Rotary hydrogen crushing furnace

A hydrogen crushing furnace and rotary technology, which is applied in the field of rare earth alloy crushing devices, can solve the problems of low pulverizing efficiency, etc., and achieve the effects of simple structure, novel design ideas, and improved safety and operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

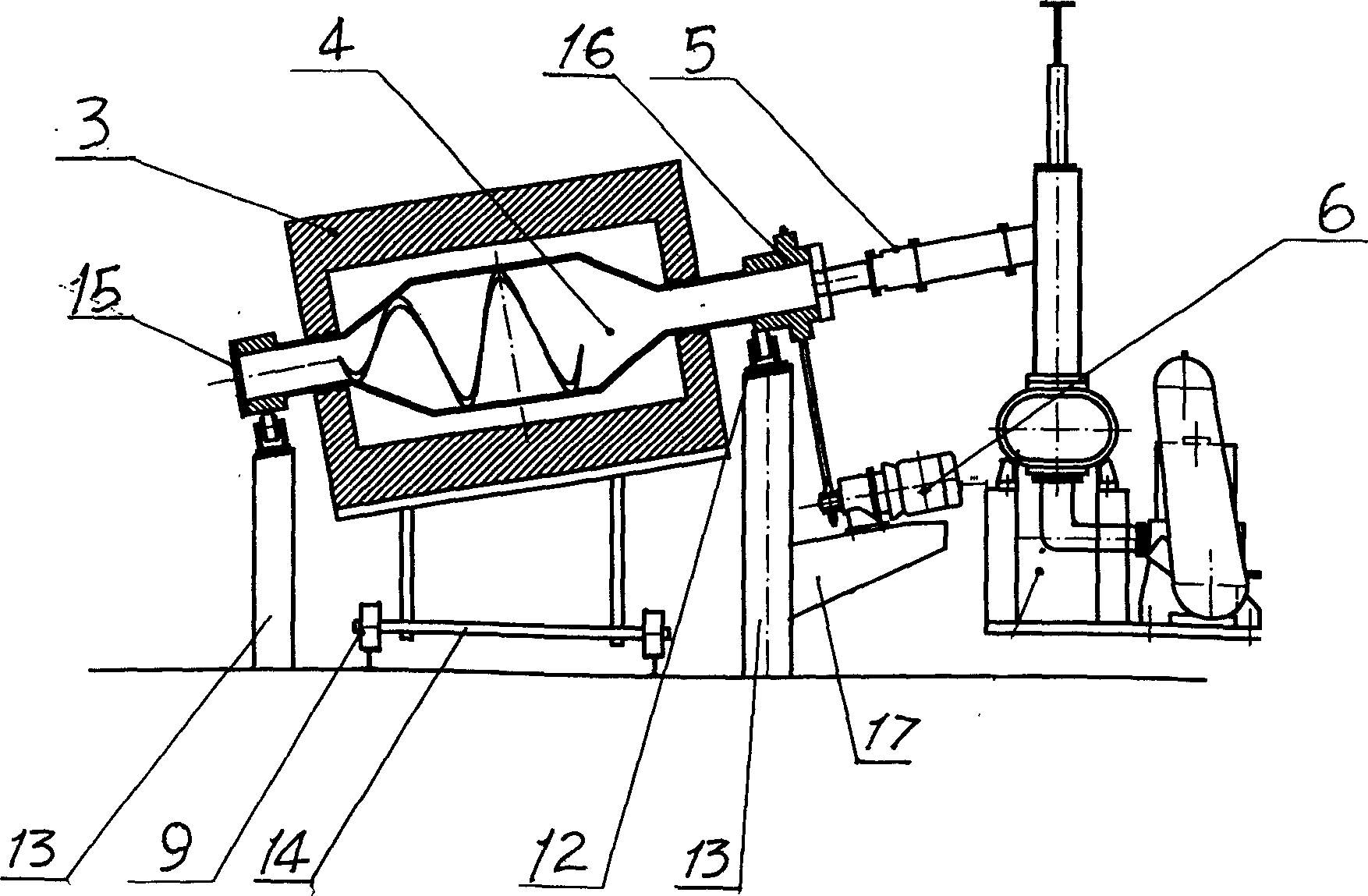

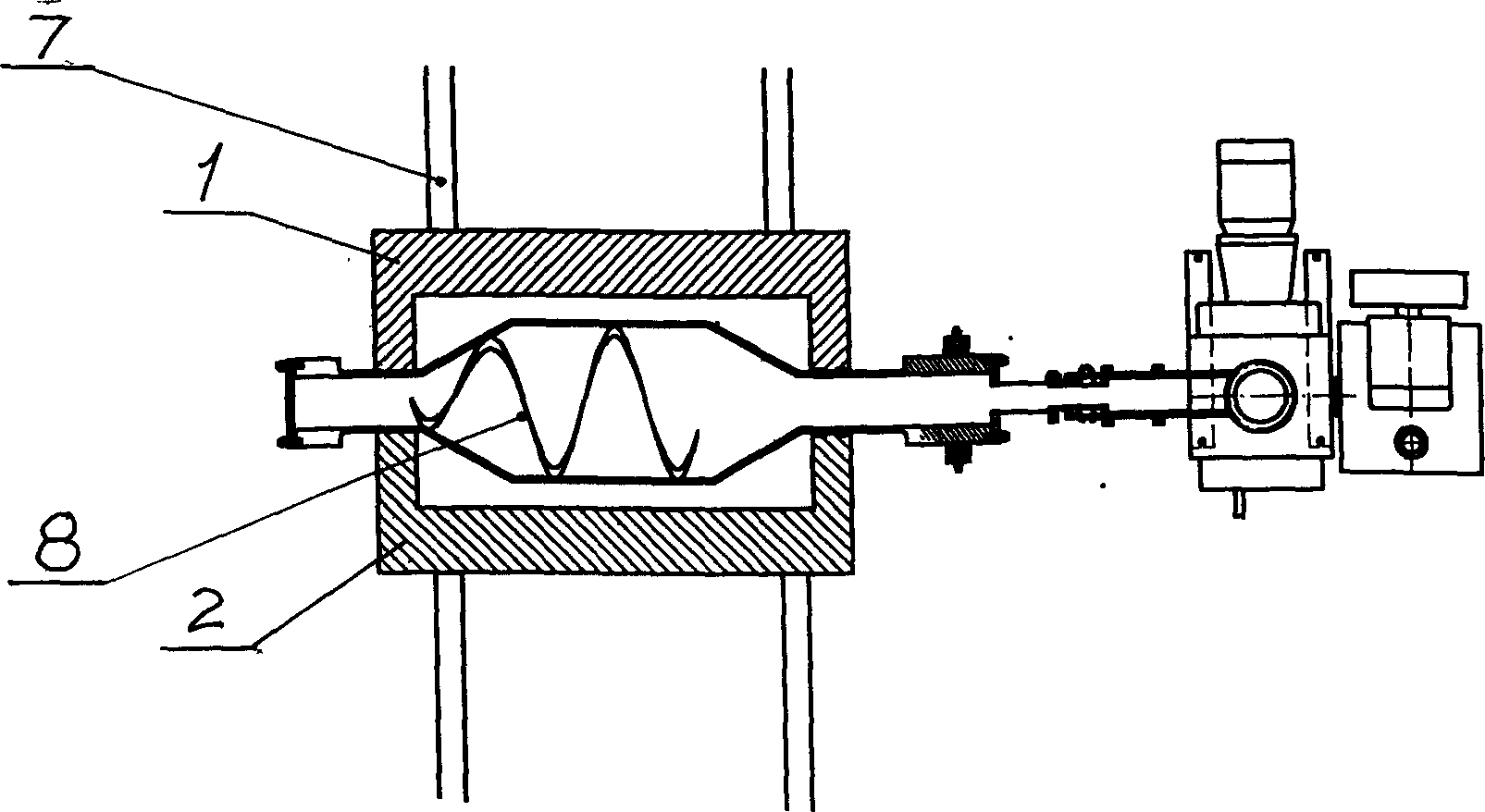

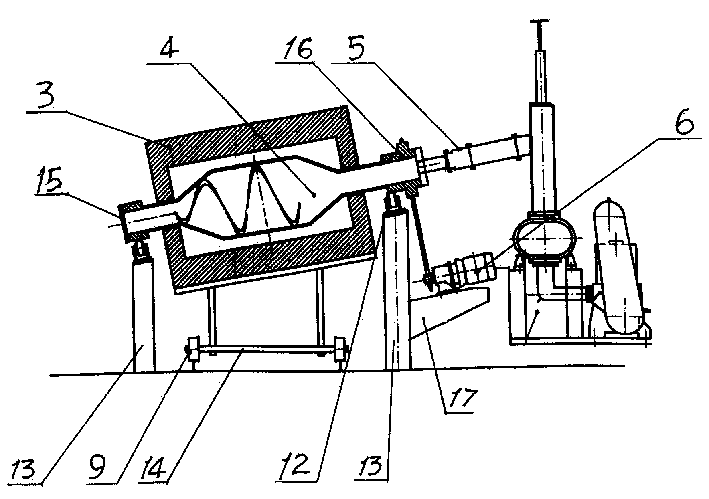

[0009] The rotary hydrogen crushing furnace includes a rotatable furnace 4 supported on supports 13 at both ends, an electric heating furnace 3 located on the outer layer of the furnace, a rotary drive mechanism for the furnace, and a furnace for vacuuming and charging hydrogen. One end of the furnace 3 is the inlet and outlet, and the other end is sealed and communicated with the vacuum device and the gas distribution device. The electric heating furnace consists of a left and right furnace body 1 that can be opened and closed. 2, the left and right furnace bodies are respectively placed on the support frame 14 with rollers 9 at the bottom. A spiral piece 8 is provided in the furnace 3 . There is a support bearing 12 at the end of the support member 13, and the two ends of the rotatable furnace are supported on the support bearing 12, so that the furnace can rotate; one end of the rotatable furnace is connected with the vacuum device and the gas distribution through the dynam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com