A high-pressure waterway anti-seepage method and a high-pressure waterway annular anti-seepage curtain

A technology of high-pressure water channel and anti-seepage curtain, which is applied in the fields of high-pressure water channel anti-seepage, high-pressure water channel annular anti-seepage curtain, and rock mass anti-seepage treatment field, achieving the effects of convenient operation, reducing leakage and saving project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

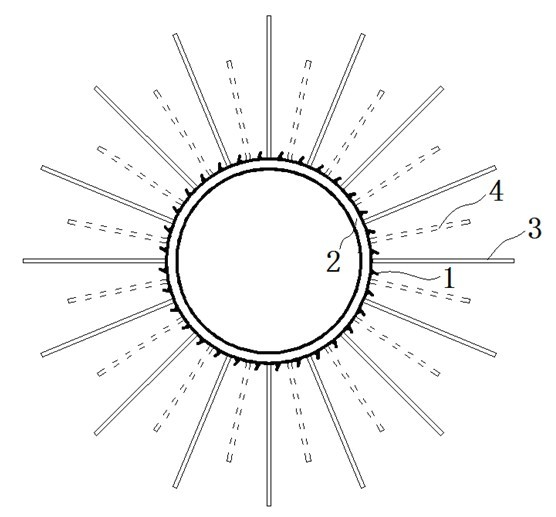

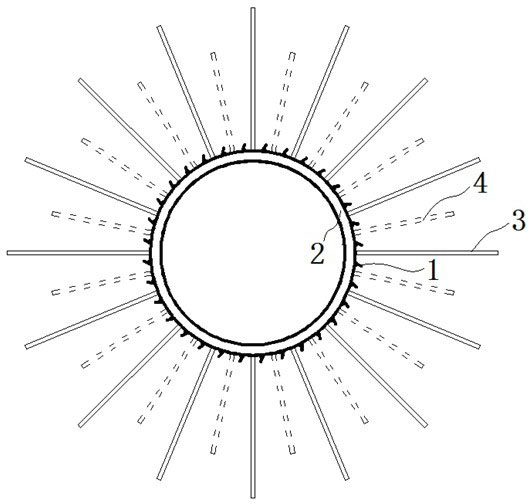

[0021] A high-pressure waterway anti-seepage method, according to the completeness of the surrounding rock mass of the high-pressure waterway, after the construction of the reinforced concrete lining 2 is completed, the consolidation grouting holes 3 and the anti-seepage grouting holes 4 are respectively arranged on the periphery of the high-pressure waterway surrounding rock 1 rock body, and then The conventional grouting pressure, that is, the grouting pressure of 0.3~0.5 is used for anti-seepage grouting and surrounding rock 1 consolidation grouting to improve the mechanical properties of the surrounding rock of the high-pressure waterway; finally, the grouting pressure close to the splitting pressure of the surrounding rock, that is, greater than 2.0Mpa, is used to respectively Consolidation grouting holes 3 and anti-seepage grouting holes 4 are subjected to superfine cement chemical grouting and anti-seepage grouting to achieve the purpose of improving the anti-seepage perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com