Bent pipe welding, positioning and locking device

A welding positioning and locking device technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problem of large power consumption, complicated pipe fitting alignment steps, and inability to achieve accurate alignment of straight pipes with branch pipes and curved pipes And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

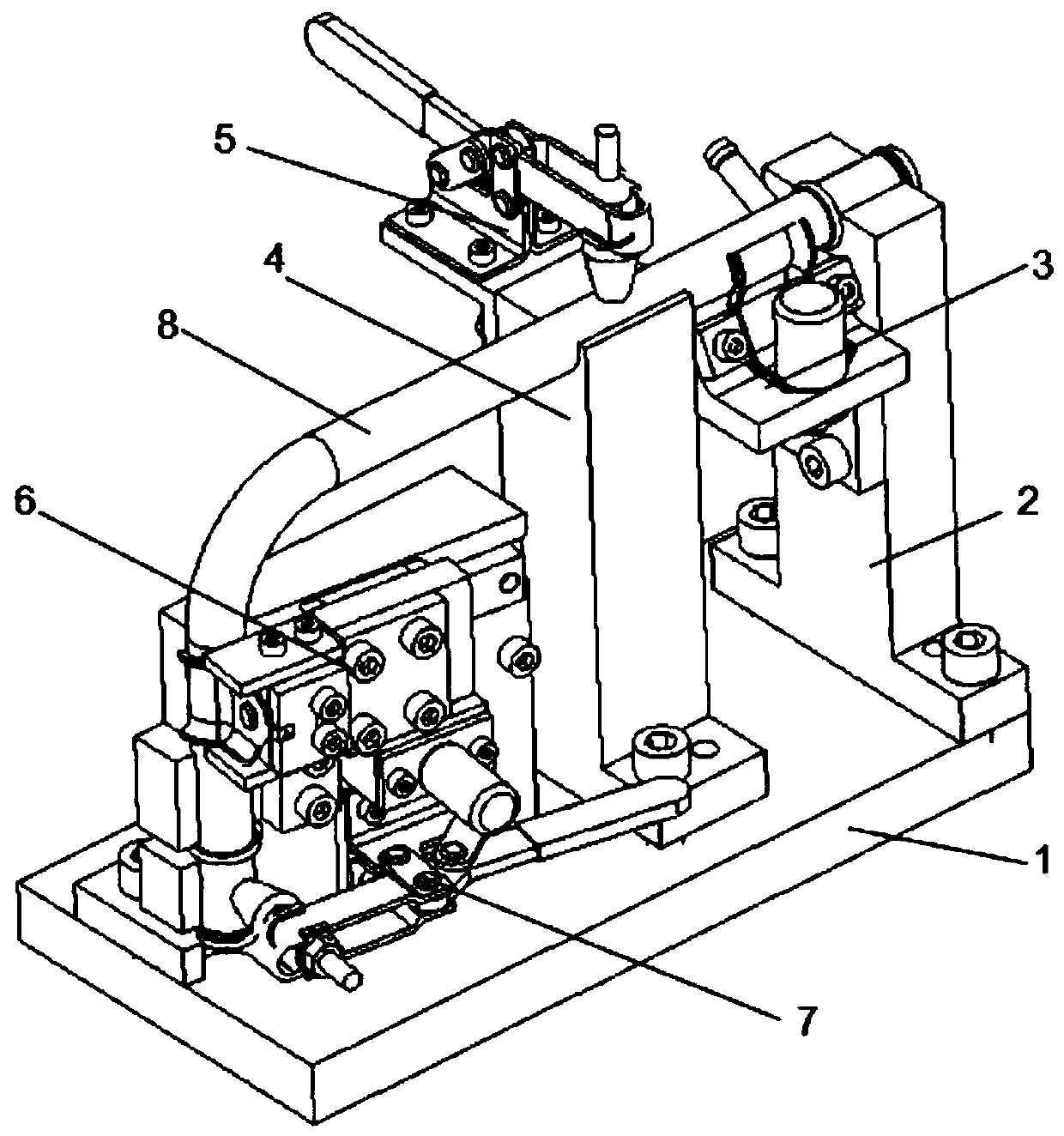

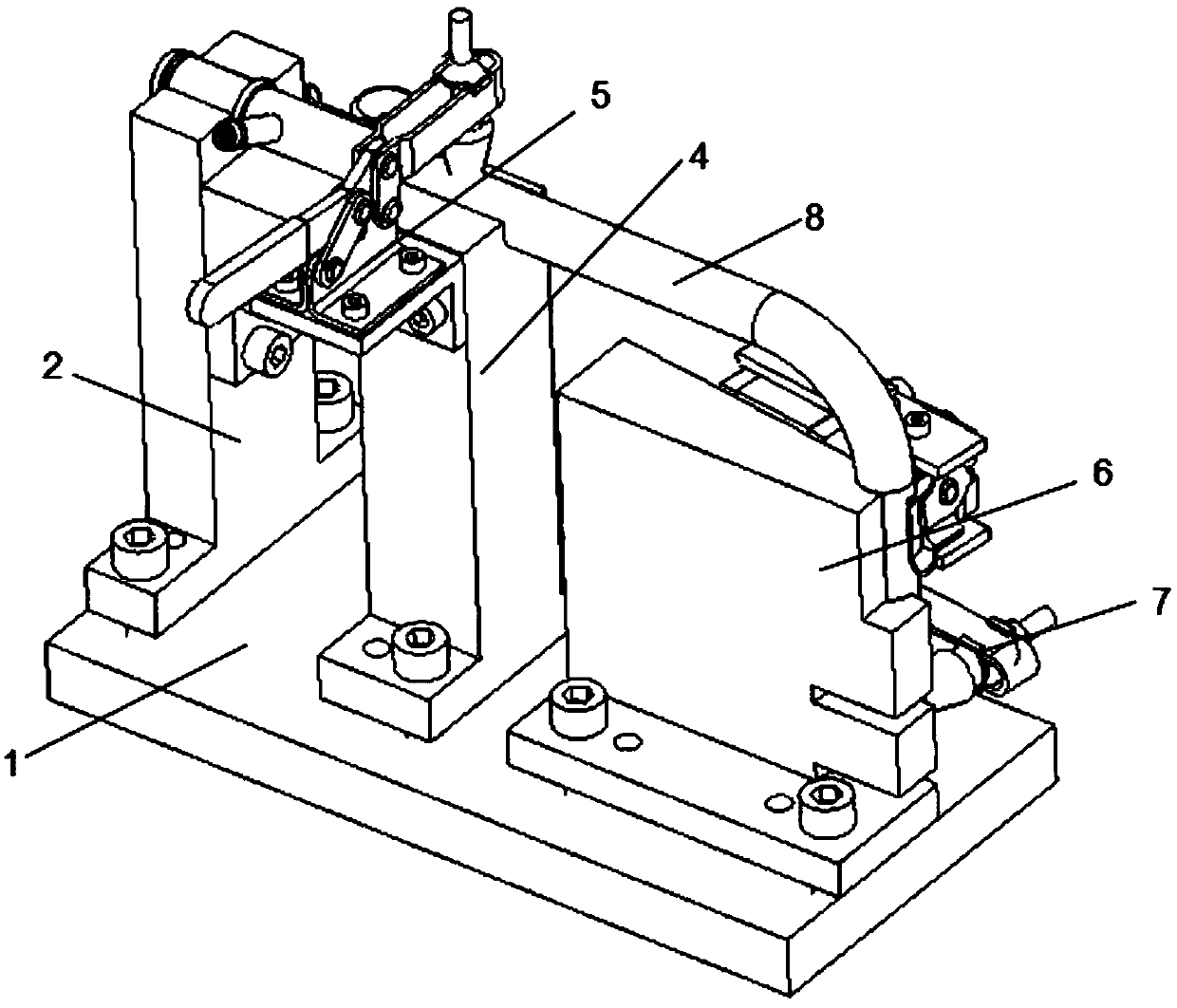

[0028] Embodiment: An elbow welding positioning and locking device.

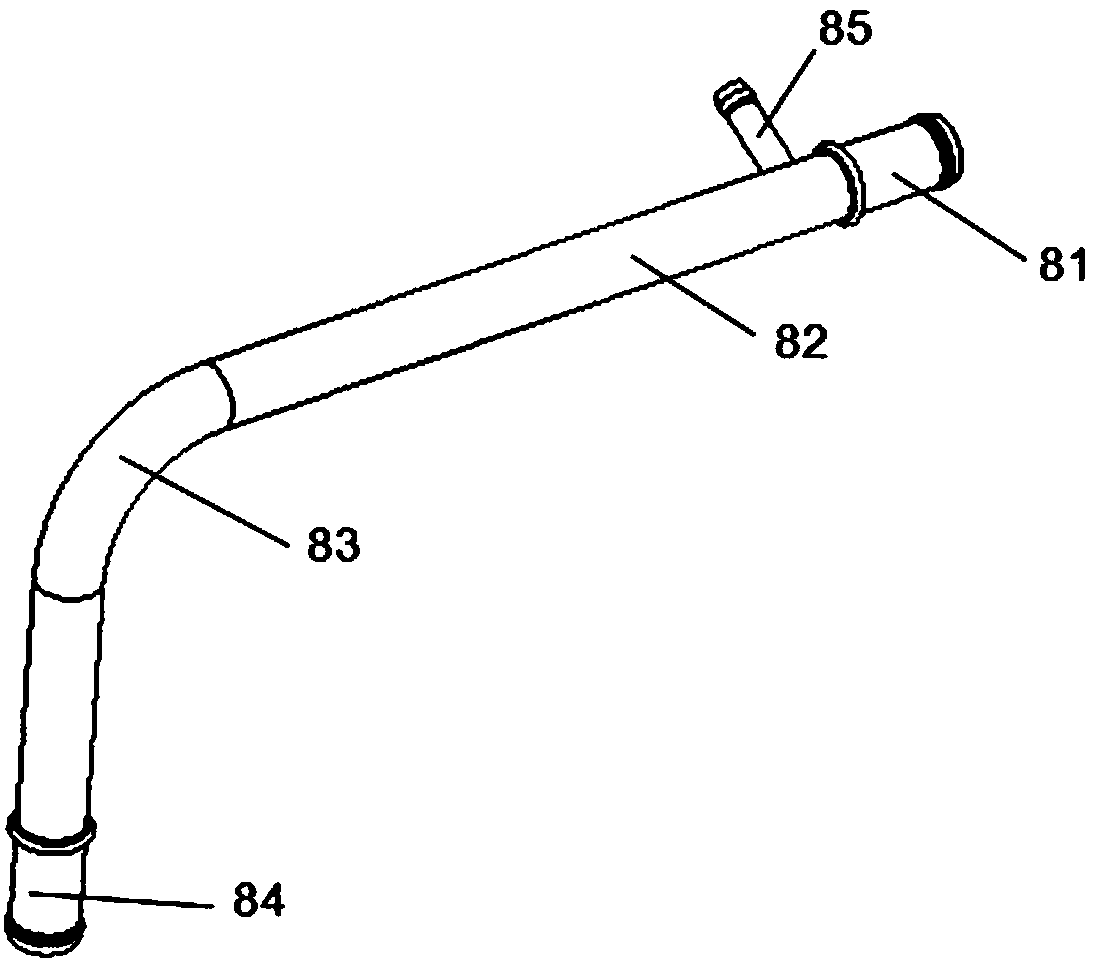

[0029] refer to Figure 1 to Figure 9 As shown, a elbow welding positioning and locking device includes:

[0030] Base 1, the base 1 is a metal plate, used to provide installation space for components such as the first support base 2, the second support base 4 and the elbow positioning mechanism 6;

[0031] The first support seat 2, the second support seat 4 and the elbow positioning mechanism 6 are installed in parallel on the base 1 in turn from right to left. The top of the first support seat 2 is provided with a first positioning groove 21, and the second support seat The top of the seat 4 is provided with a second positioning groove 41, and the centers of the first positioning groove 21 and the second positioning groove 41 are located on the same horizontal straight line, and the length of the first positioning groove 21 is the same as that of the first tube. The tubes 81 have the same length, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com