Steel pile afloat joining limiter and use method thereof

A technology of limiter and steel pile, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve the problems of limited number of door frames and difficulty in ensuring the quality of butt joint at pile mouth, so as to improve construction efficiency and ensure the quality of butt joint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

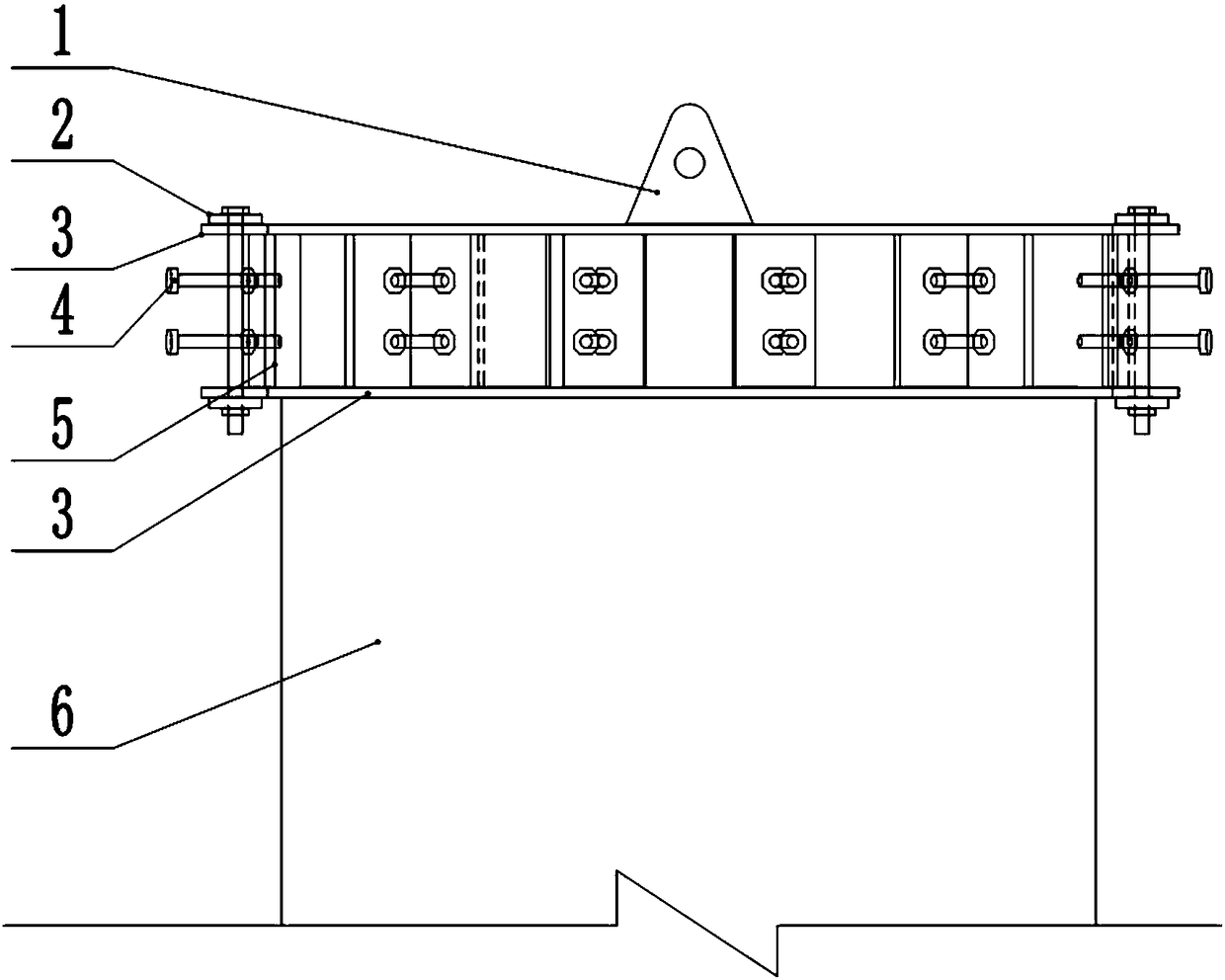

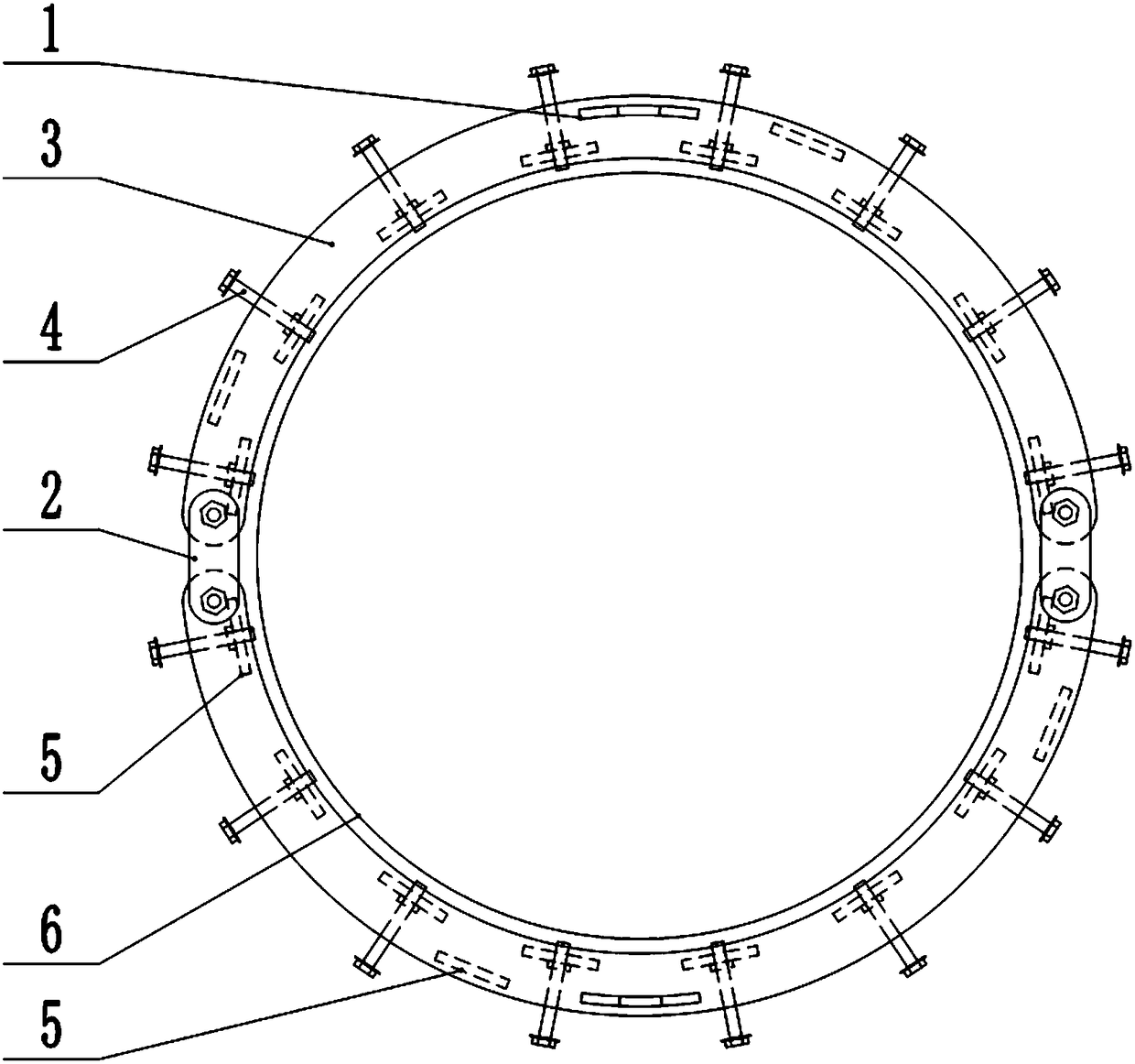

[0027] Such as Figure 1 ~ Figure 2 As shown, a steel pile docking limiter includes a flange plate 3, a vertical connecting plate 5 and a tightening bolt 4, and the flange plate 3 includes two semi-circular steel plates, and the two semi-circular steel plates are butted to form a circle An annular flange plate 3, and the connecting ends of the two semicircular annular steel plates are connected by an arc-shaped connecting plate 2, and the two ends of the arc-shaped connecting plate 2 are respectively connected with two semicircular annular steel plate bolts, and the flange plate 3 has two upper and lower sides. The two layers of flange plates 3 are arranged horizontally and coaxially, at least two lifting lugs 1 are evenly distributed on the top surface of the upper layer of flange plates 3, and the vertical connecting plate 5 is located between the two layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com