Anti-floating system combining anti-floating cement soil pile and anti-floating anchor rod and construction process of anti-floating system

A technology of anti-floating anchor rods and cement-soil piles, which is applied in the direction of foundation structure engineering, sheet pile walls, protection devices, etc., can solve problems such as cracking of grouting body, out-of-control grouting amount, and leakage of basement, and achieve anti-seepage Improve durability, ensure construction quality, and reduce construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

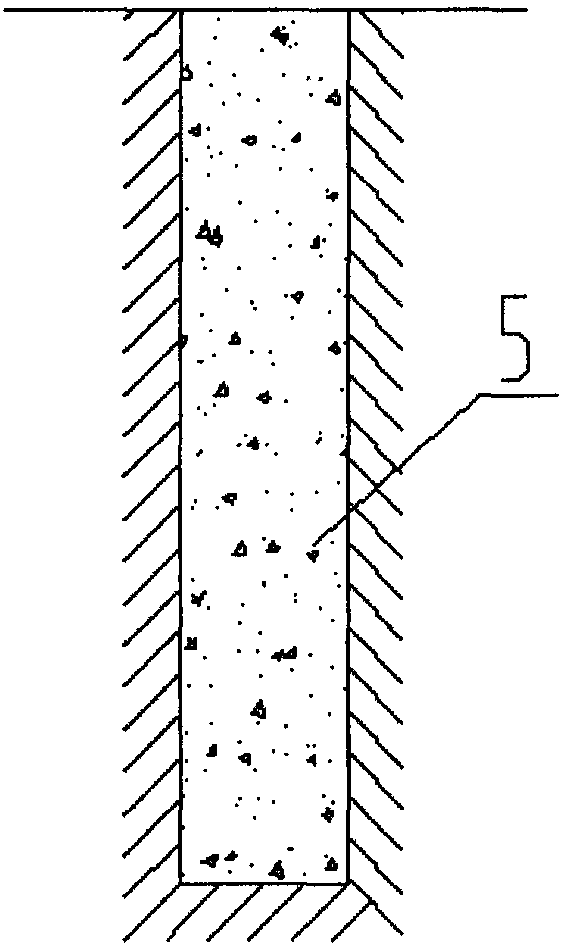

[0049] Embodiment one: Figure 5 As shown, an anti-floating system combining anti-floating cement-soil piles and anti-floating anchors is combined with the basement floor, including anti-floating cement-soil piles 5 and anti-floating anchors arranged in the anti-floating cement-soil piles 5. The top of the anti-floating cement-soil pile 5 is in contact with the lower surface of the basement floor 7 .

[0050] The basement floor 7 is provided with anchor holes.

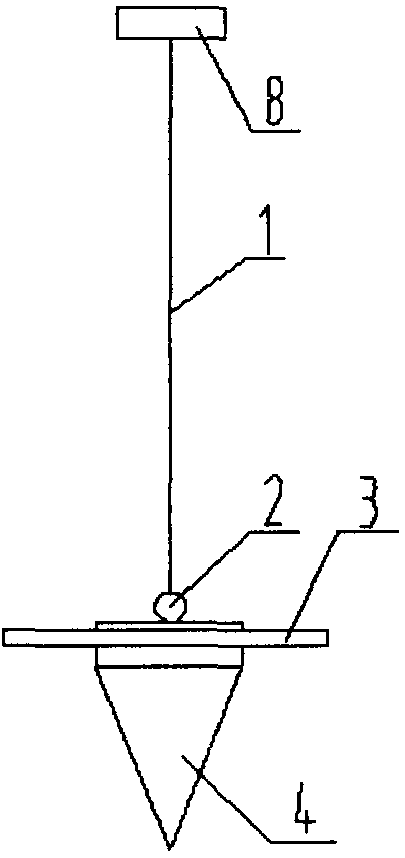

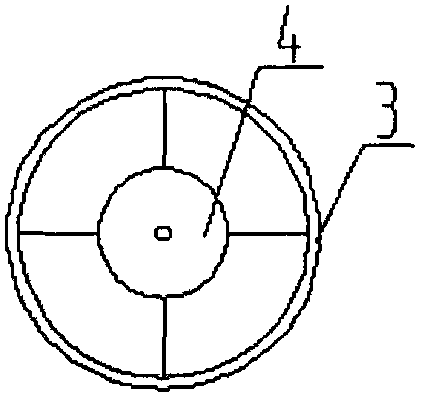

[0051] Such as figure 1 , figure 2 As shown, the anti-floating anchor rod includes an anchor cable 1, a prefabricated reinforced concrete conical anchor head 4 connected to the lower end of the anchor cable 1 through a steel ring 2, and an anchor 8 connected to the upper end of the anchor cable 1. The anchor head 4 is buried at the bottom of the anti-floating cement-soil pile 5, and the outer side of the anchor cable 1 is covered with a double-layer protective casing, the inner protective casing is a special casing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com