Horizontal milling machine with ultrahigh processing speed

A processing speed, horizontal technology, applied in the field of milling machines, can solve the problems of low processing efficiency, strong vibration, complex structure, etc., and achieve the effect of improving processing efficiency, small inertia, and increasing relative motion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

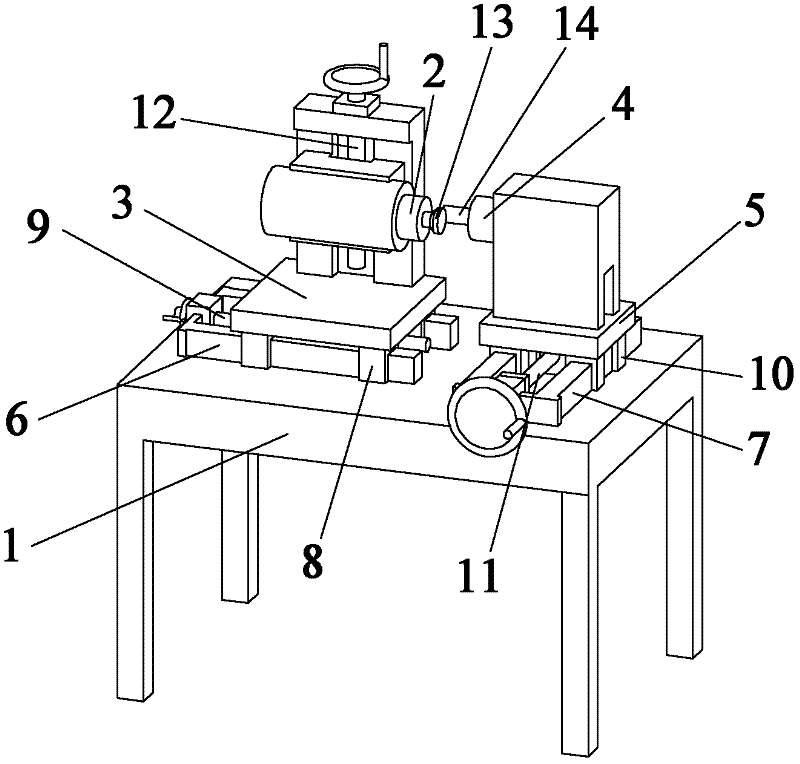

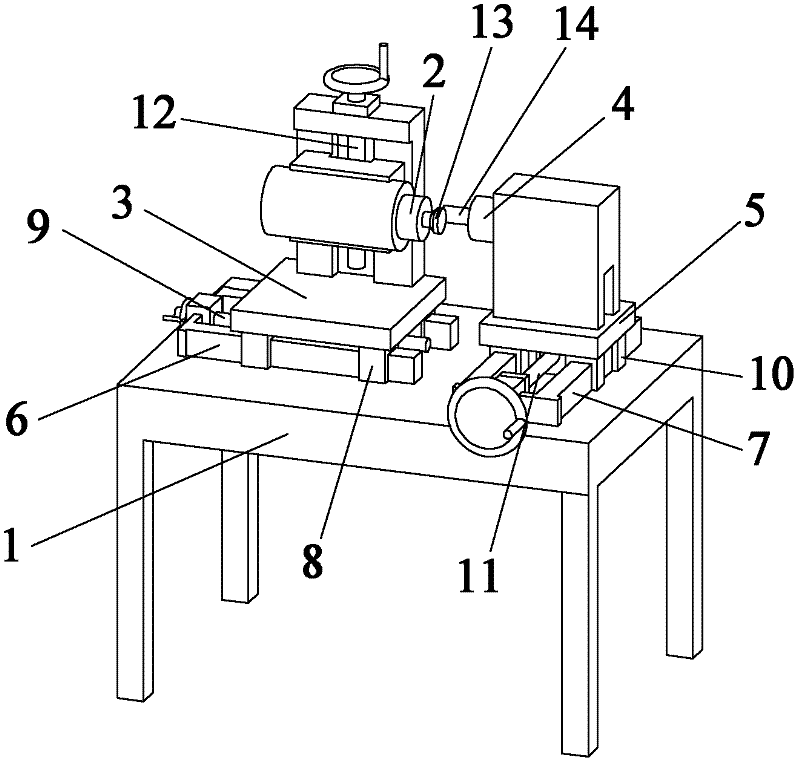

[0011] Such as figure 1 As shown, the ultra-high processing speed horizontal milling machine of the present invention includes a base 1, a first electric spindle 2, a first electric spindle reciprocating platform 3, a second electric spindle 4, a worktable reciprocating platform 5, and X-axis feed Mechanism 9 and Y-axis feed mechanism. The first electric spindle is used to install the milling cutter, and the second electric spindle is used to clamp the workpiece. Two parallel X-axis linear guides 6 and two parallel Y-axis linear guides 7 are fixedly installed on the base 1 at the same time. The extension lines of the X-axis linear guides 6 and the Y-axis linear guides 7 are perpendicular to each other. An X-axis feed mechanism is installed between the two X-axis linear guides 6 on the base, a Y-axis feed mechanism is installed between the two Y-axis linear guides 7, and the X-axis feed mechanism and Y The axial feed mechanism adopts screw nut pair transmission mechanism.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com