Small convenient efficient smashing device

A high-efficiency crushing and convenient technology, applied in the direction of grain processing, etc., can solve the problems of affecting product quality, processing production efficiency, low degree of automation, and increasing labor expenditure, so as to improve crushing efficiency and fineness, improve production efficiency, and screen high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

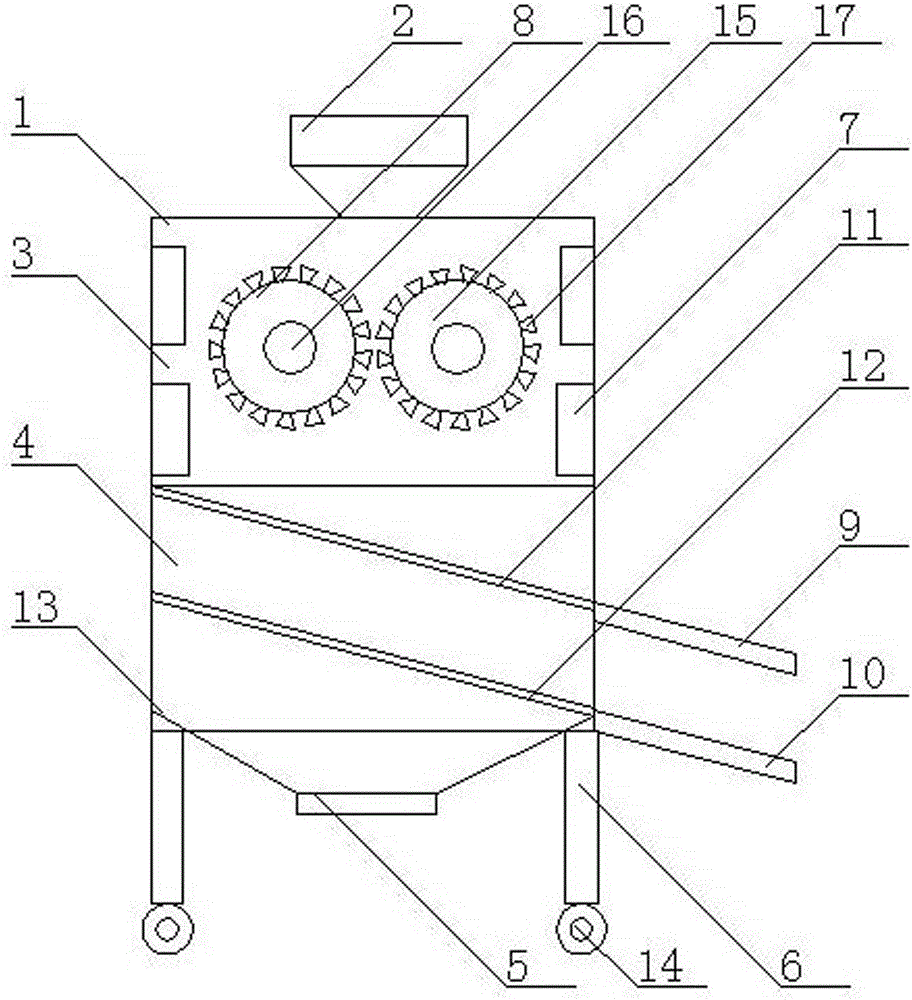

[0016] As shown in the figure, a small portable high-efficiency crushing device includes a fuselage 1, a feed funnel 2 is installed in the middle of the top of the fuselage 1, a crushing chamber 3 is installed at the upper end of the fuselage 1, and a crushing chamber 3 is installed at the lower end of the fuselage 1. A screening chamber 4, a first discharge funnel 5 is installed in the middle of the bottom end of the fuselage 1, and a support leg 6 is installed on the left and right sides of the bottom end of the fuselage 1.

Embodiment 2

[0018] As shown in the figure, a plurality of baffles 7 of different sizes are installed on the left and right sides of the inside of the crushing chamber 3 , and two side-by-side crushing devices 8 are installed at the middle end of the inside of the crushing chamber 3 .

Embodiment 3

[0020] As shown in the figure, the middle end of the right side of the screening chamber 4 is equipped with a second discharge funnel 9, the lower end of the right side of the screening chamber 4 is equipped with a third discharge funnel 10, and the upper end of the screening chamber 4 is equipped with a first inclined filter. Net 11, a second inclined filter screen 12 is installed at the middle end of the screening chamber 4, and an inclined baffle 13 is installed at the lower end of the left and right sides of the screening chamber 4, and the bottom end of the inclined baffle 13 is connected to the first discharge funnel 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com