Built-in anti-floating anchor blocking structure used in foundation mat for deep-well dewatering well and construction method

A technology for anti-floating anchor rods and foundation bottom plates, which is applied in infrastructure engineering, protection devices, buildings, etc., can solve the problems of inability to repair, long time for sealing and welding, and corrosion of steel threads, so as to improve the anti-floating performance. , Improve waterproof effect, good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In this embodiment, the technical requirements for the construction of the base plate and the cushion, the technical requirements for welding construction, the ratio of the high-pressure grouting of the bladder, etc. will not be described in detail, and the construction of the anti-floating anchor plugging structure built in the deep well dewatering well involved in the present invention will be focused on implementation.

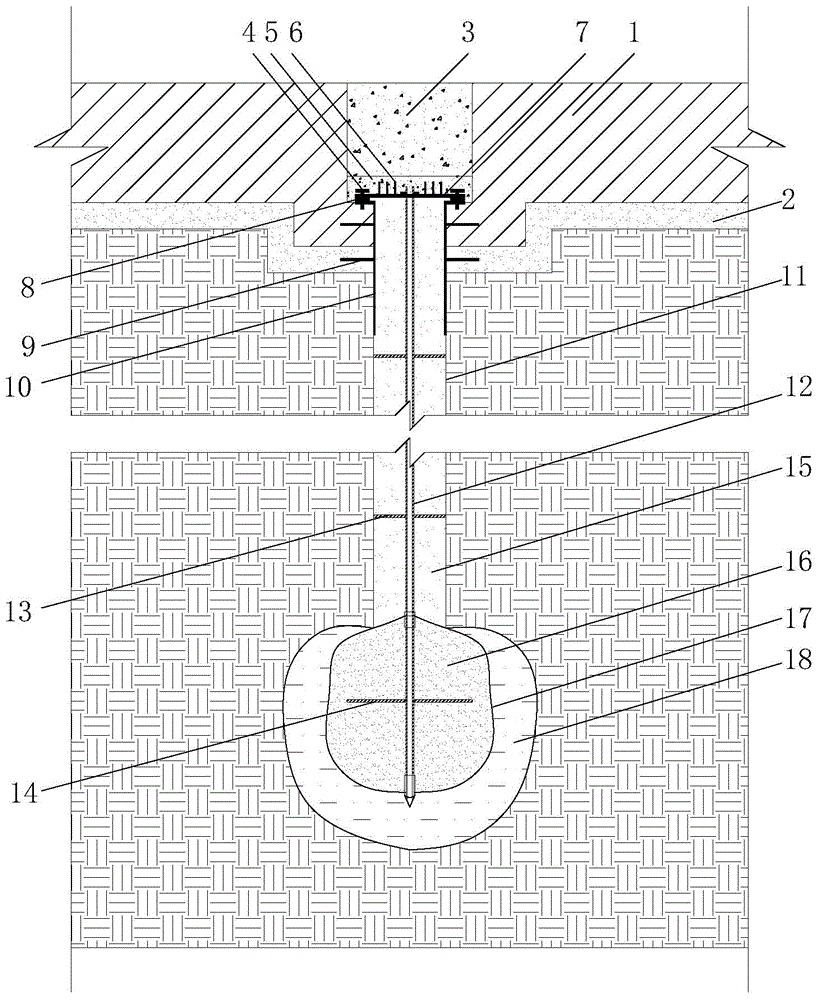

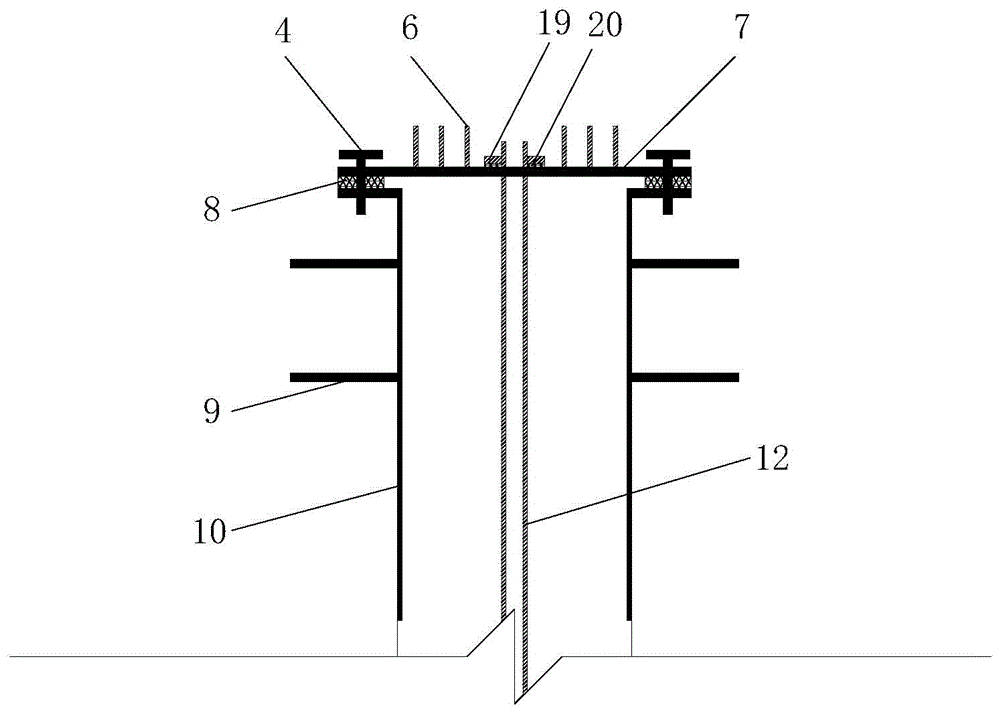

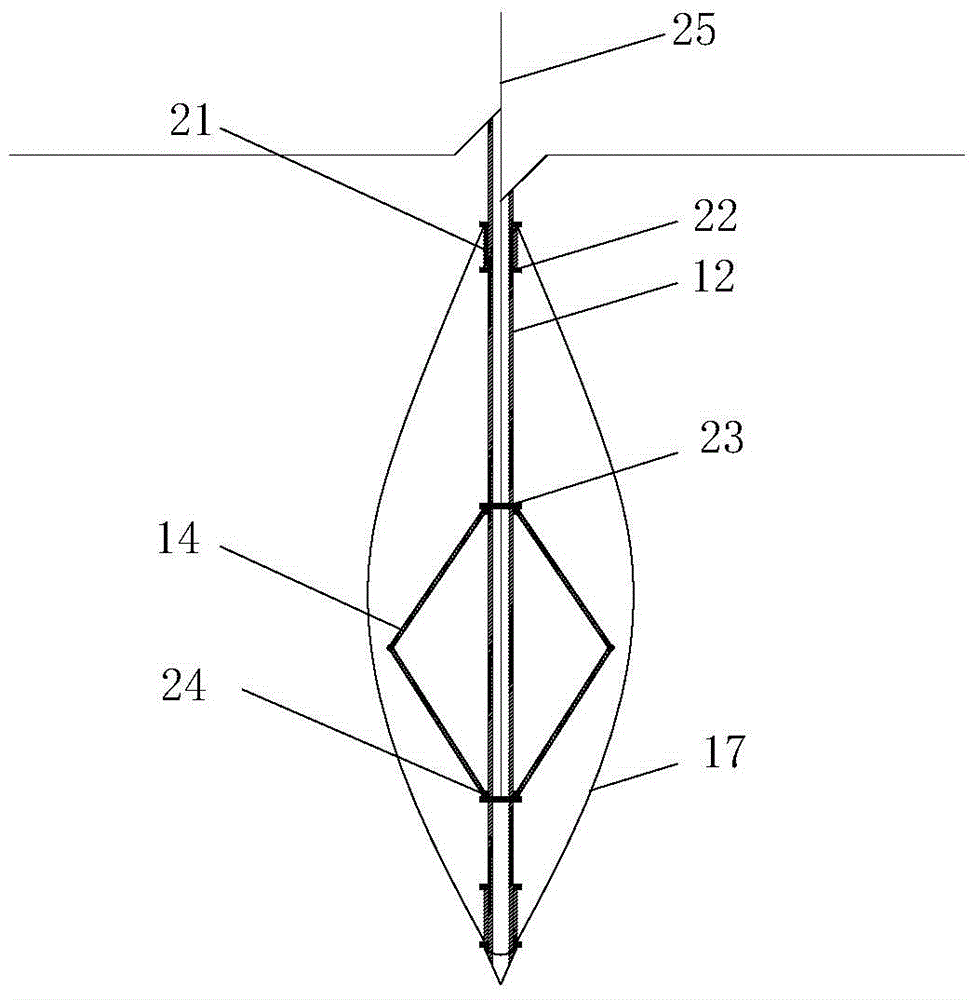

[0035] figure 1 It is a schematic diagram of the plugging structure of the built-in anti-floating anchor rod in the deep well dewatering well of the foundation floor of the present invention, figure 2 It is a schematic diagram of the connection between the steel casing and the plugging steel plate in the present invention, image 3 It is a schematic diagram of the connection between the capsule bag and the rod body in the capsule type anti-floating anchor rod of the present invention. refer to figure 1 The deep well dewatering well shown has a bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com