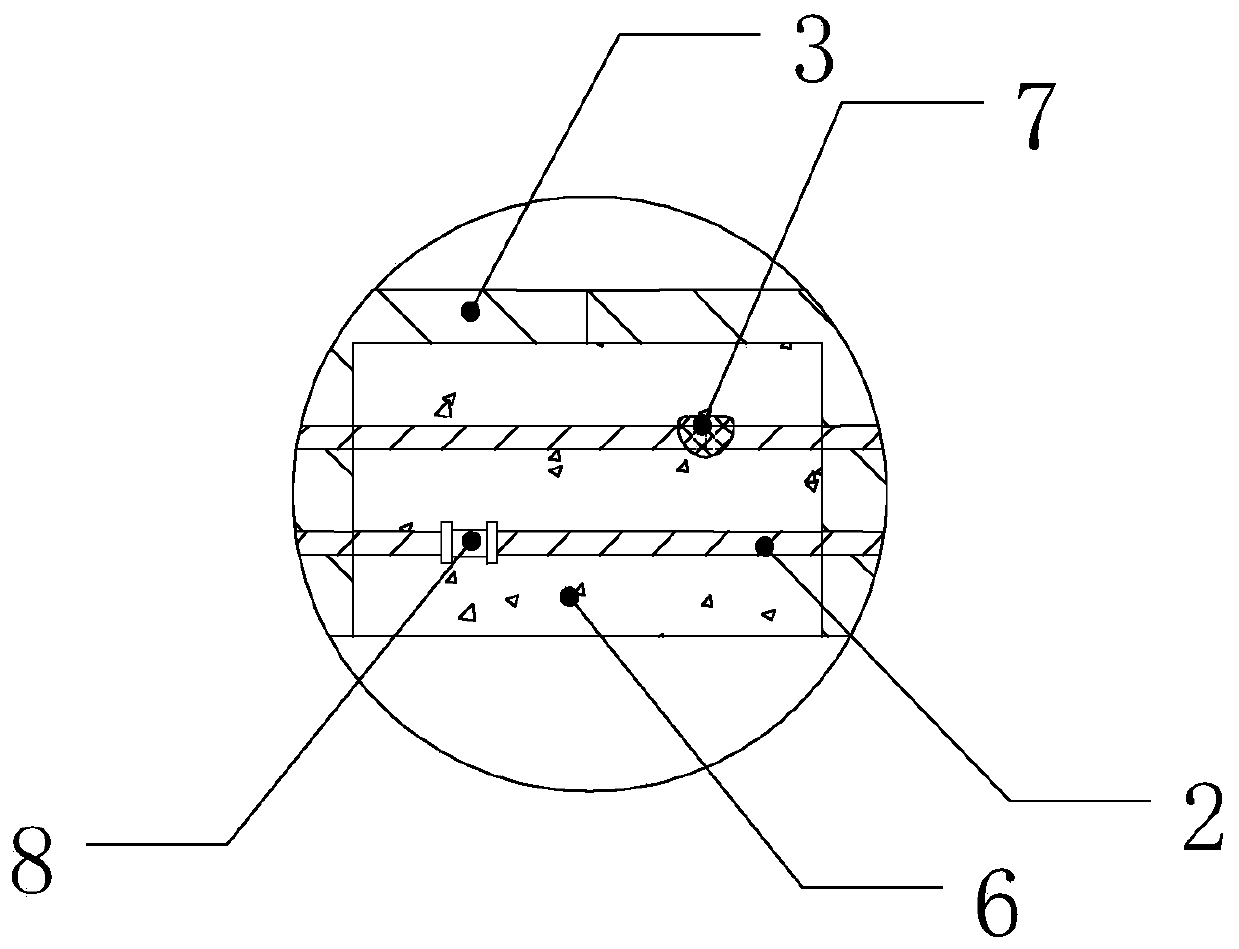

[0049] The length L1 of the static pressure assembled pool 10 is 6m, the width W1 is 6m, the height H1 is 2m, and the thickness T is 0.3m. The length L2 of the cast-in-place block 6 is 0.3m, the width W2 is 0.15m, the height H2 is 1.8m, and the length L of the cast-in-place block is 3m.

Embodiment 2

[0051] The length L1 of the static pressure assembled pool 10 is 8m, the width W1 is 8m, the height H1 is 2.5m, and the thickness T is 0.4m. The length L2 of the cast-in-place block 6 is 0.4m, the width W2 is 0.25m, the height H2 is 2.4m, and the length L of the prefabricated block is 3m.

Embodiment 3

[0053] The length L1 of the static pressure assembled pool 10 is 7m, the width W1 is 7m, the height H1 is 2m, and the thickness T is 0.35m. The length L2 of the cast-in-place block 6 is 0.35m, the width W2 is 0.2m, the height H2 is 1.9m, and the length L of the prefabricated block is 3m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com