Patents

Literature

201results about How to "Easy in and out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

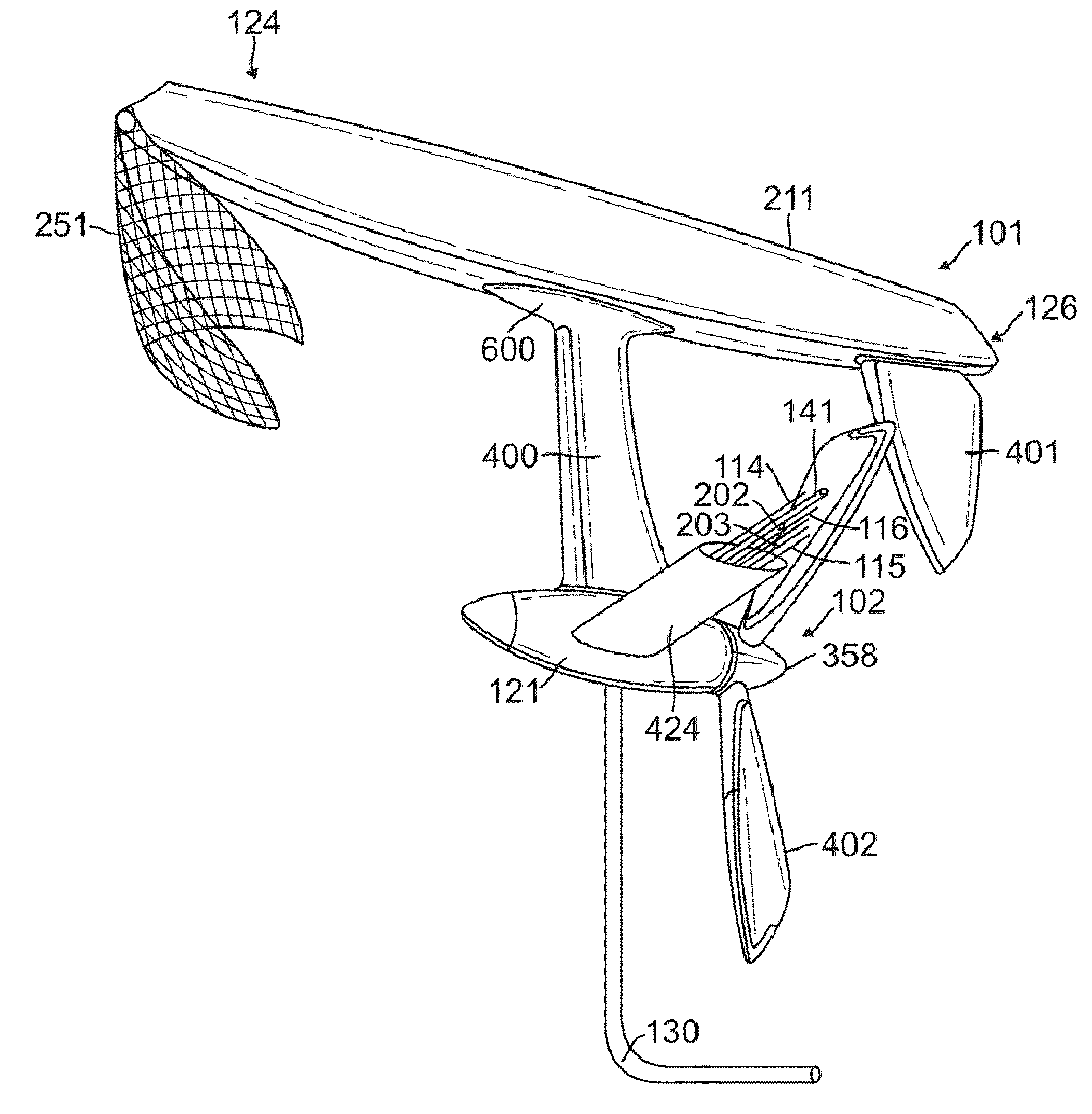

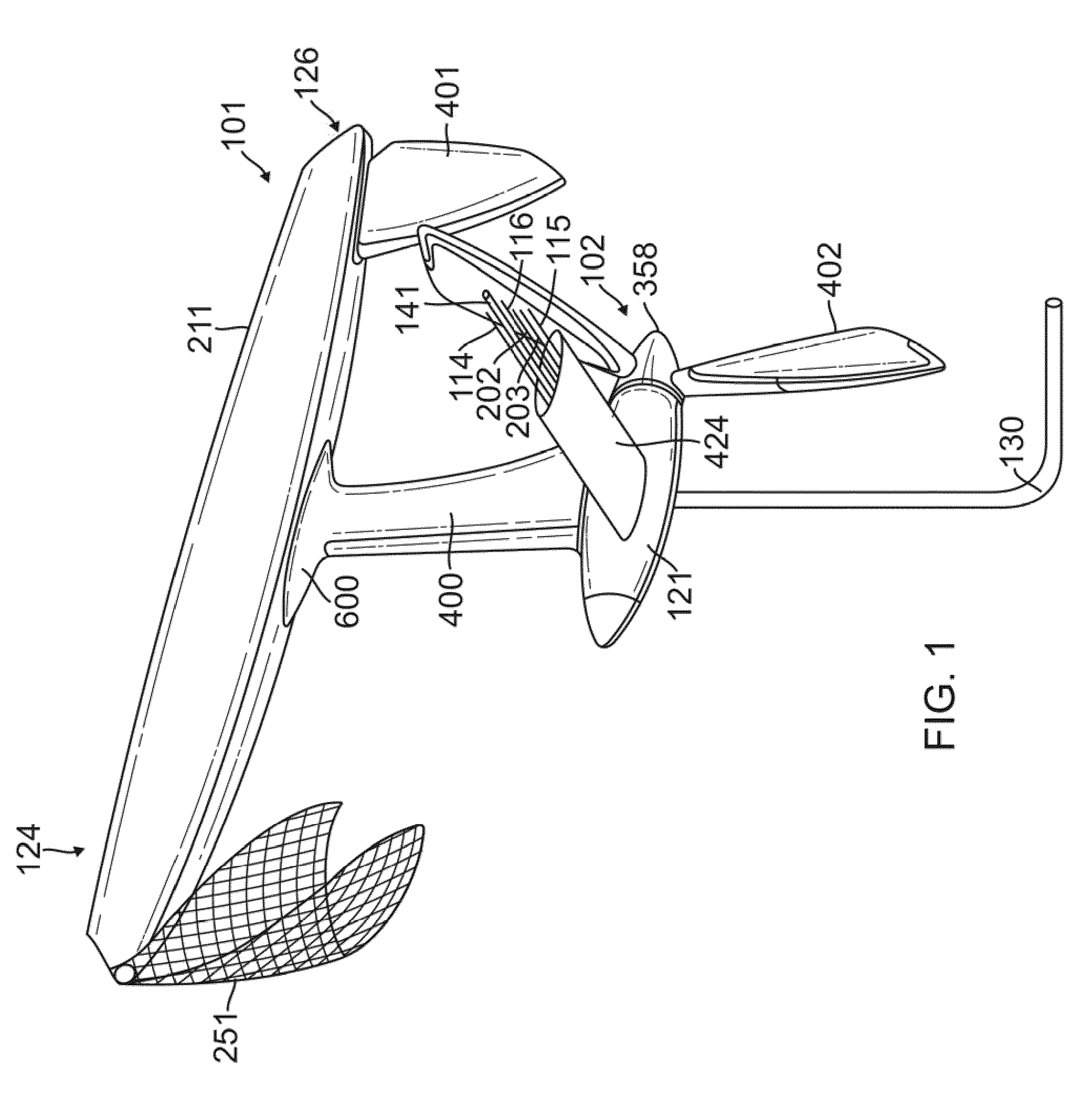

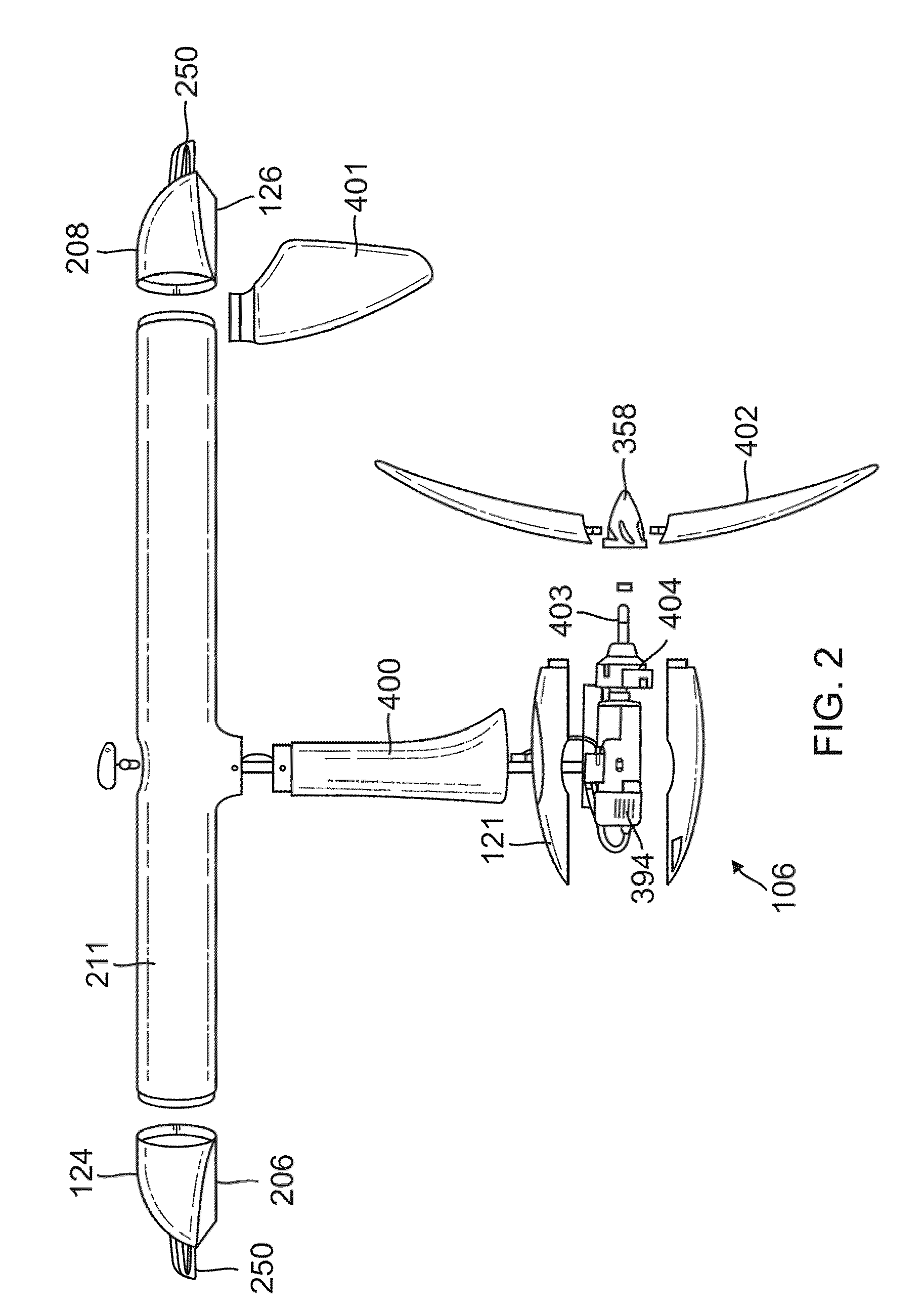

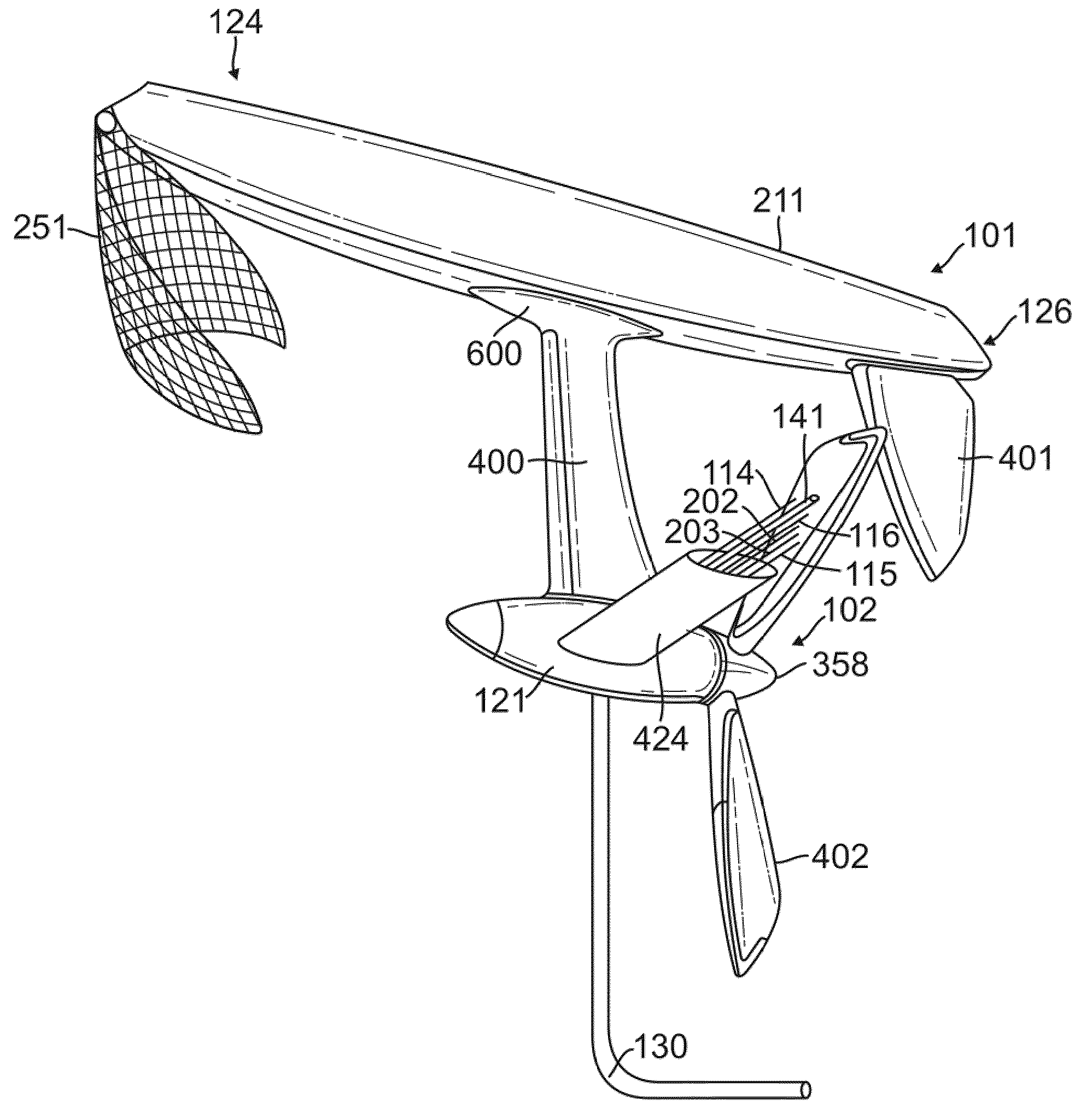

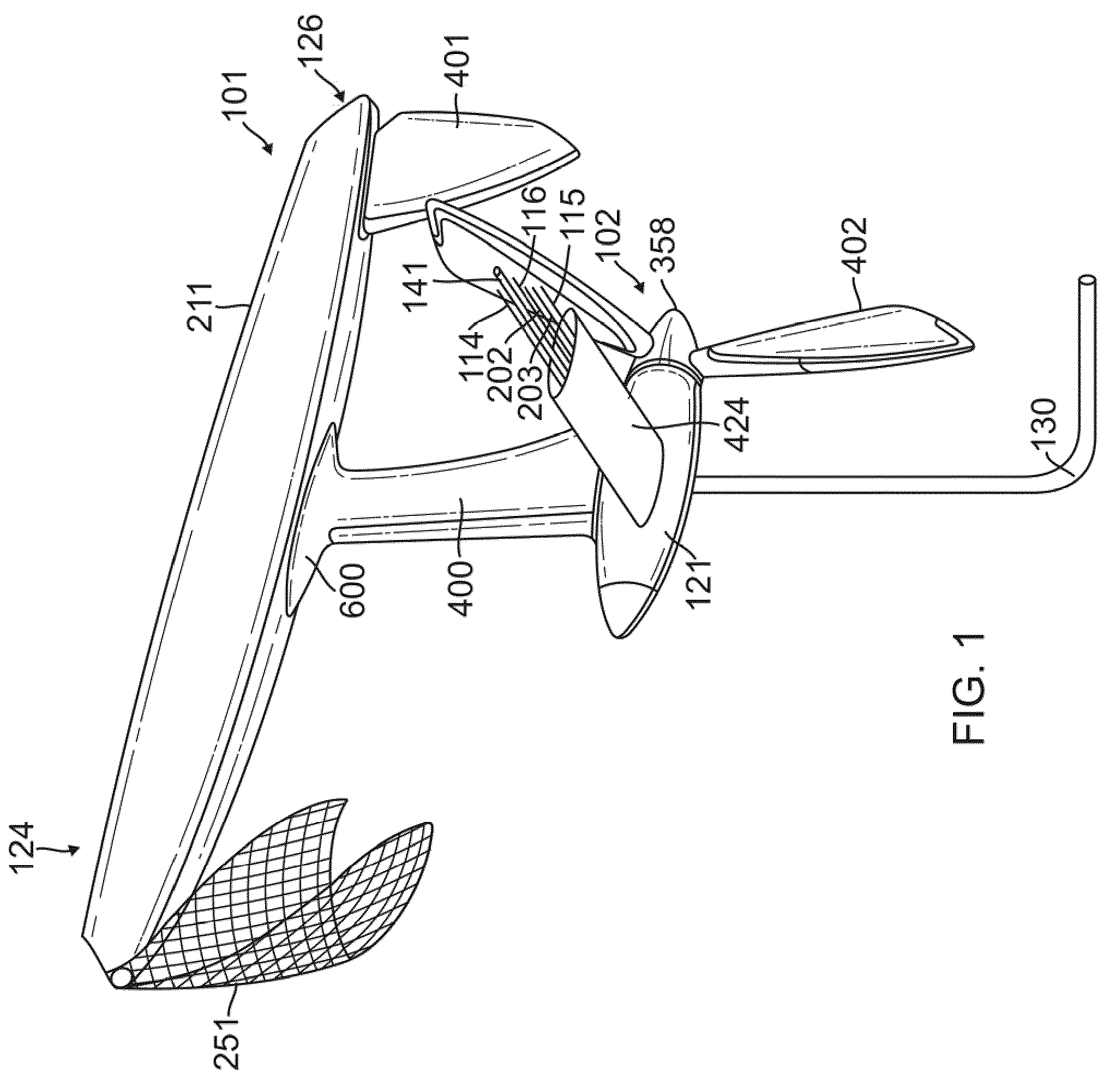

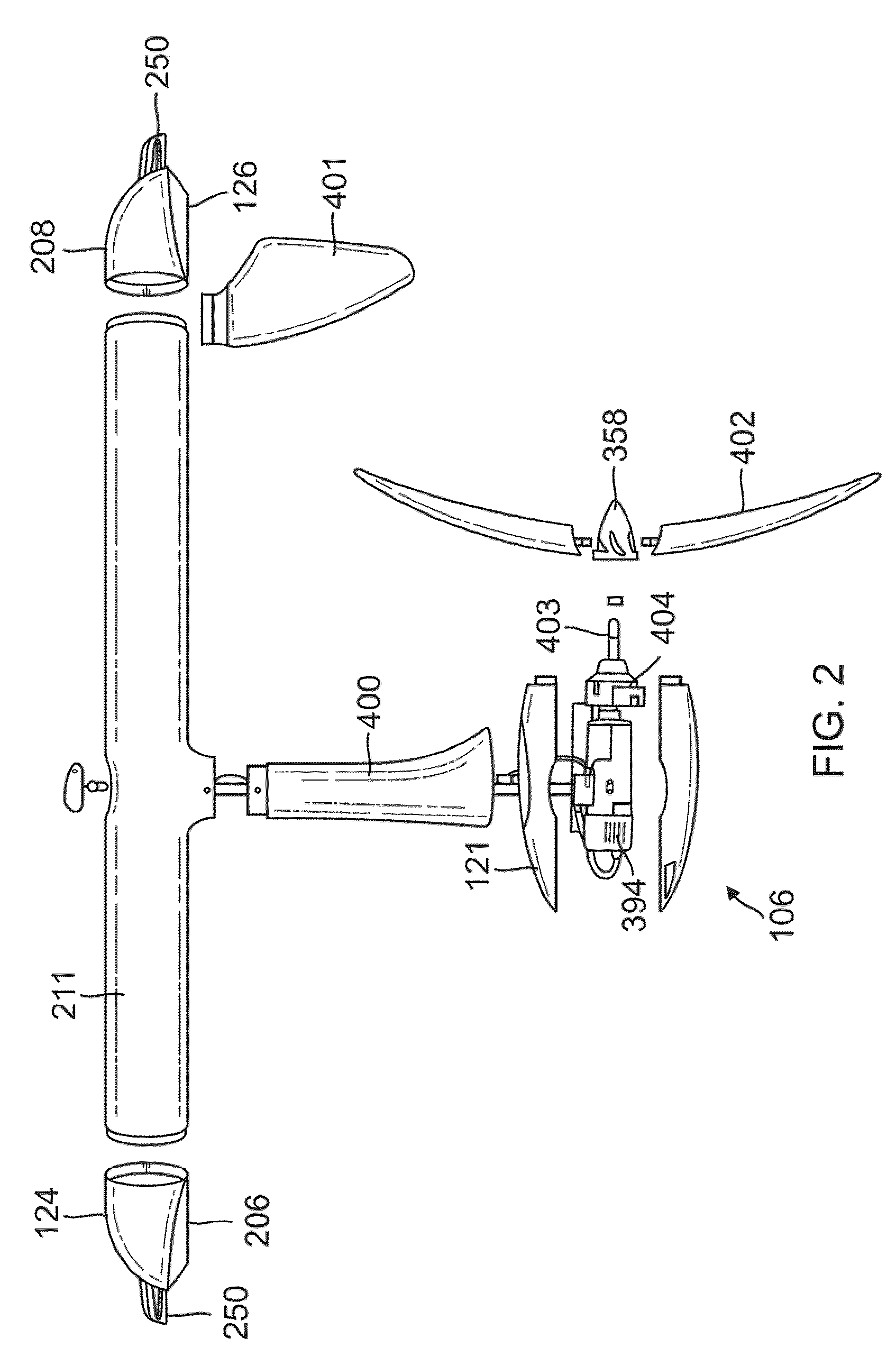

River and tidal power harvester

InactiveUS20090230686A1Reduce buildReduce installationWater resource protectionWaterborne vesselsMooring systemFluvial

An energy module comprising an energy absorber; and a mooring system, comprising a wing-shaped polymer shell attached to the energy absorber, the wing-shaped polymer shell designed to utilize the force of a passing current to create a downward force and thereby reduce any upward motion in the energy module; and a mooring cable housed inside the wing-shaped polymer shell and anchored to maintain the energy module in a fore and aft and a side-to-side position to provide stability, and to negate a rotational force on the energy module.

Owner:CATLIN CHRISTOPHER S

River and tidal power harvester

InactiveUS8102071B2Reduce buildReduce installationWater resource protectionWaterborne vesselsMooring systemEngineering

An energy module comprising an energy absorber; and a mooring system, comprising a wing-shaped polymer shell attached to the energy absorber, the wing-shaped polymer shell designed to utilize the force of a passing current to create a downward force and thereby reduce any upward motion in the energy module; and a mooring cable housed inside the wing-shaped polymer shell and anchored to maintain the energy module in a fore and aft and a side-to-side position to provide stability, and to negate a rotational force on the energy module.

Owner:CATLIN CHRISTOPHER S

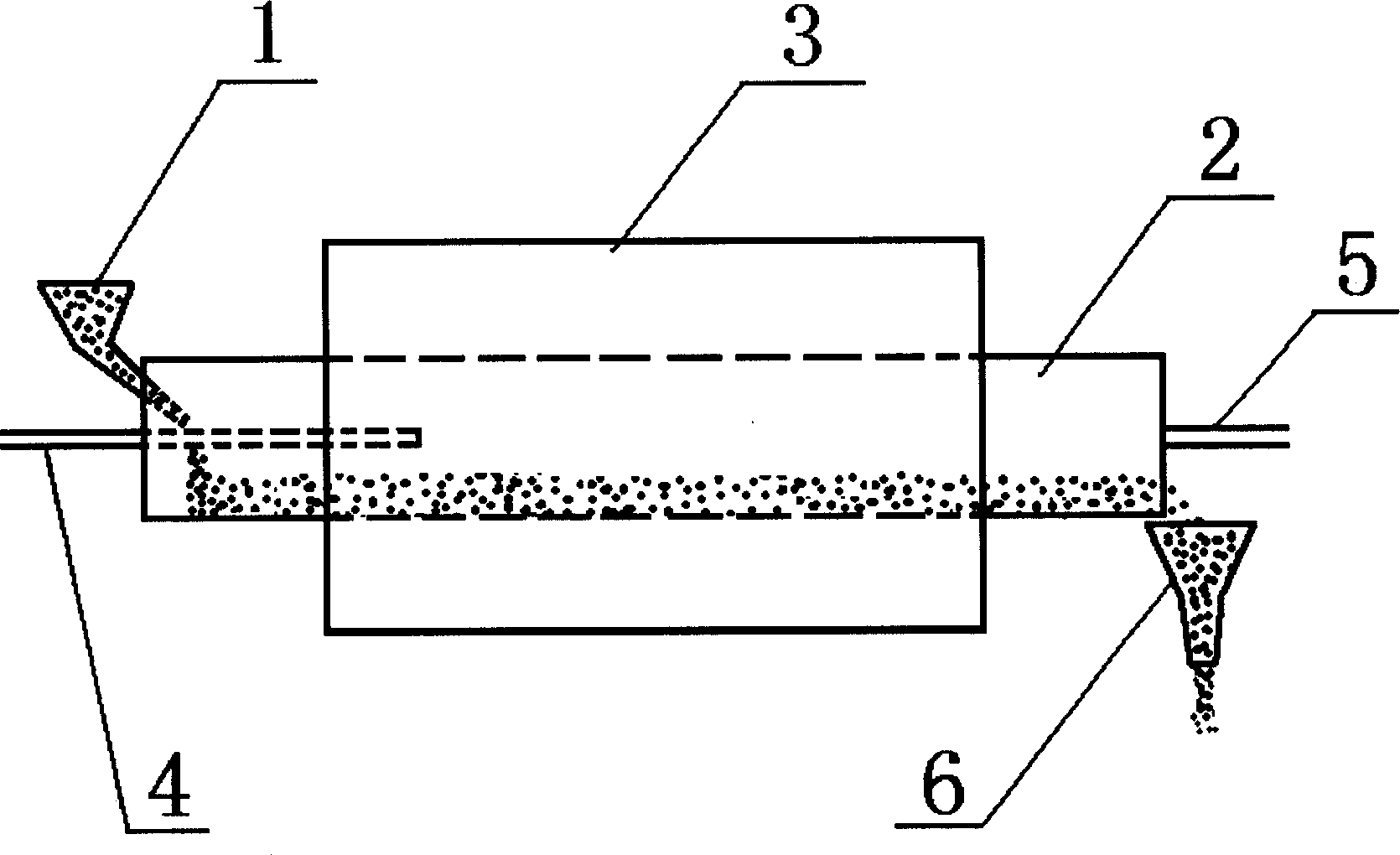

Method for synthesizing lithium ion cell positive cell polar material rotary furnace

InactiveCN1710735AImprove consistencyEvenly heatedElectrode manufacturing processesTemperature controlRotary furnace

The method includes steps: (1) loading hydrate, oxide of lithium or mixed salt with hydrate, oxide or salt of transition metal into revolving furnace; (2) controlling temperature inside revolving furnace at 600 - 950 deg.C and rotation speed at 2 - 5 turns / minute, calcining admixture in revolving furnace for 20 - 40 hours, and then cooling it; (3) anode material of lithium battery is obtained through steps of crushing and sieving cooled materiel. Since calcined materiel is heated evenly inside revolving furnace, thus, physical and chemical characters of obtained materiel are even features are: shortened time for processing in high temperature, and lowered energy consumption.

Owner:广州鸿森材料有限公司

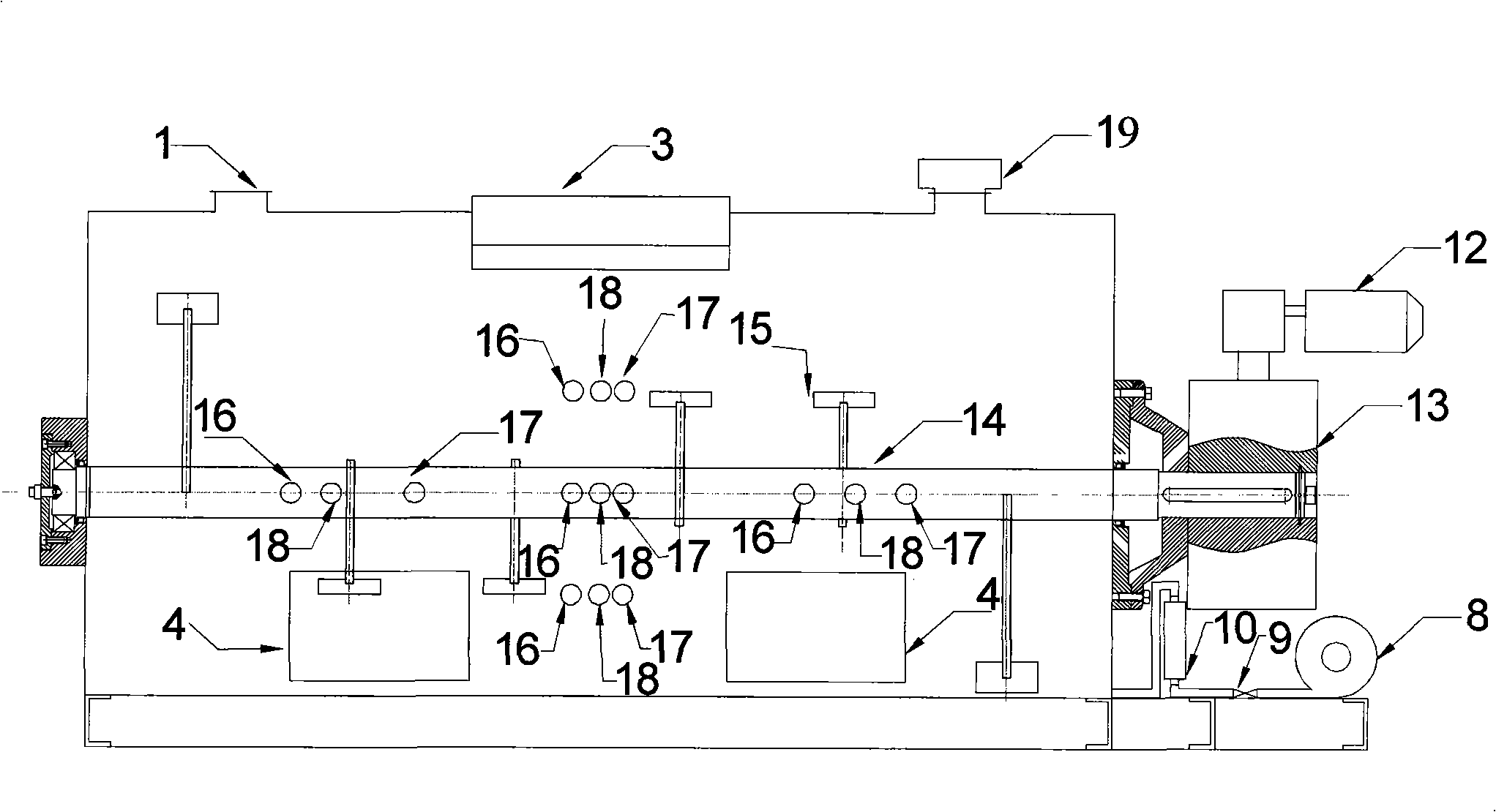

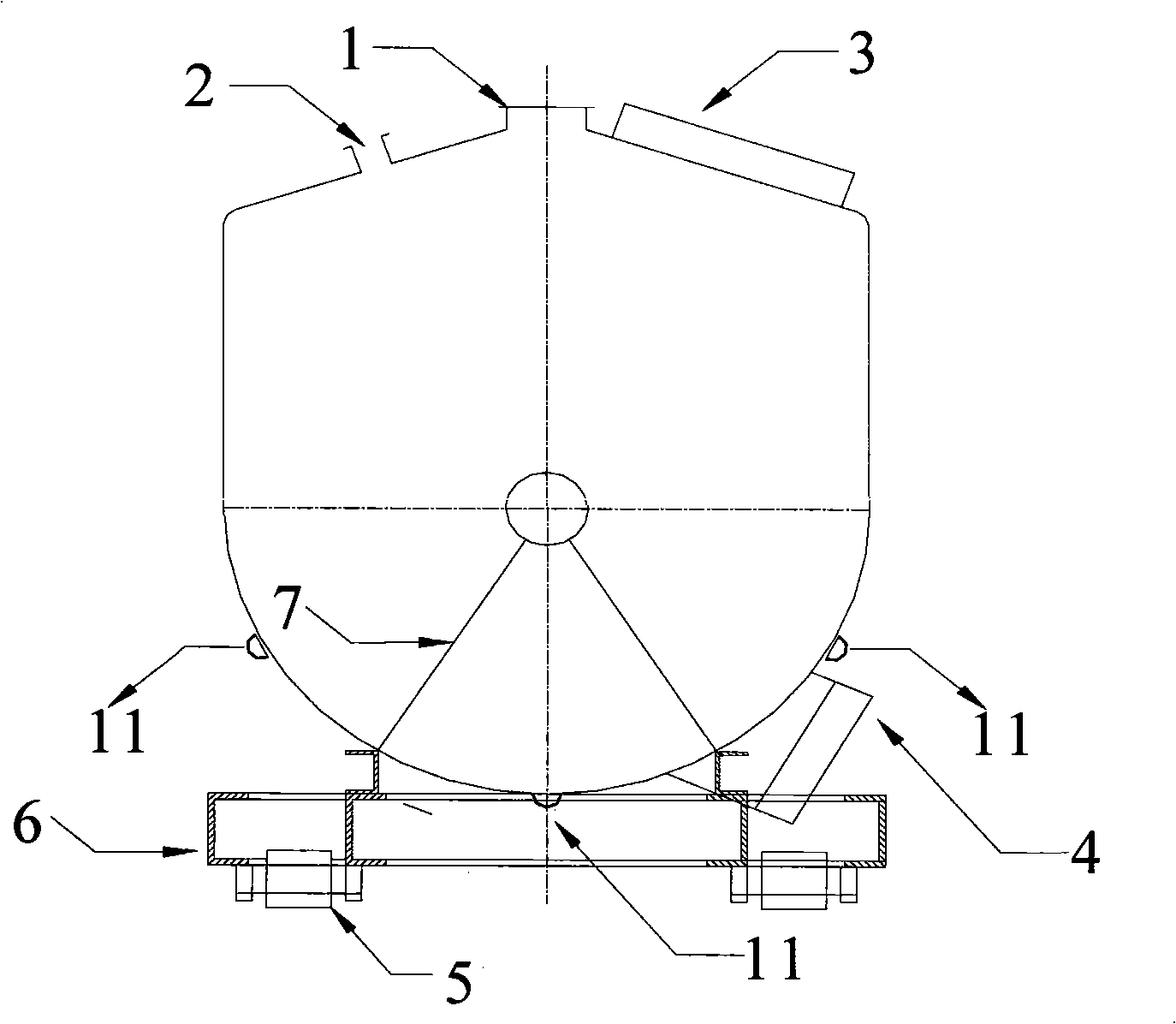

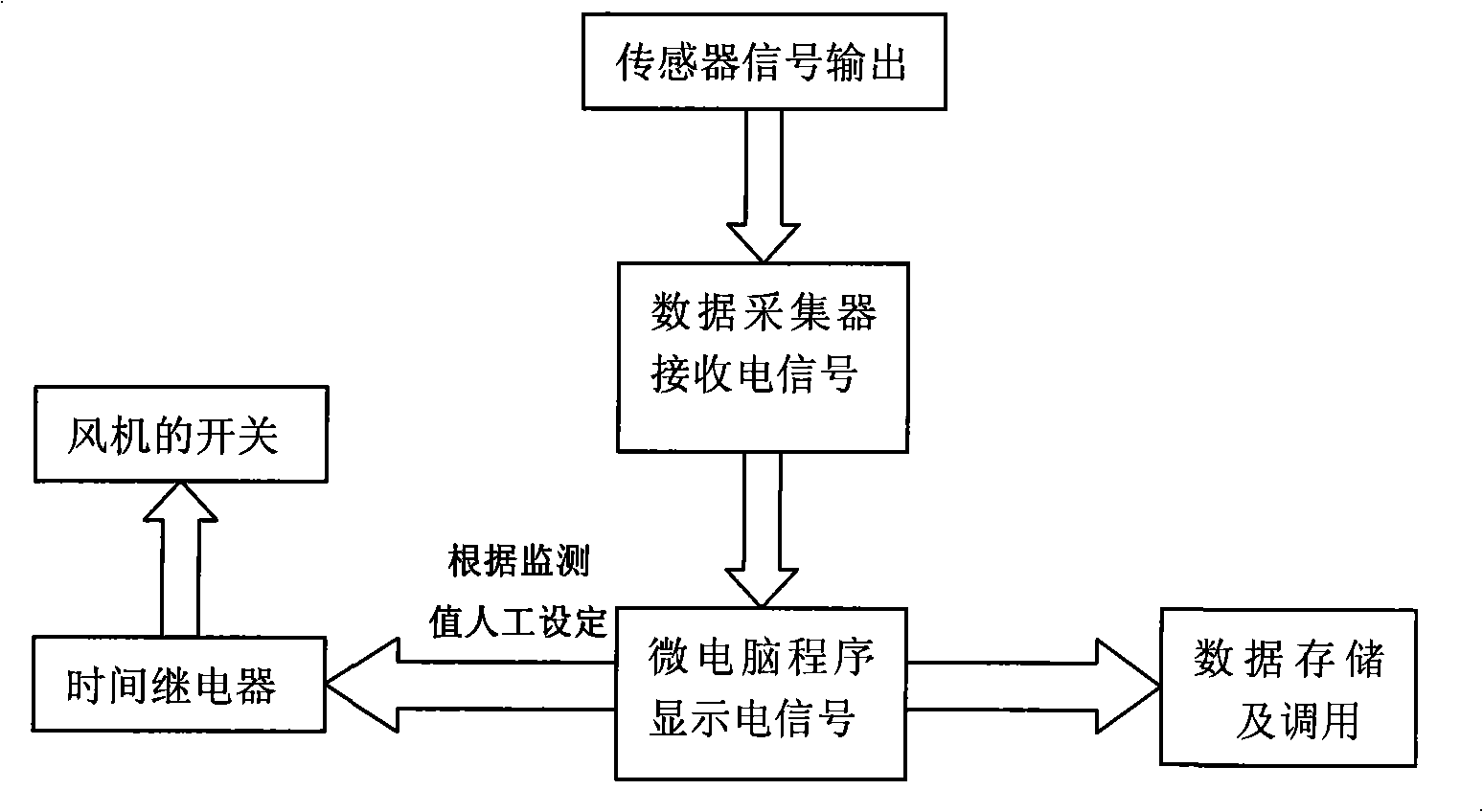

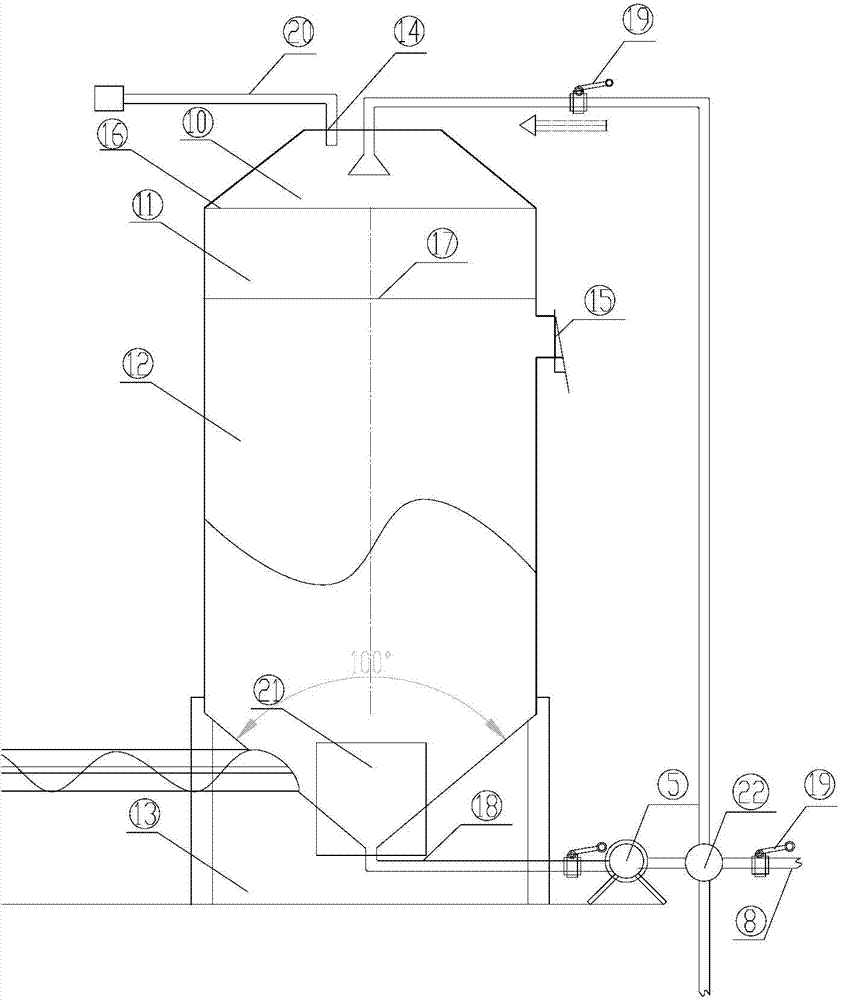

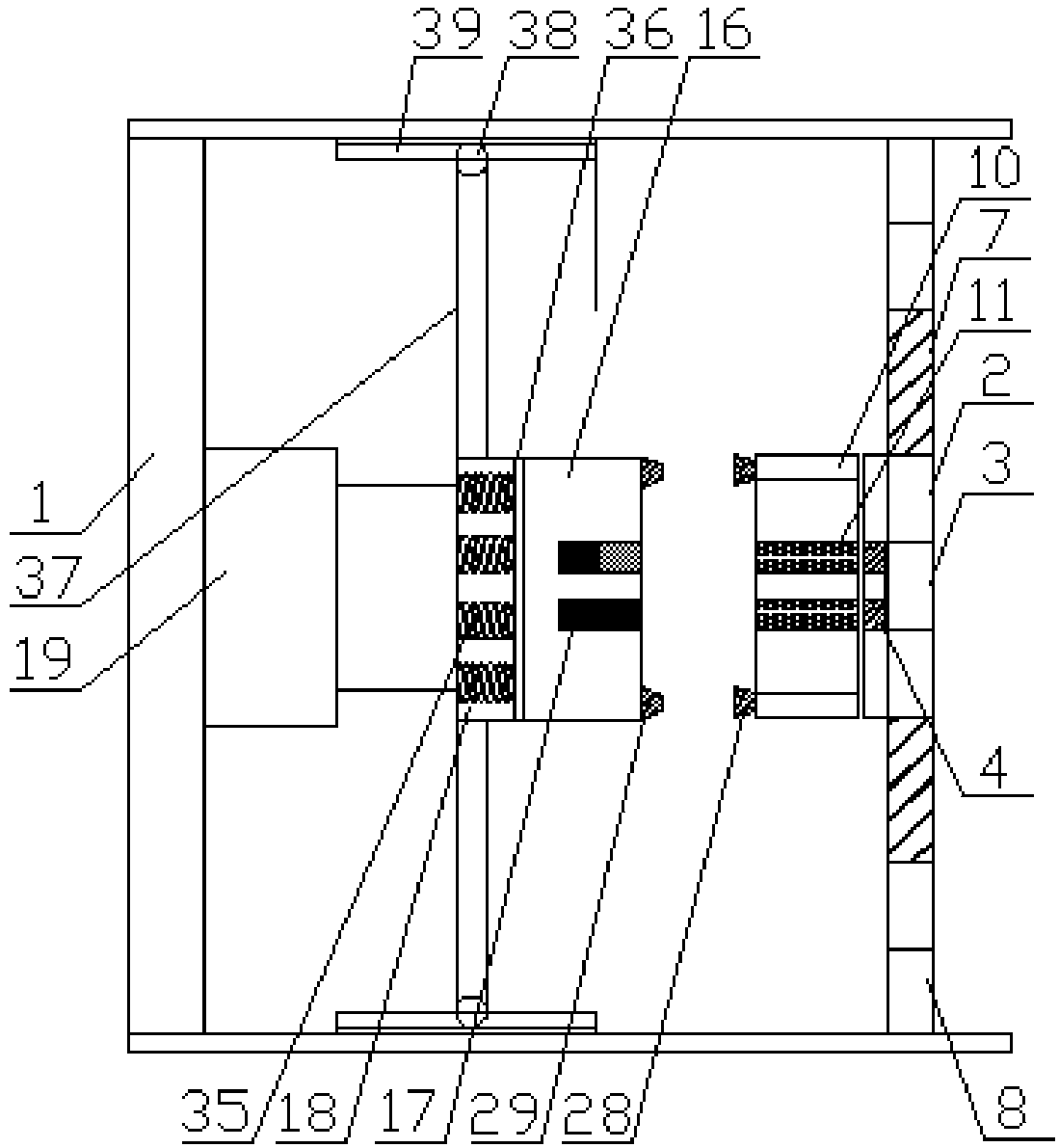

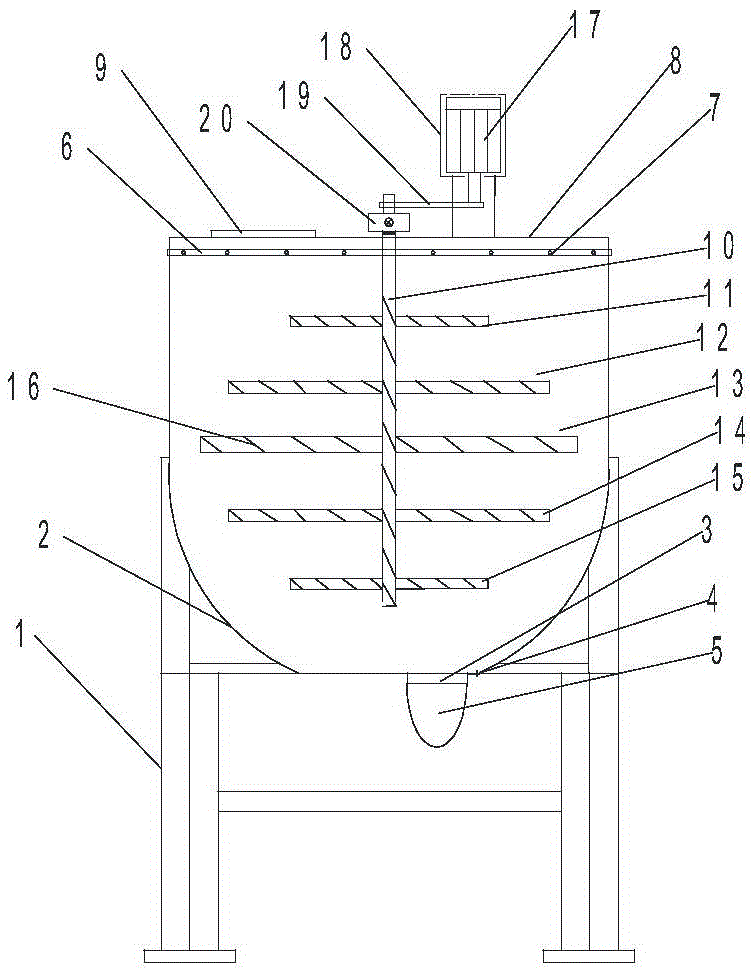

Aerobic compost reactor

ActiveCN101255077AFully fermentedEasy to evaporateBio-organic fraction processingOrganic fertiliser preparationEvaporationData acquisition

The invention provides a composting reactor including a composting tank. The top of the tank is provided with a feed inlet, a sampling port, an air outlet and the bottom of the tank is provided with a feed outlet and the internal of which is provided with a stirring device, a moisture sensor, and an O2 sensor and the wall of which is provided with a ventilating pipe with a plurality of vents communicated with the internal of the tank. The air can be a pumped into the tank through a fan. The electrical signals received by the sensor can be transferred to a computer through a data collector and the computer realizes the recording, storing, calling and various analyses of the data. The composting reactor of the invention enables materials to mix evenly and improves ventilation and makes water evaporation easy and a full fermentation of the material. The reactor has no partial hypoxia or caking, and the fan can be artificially controlled, and the reactor can realize an online monitor and data management and can call the data for analysis at any time.

Owner:CHINA AGRI UNIV

Separate two-phase anaerobic fermentation fermentation device

The invention relates to a separate two-phase anaerobic fermentation fermentation device, including a hydrolysis acidification reaction device, anaerobic fermentation device, biogas treatment device and biogas slurry oxidation device, wherein: the hydrolysis acidification reaction device includes at least two parallel hydrolysis acidification reaction devices The hydrolytic acidification reaction tank and the hydrolyzate collection tank of the unit; the anaerobic fermentation device is a closed anaerobic digestion reactor, with a feed inlet at the bottom and a biogas output outlet at the top, and a set at 80%-90% of the total height There is a biogas slurry overflow port; the biogas slurry oxidation device is a biogas slurry oxidation pond, and the biogas slurry oxidation pond is equipped with a baffle plate that is dislocated up and down; the volume ratio of the hydrolytic acidification pond, anaerobic digestion reactor, and biogas slurry oxidation pond is 2~5:1:0.2~0.5.

Owner:衢州市土肥与农村能源技术推广站 +1

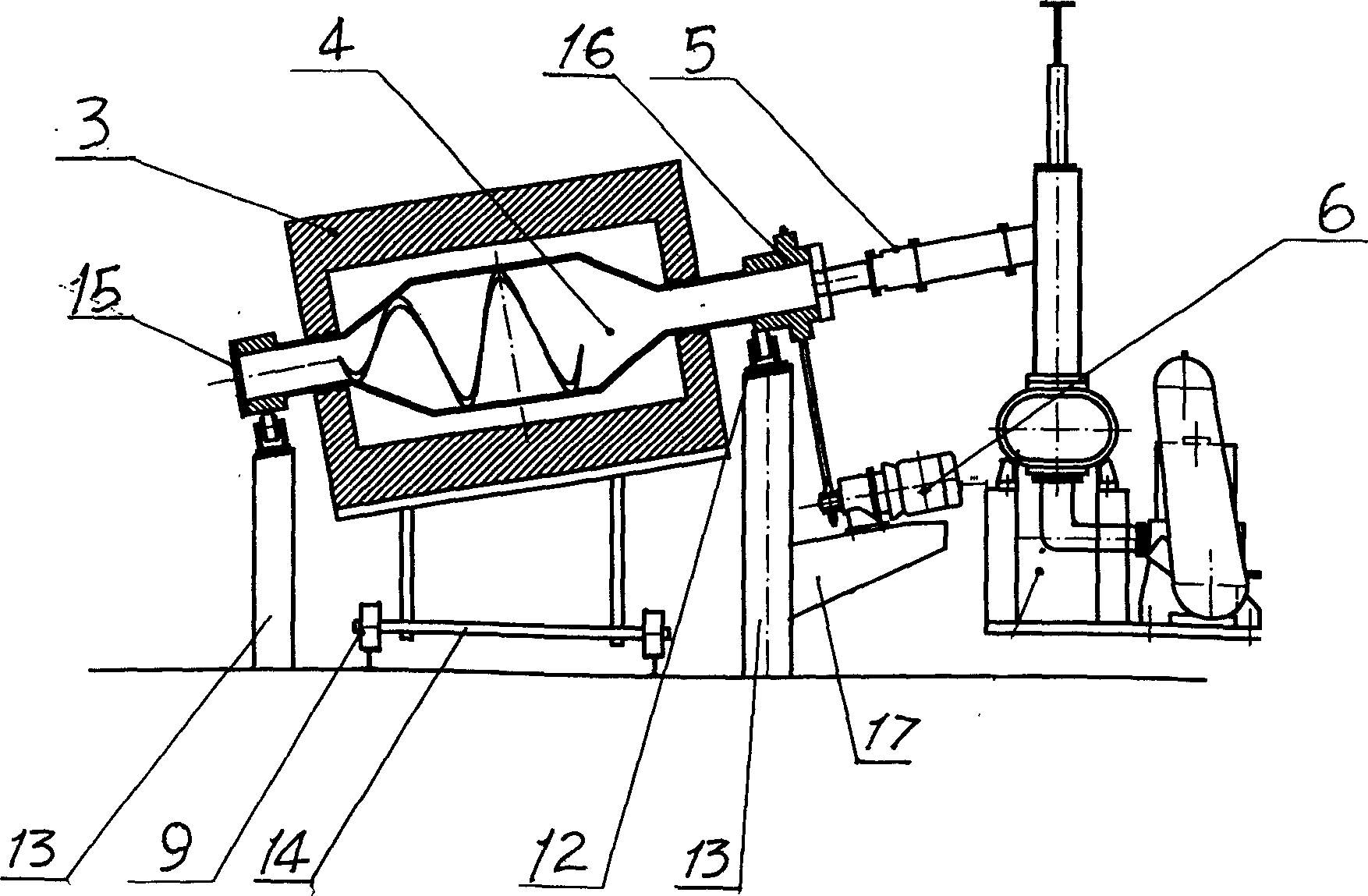

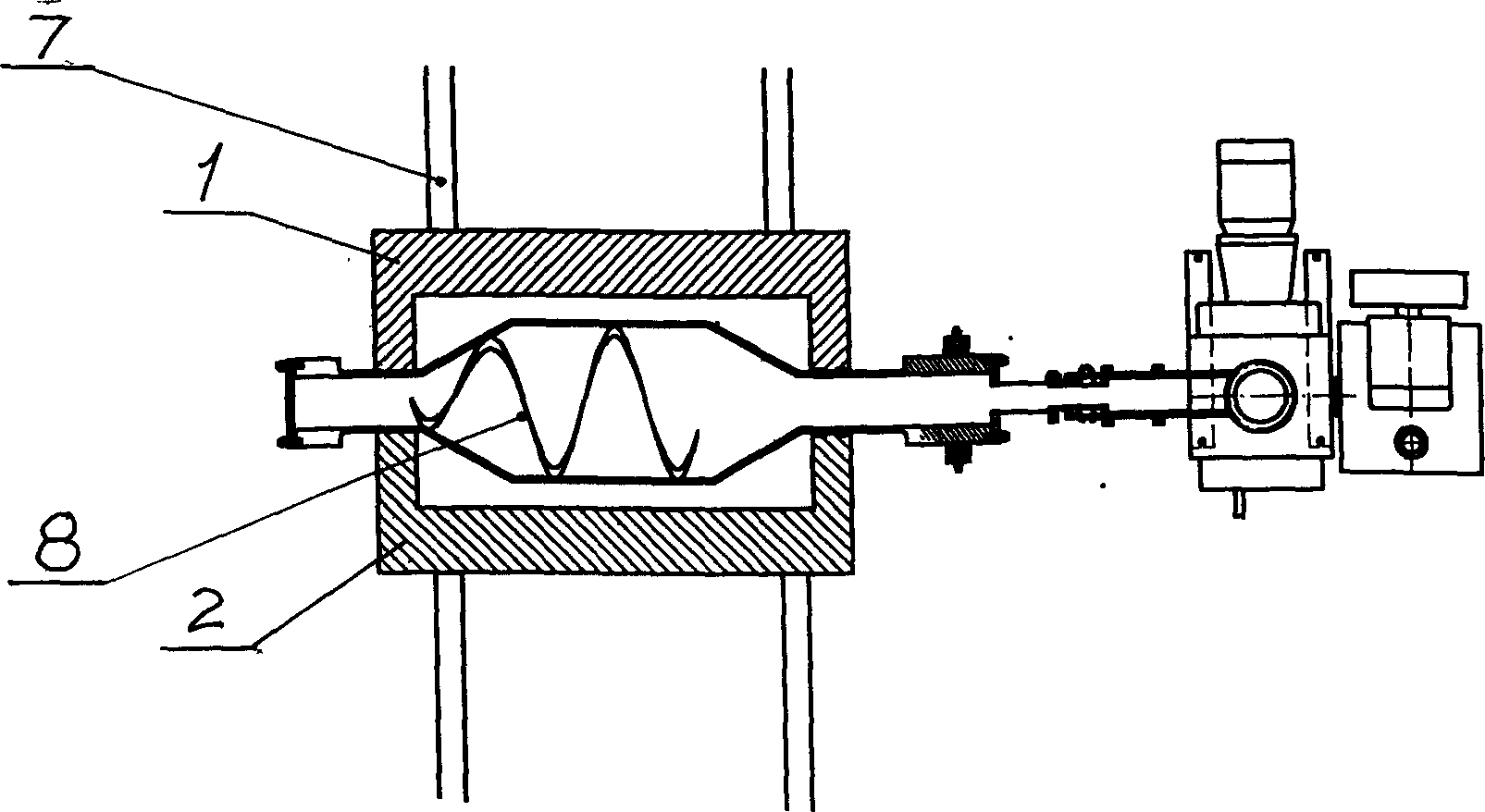

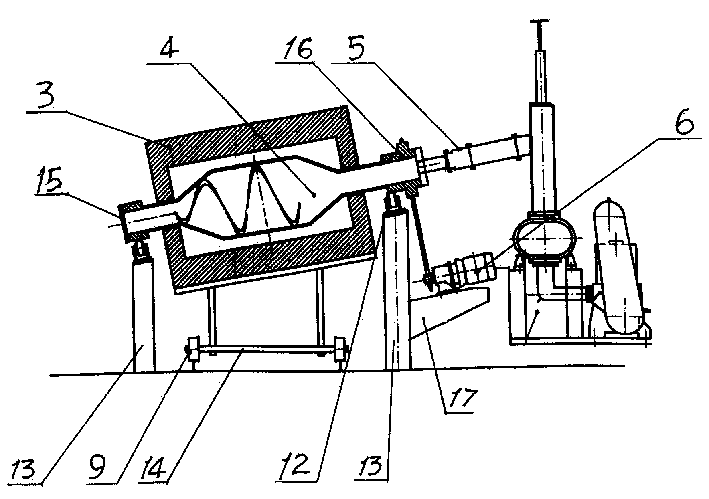

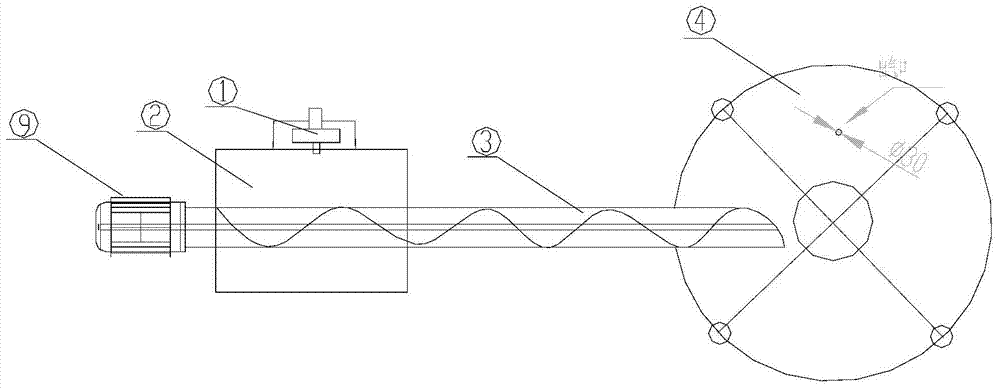

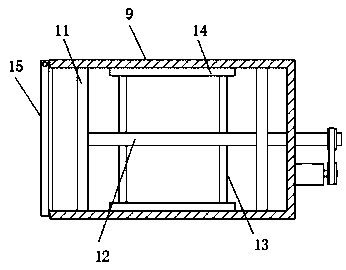

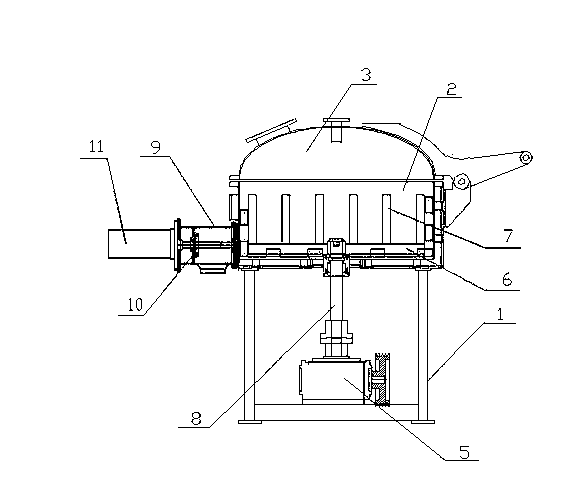

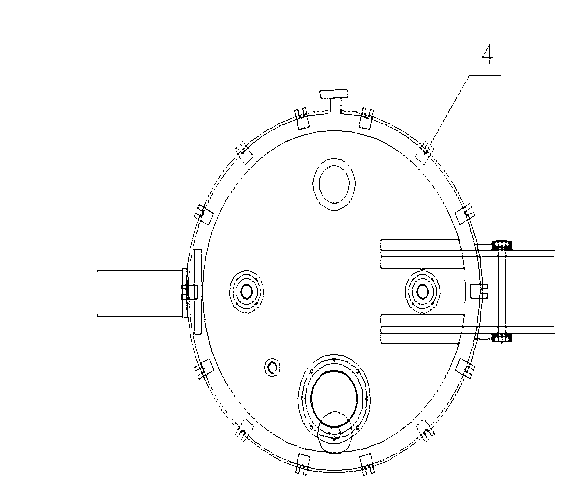

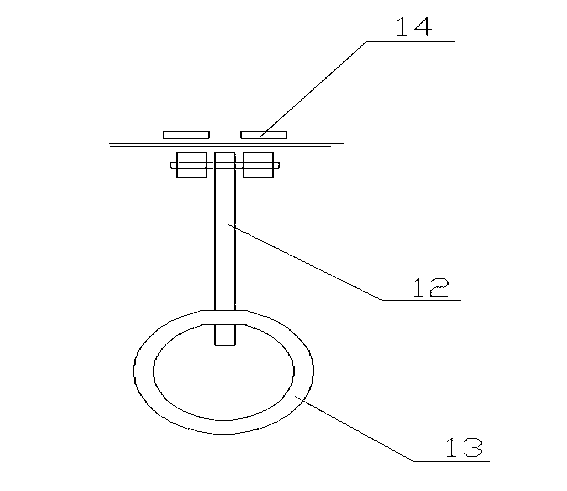

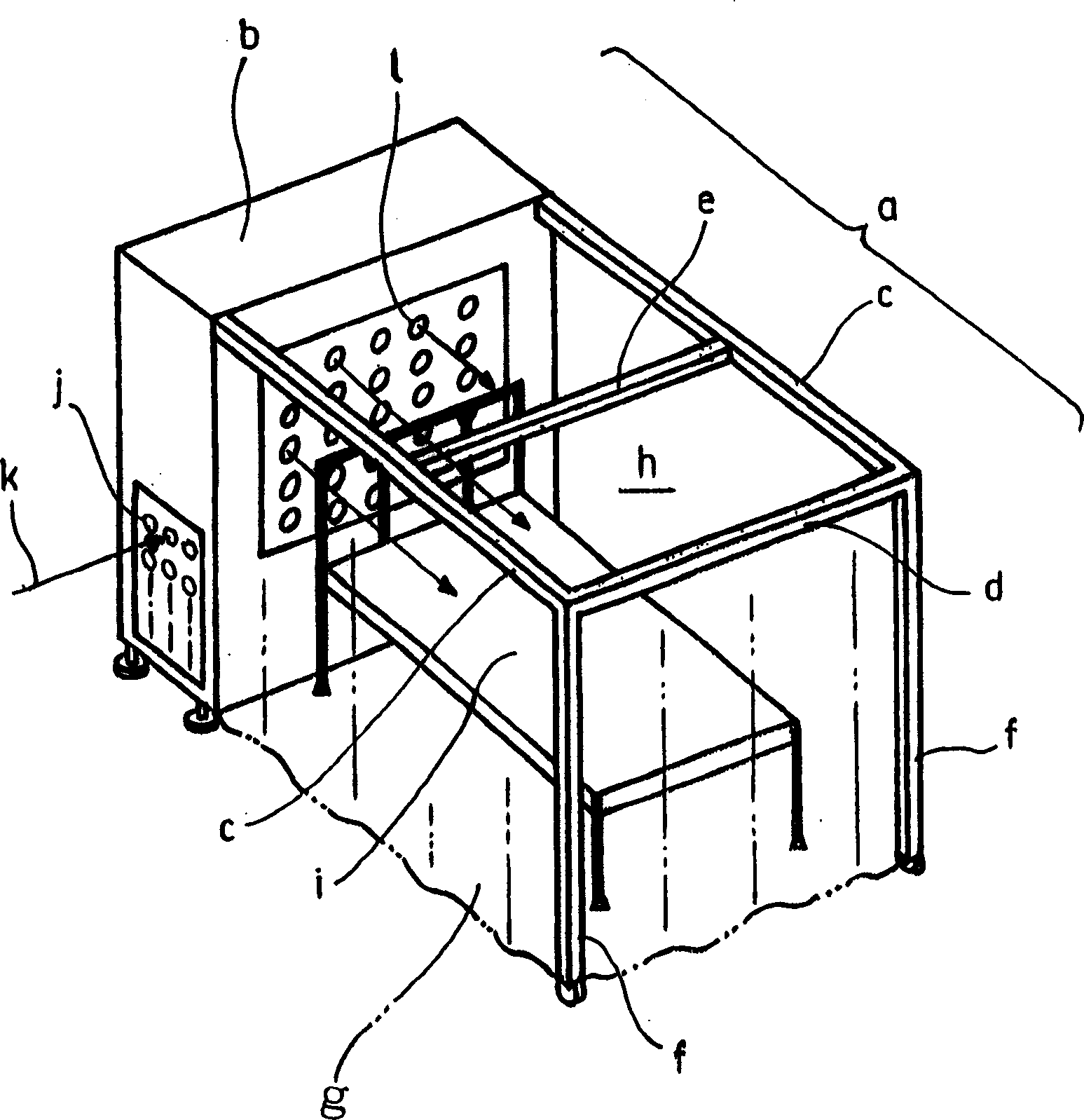

Rotary hydrogen crushing furnace

InactiveCN1421667AImprove milling efficiencyEasy in and outRotary drum furnacesVacuum pumpingHydrogen

The present invention relates to RE alloy crusher and is one rotary hydrogen crushing furnace. It includes rotary furnace, electric heater outside the furnace, furnace rotating drive mechanism and furnace vacuum pumping and hydrogen filling unit. The furnace has feeding and discharging port at one end and is connected to vacuum pumping and hydrogen filling unit at the other end. The electric heater consists of right and left bodies on the support with rollers. Inside the furnace, there are spiral sheets. Compared with available hydrogen crushing furnace with internal heater structure, the present invention with outer heater structure has fast temperature decreasing speed of the furnace and material inside it, simplified operation, high efficiency, improved safety and operation performance.

Owner:董永安

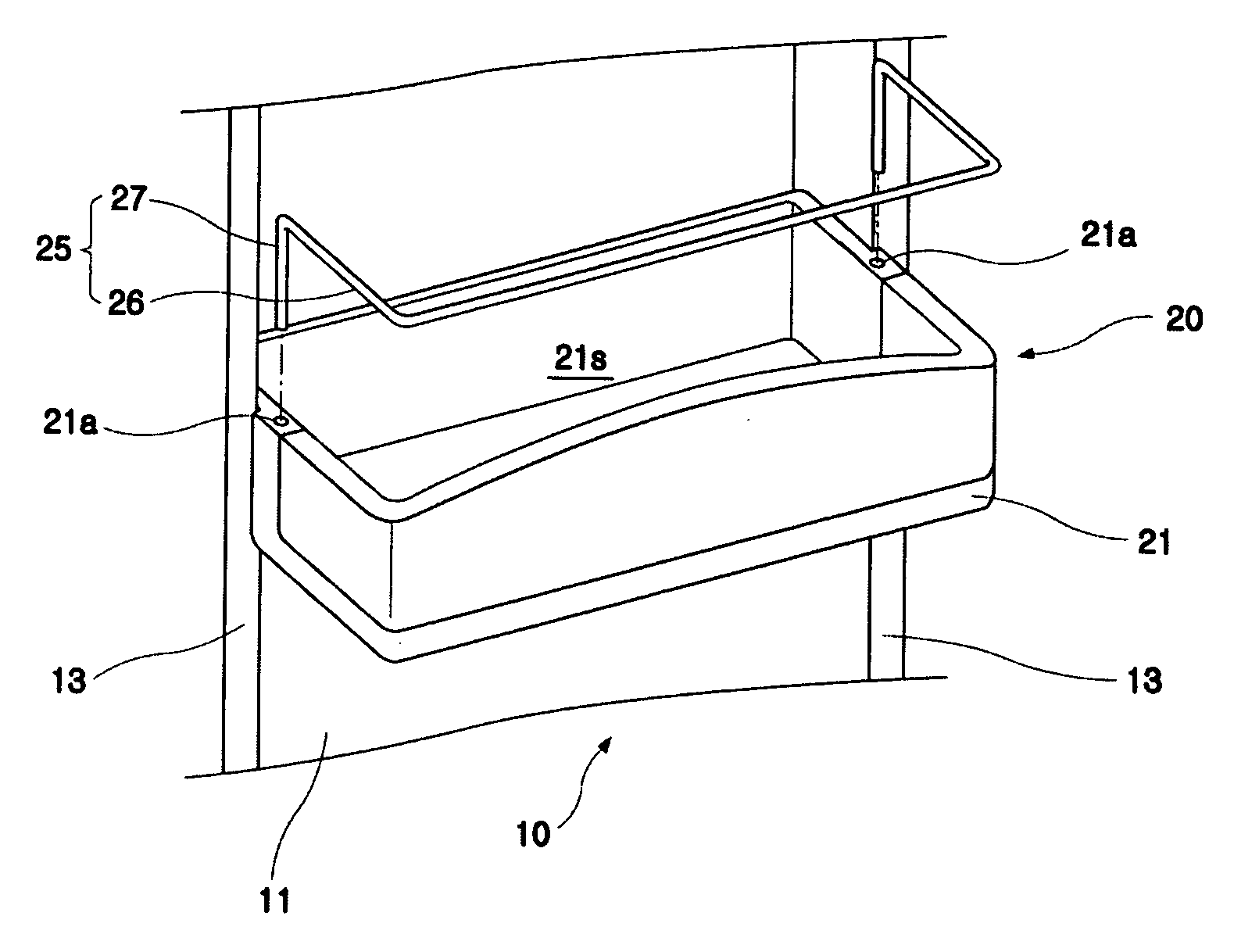

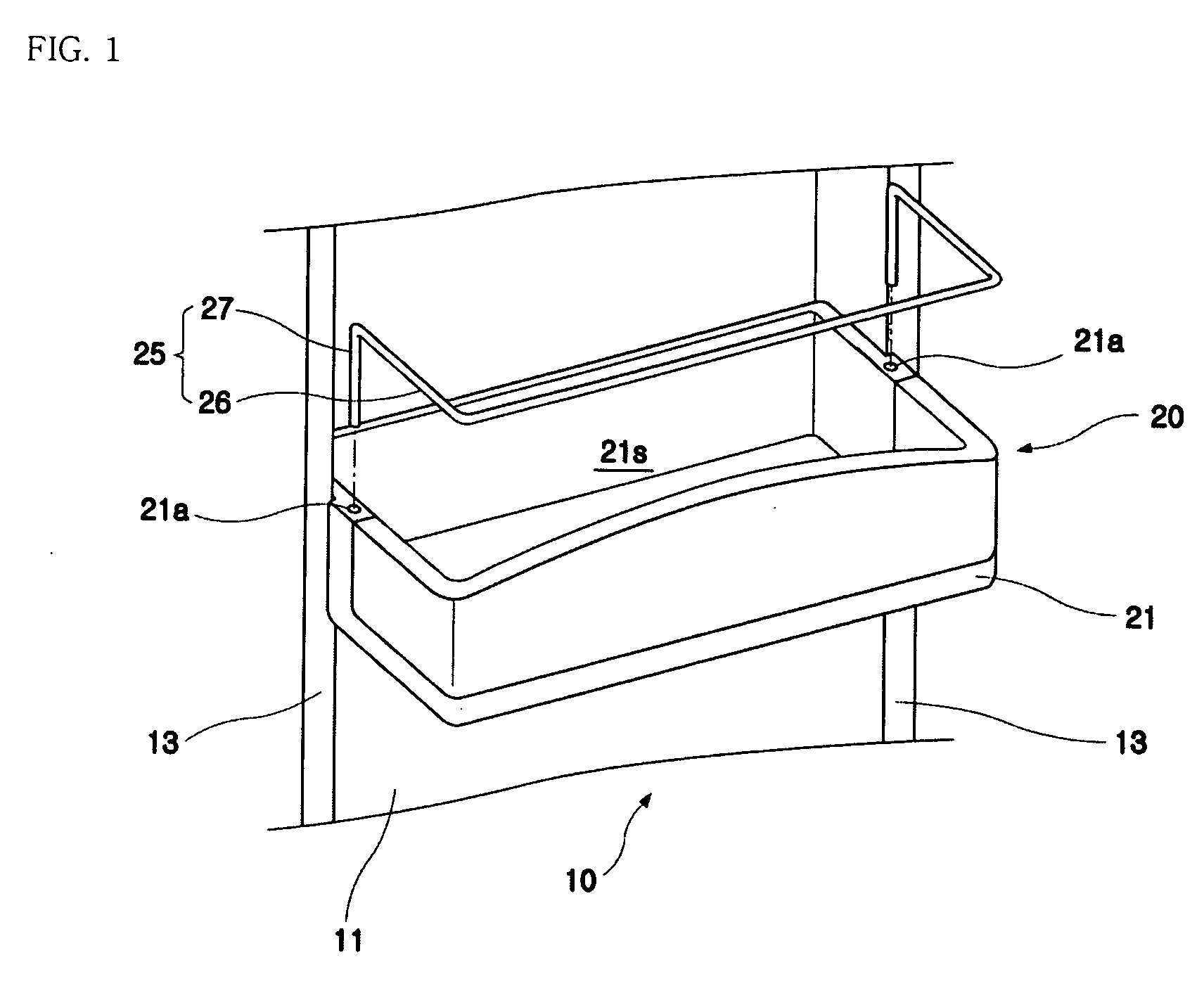

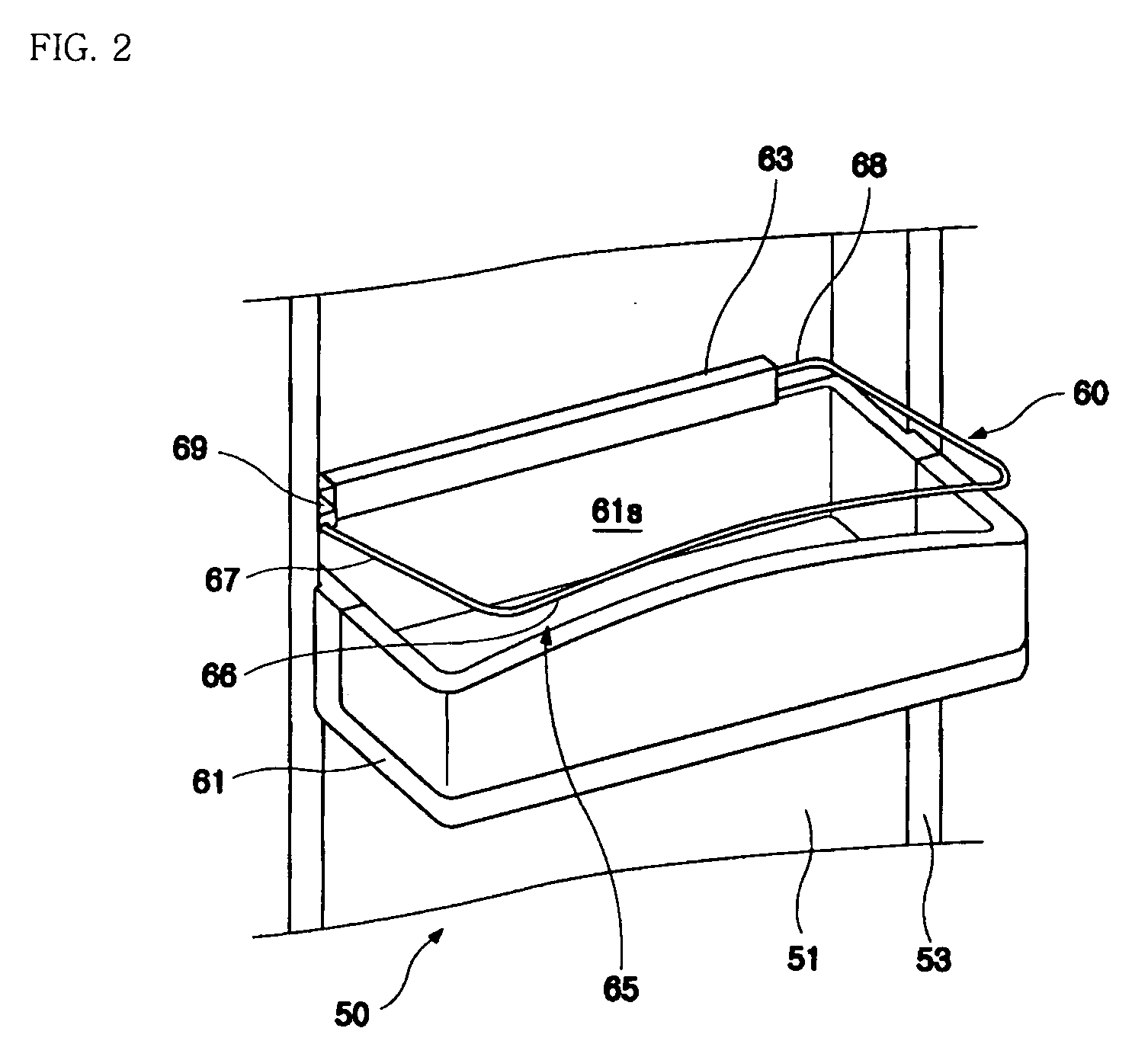

Door basket for refrigerator

InactiveUS20070126327A1Easy to carryEasy in and outLighting and heating apparatusFurniture partsEngineeringMechanical engineering

Owner:LG ELECTRONICS INC

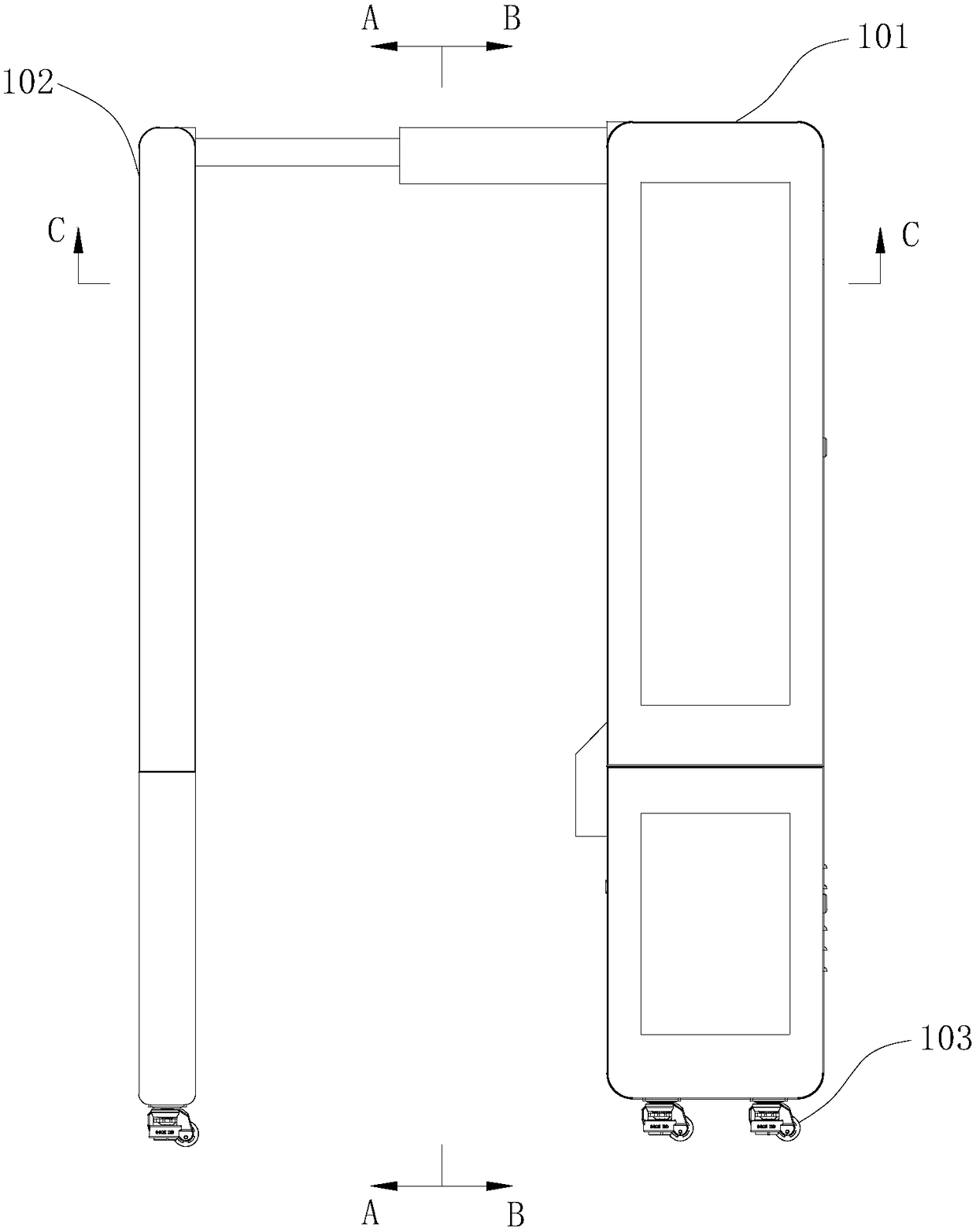

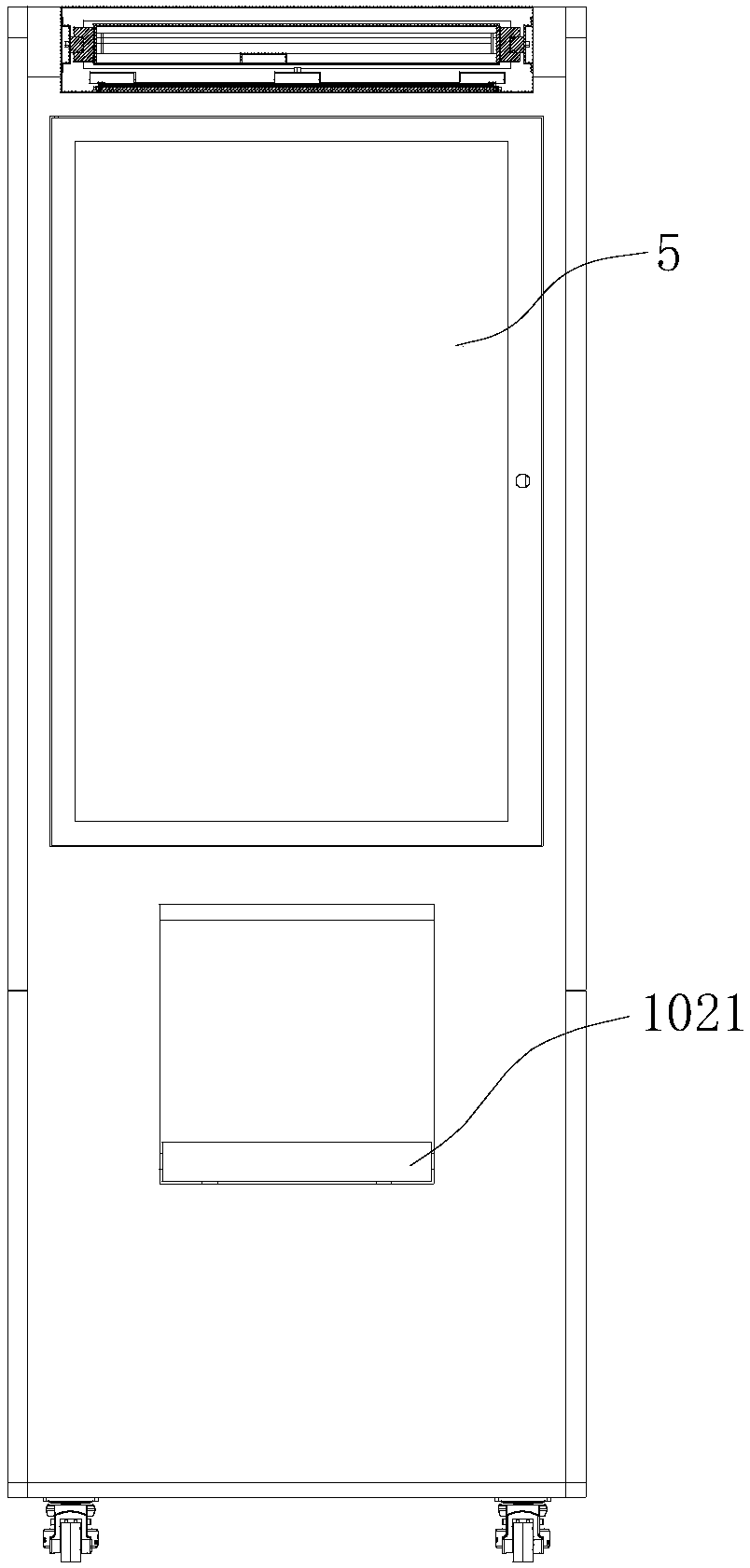

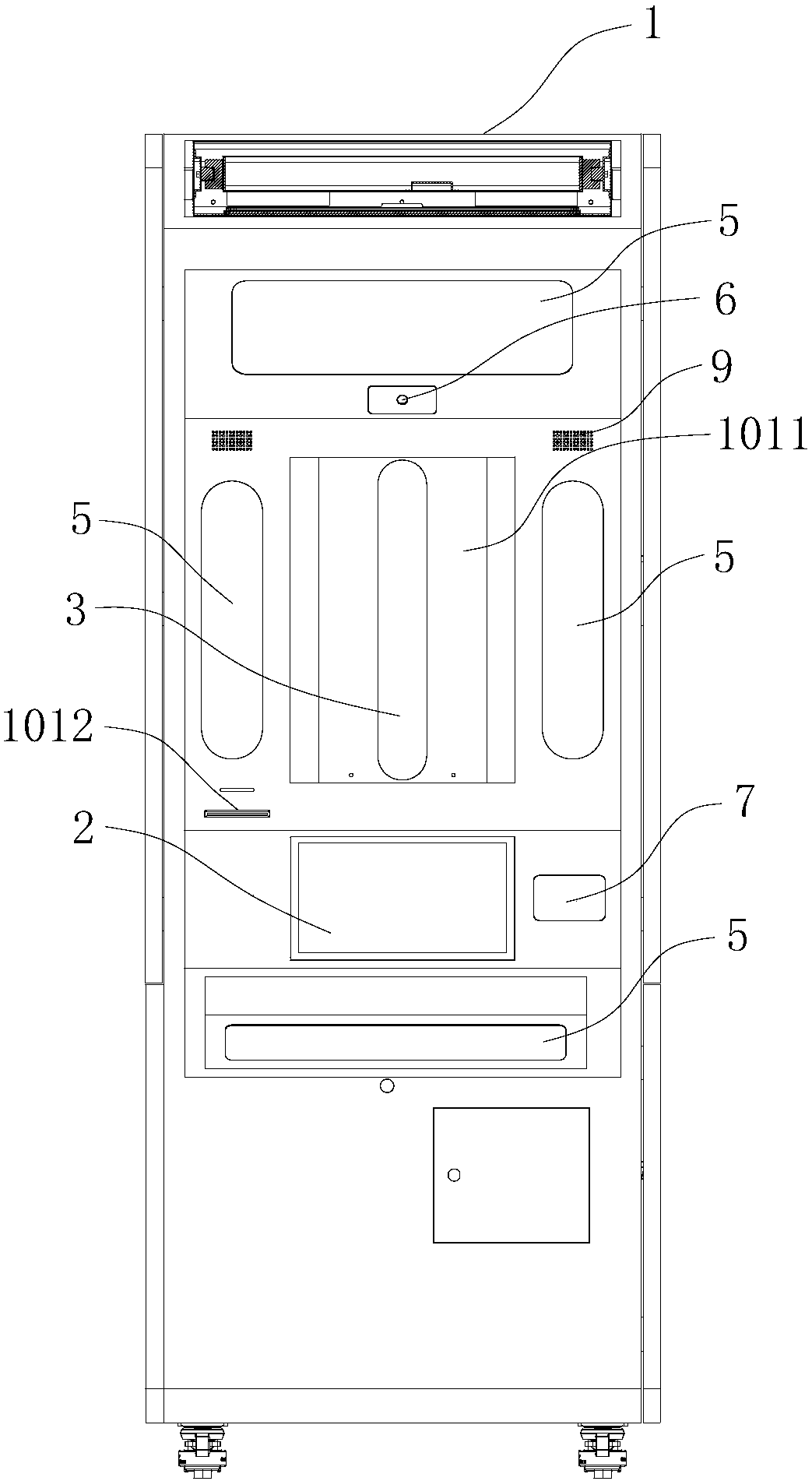

Contactless intelligent self-service license photographing equipment and method

ActiveCN108122343AWith intelligent camera functionWith telescopic functionWall stoolsTelevision system detailsKey pressingComputer module

The invention discloses contactless intelligent self-service license photographing equipment and method. The equipment comprises a chassis, an input / output module, a photographing module and an intelligent module, wherein the chassis comprises a fixed module and a scalable module, the fixed module is connected with the scalable module by virtue of a scalable part, the input / output module is arranged on the fixed module, the photographing module and the intelligent module are arranged in the fixed module, and the intelligent module is respectively connected with the photographing module and theinput / output module; and the photographing module comprises a camera module and a mobile module, and the mobile module is used for driving the camera module to move. The contactless intelligent self-service license photographing equipment and method which are disclosed by the invention can realize that hands of a user are free in a photographing process, photographing can be completed without keyor contact, an automatic photographing process is convenient and simple, industry intelligentization requirement in new times is met, and support is provided for the development of intelligent citiesand intelligent life.

Owner:GUANGZHOU HUABIAO SCIENCEAND TECH DEV CO LTD

High-solid anaerobic reaction device and method for organic garbage

ActiveCN103614288AImprove processing efficiencyGuaranteed uptimeBiological substance pretreatmentsGas production bioreactorsPipe fittingSmall footprint

The invention relates to a high-solid anaerobic reaction device and method for organic garbage. The device comprises a pulverizer, a pretreatment pond and an anaerobic fermentation tank, wherein the pulverizer is arranged above the pretreatment pond; a spiral conveying device is arranged below the material outlet of the pretreatment pond and connected with the anaerobic fermentation tank; a liquid-collecting pipe is connected to the bottom of the anaerobic fermentation tank and connected to a four-way pipe fitting; the other three ports of the four-way pipe fitting are connected with a water draining pipe, a pretreatment pond backflow pipe and a biogas slurry spraying return pipe respectively; the anaerobic fermentation tank is internally sequentially provided with a spraying perforated plate and a sieve plate from top to bottom. According to the anaerobic reaction device for the organic garbage with the high solid content, the material pulverization, pretreatment and fermentation are integrated, the material uniformity is guaranteed, an anaerobic fermentation process is facilitated, the solid concentration and uniformity of a material are regulated through fermentation liquor backflow, and the stable fermentation of organic garbage is realized; the anaerobic reaction device has the characteristics of wide adaptability, high treatment efficiency, compact layout, stable operation, small land occupation area and the like.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

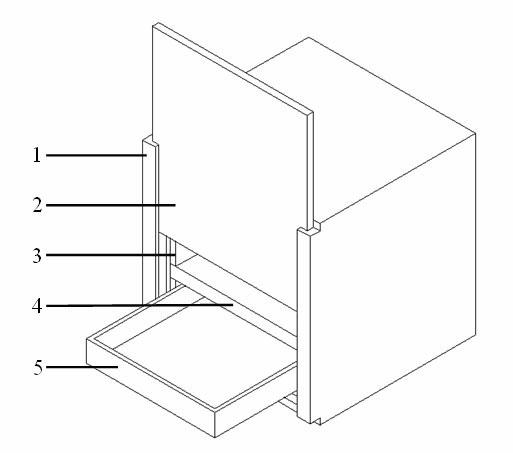

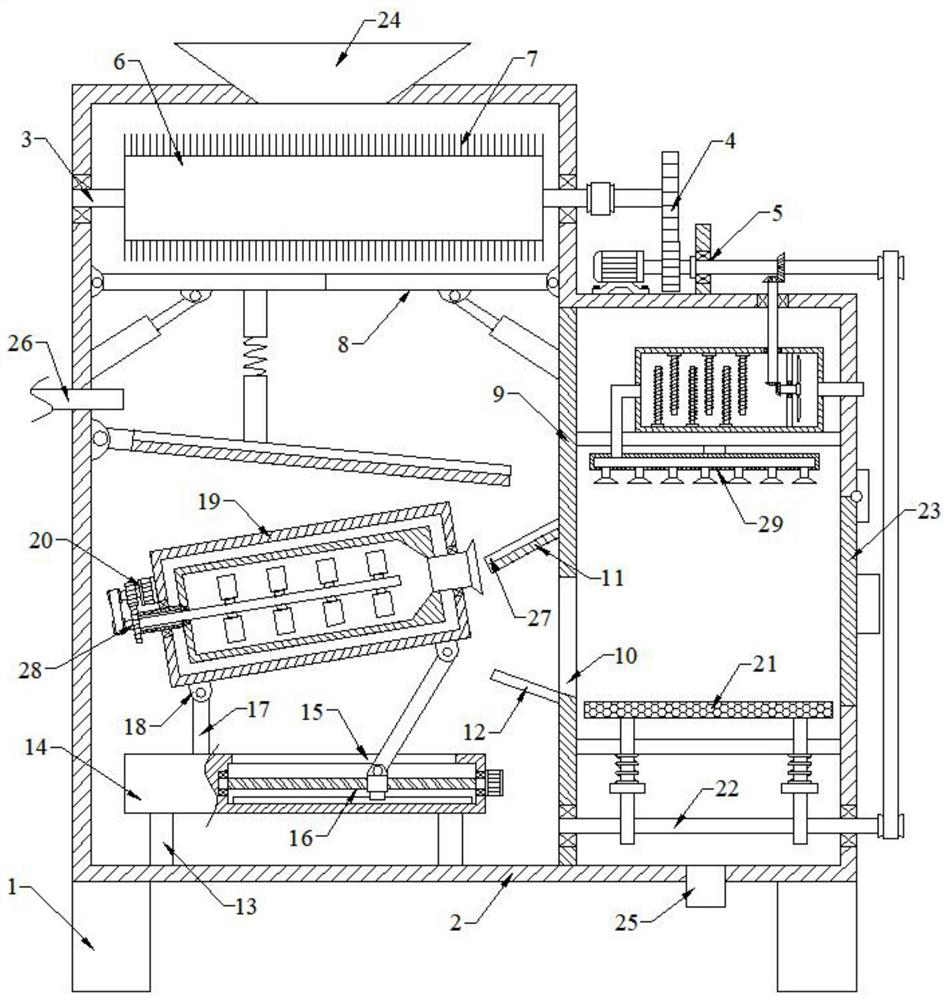

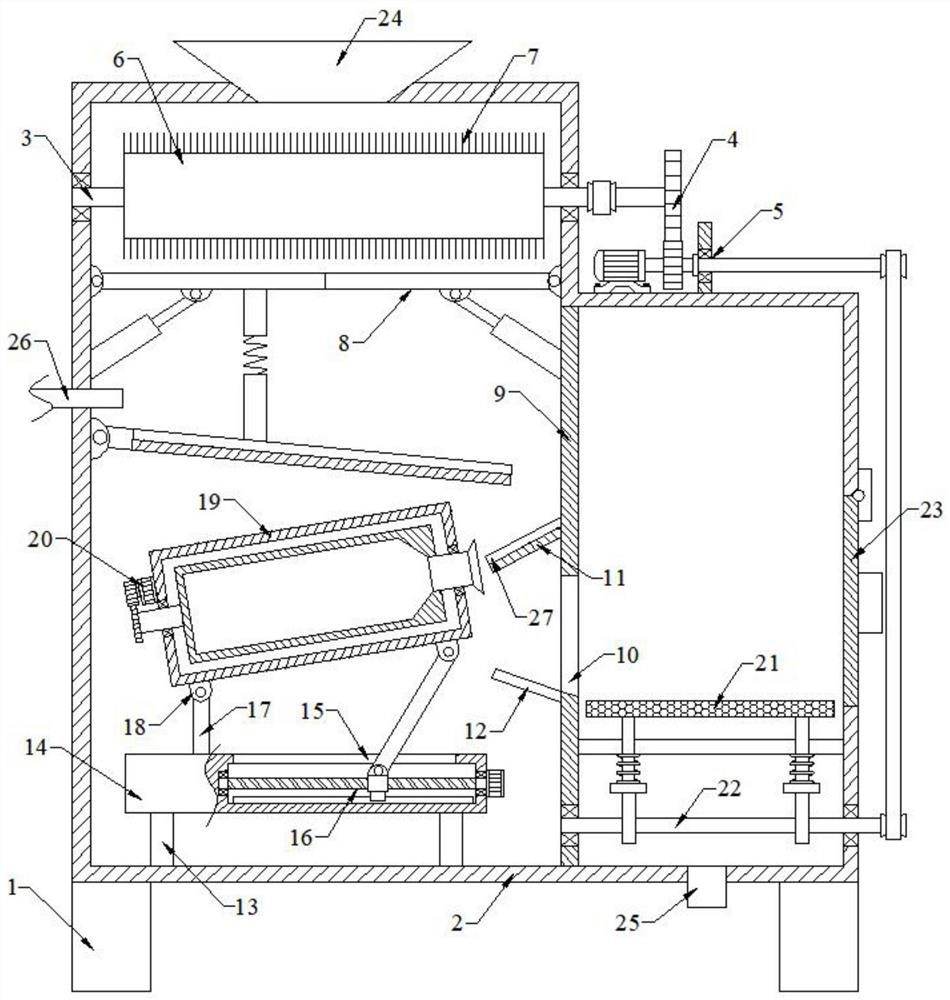

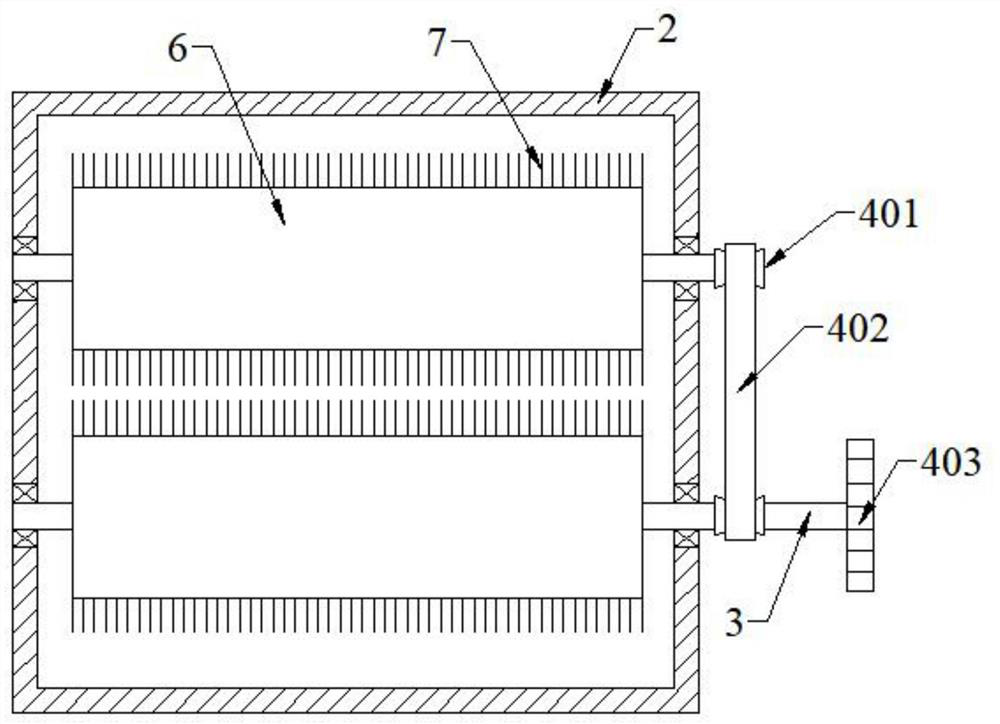

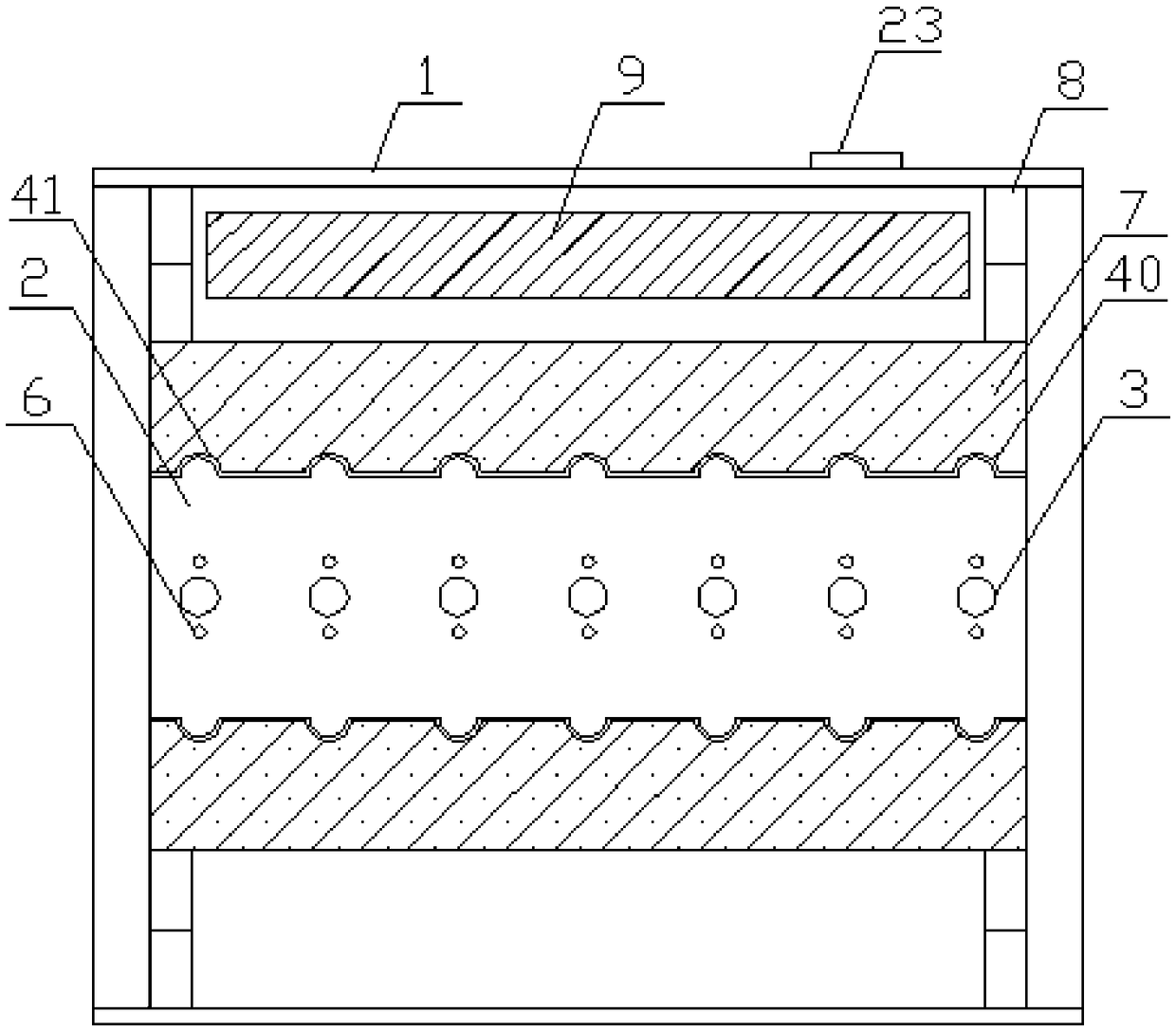

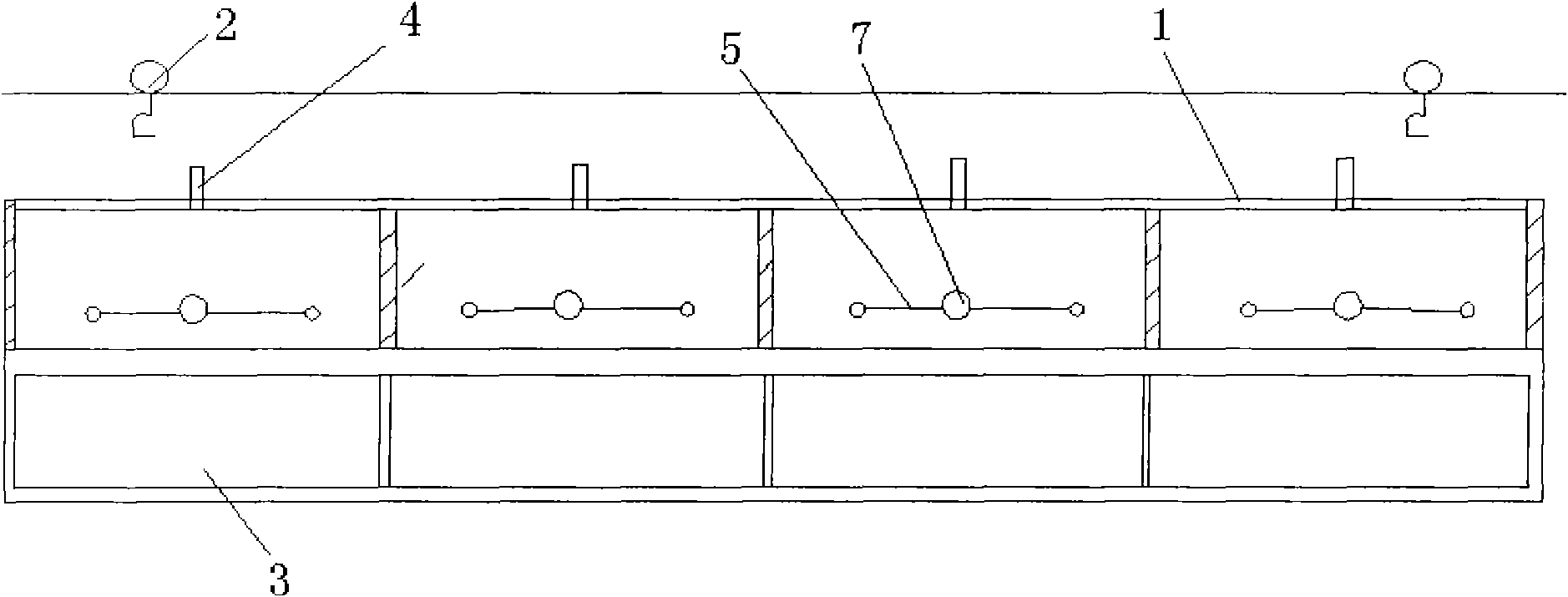

Low melting point alloy phase change heat storage device applied to solar dryer

InactiveCN102620534AMake up for low thermal conductivity, poor phase transition stability and other deficienciesNo pollutionHeat storage plantsEnergy storageHeat conductingHeat storage material

The invention relates to a low melting point alloy phase change heat storage device applied to a solar dryer, which is characterized by comprising a drying chamber box body, a drawing type material containing box, heat storage blocks and an upper and lower sliding type heat insulation door. Two to one hundred heat storage blocks are arranged in a drying space of the drying chamber box body, and the edge parts of the heat storage blocks are supported by the heat insulation blocks to be fixed with the drying chamber box body. The drawing type material containing box is located between an upper heat storage block and a lower heat storage block and is contacted with the lower heat storage bock, and drying samples are contained in the drawing type material containing box. Each heat storage block is composed of a heat storage material container, a heat storage material, a heat conducting pipe and heat conducting oil. The heat storage materials are encapsulated in the heat storage material containers, the heat conducting pipes are arranged in the heat storage material containers, the heat storage materials are encapsulated between the inner walls of the heat storage material containers and the outer walls of the heat conducting pipes, and the heat conducting oil serves as a heat conducting medium in the heat conducting pipes. The low melting point alloy phase change heat storage device applied to the solar dryer has the advantages of being convenient in feeding and discharging, reliable, safe and high in drying efficiency.

Owner:WUHAN UNIV OF TECH

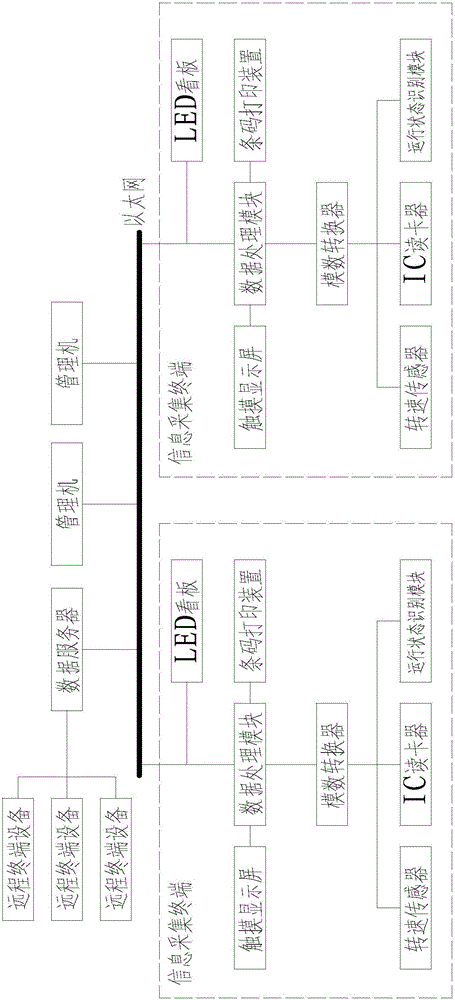

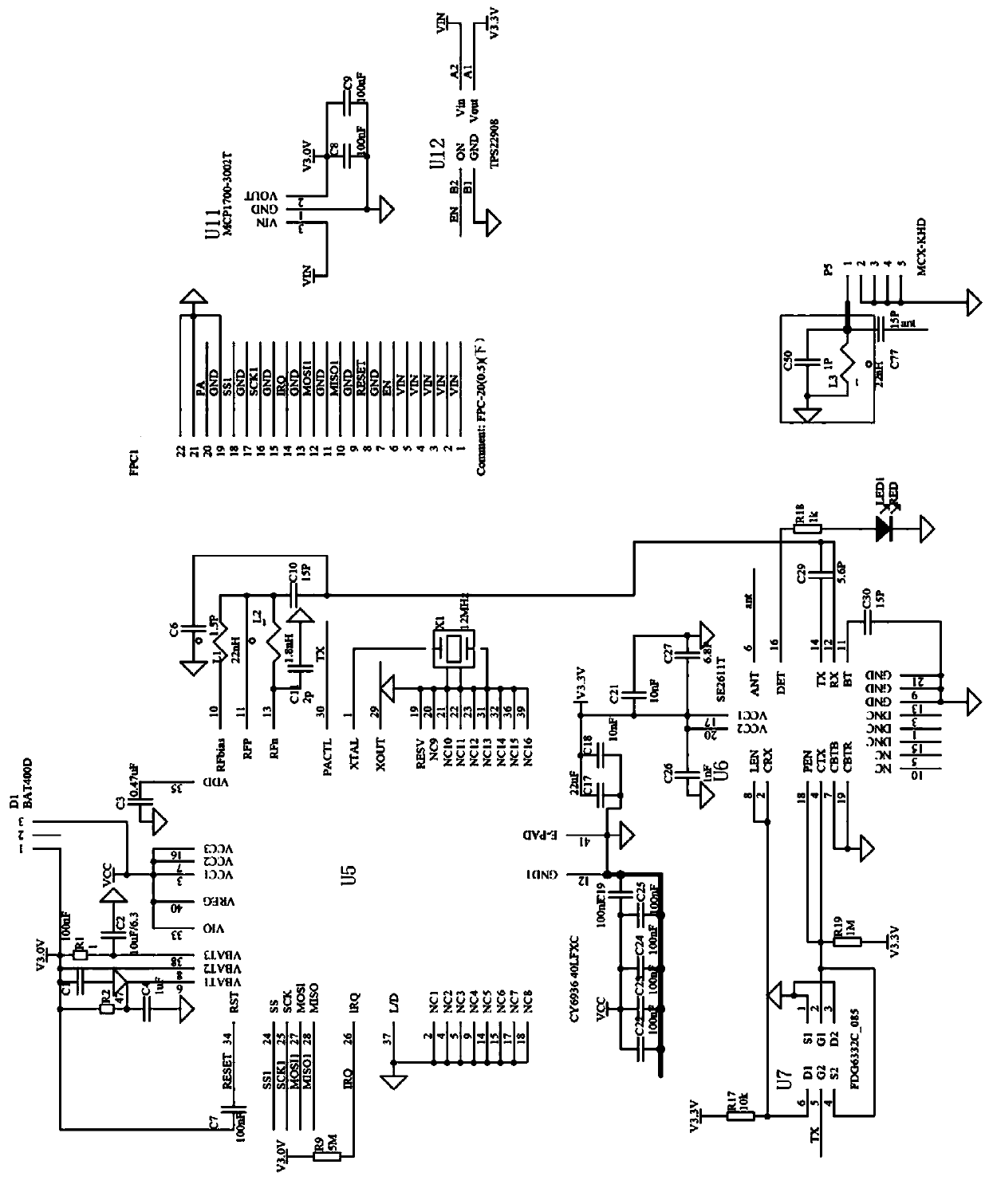

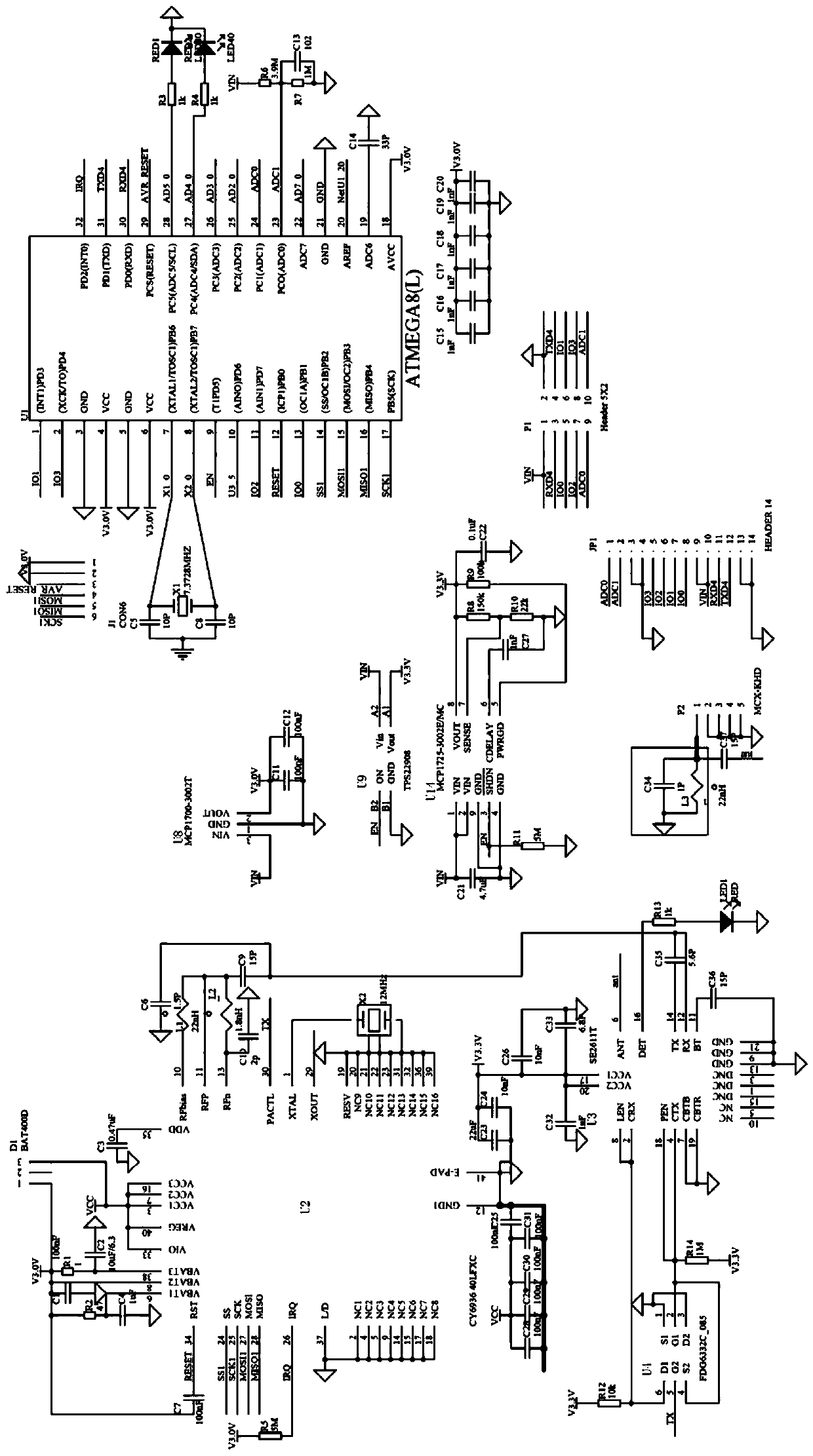

Warp knitting machine production data acquisition and management system

InactiveCN105843185AEasy to manageCode of PracticeTotal factory controlProgramme total factory controlData acquisitionElectric machinery

The invention relates to the field of weaving industry production data acquisition and management equipment, especially to a warp knitting machine production data acquisition and management system. The warp knitting machine production data acquisition and management system comprises a data server and at least one set of information acquisition terminals. Each information acquisition terminal comprises a rotating speed sensor connected with a main shaft of a main motor of a warp knitting machine, an IC card reader for identifying and extracting employee identity information data, a running state identification module installed on the main motor of the warp knitting machine, an analog-to-digital converter respectively connected whit the rotating speed sensor, the IC card reader and the running state identification module, a data processing module respectively connected with the analog-to-digital converter and the data server, and a touch display screen connected with the data processing module. The system can acquire, compute and display operation data and various production and management personnel data of the warp knitting machine.

Owner:FUZHOU INSTITUE OF TECH

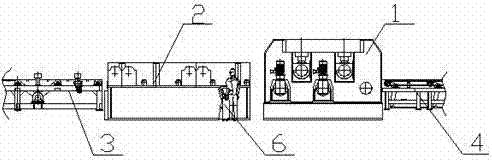

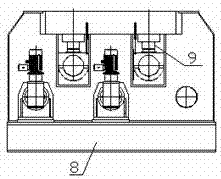

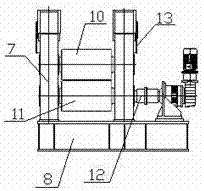

Profile straightening machine

ActiveCN107088594AStable correction processImprove stabilityMetal working apparatusControl systemPosition sensor

The invention discloses a profile straightening machine which comprises a hydraulic system, a control system, a feeding roller way, a pressure straightening mechanism, a rolling straightening mechanism and a discharge roller way; the feeding roller way, the pressure straightening mechanism, the rolling straightening mechanism and the discharge roller way are sequentially arranged back and forth; the rolling straightening mechanism is composed of a rack I, a lathe bed I, a straightening roller, an oil cylinder pressing mechanism, a main transmission mechanism and a displacement measurement mechanism; the oil cylinder pressing mechanism provides a pressing force; an upper roller can carry out up and down displacement along the guide rail surface of the rack I; the opening quantities of the upper roller and a lower roller are regulated to carry out straightening movement on a workpiece in an up and down direction; the pressure straightening mechanism is composed of a lathe bed II, a horizontal oil cylinder, a movable pressure block, a fixed stop dog and a position sensor to carry out bending on the workpiece in a horizontal direction; and the discharge roller way is a liftable roller way. Compared with the traditional workpiece straightening machine, the profile straightening machine is reasonable in structure design, convenient to operate and high in shaping efficiency and shaping accuracy.

Owner:TAIAN HUALU METALFORMING MACHINE TOOL

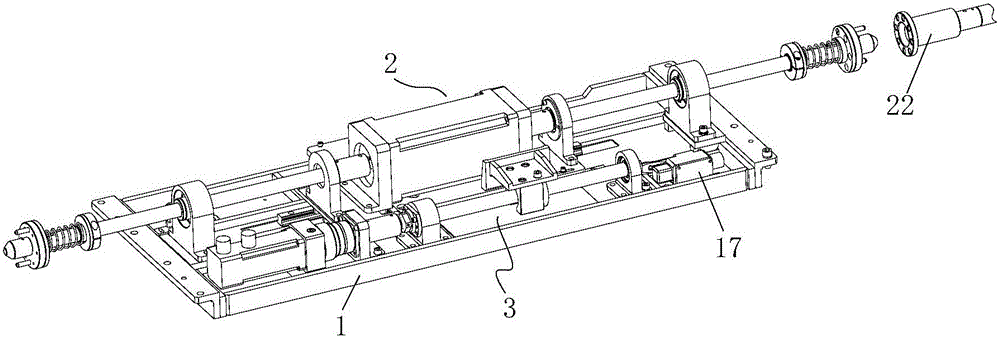

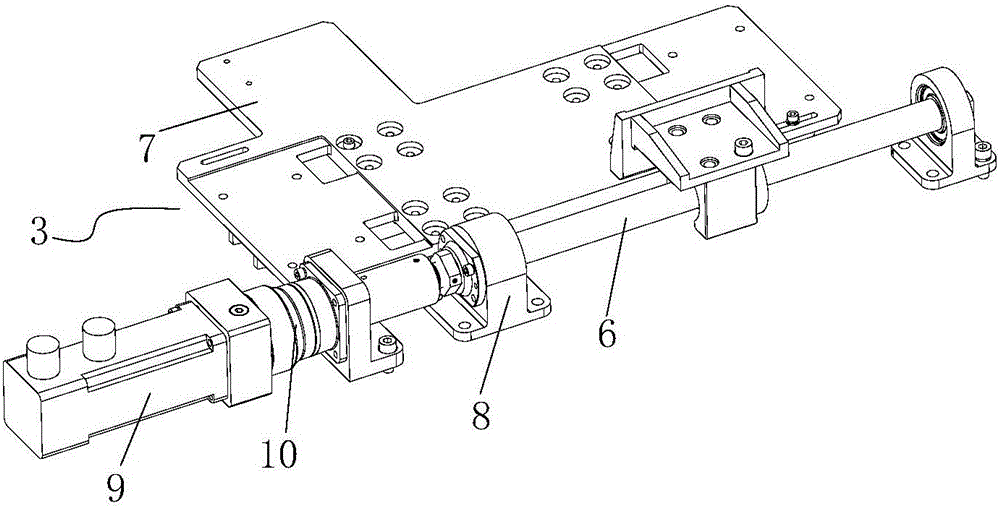

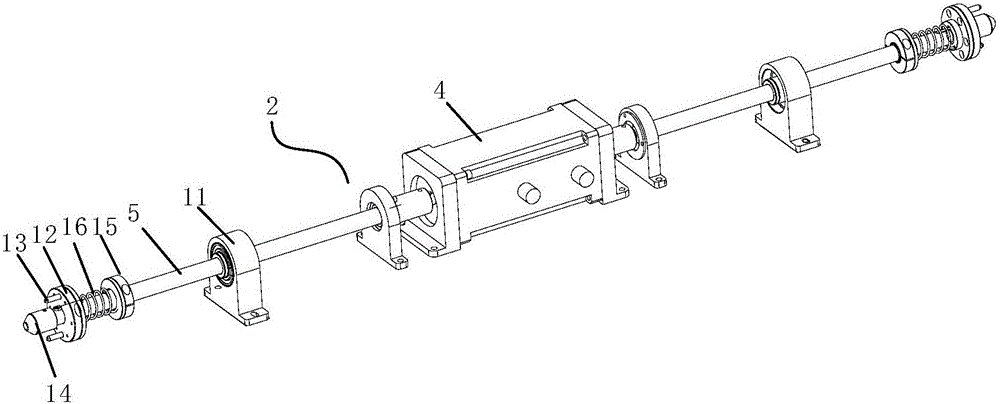

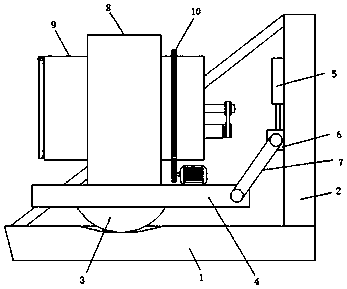

Dynamic docking mechanism for transfer roll tables, transfer roll table device and transfer storage equipment

The invention discloses a dynamic docking mechanism for transfer roll tables, a transfer roll table device and transfer storage equipment. The dynamic docking mechanism for the transfer roll tables comprises a base (1), a docking transmission mechanism (2) and a driving mechanism (3), wherein the docking transmission mechanism (2) is arranged on the base (1) and comprises a first driving motor (4), a rotary driving shaft (5) and a docking part arranged at the end part of the rotary driving shaft (5); the docking part rotates along with the rotary driving shaft (5); and the driving mechanism (3) is in driving connection with the docking transmission mechanism (2) and drives the docking transmission mechanism (2) to slide along the axial direction of the rotary driving shaft (5) relative to the base (1). According to the dynamic docking mechanism for the transfer roll tables, disclosed by the invention, the problems of low storing, transferring and conveying efficiency, high labor intensity and lower safety of no dynamic storage equipment in the prior art can be solved.

Owner:中国人民解放军火箭军工程设计研究院 +1

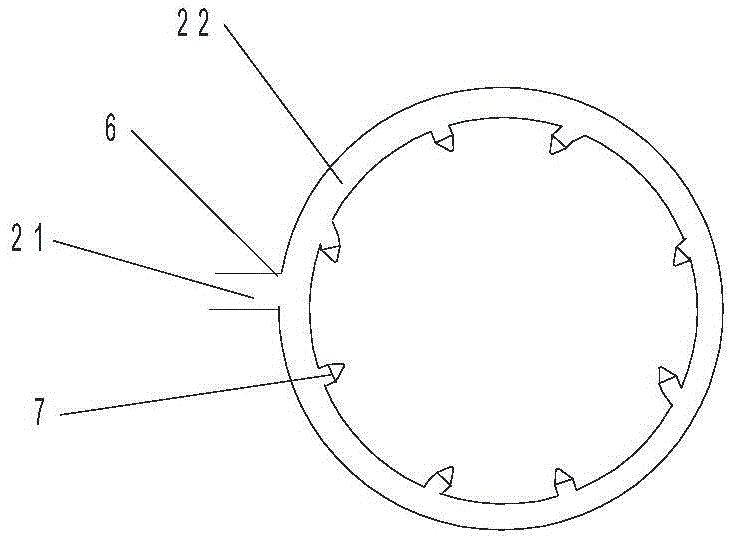

Marinating device for processing braised pork with soy sauce

InactiveCN109730261ASolve the problem that it cannot be evenly covered on the meatWell mixedRotating receptacle mixersTransportation and packagingEngineeringDouble rotation

The invention relates to the technical field of processing of braised pork with soy sauce, and discloses a marinating device for processing braised pork with soy sauce. Aiming at the problem that existing marinating materials cannot uniformly cover pork, the device comprises a base, a vertical plate is fixedly connected to one end of the top of the base, the top of the base is provided with an arcblock, a mounting plate is fixedly connected to the top of the arc block, and an adjusting rod is hinged to one end of the mounting plate; one side of the vertical plate is provided with an air cylinder, one end of the adjusting rod is hinged to an output shaft of the air cylinder, the top of the mounting plate is fixedly provided with a column, a marinating barrel is rotatably mounted on the column and fixedly sleeved with a tooth ring, a rotating shaft is rotatably mounted in the marinating barrel, the top and bottom of the rotating shaft are fixedly provided with pulling rods, one ends ofthe pulling rods are fixedly provided with pushing plates, and the pushing plates are in contact with the inner wall of the marinating barrel. According to the marinating device, through a double rotation mechanism, the uniformity of mixing the marinating materials and pork is greatly improved, the marinating quality is improved, feeding and discharging are convenient, and the marinating device iseasy to popularize.

Owner:安徽徽食食品有限公司

Cleaning equipment for automobile parts

InactiveCN111804635AFor subsequent cleaningReasonable structural designDrying gas arrangementsCleaning using toolsStructural engineeringMechanical engineering

The invention discloses cleaning equipment for automobile parts. The cleaning equipment comprises two supports, wherein a cleaning box is fixedly connected to the upper ends of the supports, a rotating assembly is connected to the right ends of first rotating shafts, a linkage assembly is connected to the rotating assembly, sweeping rollers are arranged on the two first rotating shafts, a discharging assembly is arranged in the middle of an inner cavity of the cleaning box, a lifting assembly is arranged in a supporting table, an overturning assembly is arranged in an outer cylinder, and a vibration assembly is arranged at the lower end of a filter plate; and parts are swept and brushed through sweeping brushes, a large amount of sweeps and dirt adhering to the parts can be brushed away, the parts, cleaning liquid and water in an inner barrel are driven by the overturning assembly to be overturned and cleaned, the cleaning efficiency is high, solid-liquid separation of the parts and waste liquid is achieved through the filter plate, the vibration assembly drives the filter plate to vibrate up and down in a reciprocating mode, the solid-liquid separation efficiency can be improved,parts on the filter plate are dried through a drying assembly, follow-up part treatment and use are facilitated, the cost is reduced, and the machining efficiency is improved.

Owner:杭州巾成科技有限公司

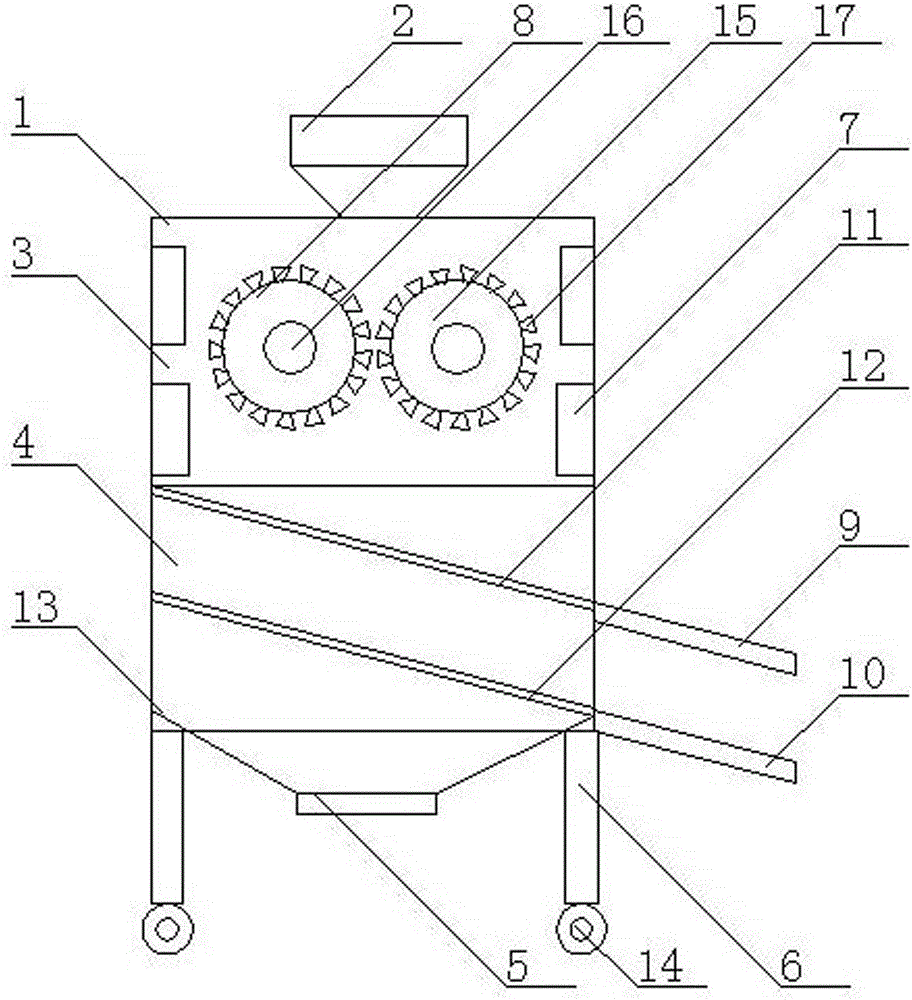

Small convenient efficient smashing device

A small convenient efficient smashing device comprises a machine body. A feeding hopper is arranged in the middle of the top end of the machine body. A smashing chamber is arranged at the upper end of the machine body. A screening chamber is arranged at the lower end of the machine body. A first discharging hopper is arranged in the middle of the bottom end of the machine body. The left side and the right side of the bottom end of the machine body are each provided with a supporting leg. The small convenient efficient smashing device is high in smashing efficiency and smashing fineness, and multi-grade screening can be carried out on smashed materials; and meanwhile, smashing and screening on the materials are completed, operation is easy, use is convenient, and time and labor are saved.

Owner:哈尔滨尼亚农业有限公司

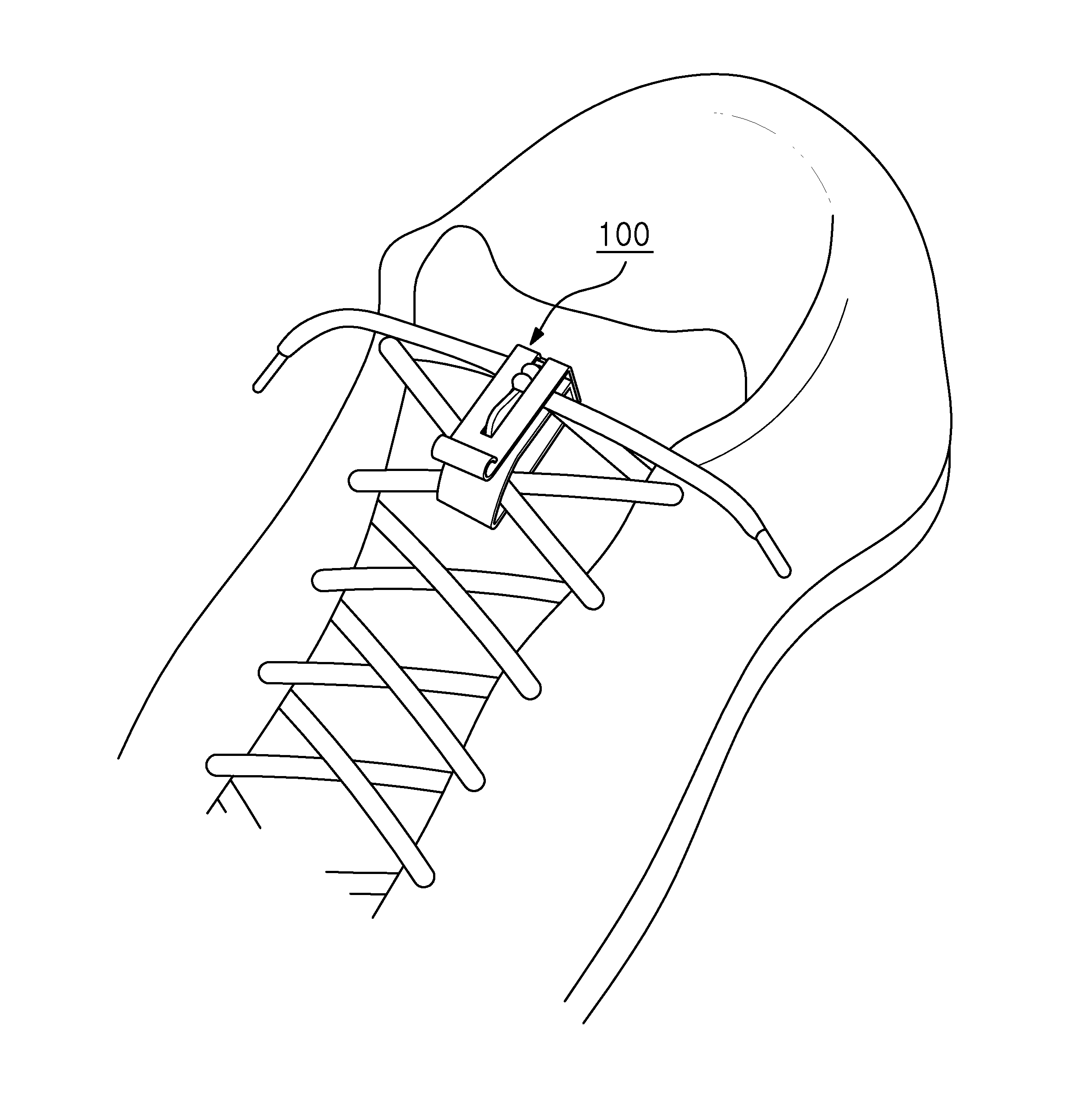

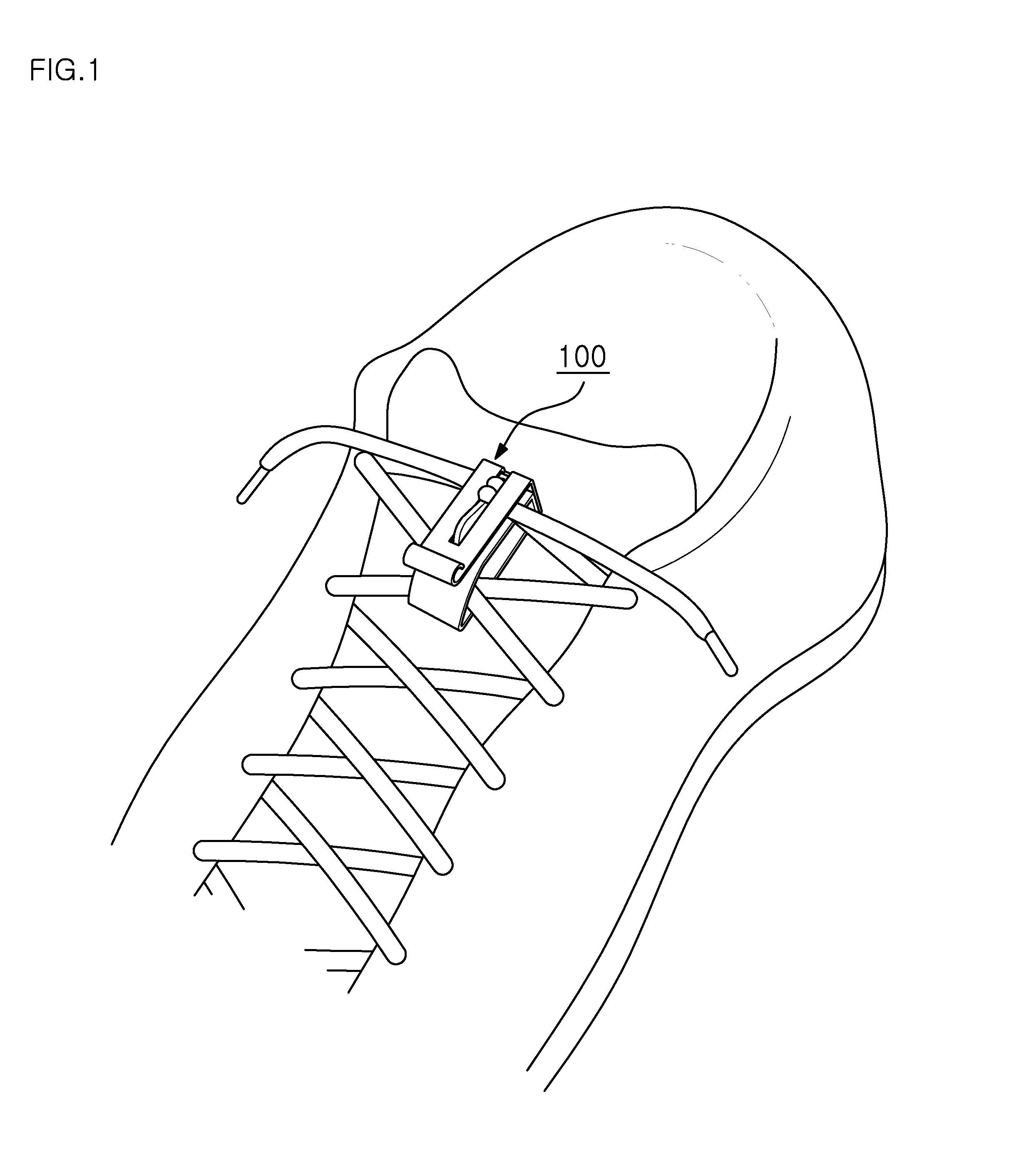

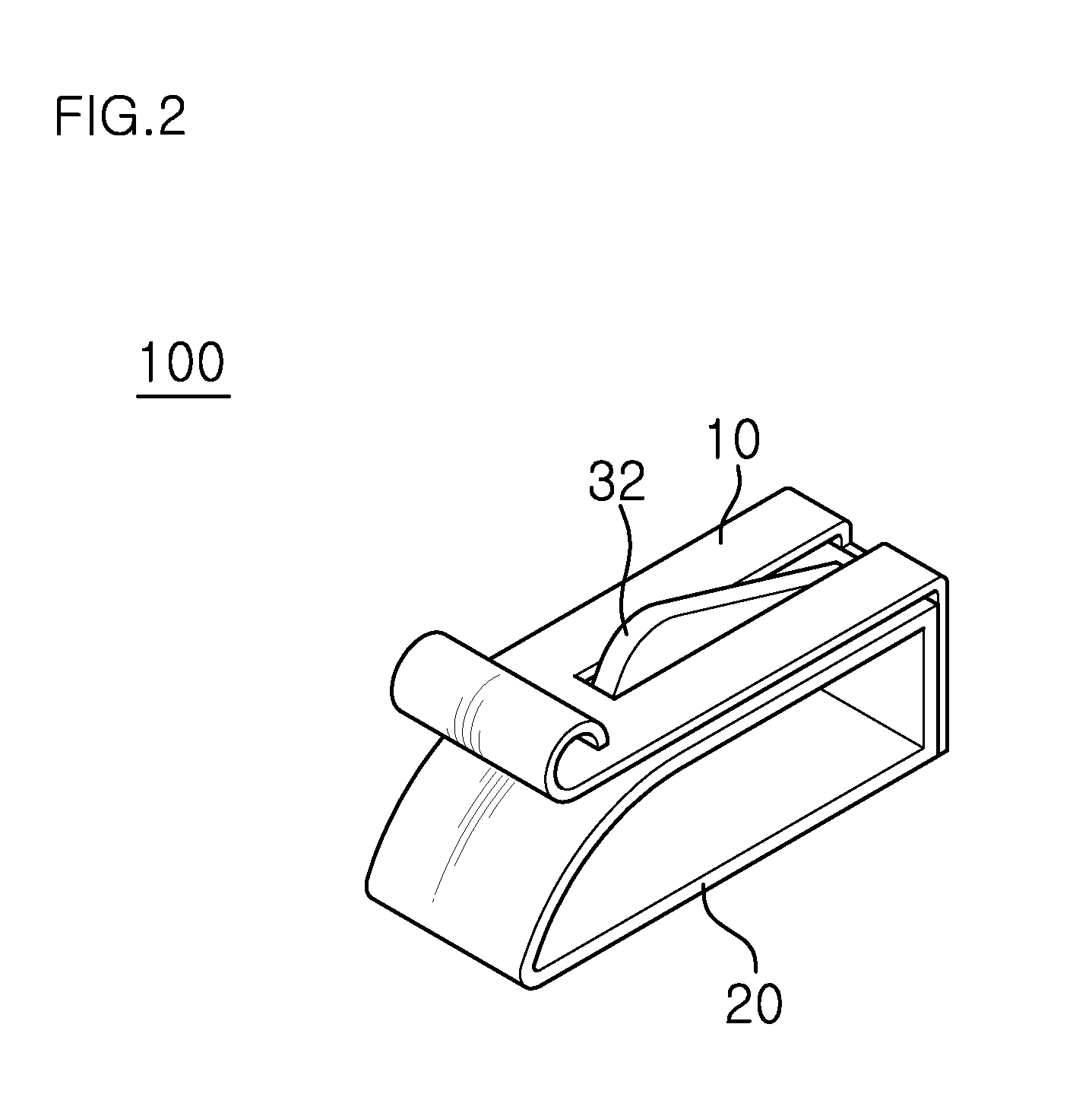

Shoelace retaining device

InactiveUS20150216264A1Simple structureEasy in and outShoe lace fasteningsHaberdasheryEngineeringMechanical engineering

Owner:KIM ILKWON

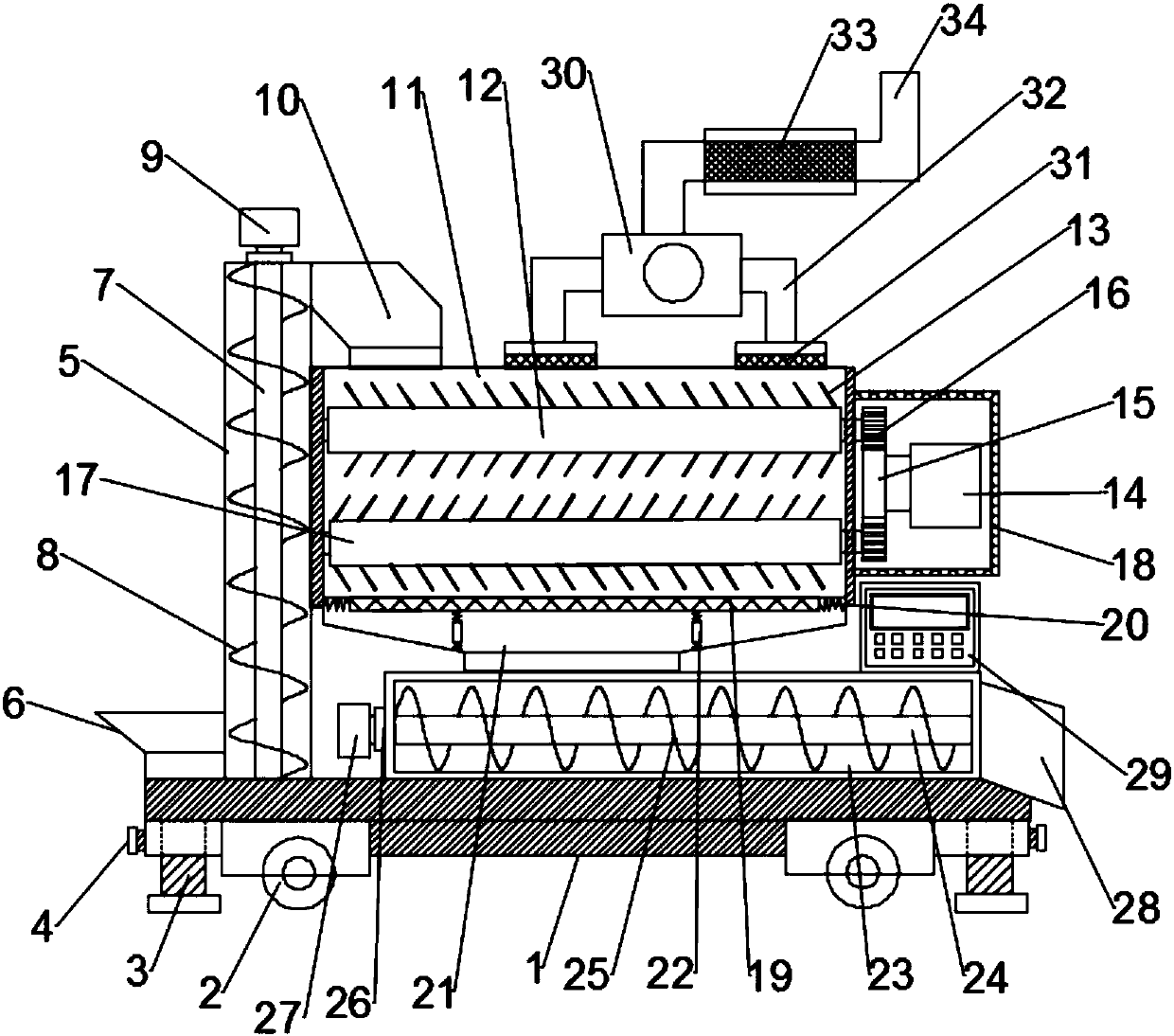

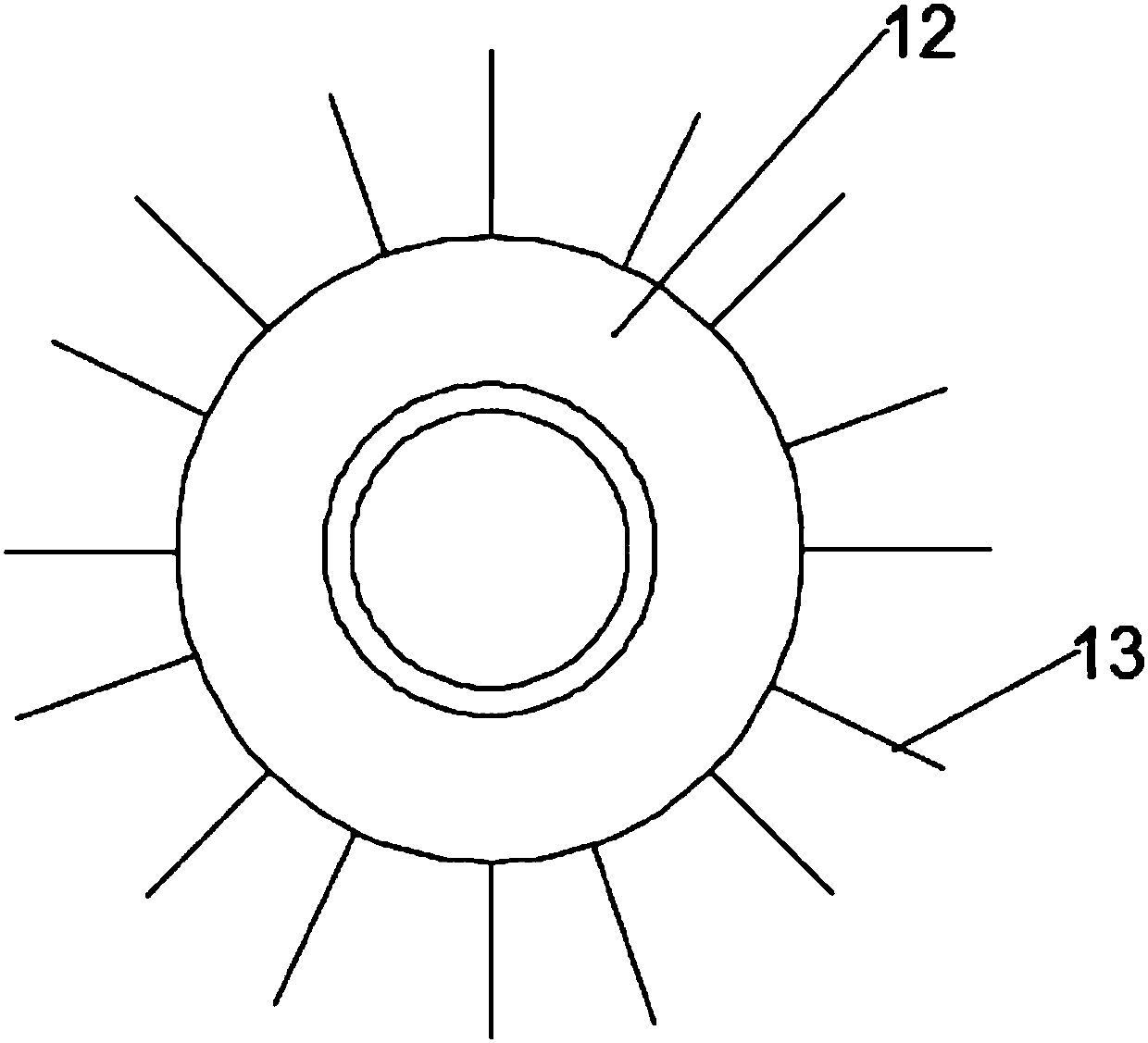

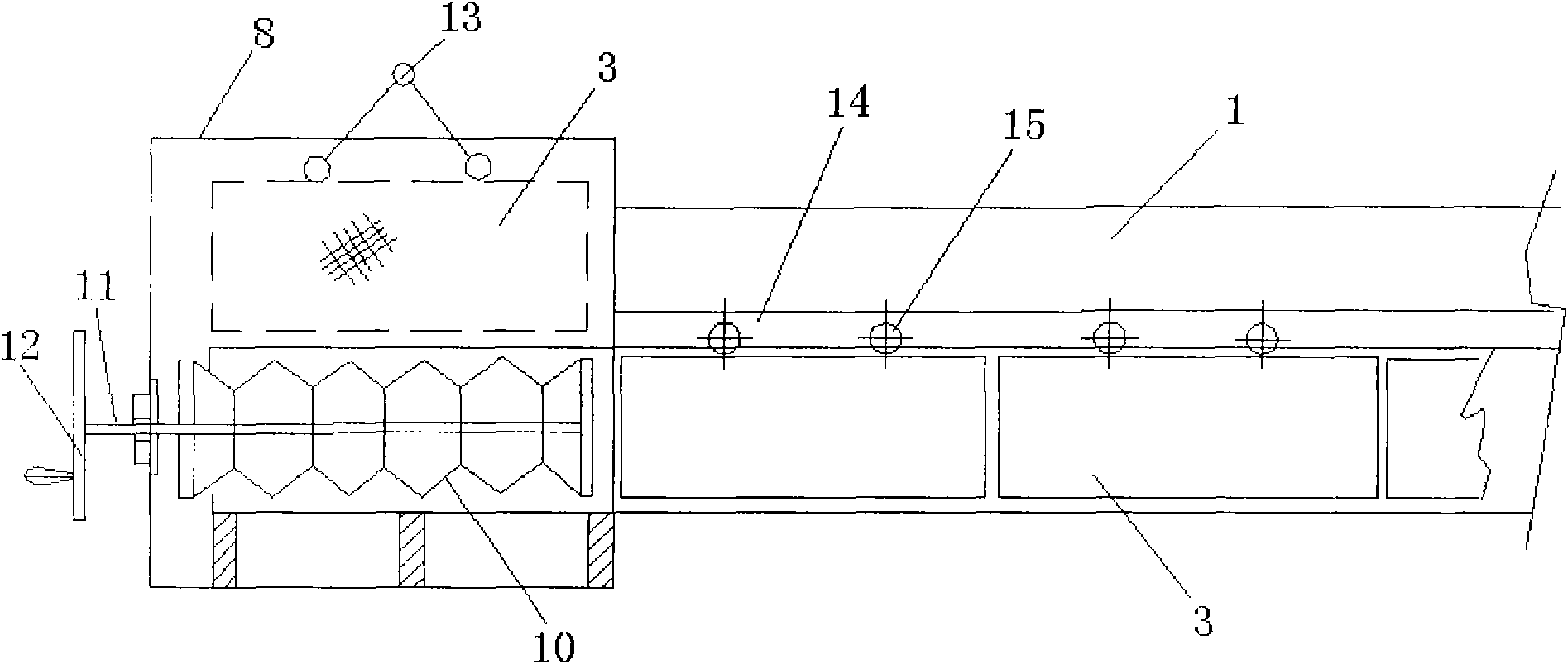

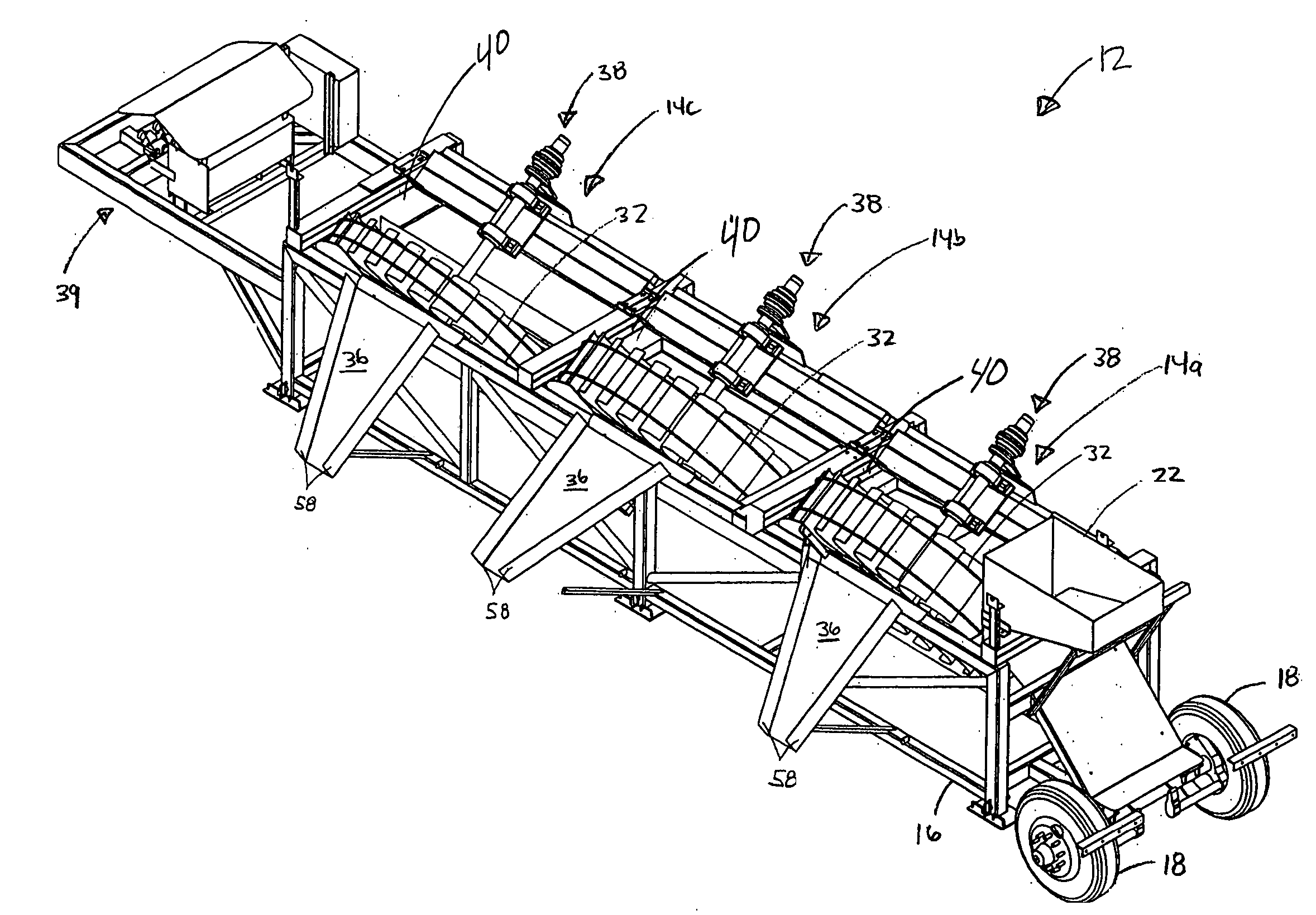

Highly-efficient corn thresher facilitating feeding and discharging

InactiveCN107896646AHigh degree of automationWith dust removal effectThreshersReduction driveEngineering

The invention discloses a highly-efficient corn thresher facilitating feeding and discharging. The highly-efficient corn thresher comprises a fixed chassis, pulleys and fixed thread lift-drop seats, wherein the left and right ends of the fixed chassis are respectively provided with a stop nut; the upper end of the fixed chassis is provided with a conveying drum; the temporal part of the conveyingdrum is provided with a second rotating shaft; a screw conveying mechanism is arranged on the second rotating shaft; the left end of the second rotating shaft is provided with a speed reducer; the left side of the speed reducer is provided with a conveying motor; the right end of the conveying drum is provided with a discharge outlet; the upper end of the conveying drum is provided with a threshing box; and the left side of the threshing box is provided with a lift drum. The highly-efficient corn thresher provided by the invention has simple and reasonable structural design, is simple and rapid to operate in use, is used for the work of corn threshing, has high degree of automation in the process of working, saves a great amount of labor, has high threshing efficiency and dedusting effect,is convenient for feeding and discharging, and has great practicability.

Owner:房立洲

Small flat-bottom drying machine

InactiveCN103234332AImprove drying efficiencySimple structureDrying machines with non-progressive movementsDrying solid materialsPulp and paper industryEngineering

The invention discloses a small flat-bottom drying machine. The small flat-bottom drying machine is characterized by comprising a machine frame, a drying cavity for drying materials and a stirring device for stirring the materials and accordingly accelerating material drying, wherein the drying cavity is fixed on the upper side of the machine frame, the stirring device is arranged in the drying cavity, and the side face of the drying cavity is provided with an automatic blanking device. An interlayer for steam to be lead into and perform heating is arranged in a side wall of the drying cavity, the stirring device is composed of a main rod and vertical rods vertically distributed on the main rod, the lower side of the middle of the main rod is provided with a vertical rotary shaft penetrating through the drying cavity, and the vertical rotary shaft is driven by a motor. By means of the technical scheme, the small flat-bottom drying machine is simple in structure, low in manufacture cost, simple and convenient to operate, convenient to discharge, high in drying efficiency and good in effect.

Owner:NANTONG KNEADING MIXING MACHINE

Locking device of electric appliance

The invention discloses a locking device of an electric appliance. The locking device comprises a casing, the front side of the casing is provided with a work panel, the work panel is provided with grooves, each groove is internally provided with a jack, a plug is arranged outside the grooves, the top and the bottom of each groove are provided with infrared sensors respectively, the top and bottomof the work panel are provided with movable cardboards respectively, one end of each movable cardboard is provided with a first pressure bar, the inner side of the work panel is provided with a transitional connection board, and the transitional connection board is provided with through grooves. Power on / off is realized via memory alloy, the plug is clamped or loosened by utilizing the characteristic that the memory alloy expands with cold and contracts with heat, and the plug is plugged firmly and plugged in / out easily; and the infrared sensors send a signal to a PLC when it is detected thatthe distance to the hands is very near, the PLC controls the movable cardboards and a second pressure bar to work, the plug is connected with a socket and fastened, and electric shock caused by poweron by inserting the plug directly is avoided.

Owner:ANHUI WEIHONG STEEL STRUCTURE GRP

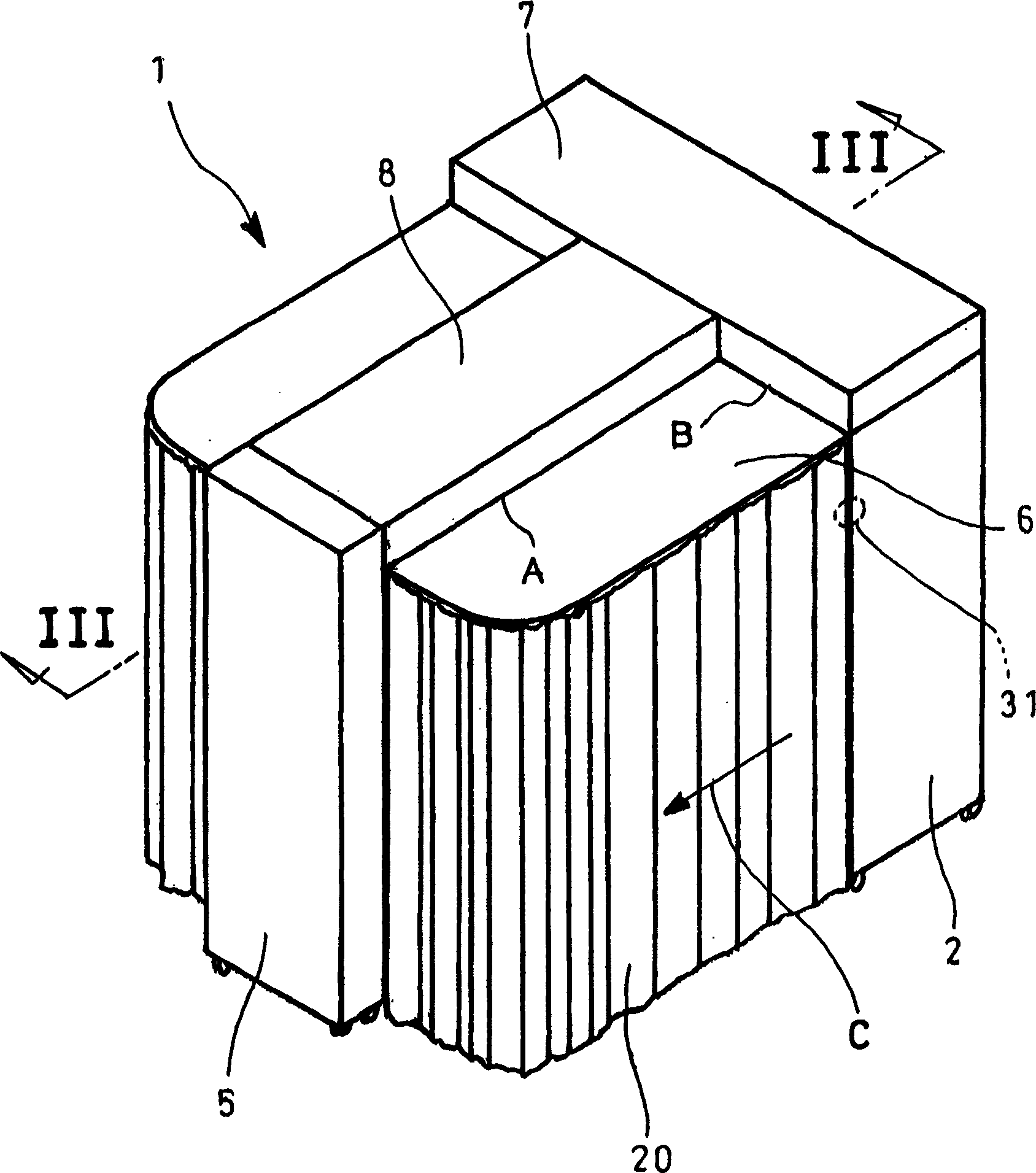

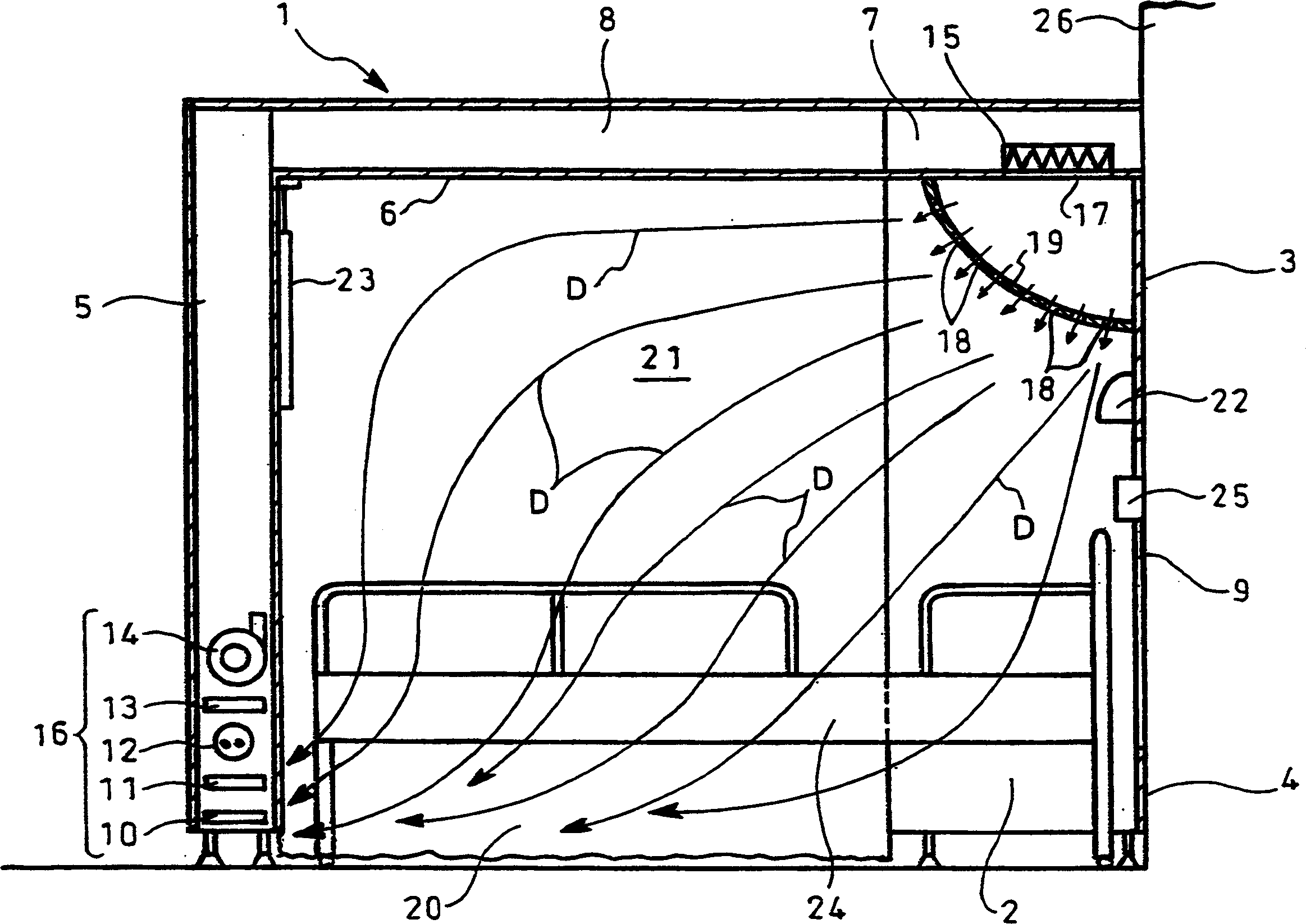

Desinfection chamber unit

InactiveCN1541635AIncrease air volumeReduce air volumeBreathing protectionTreatment roomsInterior spaceAir cleaning

The desinfection chamber consists of frame on floor and hanging curtain to enclose one inner space. The frame has an opened side part and the hanging curtain is used to open or close the opened side part selectively. The frame is provided with an airflow passage, and inside the airflow passage, there is air purifier extending from the foot part of patient to the head blowing canal to convey air via the frame. Via the blowing canal, purified air is blown into the desinfection chamber. The frame has one opening near the head of the patient, and via the opening, medical operating apparatus may be transferred into the desinfection chamber, and the frame is near the wall.

Owner:SANKI ENG CO LTD

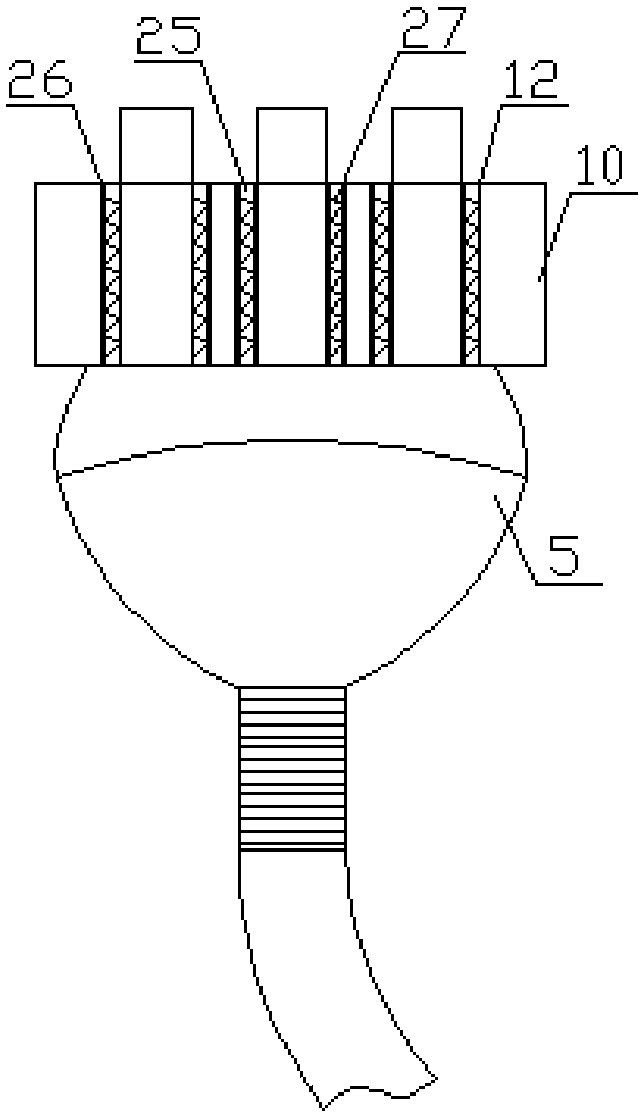

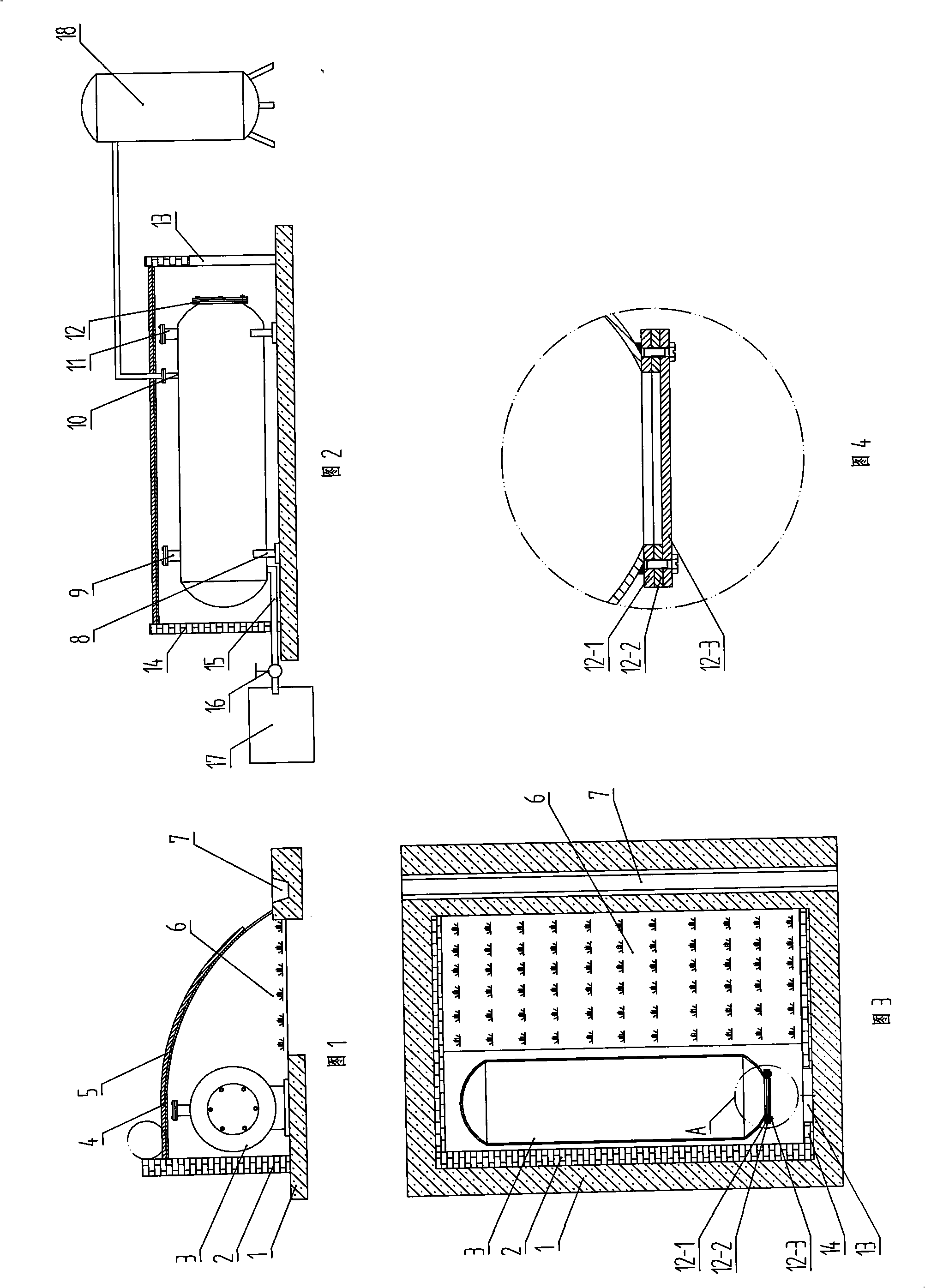

Process and equipment forsolar energy gasification of plant stalk and comprehensive utilization of waste slag

InactiveCN101318853AEasy in and outAvoid pollutionBio-organic fraction processingEnergy inputSocial benefitsSlag

The invention provides a process and devices for plant straw gasification by solar energy and comprehensive utilization of waste residue. The process flow comprises the following steps of: 1. spontaneous fermentation; 2. gasification; 3. residue discharging; 4. planting edible fungi by the waste slag; and 5. fertilizing fungi residue in farmland. The devices for realizing the process comprise a solar greenhouse, a gasification tank arranged in the greenhouse and a gas storage tank arranged outside the greenhouse; a low part in the front of the solar greenhouse is a planting area for planting vegetables and flowers. The gasification tank is a cylindrical sealed tank made of steel; one end of the gasification tank is provided with a manhole; the manhole comprises a flange welded on the end part of the gasification tank, a gasket and a manhole door, which are connected through bolts; an upper part of the gasification tank is respectively provided with a feeding hole, a discharge hole and a vent; and a lower part of the gasification tank is provided with a water outlet which is connected with a fertilizer storage tank through a valve. The process and the devices realize high-efficiency disposal of straw resource of wheat and rice and no environmental pollution disposal of manure, comprehensively utilize the waster residue, and improve the economic and social benefits.

Owner:苗晓

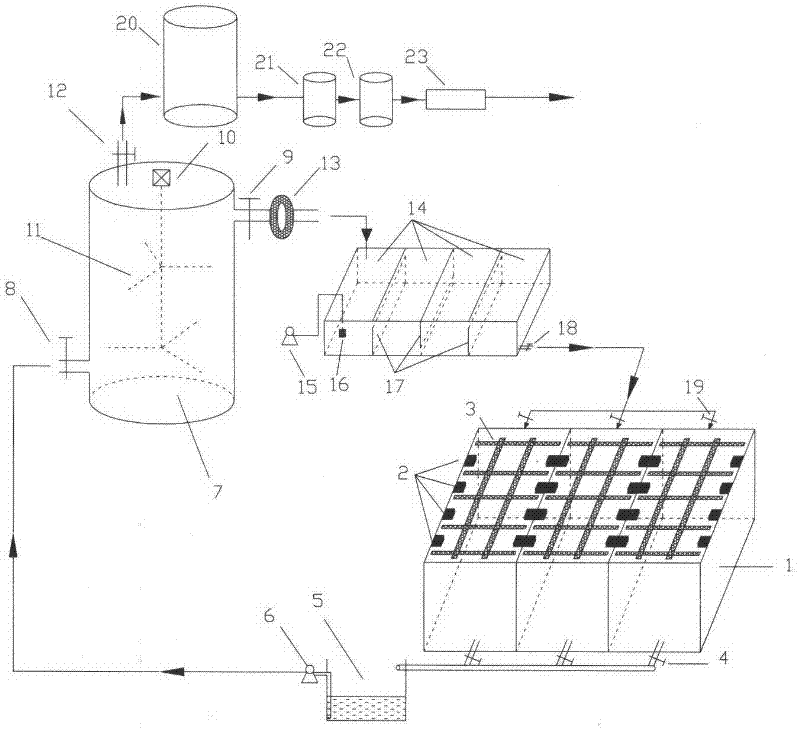

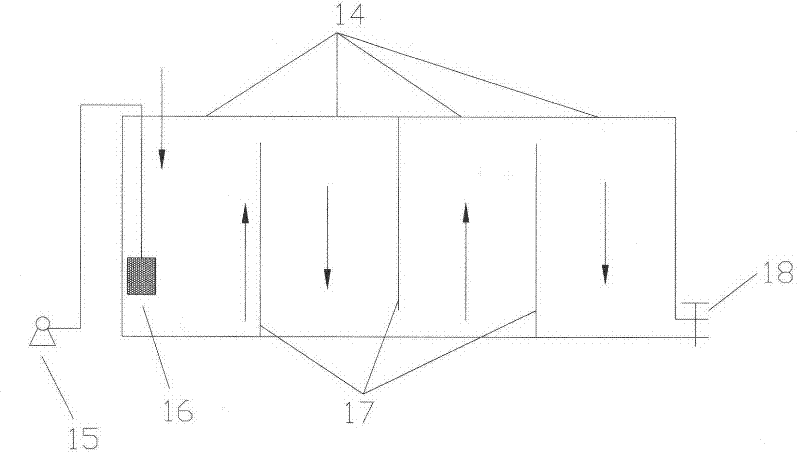

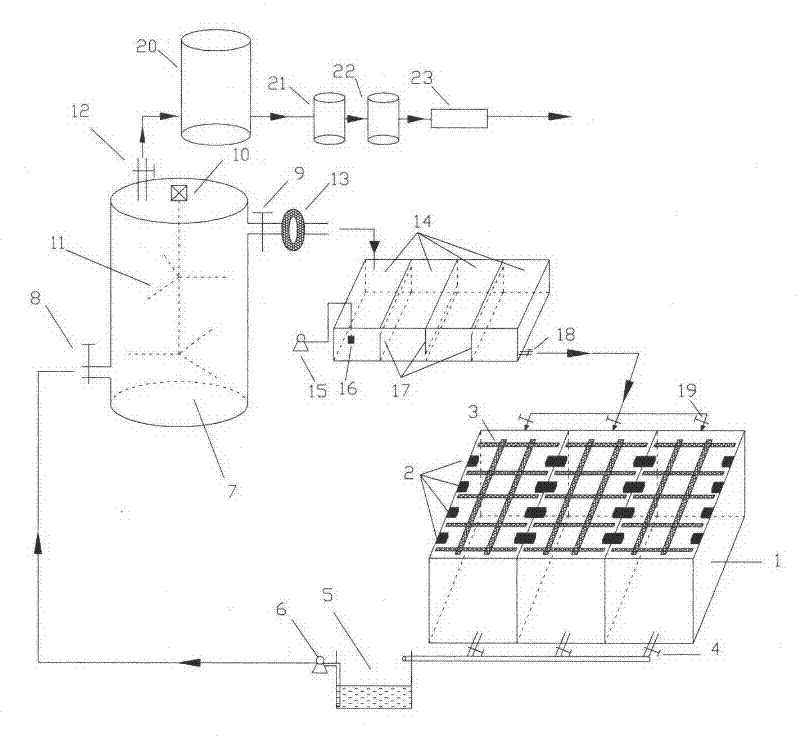

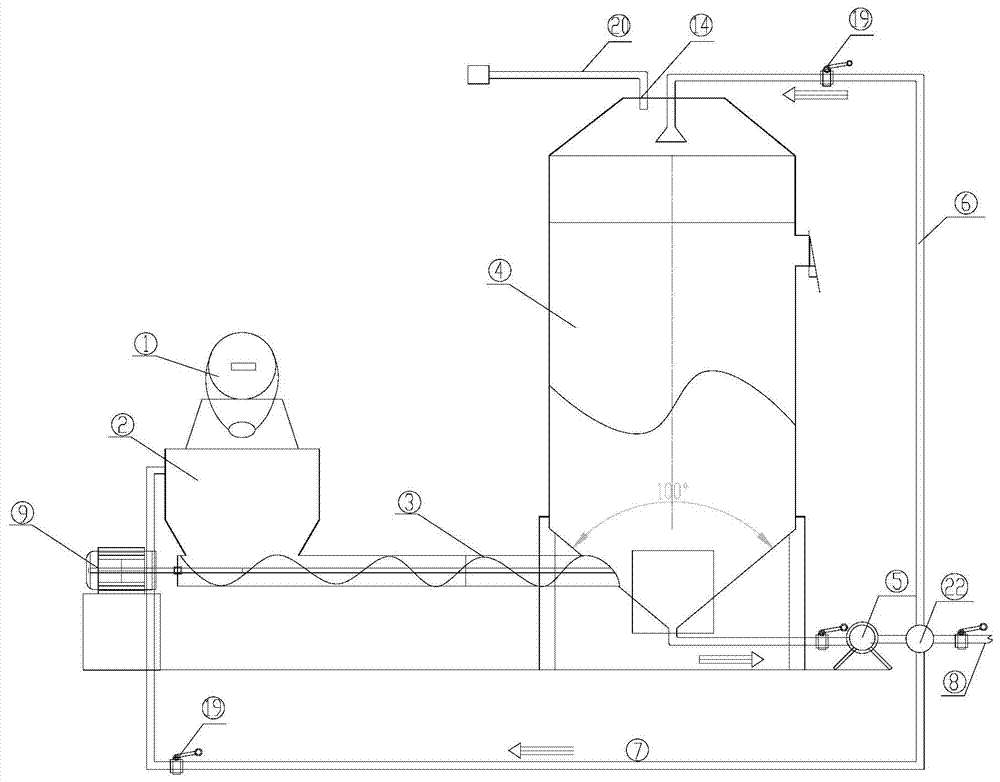

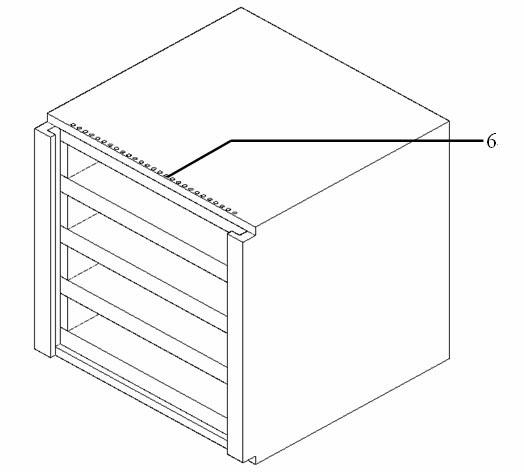

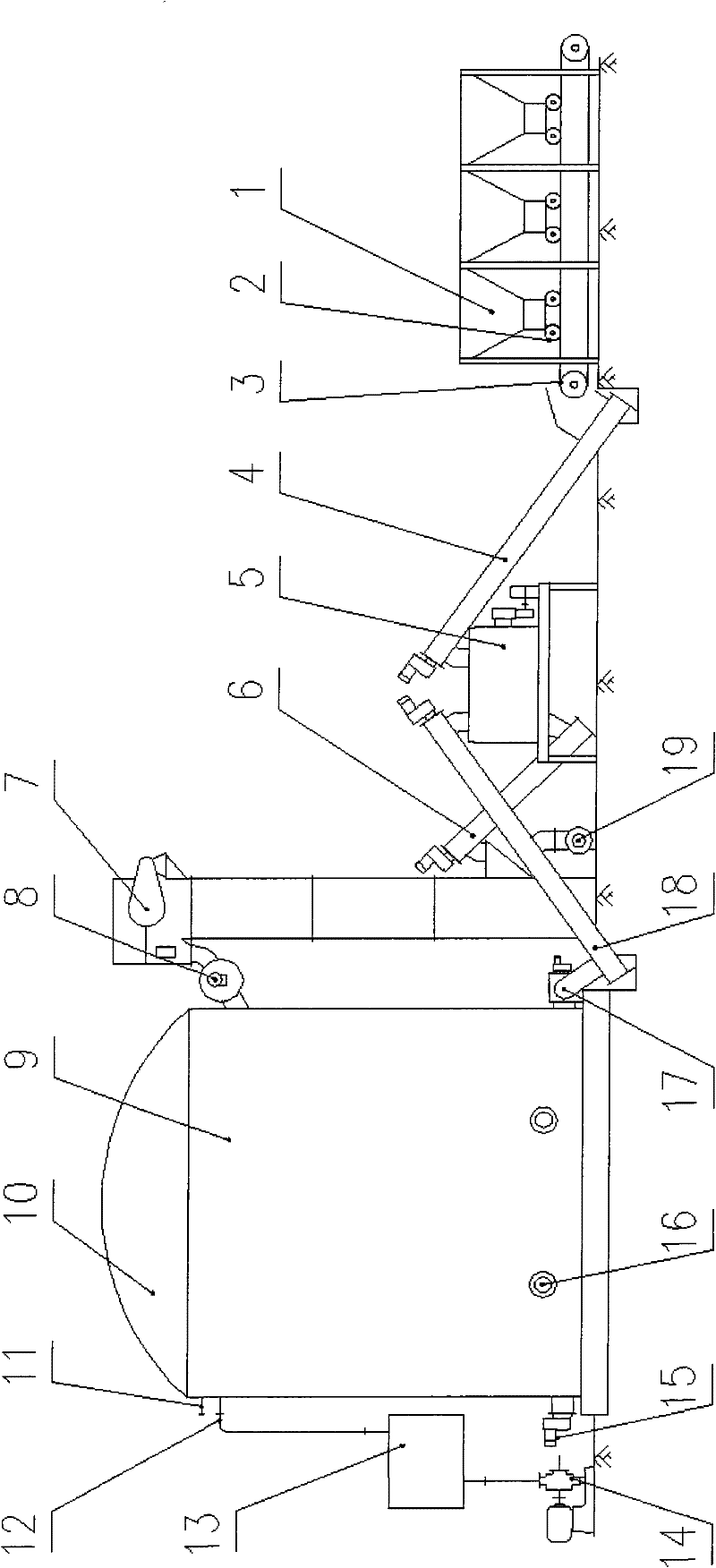

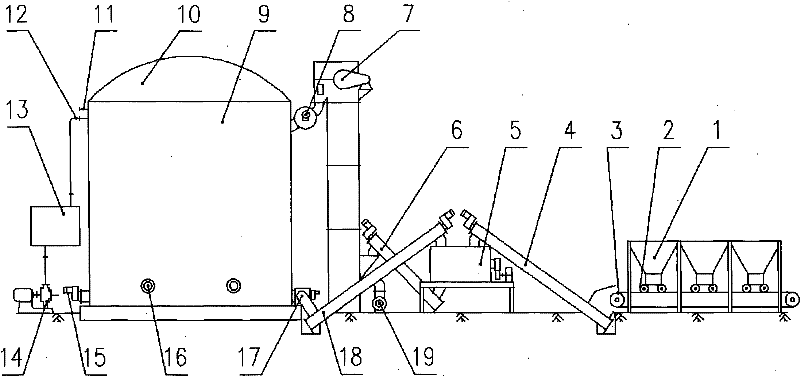

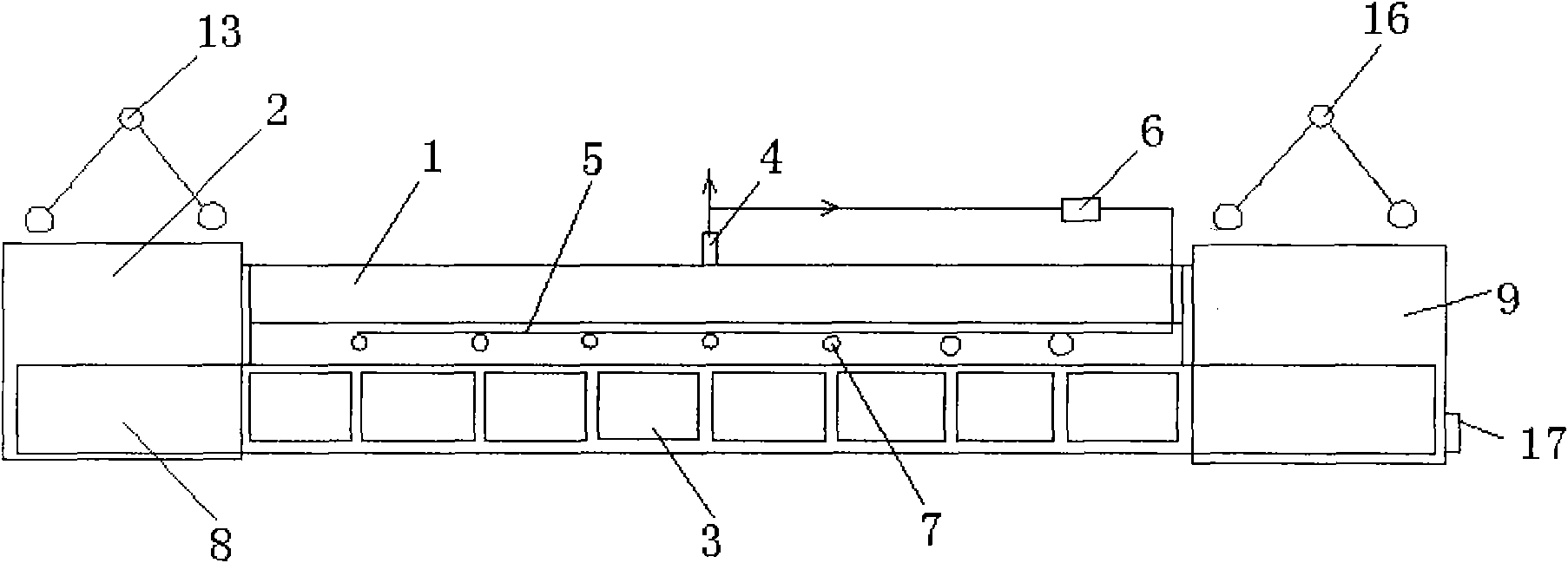

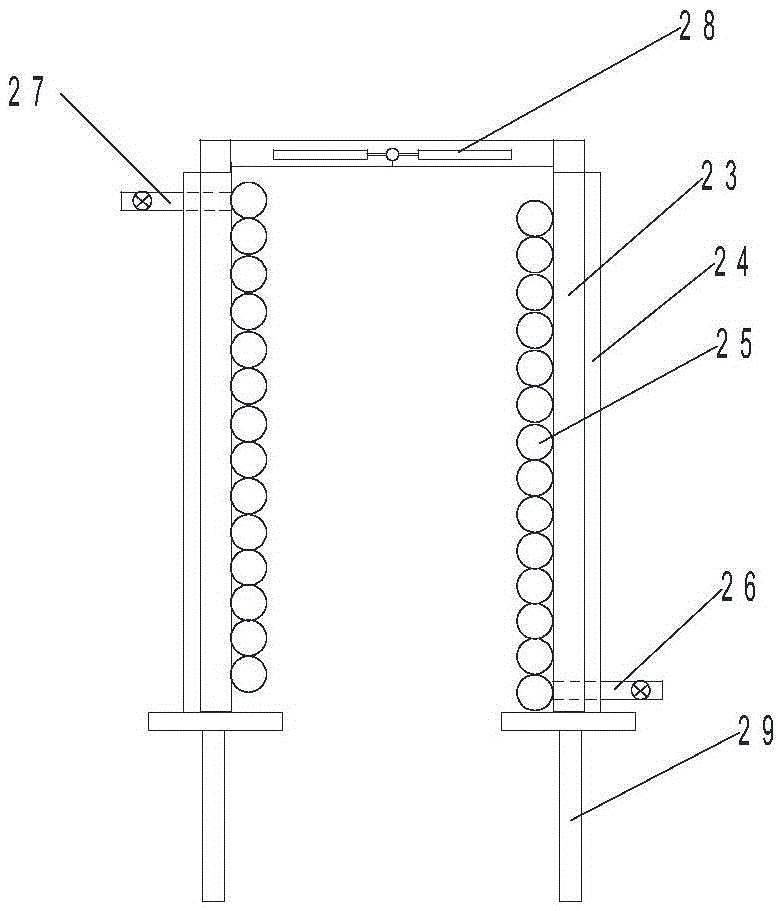

Process and equipment for preparing biogas by continuous mode dry fermentation

InactiveCN102453731ASmall footprintReduce energy consumptionBioreactor/fermenter combinationsBiological substance pretreatmentsControl systemGreen materials

The invention discloses a process and equipment for preparing biogas by continuous mode dry fermentation. The process comprises the following steps of: mixing various green materials (animal manure, straw, organic waste and the like) uniformly, delivering into a fermentation tank, feeding and discharging once per day, recovering 25-35% of discharged materials into a stirrer and mixing with green materials uniformly, and heating the percolate in the fermentation tank through a spray pump by a heat exchanger and then spraying into a reaction tank. The major equipment comprises a storage bin, a measuring belt, a gathering belt, a screw feeder, a stirrer, a feed screw, an elevator, a feeder, a fermentation tank, a gas reservoir, a biogas outlet tube, a spray tube, a heat exchanger, a spray pump, a discharge screw, a gathering screw, a discharging machine, a recovery screw, a flow-dividing screw, a control system and the like.

Owner:QINGDAO TIANREN ENVIRONMENT

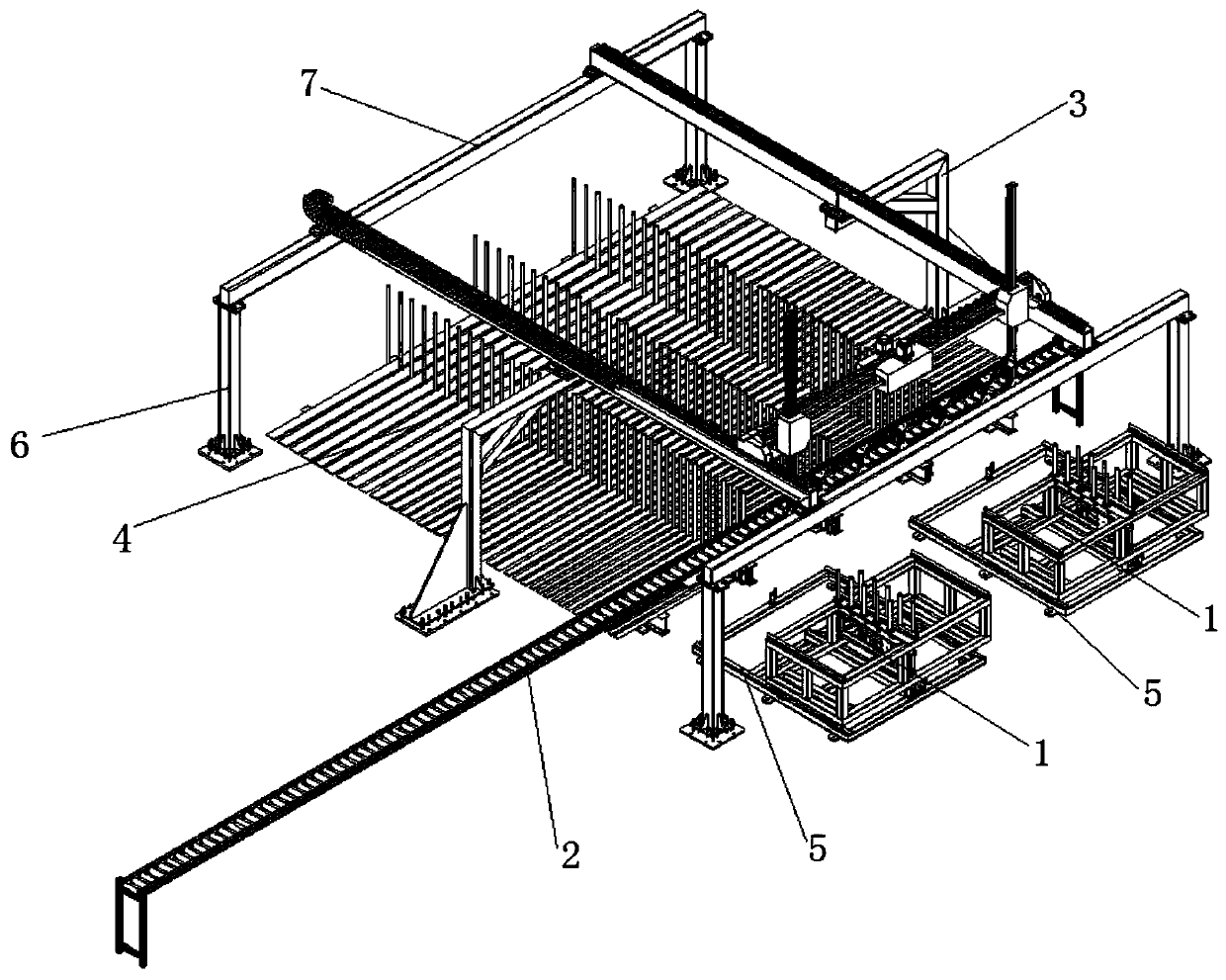

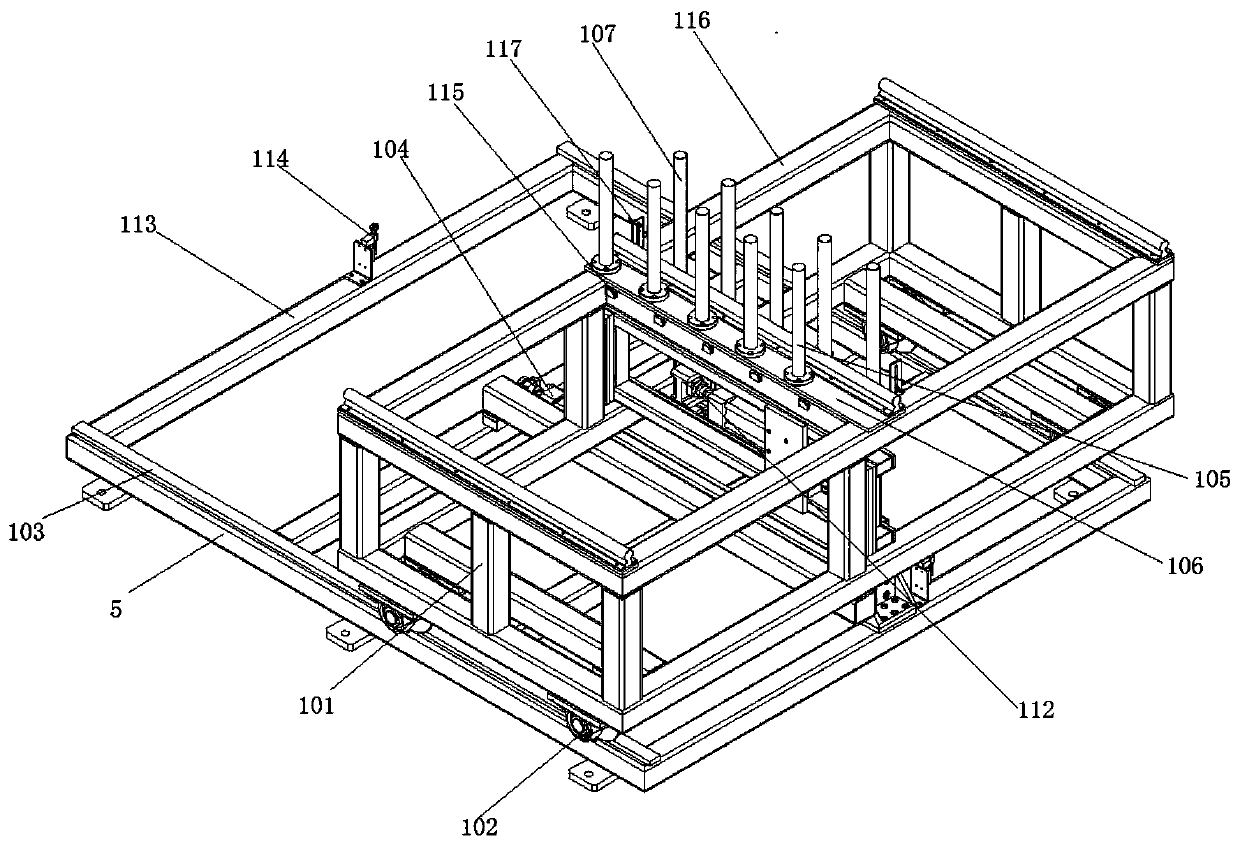

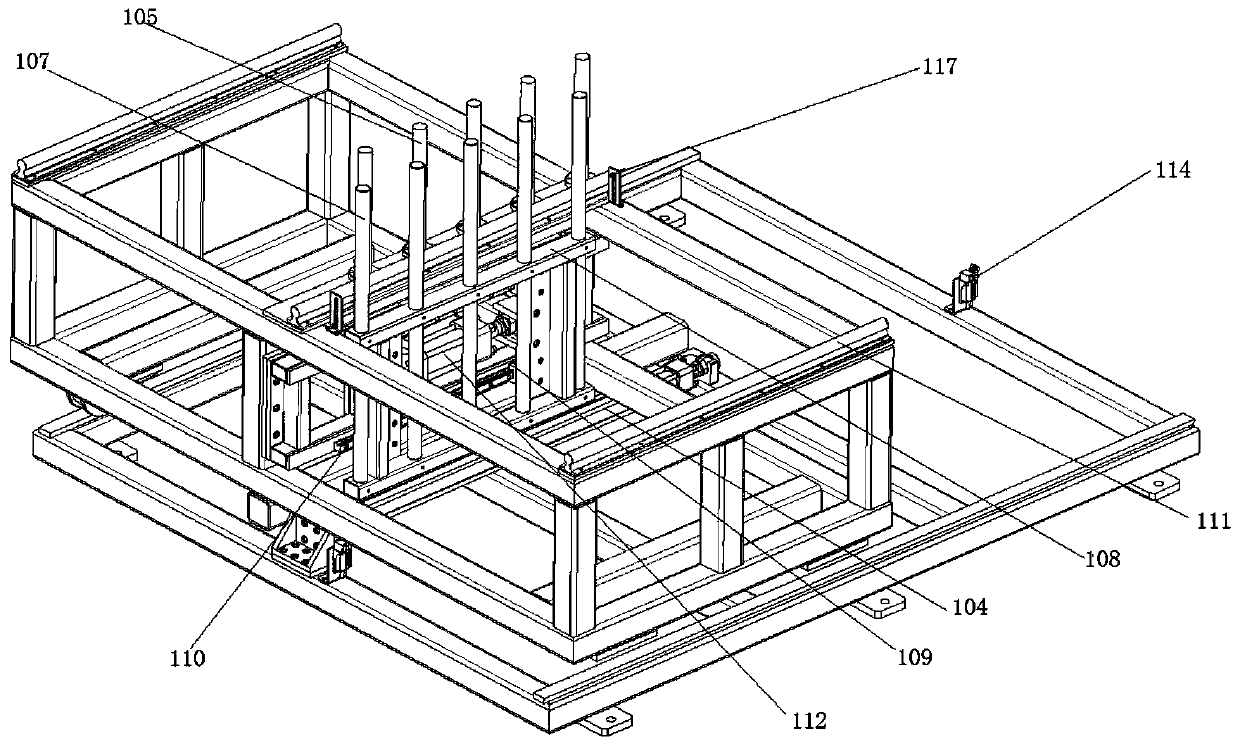

Automatic copper bar transplanting warehouse

The invention relates to an automatic copper bar transplanting warehouse which is used for carrying out warehouse-in and warehouse-out treatment on copper bar workpieces. The transplanting warehouse comprises a feeding and pushing platform, a roller conveying line, a truss manipulator and a copper bar storage location. The feeding and pushing platform is located at a feeding end of the truss manipulator. A bottom rack of the feeding and pushing platform is connected and fixed to the ground through an expansion bolt. The roller conveying line is located at the feeding end of the truss manipulator so as to carry out positioning operation on the copper bar workpieces. The truss manipulator comprises a steel structure transverse shaft supported by a stand column, a grabbing mechanism and a moving mechanism, wherein the grabbing mechanism and the moving mechanism are located on the transverse shaft. And the truss manipulator is used for completing warehouse-in and warehouse-out operation ofthe workpieces, and the copper bar storage location is located right below the truss manipulator and is used for storing the copper bar workpieces. The automatic transplanting warehouse can grab thecopper bars with different specifications, is excellent in compatibility, and can carry out classified warehouse-in and warehouse-out operation according to products with different specifications.

Owner:杭州研卓智能科技有限公司

Efficient directly burning sealed metal magnesium reducing smelter

InactiveCN1811313AImprove productivityImprove combustion efficiencyFurnace typesProduction rateHigh density

The efficient directly burning sealed metal magnesium reducing smelter is superior to traditional metal magnesium reducing smelter, which has the demerits of poor heat transmission, low heat utilization rate, etc. The present invention has directly burning high density arranged reducing pots, homogeneous heat field, mechanical ash discharging, high production efficiency, high heat utilization rate, high yield and high product quality.

Owner:维恩克材料技术(北京)有限公司

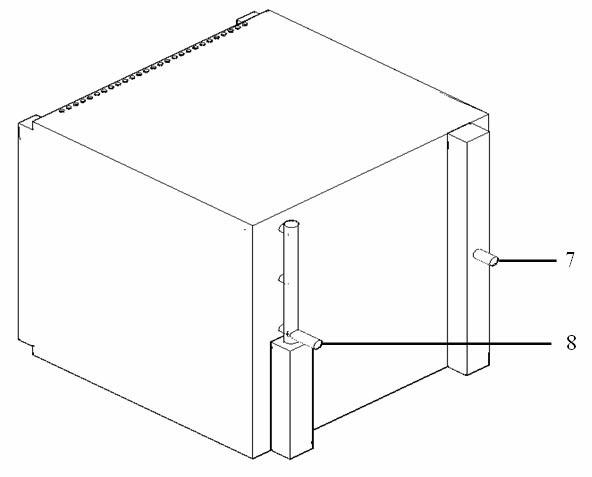

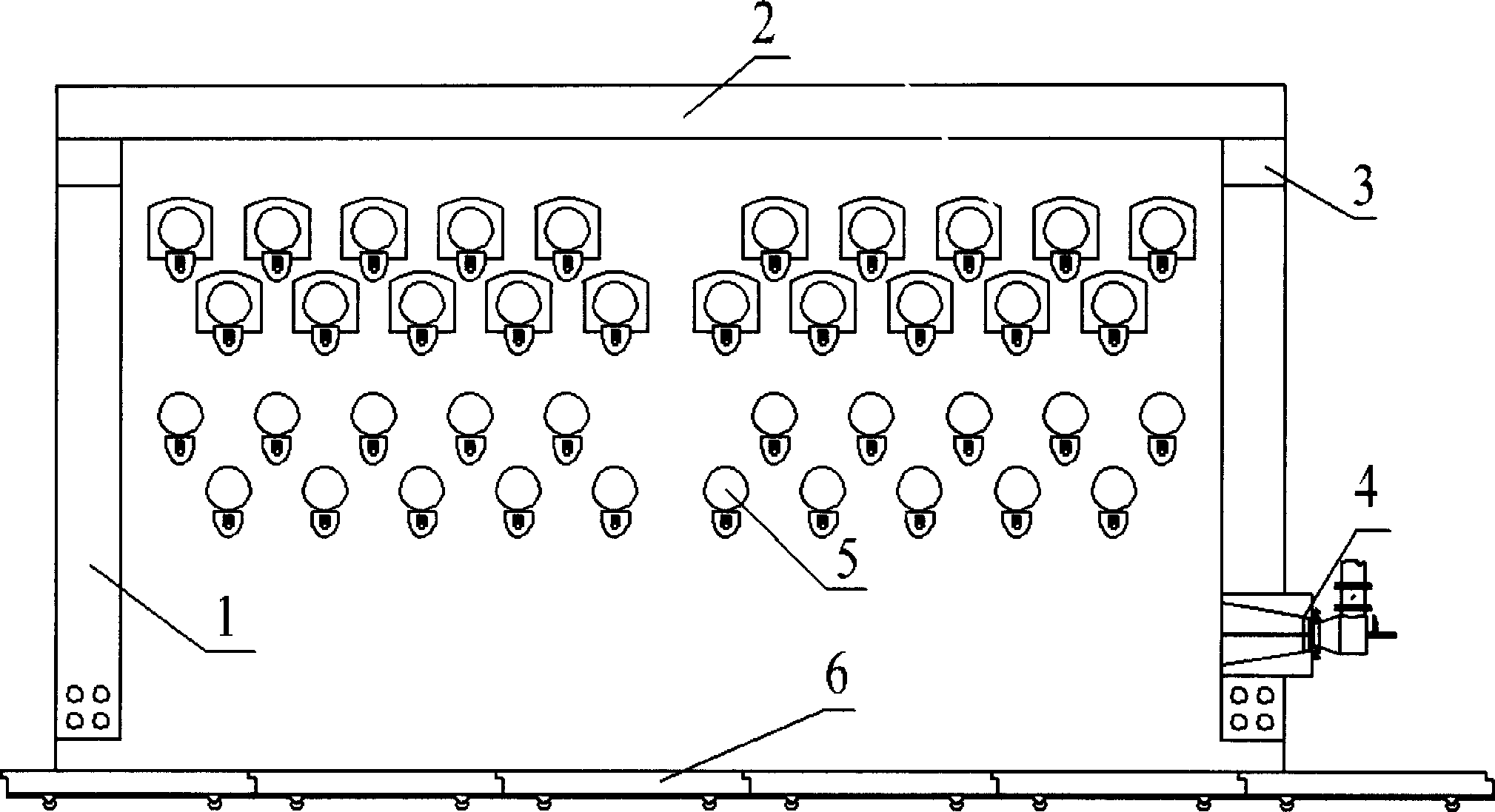

Net cage plug flow type fermentation device and operational method thereof

InactiveCN102120958AIncrease temperatureAvoid crust cloggingBioreactor/fermenter combinationsBio-organic fraction processingCompression PumpEngineering

The invention relates to a net cage plug flow type fermentation device and an operational method thereof. The net cage plug flow type fermentation device is characterized by comprising a gallery, wherein feed liquid is filled into the gallery; a net cage delivering device used for delivering the net cage into and out of the gallery is arranged on the gallery; a gas guide pipe and a gas return pipe are arranged at the inner upper part of the gallery; the output end of the gas guide pipe is provided with two pipelines of which one is connected with a biogas collecting device and the other one is connected with a biogas compression pump; the output end of the biogas compression pump is connected with the input end of the gas return pipe; a plurality of jet exhausts are arranged at intervals on the gas return pipe; one net cage is correspondingly positioned below each jet exhaust; and a heating pipe is also arranged at the inner upper part or the inner lower part of the gallery and connected with hot circulating water. The net cage plug flow type fermentation device is convenient to operate, has low energy consumption and high gas yield, can effectively avoid incrustation and blockage of the gallery, and provides a favorable anaerobic environment, thus being widely used in the fermentation process of excrement and straw.

Owner:绿能生态环境科技有限公司

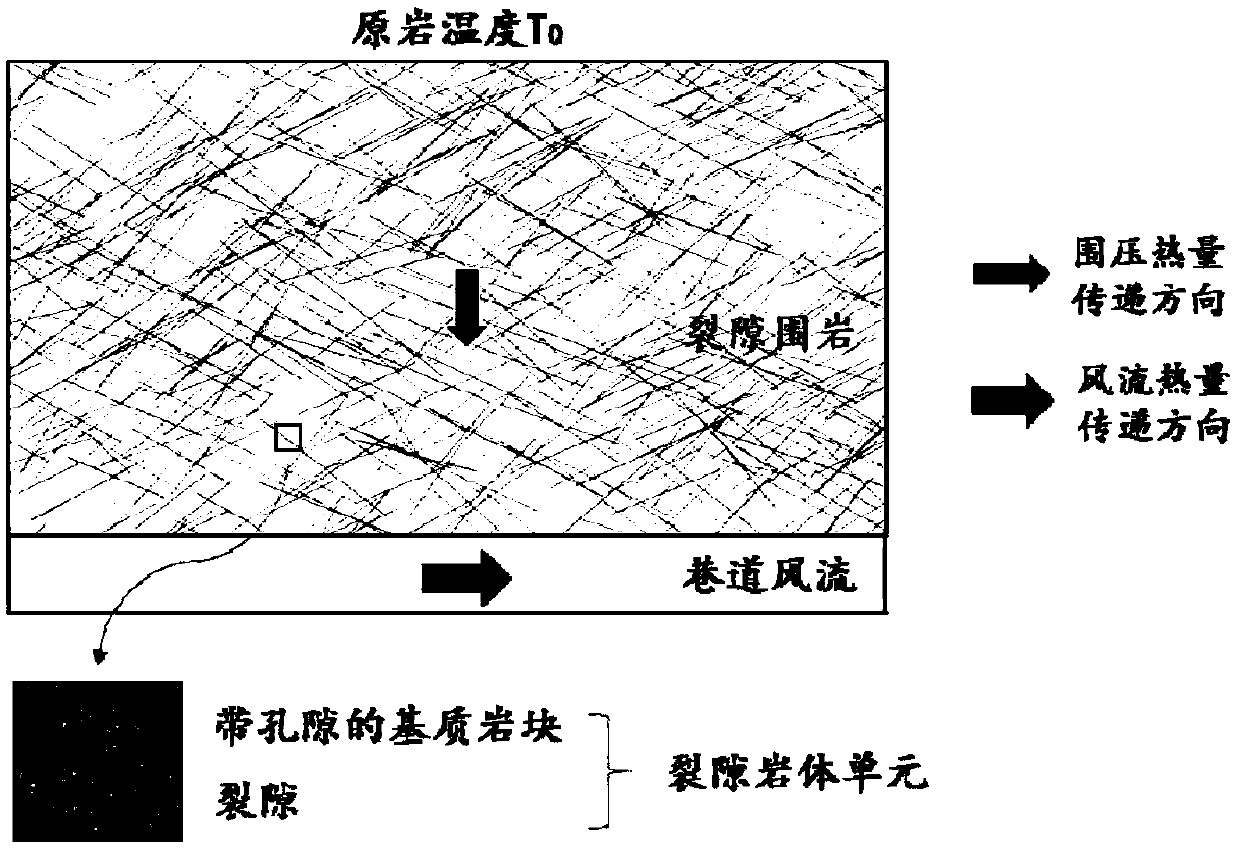

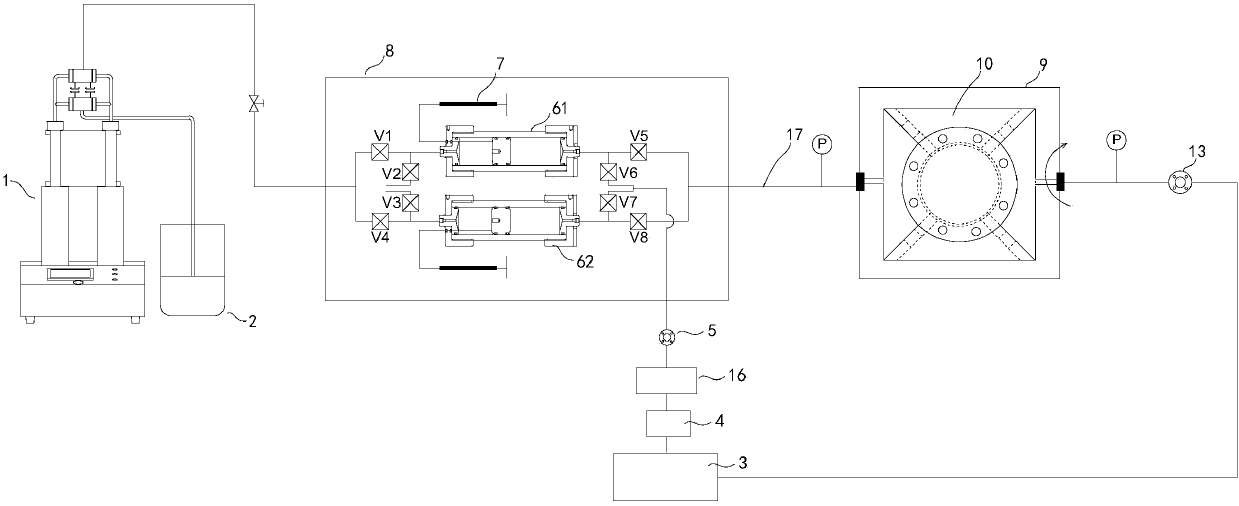

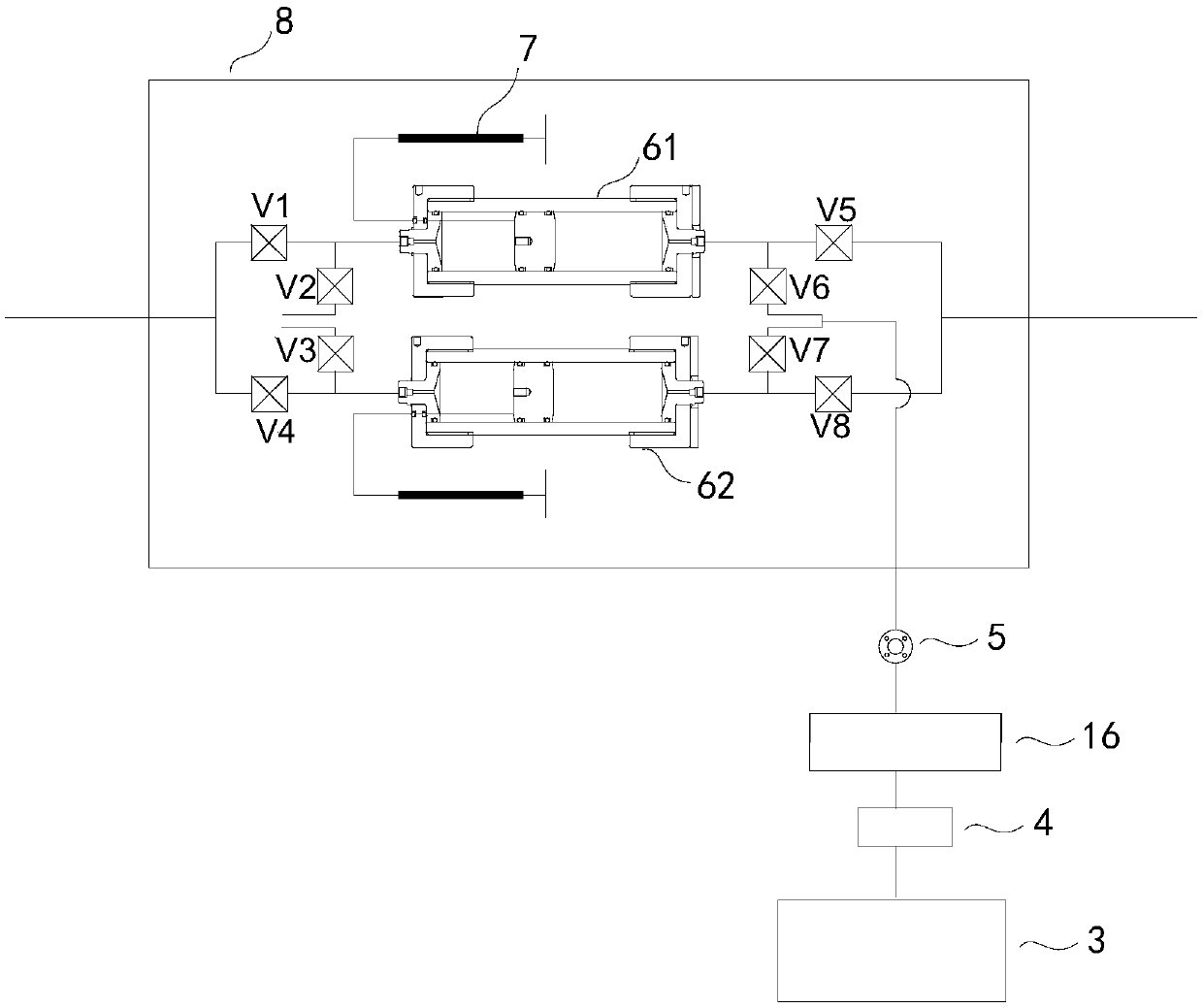

Equivalent thermal conductivity coefficient measurement system and calculation method for fractured rock mass unit structure

PendingCN109668926AEasy to holdPrecisely adjust the rotation angleMaterial heat developmentGeothermal energy generationPorosityHeat flow

The invention discloses an equivalent thermal conductivity coefficient measurement system and calculation method for a fractured rock mass unit structure. A single fracture seepage plate is arranged in a heating thermal insulation box body, an extracted fractured rock mass unit structure is simulated as matrix rock blocks with different porosity and single fractures, the equivalent thermal conductivity coefficient measurement system for a fractured rock mass unit is designed through the fact that the periphery of the single fracture seepage plate in the heating thermal insulation box body is filled with the matrix rock blocks simulated by rock like materials, and then the single fractures at different angles can be simulated by adjusting the included angle between the single fracture seepage plate and the heat flow direction; and after changing the test conditions, equivalent thermal conductivity coefficients of the matrix rocks with the different porosity, the single fractures at thedifferent angles, different fracture widths, fluid types, fluid flow in different fractures or pressure gradients can be analyzed. According to the equivalent thermal conductivity coefficient measurement system and calculation method for the fractured rock mass unit structure, the equivalent thermal conductivity coefficient of the fractured rock mass unit under the porosity matrix blocks and single fracture water seepage conditions can be studied, and a foundation for study of moisture and heat migration of a whole fractured rock mass is laid.

Owner:CHINA UNIV OF MINING & TECH

Small overheating-resistant concrete stirrer

InactiveCN105538505AReduce the temperatureDischarge in timeHollow article cleaningCement mixing apparatusContinuous useAgricultural engineering

The invention discloses a small overheating-resistant concrete stirrer. The concrete stirrer comprises a stirring barrel, a water inlet pipe, pressure nozzles, a frame, a round cover body, a stirring shaft, a motor, and an anti-overheating protective sleeve. The anti-overheating protective sleeve is sleeved on the exterior of the motor and comprises a sleeve body and a sleeve cover; an anti-overheating interlayer, which is composed of condenser pipes, is arranged on the sleeve body, the sleeve cover is provided with an exhaust fan; the water inlet pipe is embedded in the inner wall of the stirring barrel along the peripheral direction of the upper part of the stirring barrel, pressure nozzles are arranged on the water inlet pipe at intervals; the stirring shaft comprises a main shaft and multiple auxiliary shafts, threads are arranged on the stirring shaft, the main shaft is vertically arranged in the stirring barrel, multiple auxiliary shafts are vertically fixed and arranged on the main shaft in pairs, and the lengths of the auxiliary shafts increase and then decrease from top to bottom. The provided stirrer can prevent motor from getting overheated and has the advantages of long continuous using time, high stirring efficiency, easy maintenance and washing, and long service life.

Owner:李柳晶

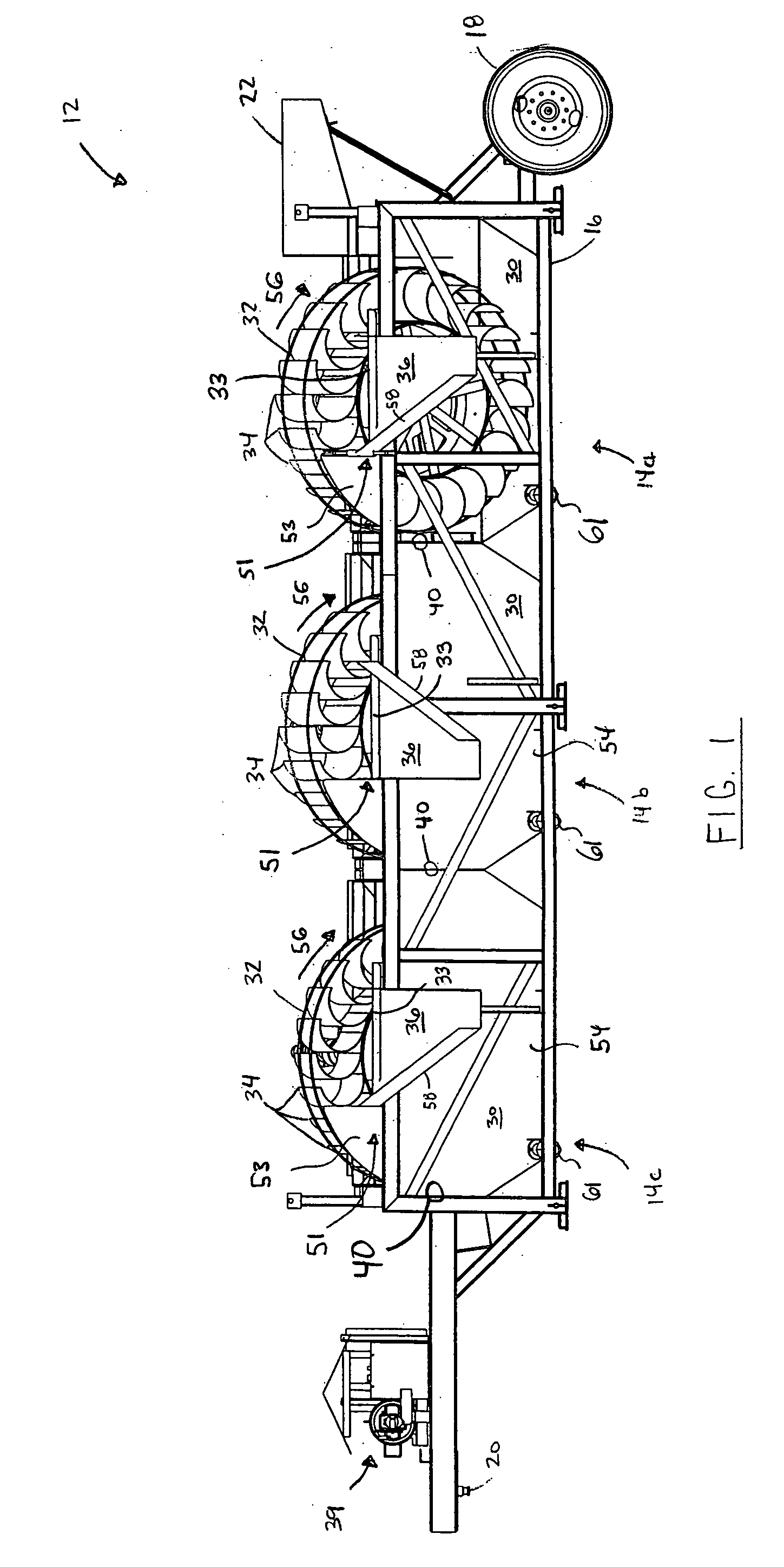

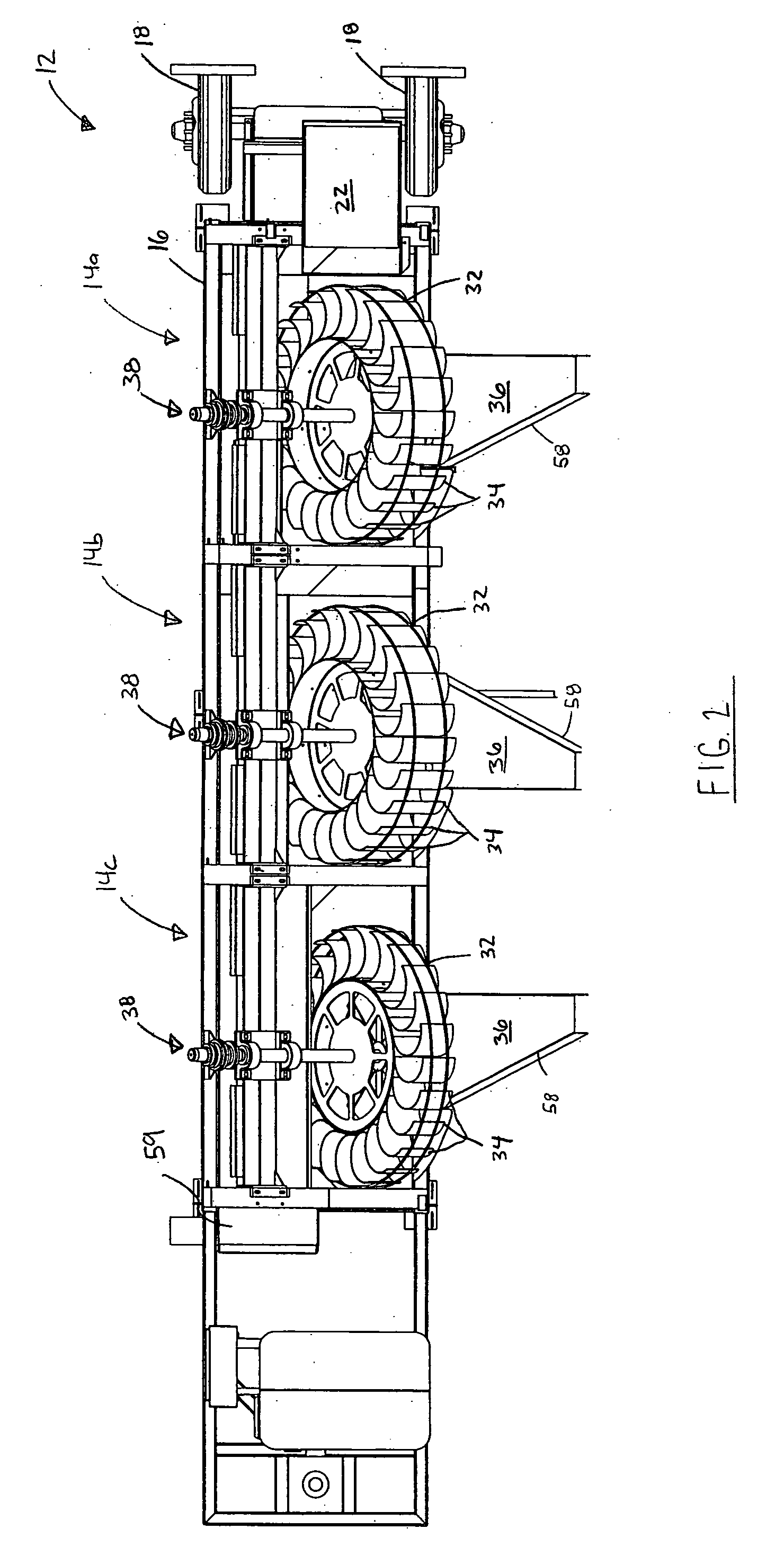

Material classifier having a scoop wheel

InactiveUS20050098484A1Easy and less-costly to manufactureEasy to transportSievingGas current separationEngineeringLiquid solid

A material classifier for classifying a liquid-solid mixture containing solid material to be separated is provided. The material classifier includes a tank defining a reservoir for receiving the liquid-solid mixture, and a scoop wheel including a plurality of circumferentially spaced apart scoops for scooping material from the tank and subsequently discharging the scooped material from the tank during rotation of the scoop wheel. A classification system and method of classifying material is also provided.

Owner:THOR GLOBAL ENTERPRISES

Warehouse management method based on active electronic tag

InactiveCN110020700AEasy to findEasy to countCo-operative working arrangementsSoftware engineeringLocation area

The invention relates to the technical field of article management, in particular to a warehouse management method based on an active electronic tag. According to the invention, the positioning base stations are arranged in different storage location areas; each positioning base station checks the electronic tags in the signal receiving and transmitting range of the positioning base station, so that all the articles existing in each area are known, and whether the actual inventory positions of the articles are consistent with the inventory positions recorded in the inventory information or notcan be inquired by comparing the numbers of the electronic tags arranged on the articles in a sleeving manner with the inventory information. And if inconsistency is found, the inventory positions ofthe articles can be adjusted immediately through manual work, so that the actual storage locations of the articles are consistent with the inventory positions recorded in the inventory information, and the articles can be conveniently searched, counted and put in and out of the warehouse. Meanwhile, whether the articles are in the warehouse or not can be known in real time, if it is found that the articles in the inventory list are not in the warehouse, recovery measures can be started in time, and the recovery probability of lost articles is greatly improved.

Owner:SHENZHEN LIANZHI INTERNET OF THINGS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com