Patents

Literature

83results about How to "With dust removal effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

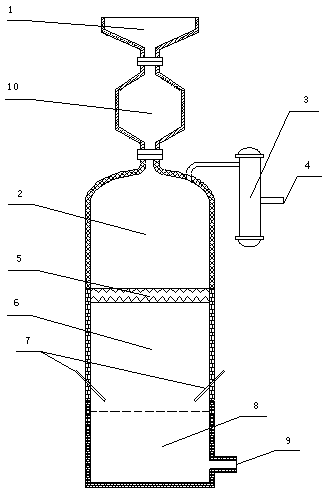

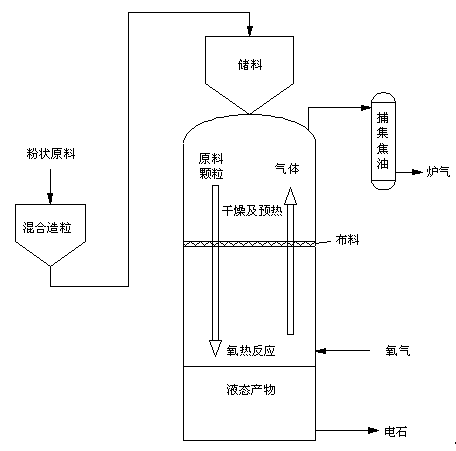

Composite bed reactor and method for combined production of calcium carbide, gas and tar

ActiveCN103272536ATake advantage ofReduce heat lossCalcium carbideSpecial form destructive distillationReaction rateMolten bath

The invention relates to a composite bed reactor and a method for combined production of calcium carbide, gas and tar, and belongs to the field of calcium carbide production. The reactor comprises a hopper, a brake bunker, a moving bed preheating chamber, a tar collector, a gas outlet, a distributing device, an oxygen heat reaction chamber, oxygen spraying burners, a product molten pool and a product outlet, and the hopper is connected with the moving bed preheating chamber by the brake bunker, and the top side surface of the moving bed preheating chamber is provided with the tar collector, and the tar collector is provided with a gas outlet, and the moving bed preheating chamber bottom is provided with a distributing device, and the moving bed preheating chamber is communicated with an oxygen heat reaction chamber by a distributing device, and the oxygen heat reaction chamber bottom is connected with a product molten pool, and the upper portion of the connection between the oxygen heat reaction chamber and the product molten pool is provided with the oxygen spraying burner, and the middle bottom of the product molten pool is provided with a product outlet. The reactor of the invention has the advantages of simple structure and high efficiency, and large scale production is easy to realize, and the raw material is pelleted by powder form carbonaceous raw material and powder form calcium containing raw material, and the contact surface between raw materials is large, the reaction rate is fast, and reactor is convenient for reusing calcium carbide slags.

Owner:BEIJING UNIV OF CHEM TECH

Process for removing sulfur dioxide for smoke using papermaking white mud

A craft that makes use of paper making white mud to eliminate sulfur dioxide in soot comprises the steps of: Add the circular water from pellucid pool and white mud to slurry pool; After mixing round, put them to serum pool, put them to desulfurization tower by add-pressure pump to contact with soot; Reacted liquor flow from the bottom of desulfurization tower and go to deposition pool; The circular water goes to pellucid pool to be used again. The present invention uses simple equipment, has high efficiency of desulfurization and low cost. It uses paper making white mud as desulfurization to change waster to treasure and has a large value to apply and extend.

Owner:吴金泉

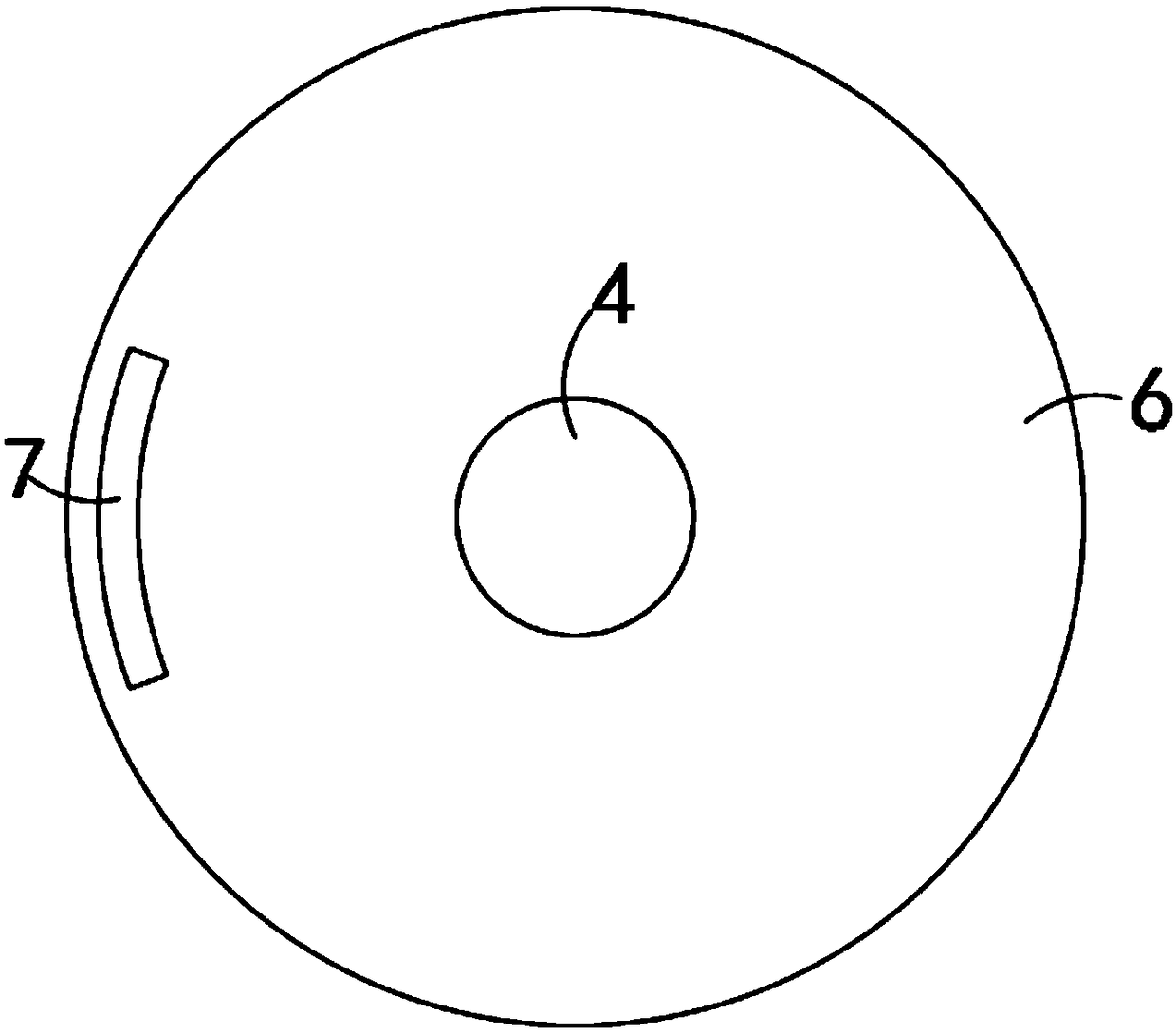

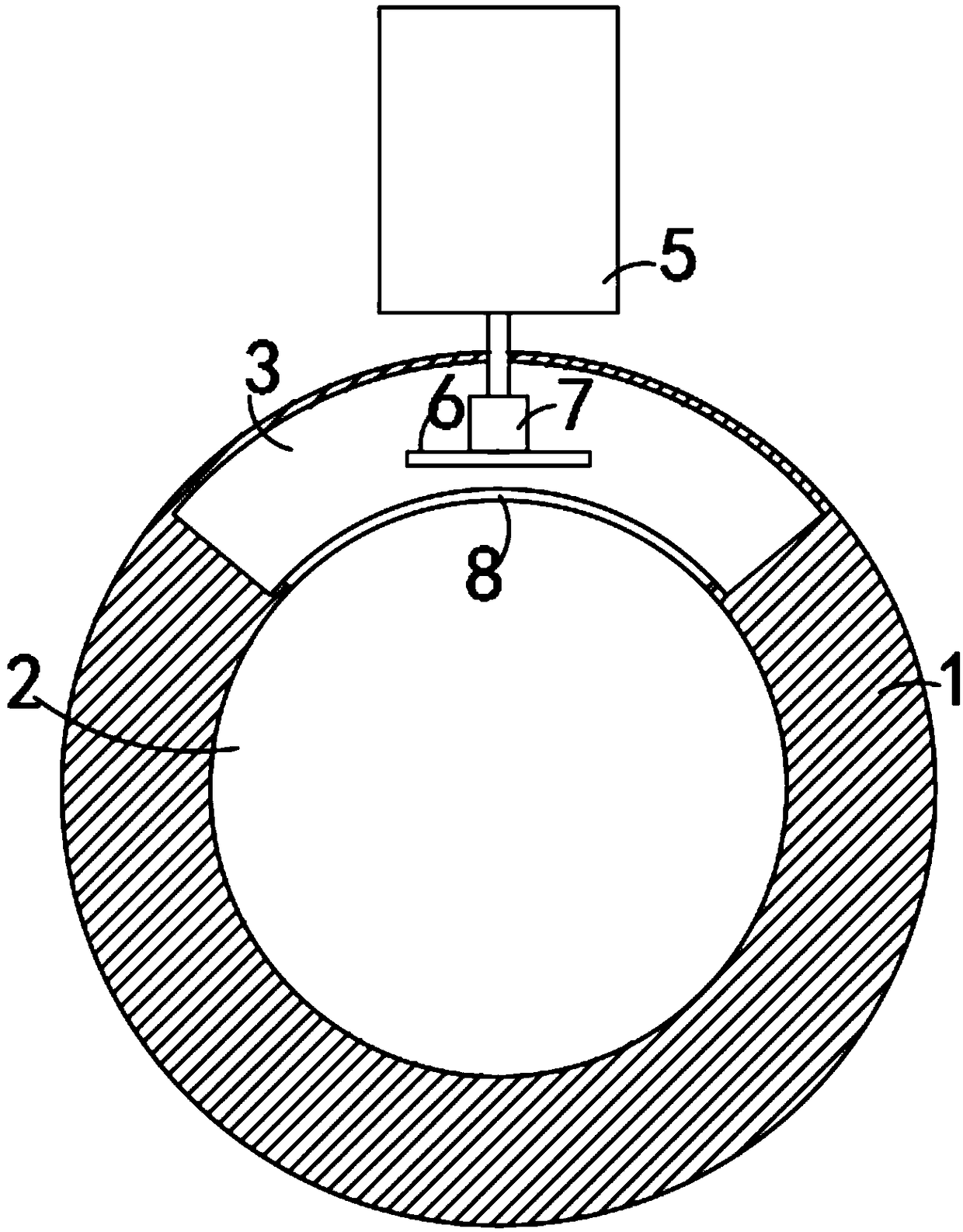

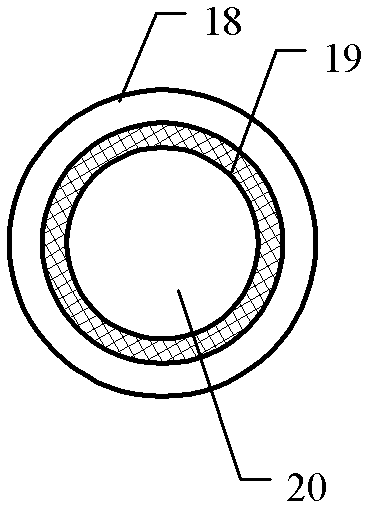

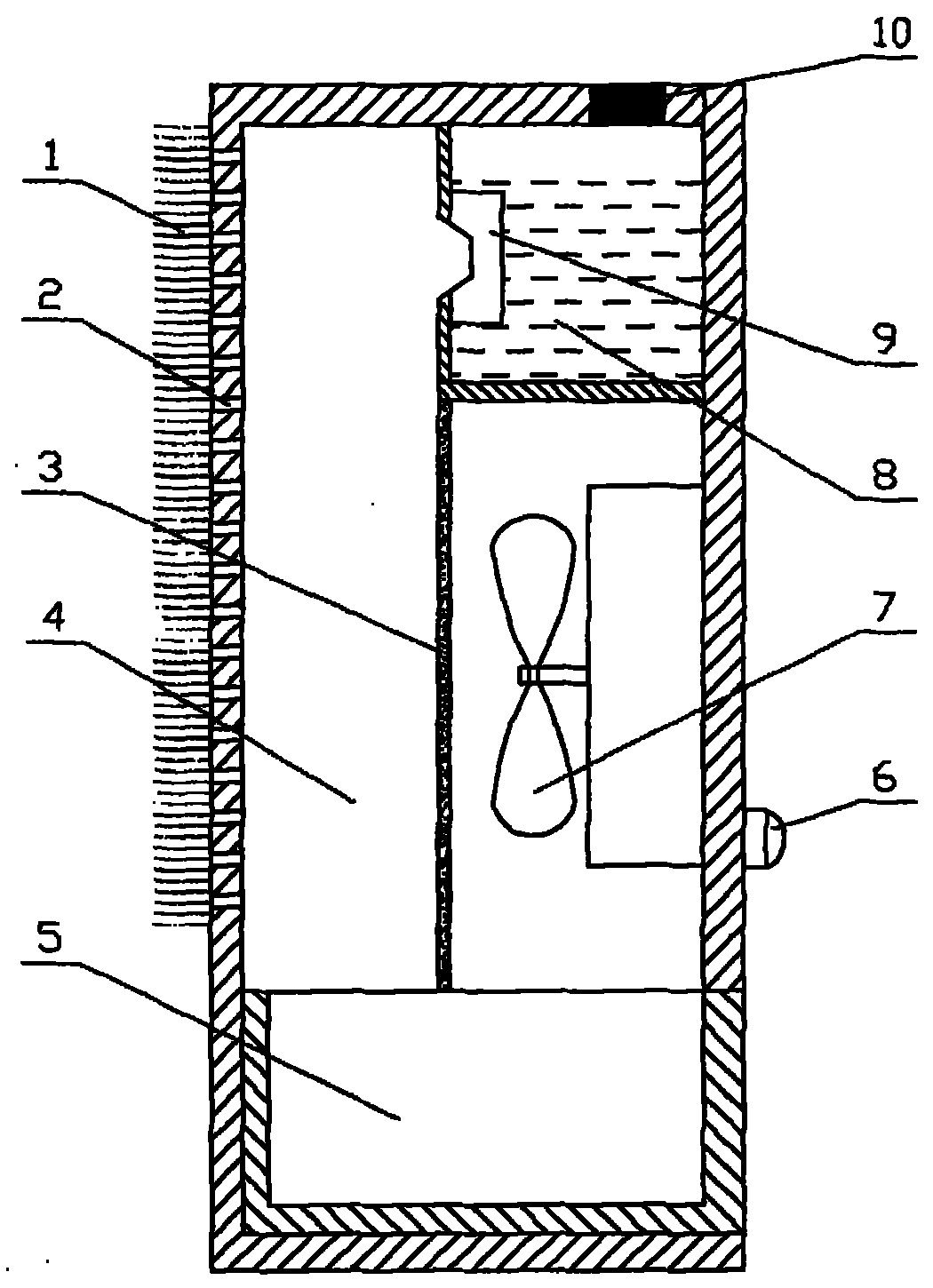

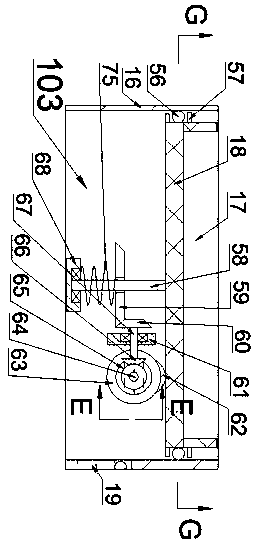

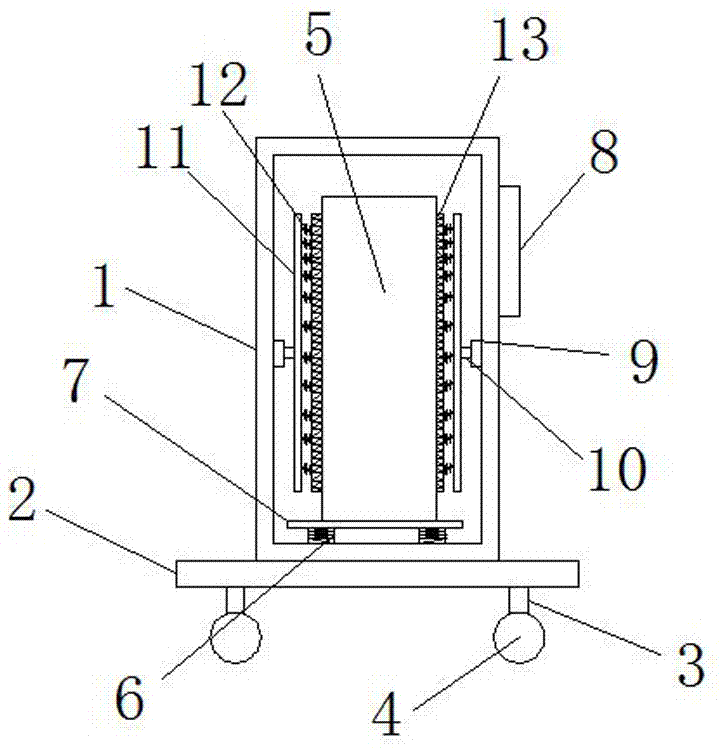

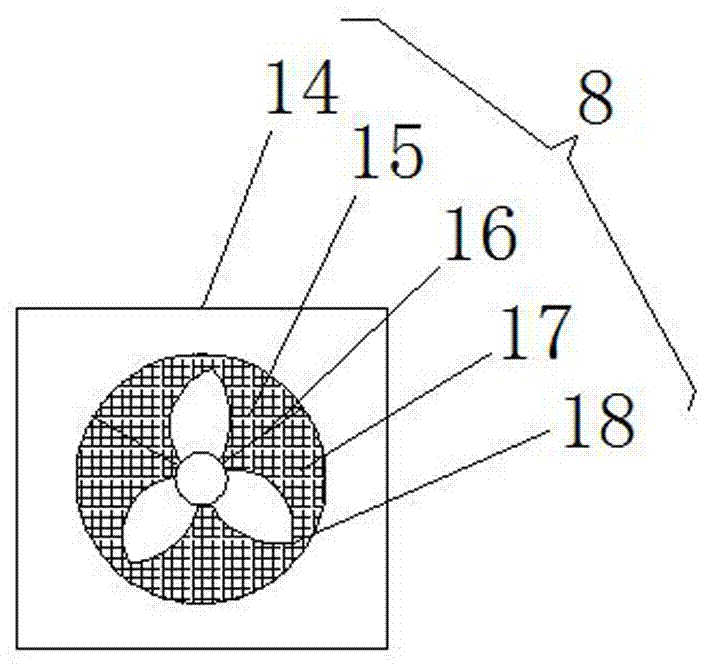

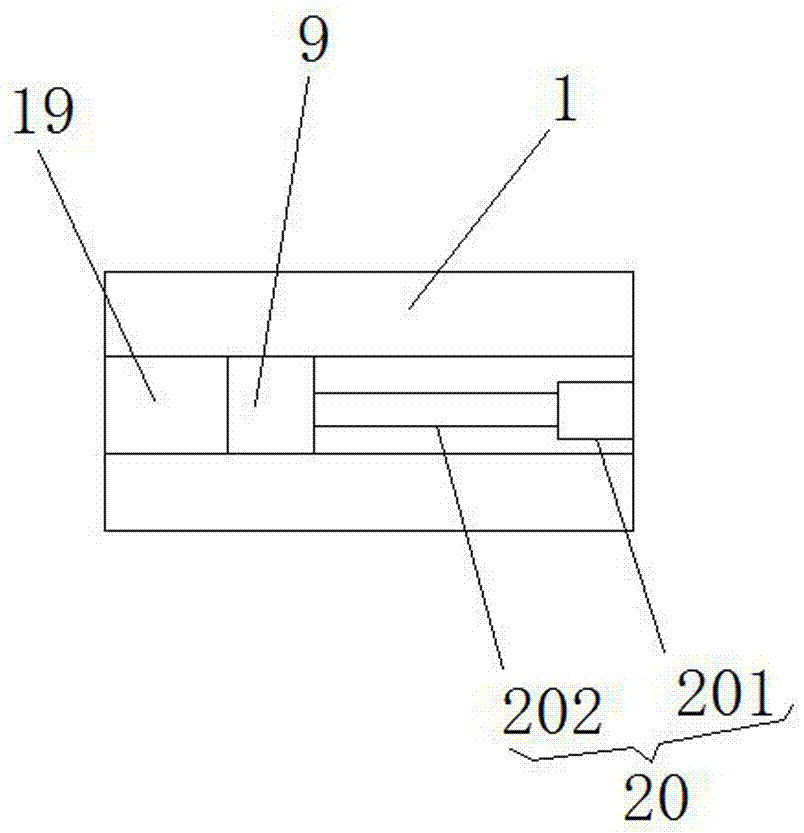

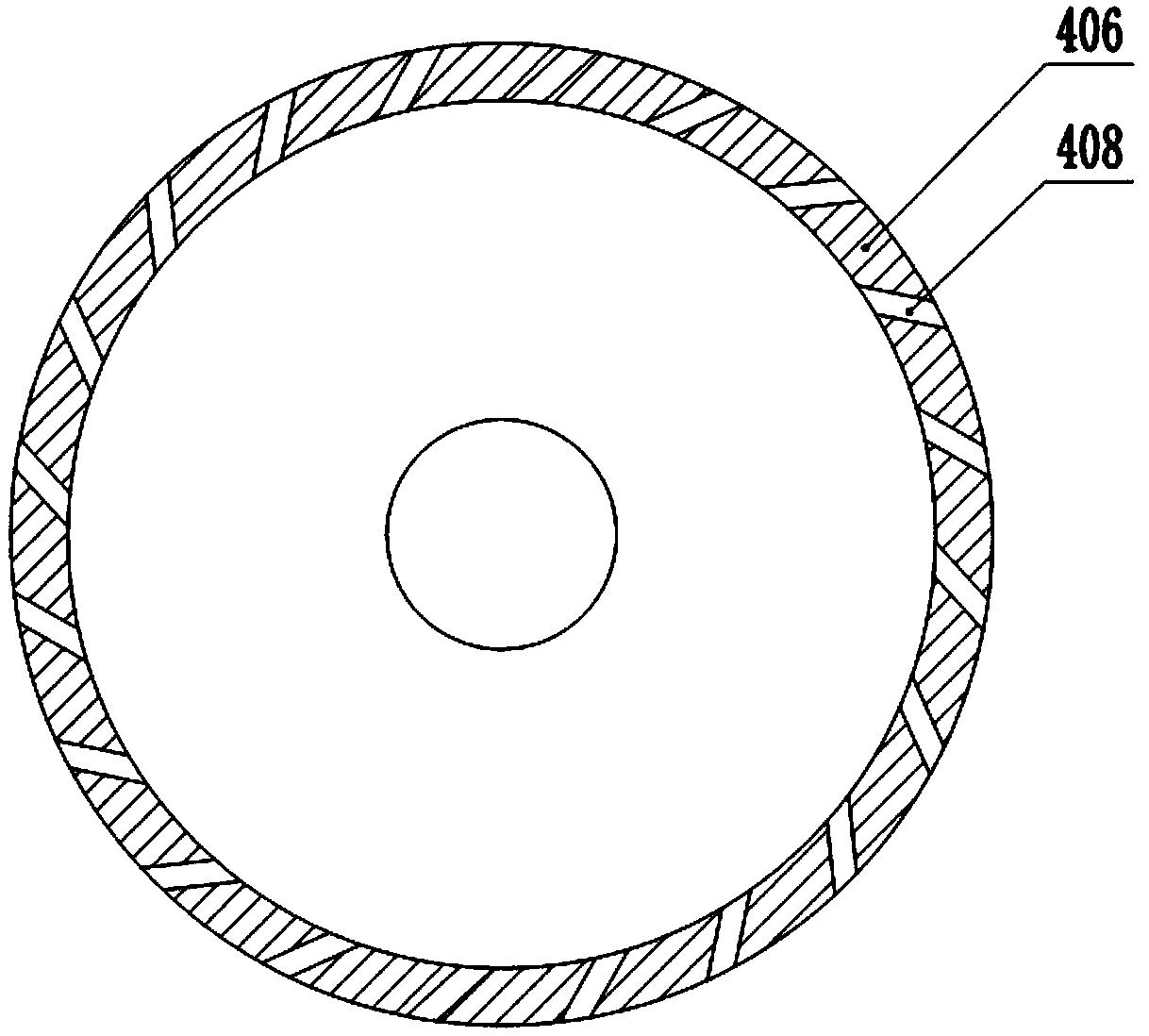

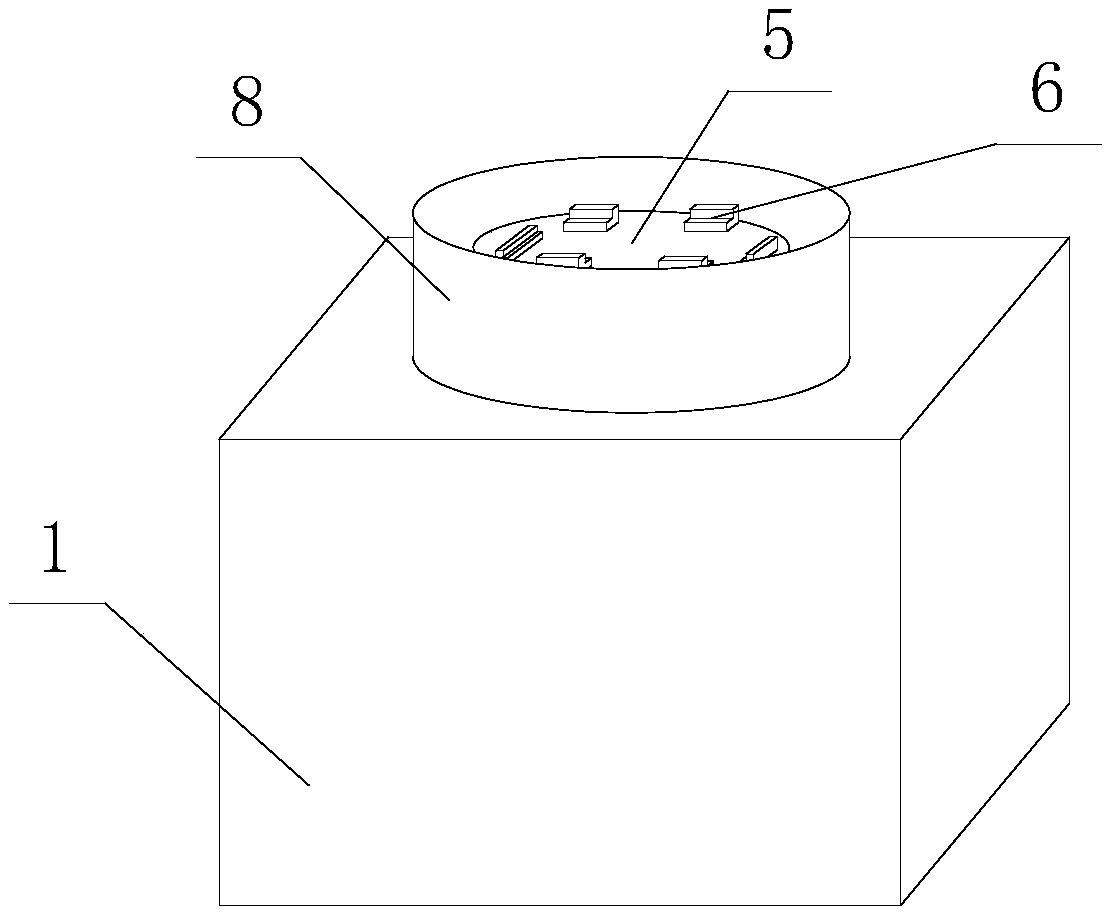

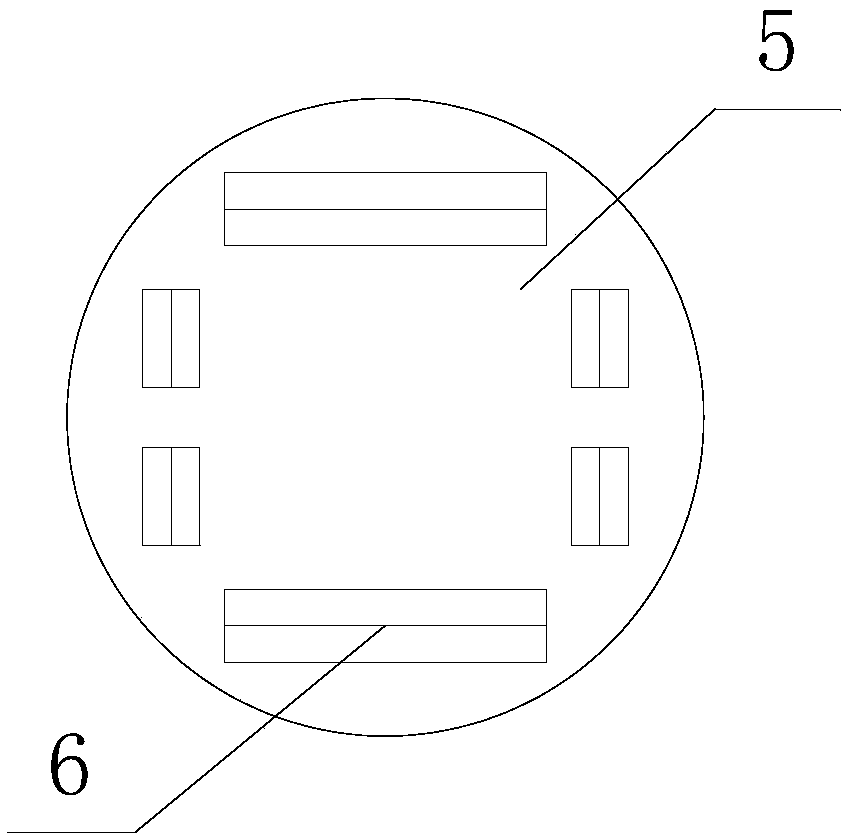

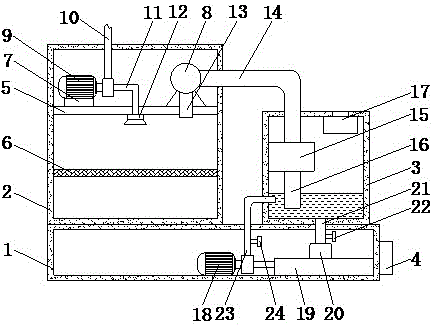

Vehicle-mounted camera with dust removal effect

ActiveCN109451209AWith dust removal effectQuality assuranceTelevision system detailsColor television detailsCamera lensMagnet

The invention belongs to the technical field of monitoring camera equipment and in particular relates to a vehicle-mounted camera with a dust removal effect. The vehicle-mounted camera comprises a camera body, a lens is mounted in the camera body in a sealing way, a first cavity is arranged in the side wall of the upper end of the camera body, a through hole communicating inside with outside is formed in the top surface of the first cavity, a rotary rod is arranged in the through hole in rotatable and penetrating ways, a vertical fan is mounted at the upper end of the rotary rod, the lower endof the rotary rod is fixedly connected with a disk, a magnet is fixedly connected with the edge of the upper end of the disk, a dust removal port used for removing dust on the lens is arranged at thebottom of the first cavity, a fourth unidirectional pressure value is mounted in the dust removal port, an air inlet used for pumping hot air in the camera body is formed in the bottom of the first cavity, and a first unidirectional pressure valve is mounted in the air inlet. The vehicle-mounted camera provided by the invention has the advantages that dust removal can be performed on the lens ofthe camera and the phenomenon that water drops on the surface are frozen when the lens is used in winter also can be prevented.

Owner:浙江咪网电子科技有限公司

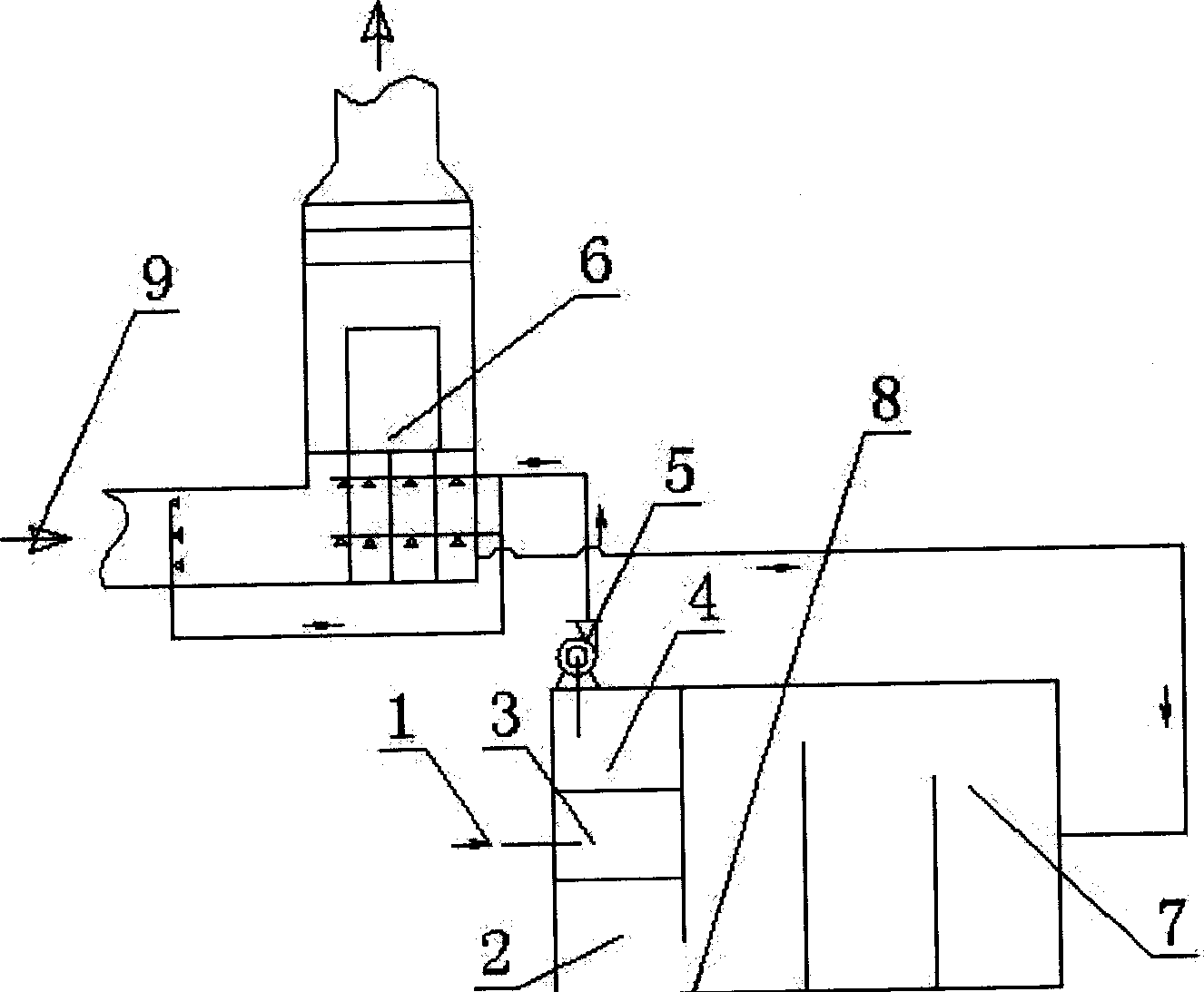

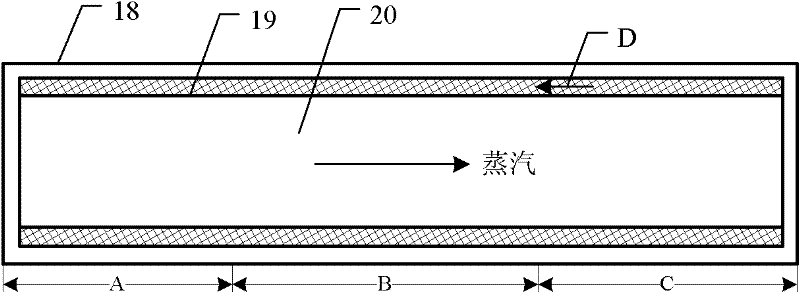

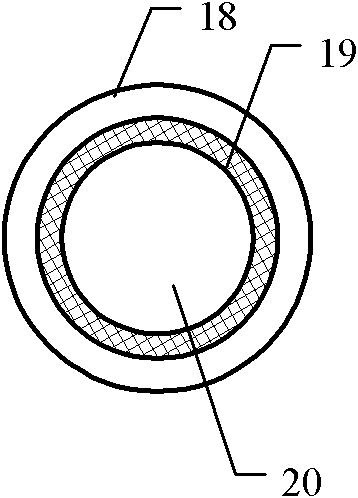

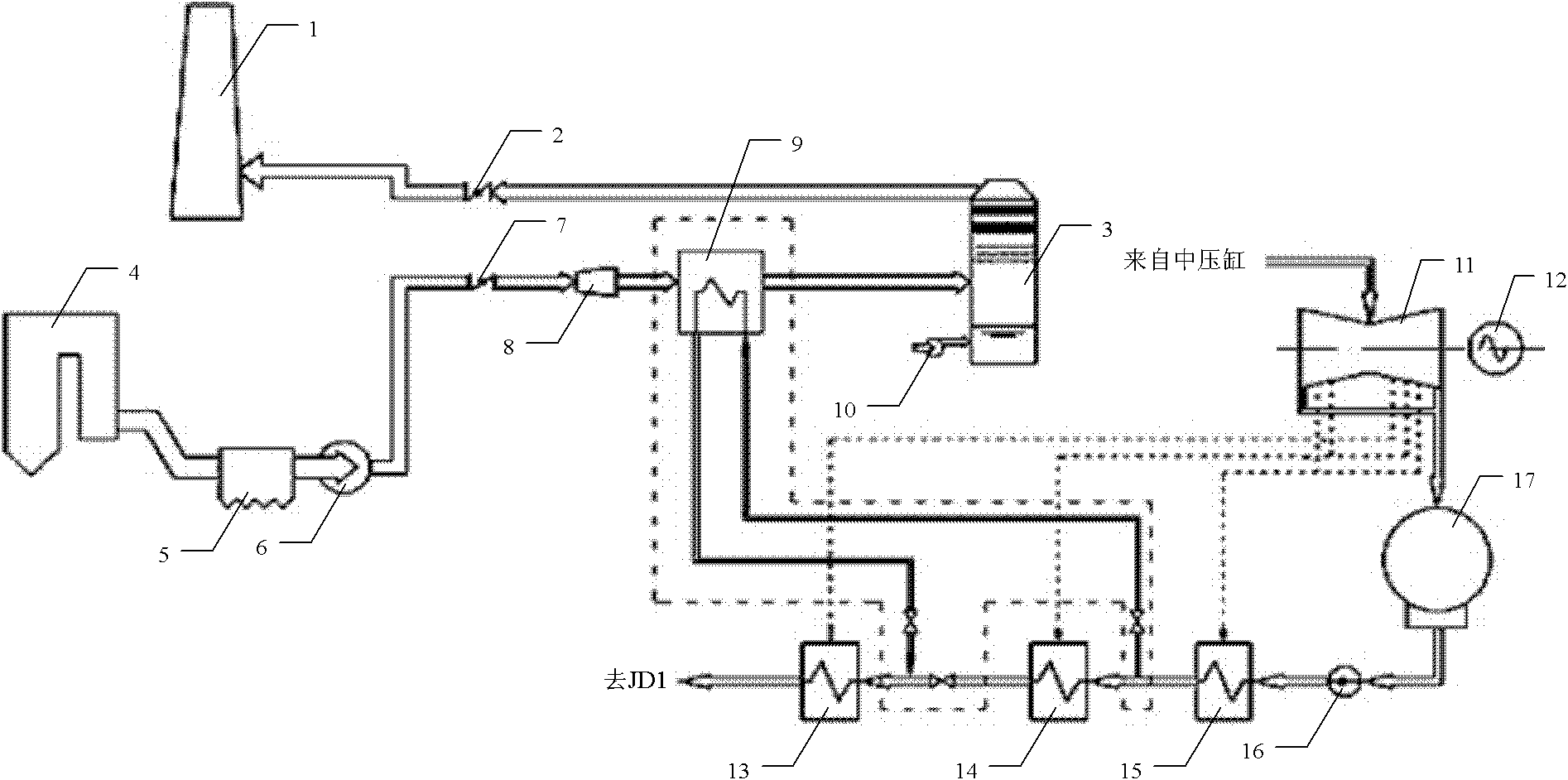

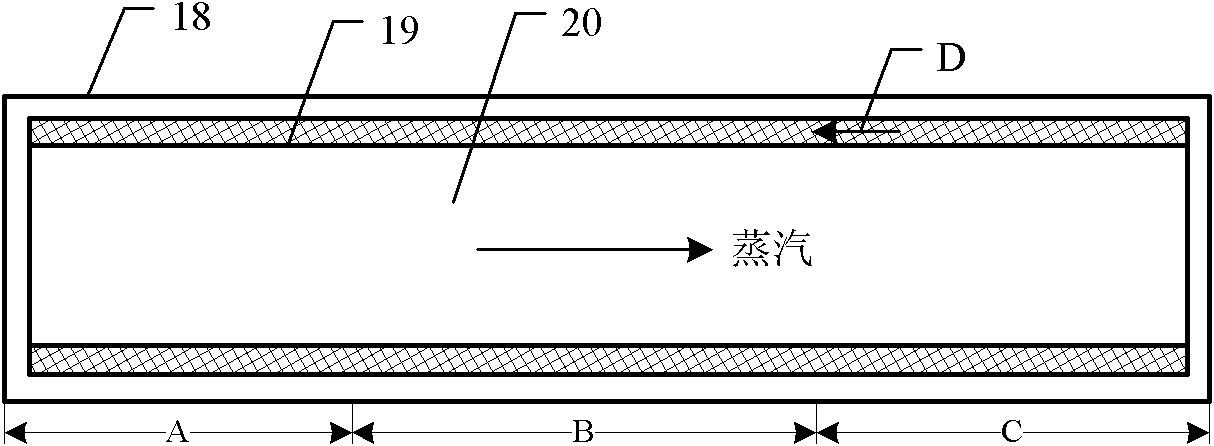

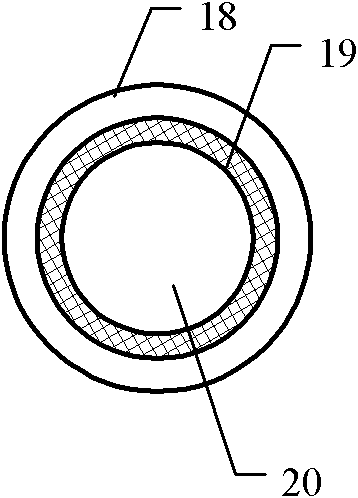

Coal power plant controllable type heat pipe flue gas waste heat recovery system and method

InactiveCN102444900AExcessive heatImprove efficiencyCombustion processIndirect carbon-dioxide mitigationWater vaporFlue gas

The invention discloses a coal power plant controllable type heat pipe flue gas waste heat recovery system and method. The system comprises a boiler, a deduster, a draught fan, a booster fan, a controllable type heat pipe heat exchanger component, a desulfurizing tower and a chimney which are sequentially connected in a cooperation mode through pipelines. The method comprises the following steps: additionally arranging the controllable type heat pipe heat exchanger component in a gas flue system of a coal power plant, and recycling heat and water vapor of the gas flue system; and a bypass gas flue is led out between the draught fan and the booster fan of the gas flue system and is connected between the desulfurizing tower and the chimney of the gas flue system. The coal power plant controllable type heat pipe flue gas waste heat recovery system and method disclosed by the invention can overcome the defects of poor energy conservation performance, poor environmental protection performance, high cost, poor reliability, large occupation space and the like so as to realize the advantages of good energy conservation performance, good environment protection performance, low cost, good reliability, small occupation space and wide application scope.

Owner:辽宁赛沃斯节能技术有限公司

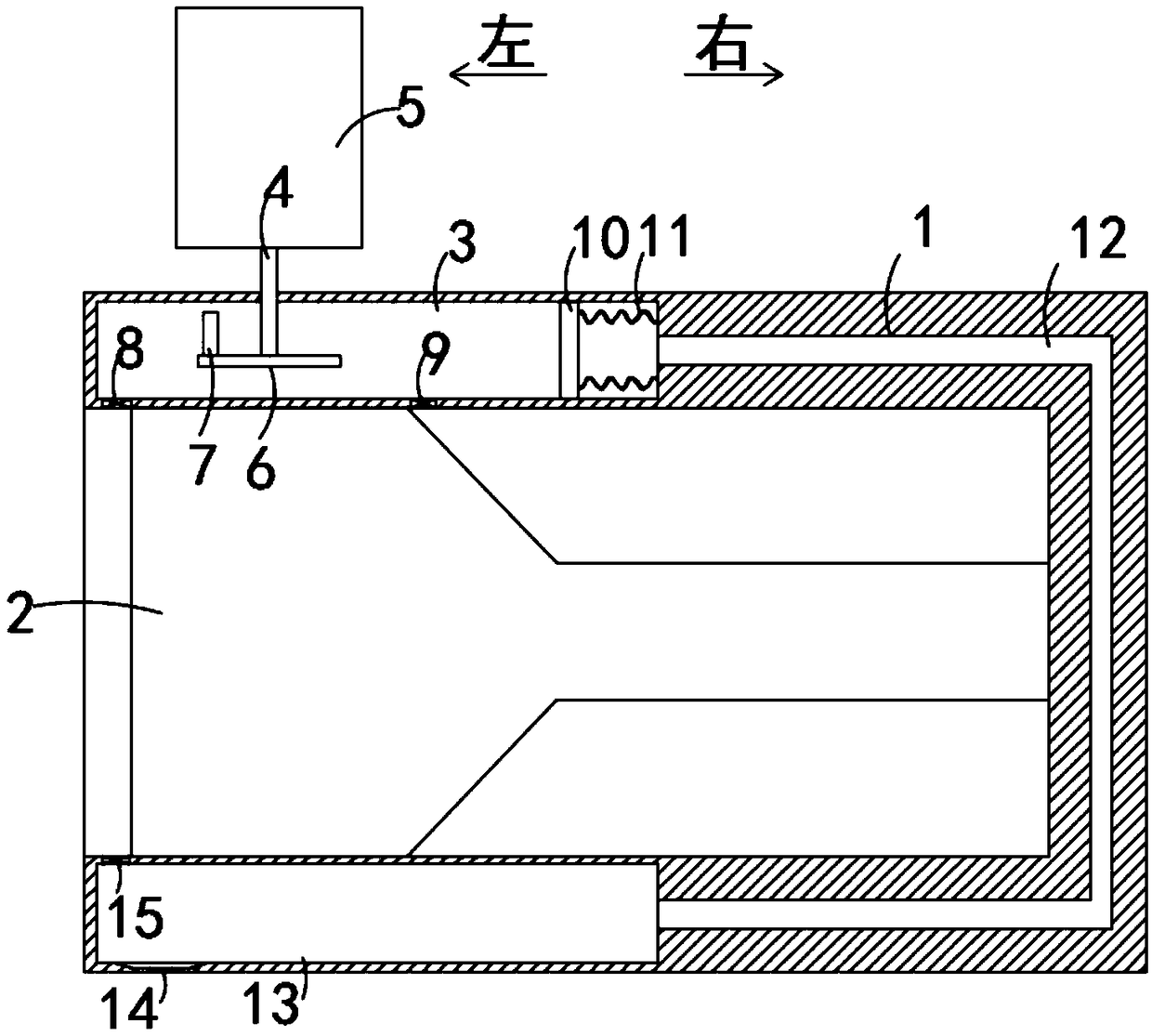

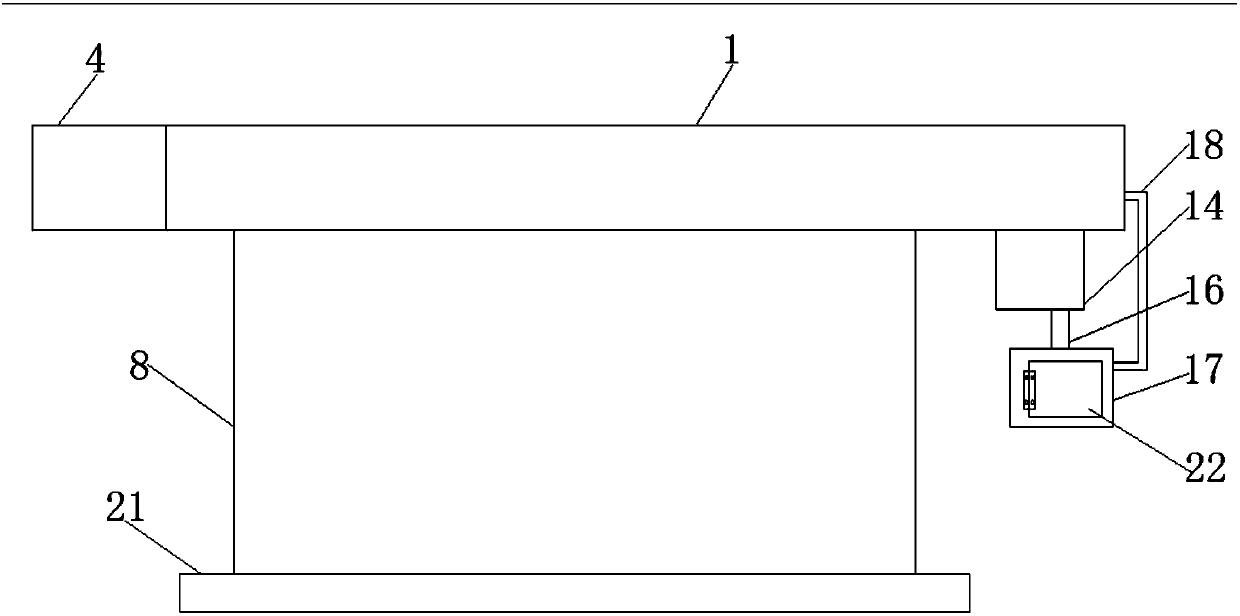

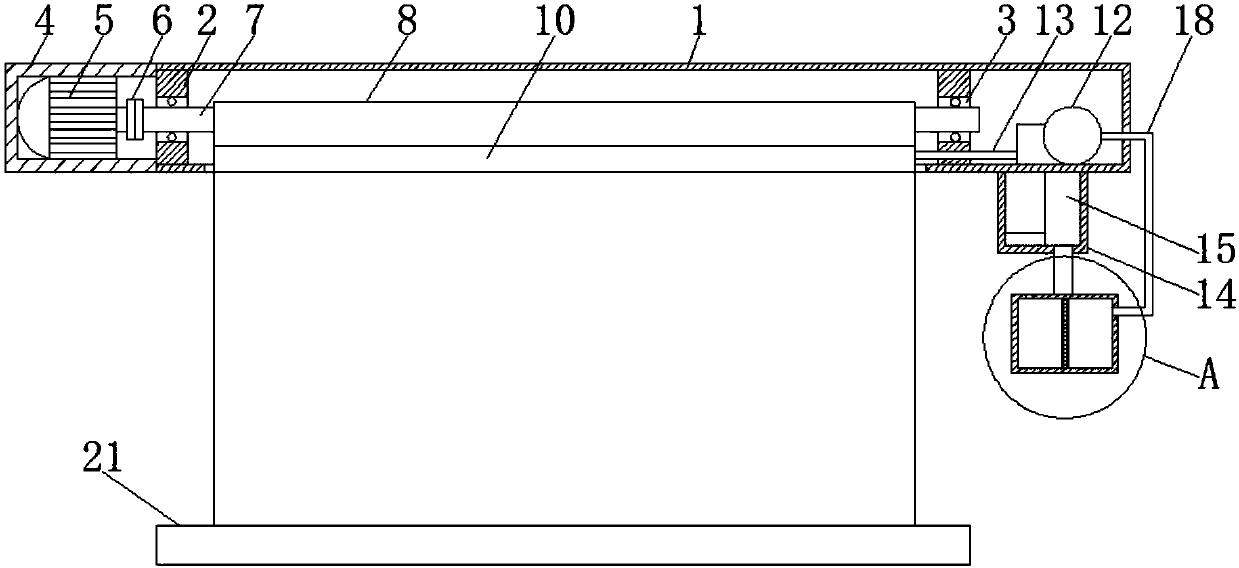

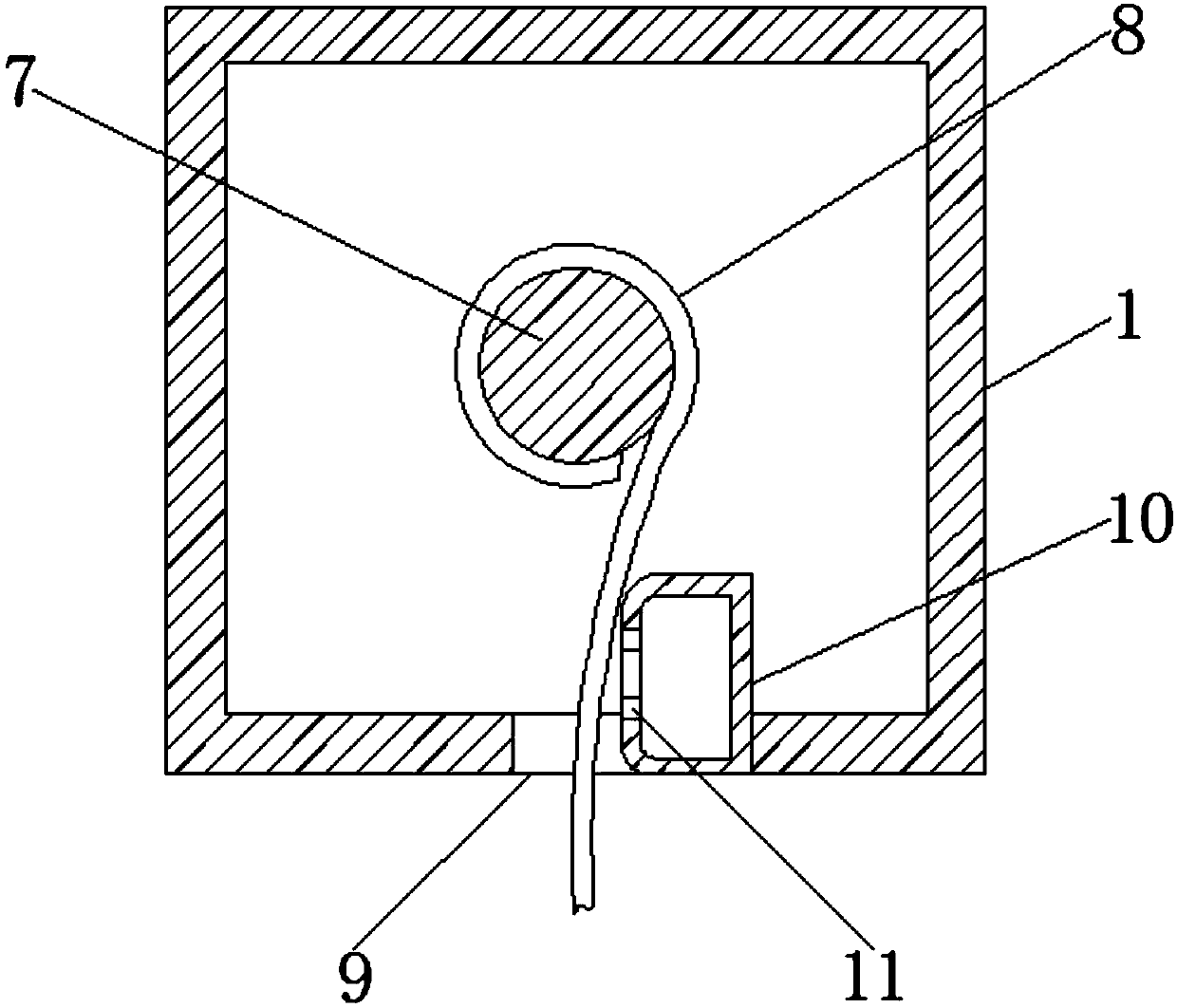

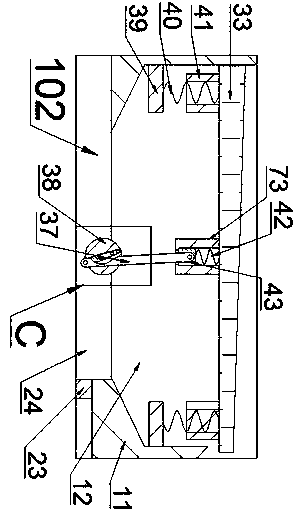

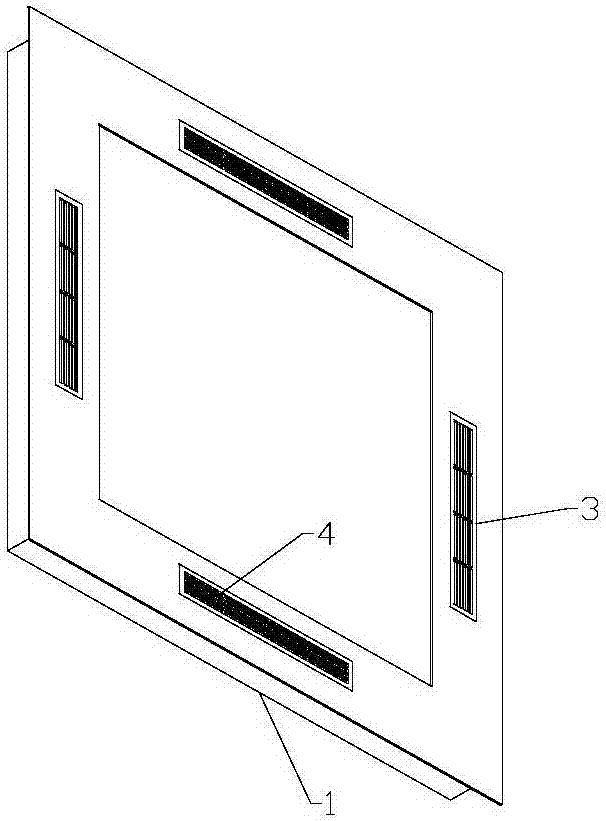

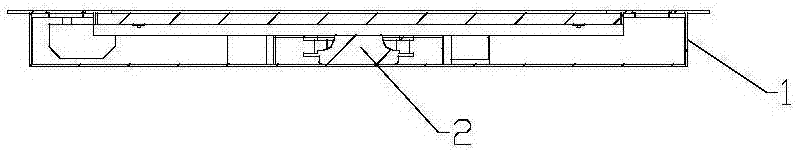

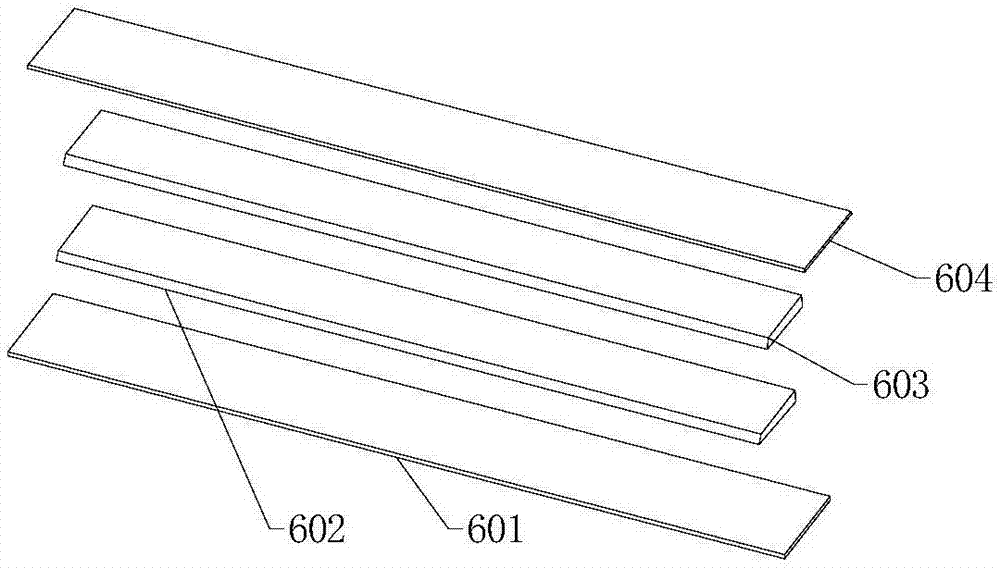

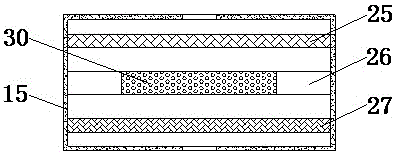

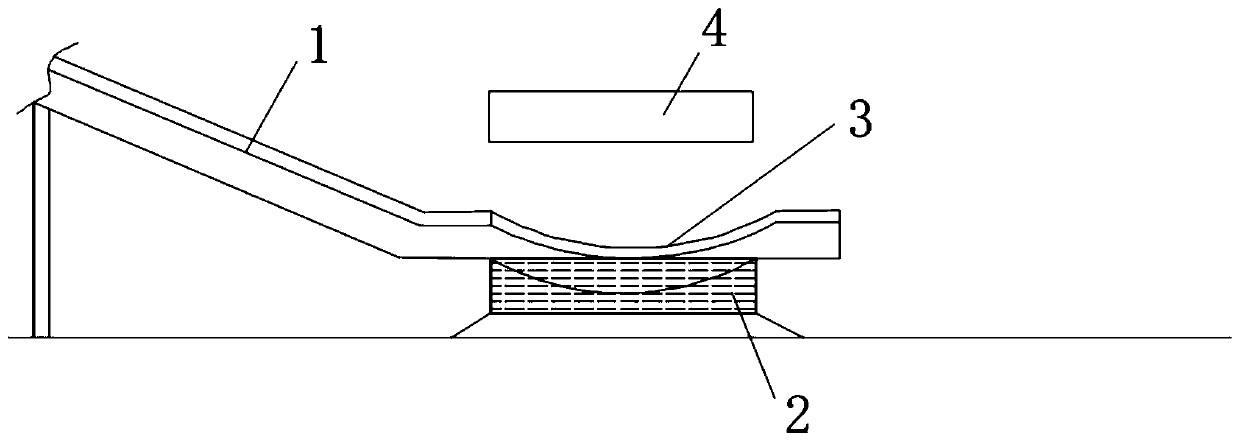

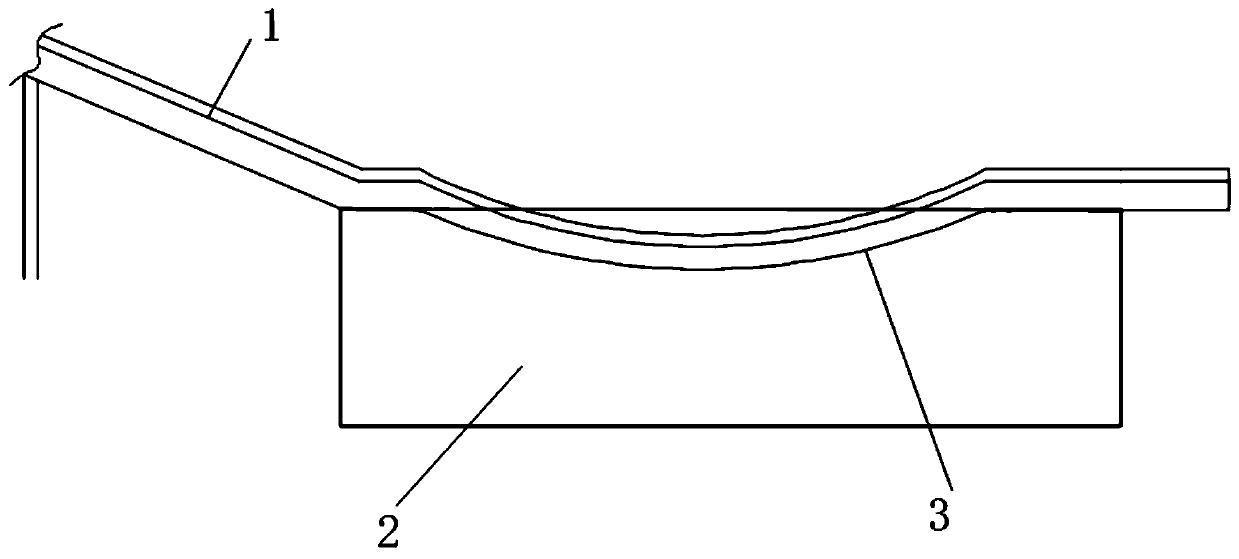

Projection screen used for multimedia teaching and with dust removal effect

InactiveCN107918242AWith dust removal effectEasy to take backProjectorsCleaning using gasesCouplingProjection screen

The invention discloses a projection screen used for multimedia teaching and with a dust removal effect, and relates to the technical field of a projection screen. The projection screen used for multimedia teaching and with the dust removal effect comprises a shell; two baffles are fixedly connected with the two ends of the shell and in an inner cavity of the shell; two bearings are embedded in the centers of the two baffles; a first fixed box is connected with the left side surface of the shell and positioned on the left side of the baffles; a motor is fixedly mounted in an inner cavity of the first fixed box; and the tail end of the output shaft of the motor is fixedly connected with a rotary rod through a coupling. By adoption of the projection screen used for multimedia teaching and with the dust removal effect, air exhausting and dust removal can be performed in curtain retracting by starting an exhaust fan; through air holes, dust can be conveyed to a dust collection box finally;through an electric push rod, the dust collection box can be conveyed from the upper part to the lower part, so that internal dust of the dust collection box can be cleaned regularly by an operator conveniently; and meanwhile, by virtue of dust removal of the projection curtain, the multimedia teaching quality is improved.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

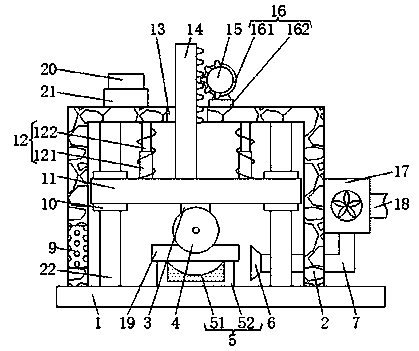

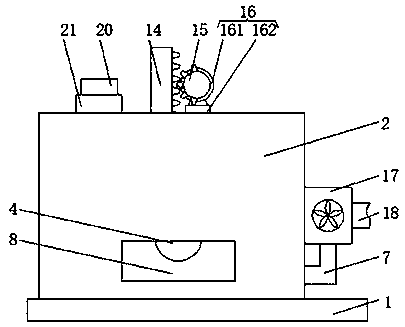

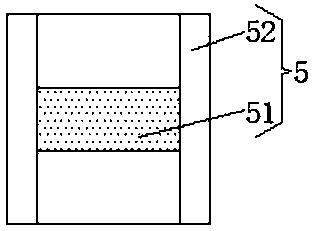

Cutting device for PVC plate processing with dust removal effect

The invention discloses a cutting device for PVC plate processing with a dust removal effect, and relates to the technical field of PVC plates. The cutting device comprises a bottom plate, wherein theupper surface of the bottom plate is fixedly connected with the lower surface of a shell, the right side surface of the shell is fixedly connected with the left side surface of a fan, and the air outlet end of the fan communicates with the left end of an air outlet pipe. According to the cutting device for PVC plate processing with the dust removal effect, through the mutual cooperation of a collecting opening, an air inlet pipe, the air outlet pipe, the fan, the shell and a positioning device, when a plate is cut under a cutting blade, a worker controls the fan to work, the fan sucks air from the inner portion of the shell through the air inlet pipe, debris flows along with the air under the suction effect of the fan and is discharged out of the shell, and one end of the air outlet pipeis connected to a water tank or a container for collecting the debris, so that the worker can conveniently the debris generated in the cutting process of the plate, and harm to human bodies caused bythe debris or dust inhaled by the worker is reduced.

Owner:黄山豪泰塑胶有限公司

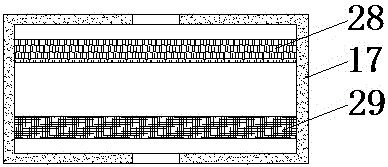

Dust-free blackboard eraser

InactiveCN102029849AGood dust removal effectEasy to pourBoard cleaning devicesAbsorption effectEngineering

The invention provides a dust-free blackboard eraser, belonging to a cleaning tool. The dust-free blackboard eraser comprises felt and a box body. The felt is uniformly adhered to a surface of the box body in rows; the box body is internally provided with a dust absorption box and a fan; the dust absorption box is arranged close to the felt; a plurality of through holes are uniformly arranged on the box body wall between the dust absorption box and the felt and among the gaps of the felt; the fan is arranged at the rear of the dust absorption box; a filtering screen is arranged on the box body wall between the dust absorption box and the fan; the box body is also internally provided with a water box, a dust collection box and a switch; the water box is arranged at the rear of the dust absorption box and above the fan; a water mist generator is arranged on the shared side wall of the water box and the dust absorption box; the opening of the water mist generator faces to the interior of the dust absorption box; the dust collection box is arranged below the dust absorption box and communicated with the dust absorption box; the dust collection box can be pulled out of the box body; and the switch is arranged on the rear side surface of the box body and connected with the circuits of both the fan and the water mist generator. The dust-free blackboard eraser has the advantages of simple structure, low manufacture cost and good dust absorption effect and is convenient to use.

Owner:张文清

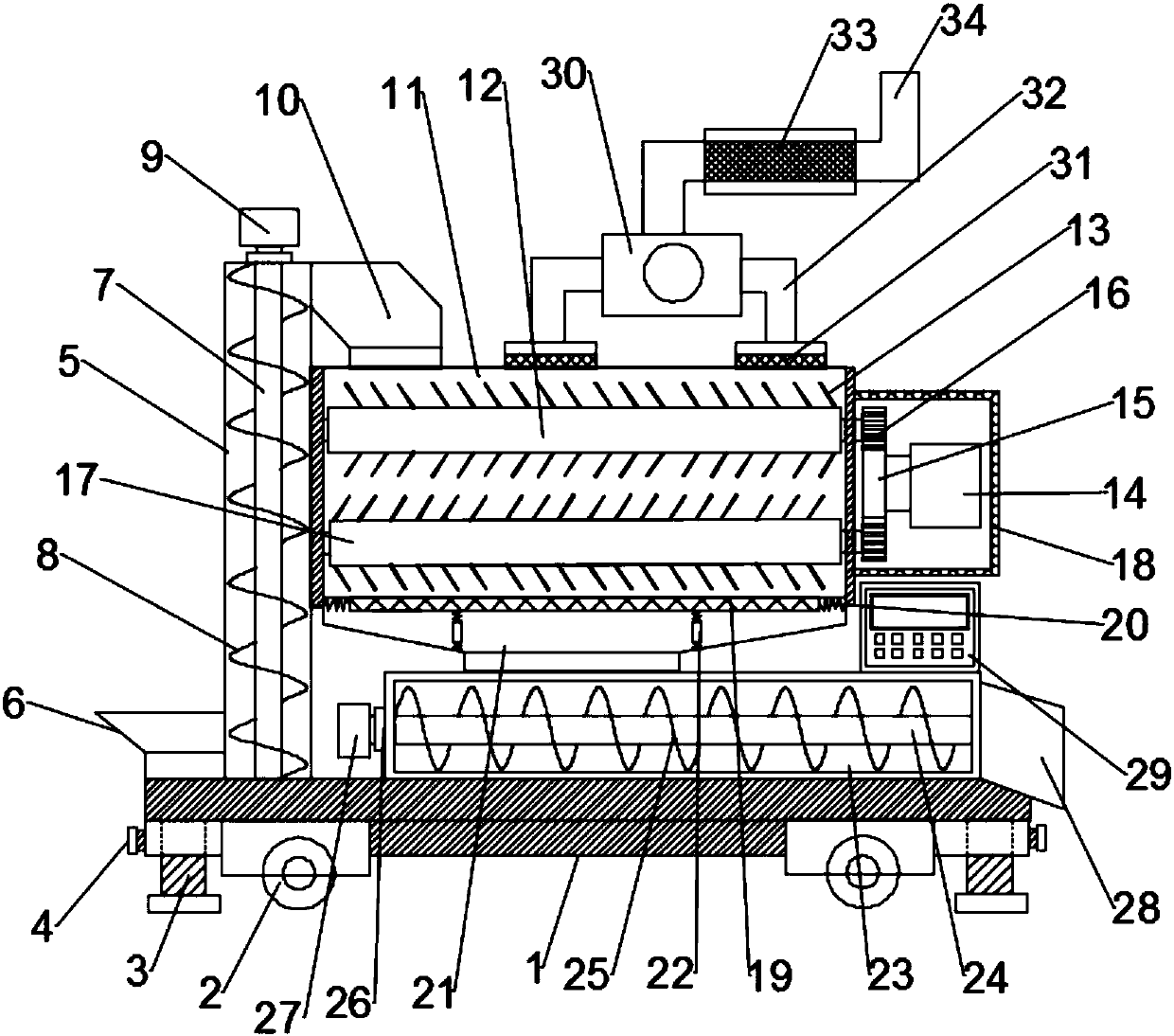

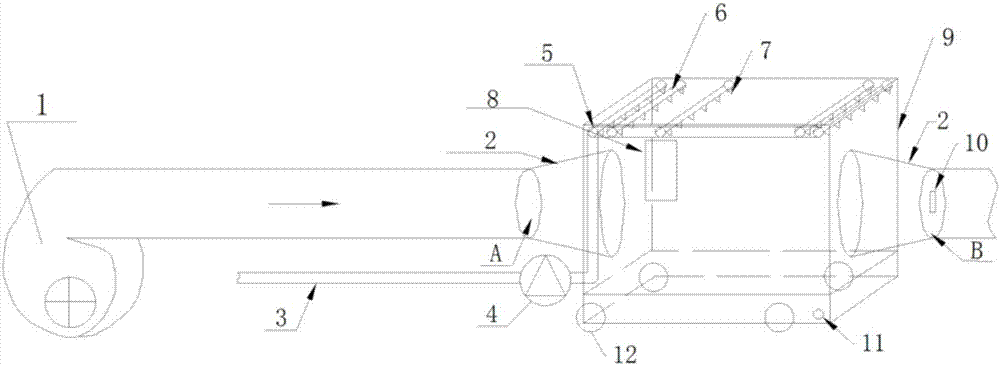

Highly-efficient corn thresher facilitating feeding and discharging

InactiveCN107896646AHigh degree of automationWith dust removal effectThreshersReduction driveEngineering

The invention discloses a highly-efficient corn thresher facilitating feeding and discharging. The highly-efficient corn thresher comprises a fixed chassis, pulleys and fixed thread lift-drop seats, wherein the left and right ends of the fixed chassis are respectively provided with a stop nut; the upper end of the fixed chassis is provided with a conveying drum; the temporal part of the conveyingdrum is provided with a second rotating shaft; a screw conveying mechanism is arranged on the second rotating shaft; the left end of the second rotating shaft is provided with a speed reducer; the left side of the speed reducer is provided with a conveying motor; the right end of the conveying drum is provided with a discharge outlet; the upper end of the conveying drum is provided with a threshing box; and the left side of the threshing box is provided with a lift drum. The highly-efficient corn thresher provided by the invention has simple and reasonable structural design, is simple and rapid to operate in use, is used for the work of corn threshing, has high degree of automation in the process of working, saves a great amount of labor, has high threshing efficiency and dedusting effect,is convenient for feeding and discharging, and has great practicability.

Owner:房立洲

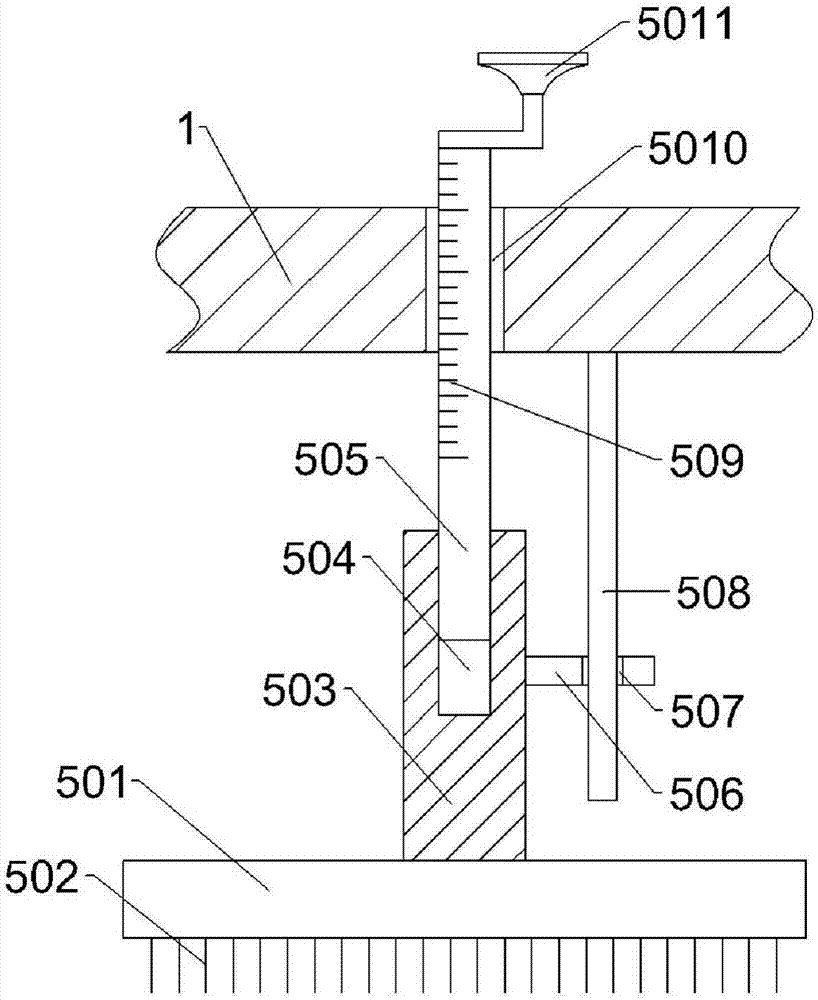

Impurity removing equipment for grain processing

InactiveCN110639811AImprove adaptabilityQuickly adjust the amplitudeSievingGas current separationVibration amplitudeCrank

The invention discloses impurity removing equipment for grain processing. The equipment comprises a vibration box; a vibration cavity is formed in the vibration box; a dust removing device for removing dust by using air currents is arranged on the left side of the vibration box; a vibration device is arranged in the vibration cavity; a screening box is fixedly connected to the lower side end surface of the vibration box; a screening cavity communicating with the dust removing device is arranged in the screening box; a screening device is arranged in the screening cavity; and the screening device uses rotary vibration for removing impurities larger than grain particles. A primary vibration screening device can quickly adjust the length of a crank in a crank slide block mechanism through rotation of a knob, so that the vibration amplitude adjusting function is achieved, operators conveniently adjust the vibration amplitude, the impurity removing adaption to different grains is improved,the impurity removing effect is improved, and meanwhile, dust generated by screening can be removed.

Owner:永康串行电子有限公司

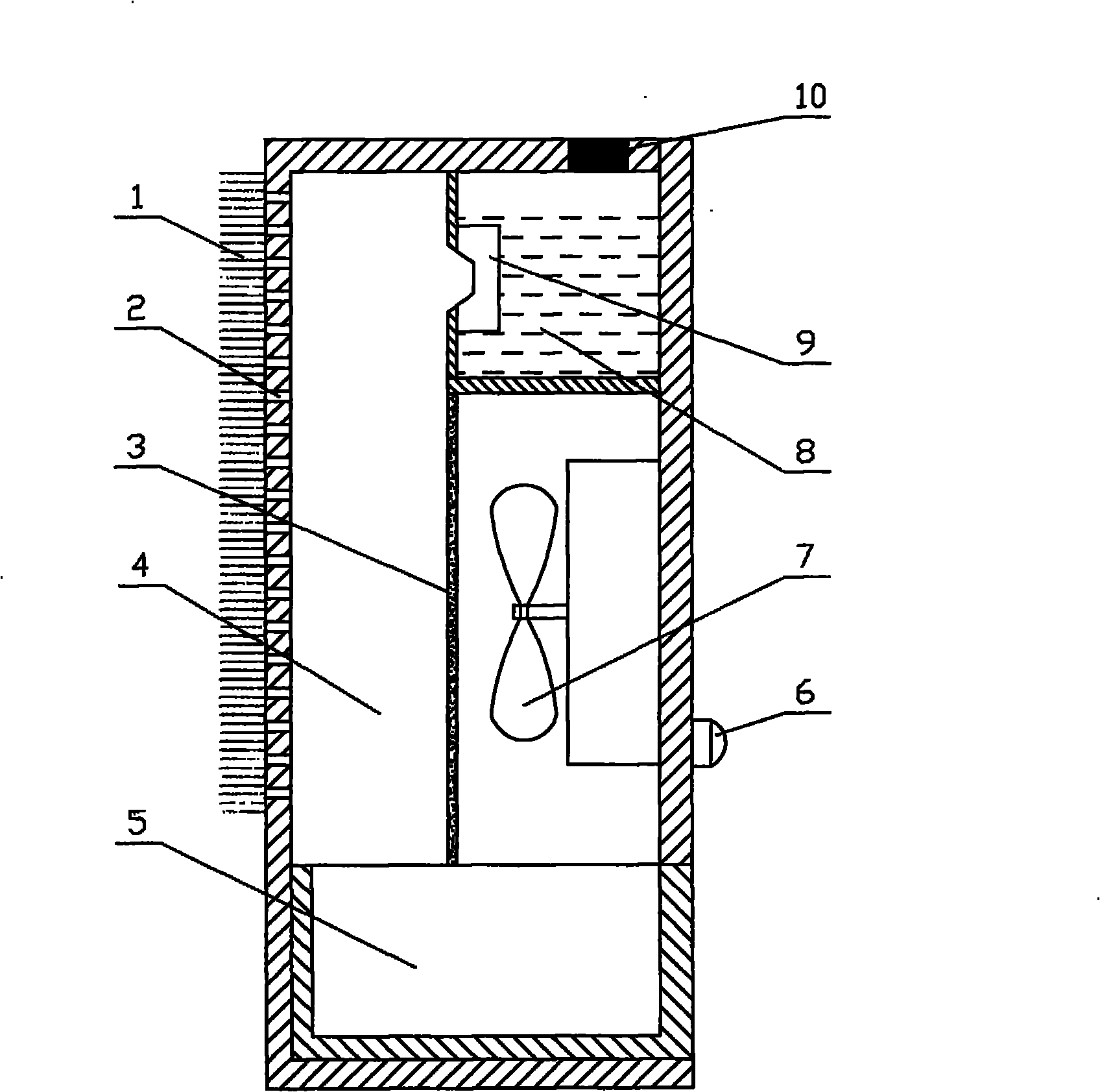

Local cooling device and method for mine

InactiveCN106948856ASimple structureReduce mining costsDust removalFire preventionWater sourceCooling chamber

A mine local cooling device, including fan, air duct, water inlet pipe, water pump and cooling chamber, the top of the cooling chamber is provided with a spray device, and the cooling chamber is provided with an air inlet and an air outlet, wherein: the fan communicates with the air inlet through the air duct Connection, the water inlet pipe is connected with the spray device, the water inlet pipe is provided with a water pump, and the air outlet is connected with the working surface through the air cylinder. The cooling method includes the following steps: start the fan, let the high-temperature air in the mine flow into the cooling chamber through the air duct through the air inlet; The high-temperature air exchanges heat to form a cooling air flow and a water source after heat exchange. The cooling air flows into the working surface through the air outlet, and the temperature of the cooling air flow is controlled according to the cooling requirements to achieve local cooling. The device of the invention has simple structure and convenient operation, and the cooling method can avoid economic losses and accident hazards caused by high temperature underground in coal mines, and at the same time realize energy saving and emission reduction, and have high economic benefits.

Owner:LIAONING TECHNICAL UNIVERSITY

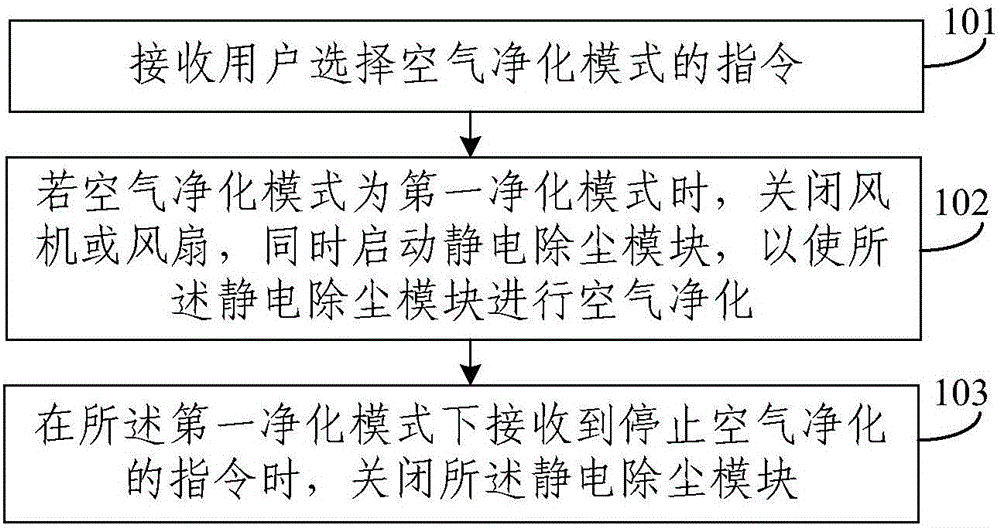

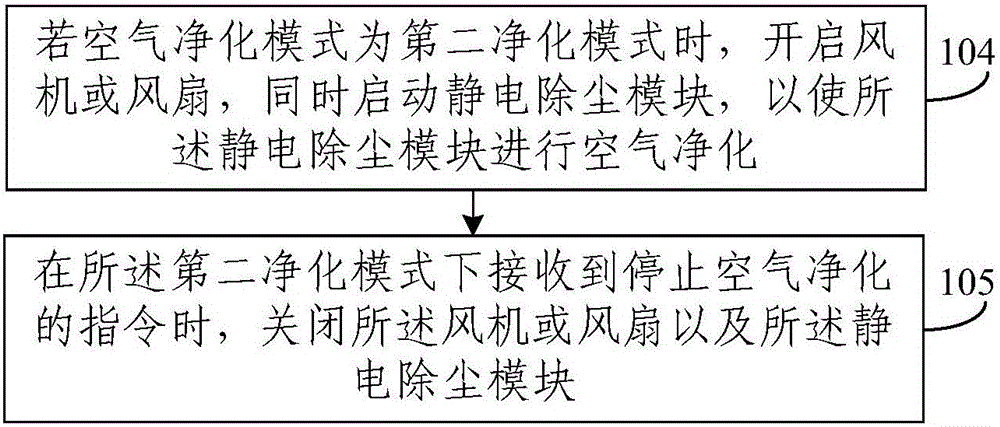

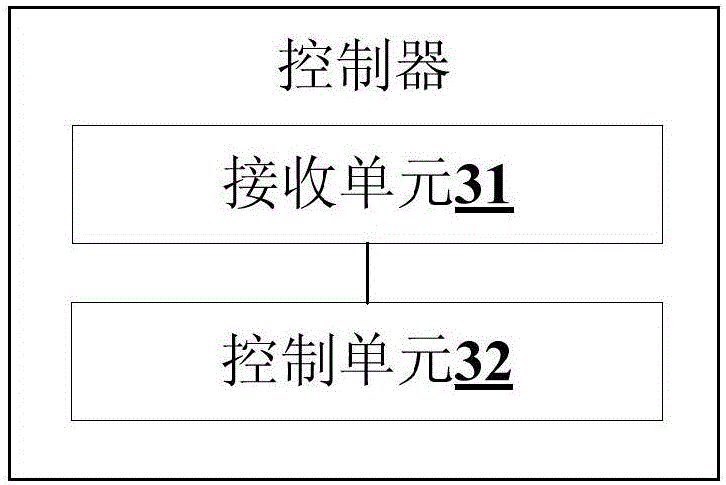

Air purification method, controller, air purification device and air-conditioner

InactiveCN105157166AWith dust removal effectReduce energy consumptionHuman health protectionMechanical apparatusEngineeringAir purification

The invention discloses an air purification method, a controller, an air purification device and an air-conditioner, and relates to the technical field of air purification. The air purification method includes the steps that a command of a user for selecting an air purification mode is received; if the air purification mode is a first air purification mode, a draught fan or a fan is stopped, meanwhile, an electrostatic precipitation module is started, and therefore the electrostatic precipitation module is used for air purification; and when a command of stopping air purification is received under the first purification mode, the electrostatic precipitation module is stopped. By means of the air purification method, the controller, the air purification device and the air-conditioner, control over the draught fan or the fan and control over electrostatic precipitation are separated independently, and the precipitation effect is achieved under the lower-running-power working condition.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

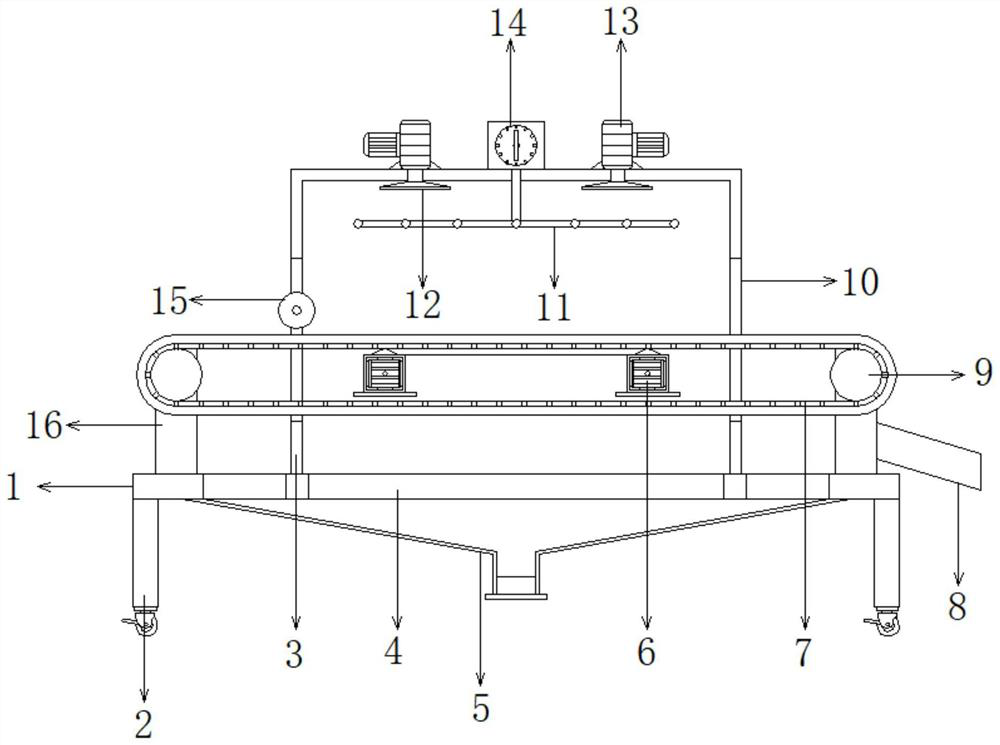

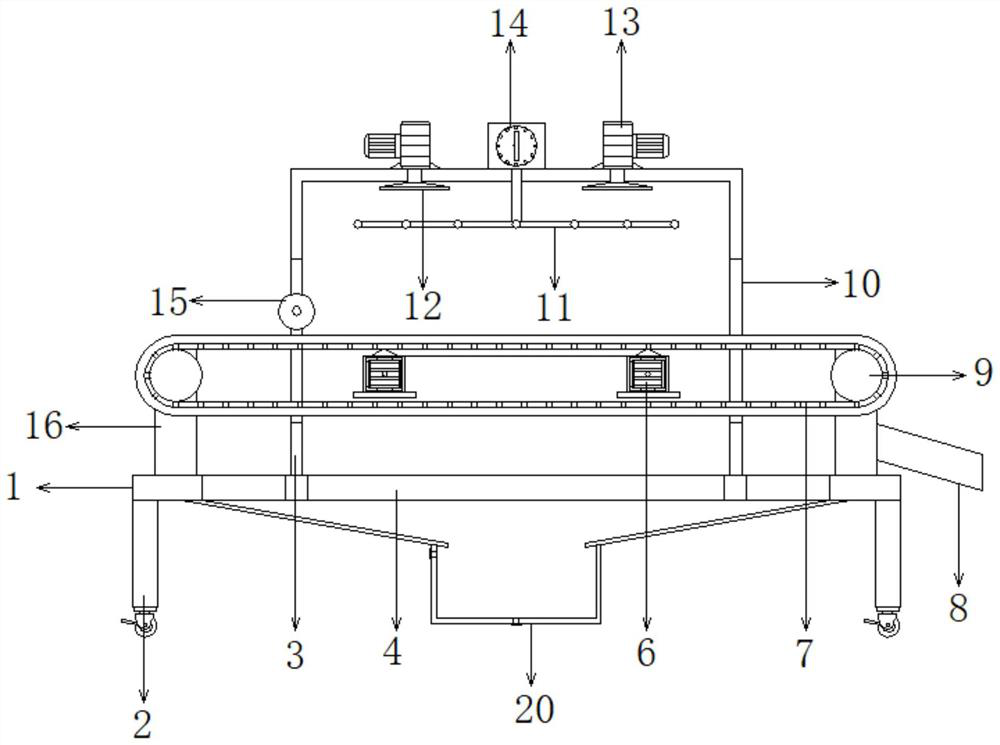

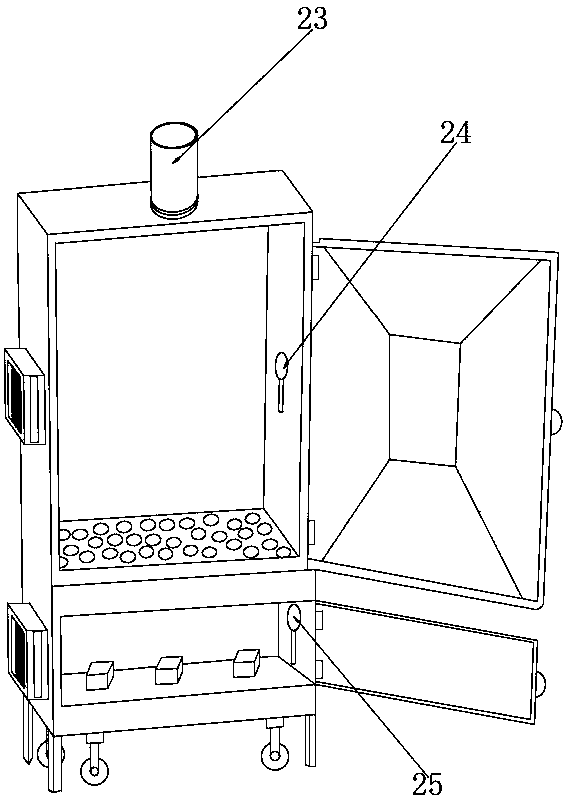

Drying device for agricultural processing

InactiveCN111649574AEasy to dryEasy to operateDrying solid materials with heatDrying gas arrangementsAgricultural scienceAgricultural engineering

The invention discloses a drying device for agricultural processing. The drying device for agricultural processing comprises a supporting table, wherein the middle position of the top outer wall of the supporting table is fixedly connected to a drying oven; inlets and outlets are formed in bottoms of two sides of the drying oven; the top four corners of the supporting table are fixedly connected to supporting columns; tops of outer walls of opposite sides of the supporting columns are rotatably connected to transmission rollers; sides of the supporting columns are fixedly connected to unloading hoppers; outer walls of the transmission rollers are in transmission connection to a conveyor belt; the two sides of the outer wall of the conveyor belt are bonded with protective plates; the conveyor belt passes through the inner parts of the inlets and outlets; and the top of one side of one supporting column is fixedly connected to a motor. The drying device performs heating treatment insidethe drying oven, blows hot gas onto the conveyor belt through a fan, is convenient for drying cereals, vibrates the cereals, and enables the cereals to be sufficiently in contact with hot gas, so thatdrying efficiency is improved, and impurities such as dust particles in the cereals are screened, and therefore, the device has dust-removal effect.

Owner:任静

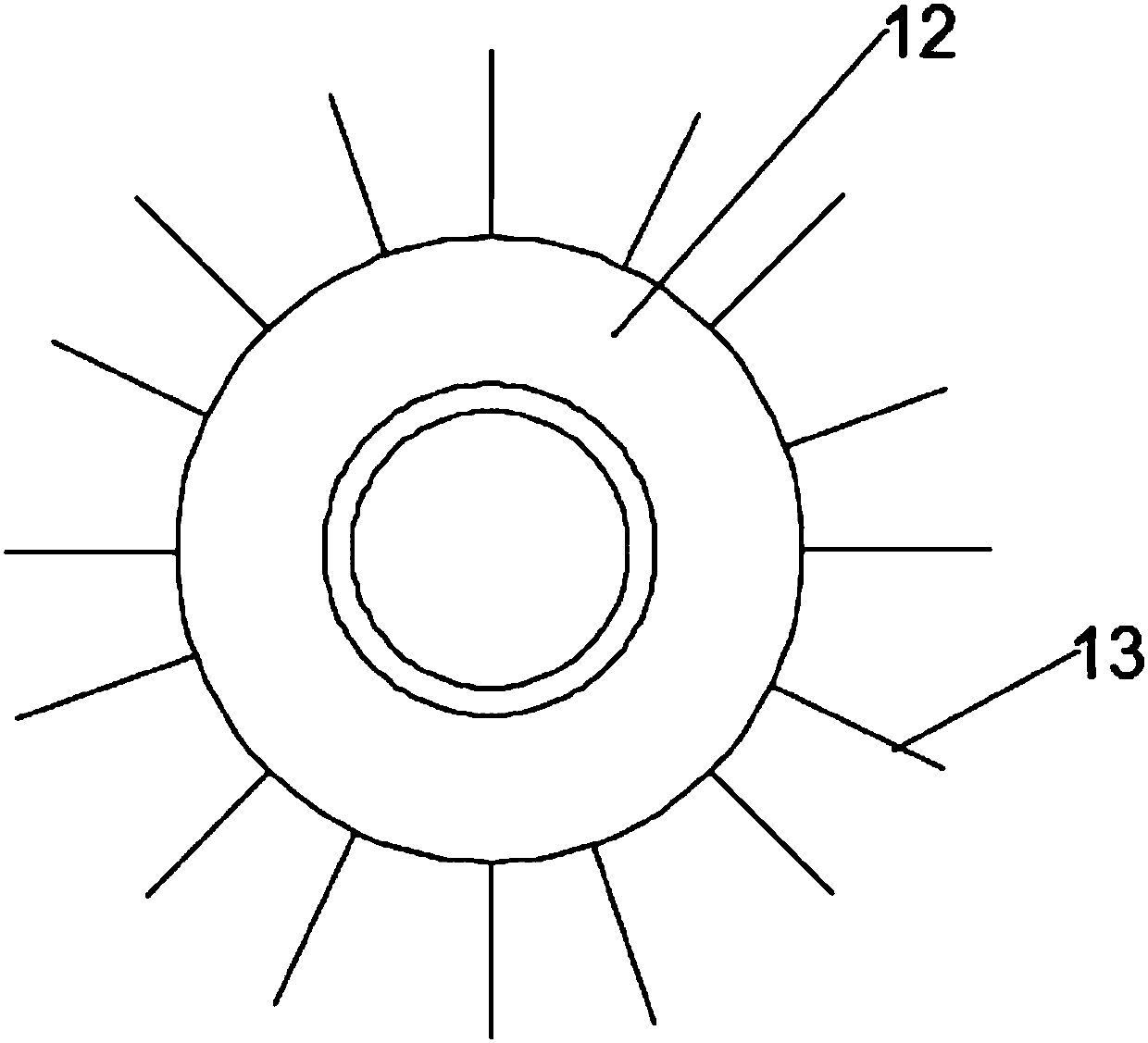

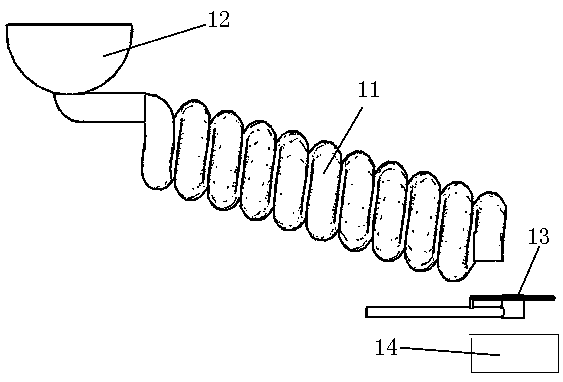

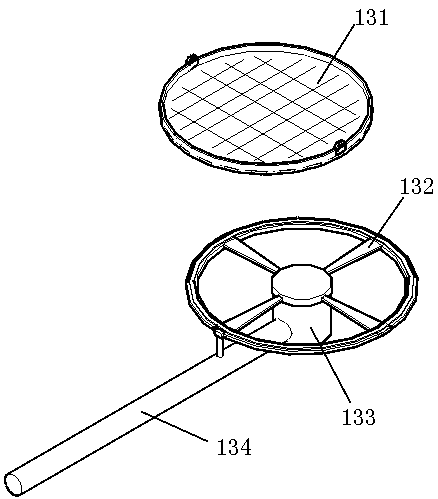

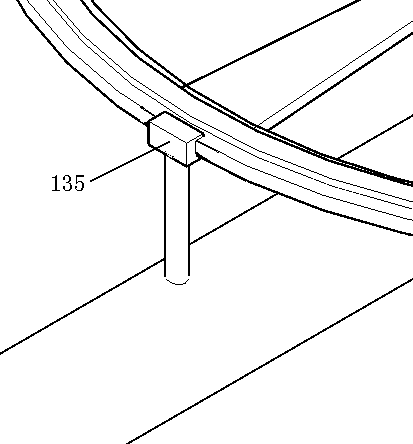

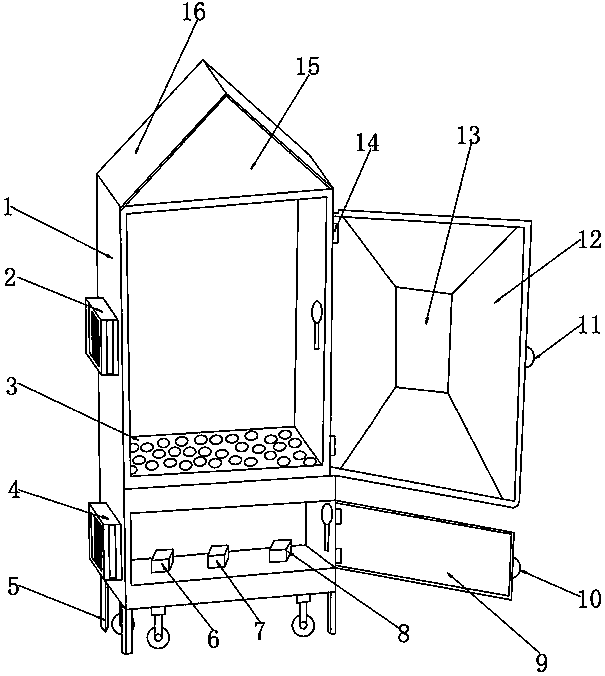

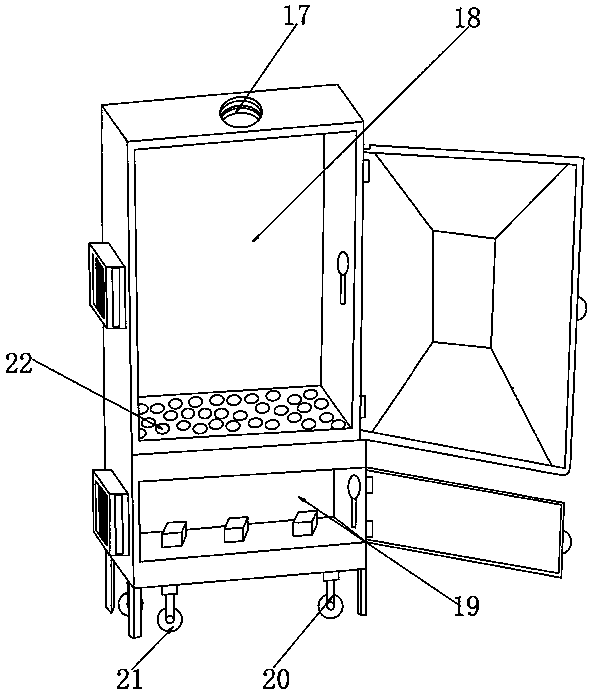

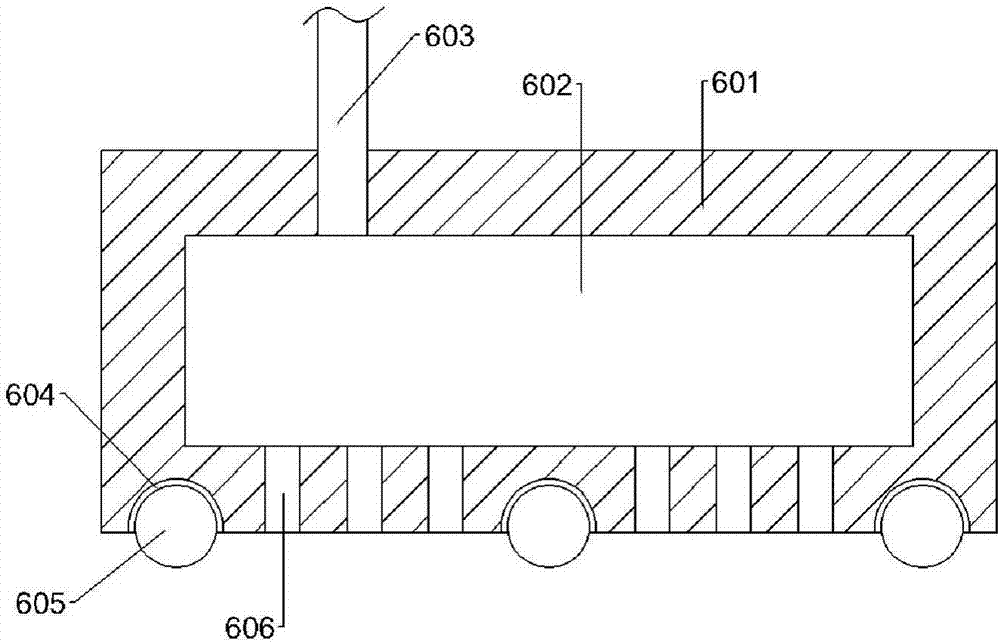

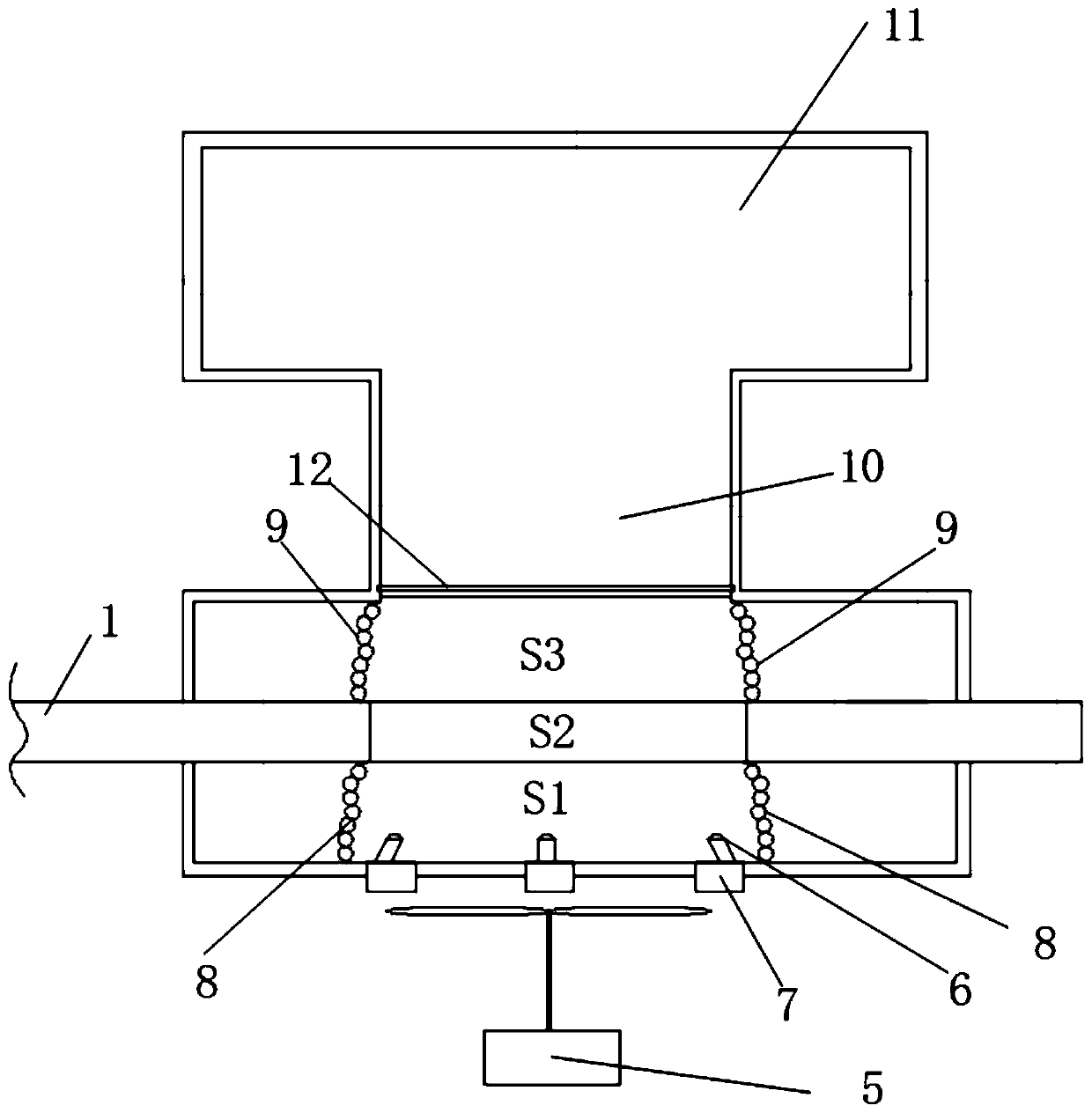

Tea fixating apparatus and tea processing method

PendingCN109452402AEven distribution of hot air circulationImprove the efficiency of finishingPre-extraction tea treatmentCleaning using liquidsComputer scienceDust control

The invention relates to the technical field of tea processing, and specifically discloses a tea fixating apparatus and a tea processing method. The tea fixating apparatus comprises the following parts: a fixating tube; a first fixating screen, a second fixating screen and a third fixating screen which are sequentially arranged inside the fixating tube from the top to the bottom; and a vibrating part which is used for allowing the first fixating screen or the second fixating screen to vibrate up and down. A hot air circulation chamber is arranged, in isolated arrangement, at an inner bottom ofthe fixating tube via a clapboard with through holes; and a draft fan is arranged inside the hot air circulation chamber. The tea fixating apparatus disclosed by the invention is capable of carryingout hot-air fixation when tea leaves are vibrated to fall; so that, piling of tea leaves during fixation is avoided. Moreover, uniform hot air circulation and distribution are ensured, so that, high tea fixation efficiency and full fixation effect are achieved so as to have tea quality improved; moreover, the tea fixating apparatus also has a dust-removing effect.

Owner:宣城市鹤鸣茶叶机械制造有限公司

Novel computer case device

InactiveCN107390819ASimple structureEasy to operateDigital processing power distributionComputer engineeringComputer case

The invention discloses a novel computer case device. The novel computer case device comprises a case body, a host and a heat dissipating device, wherein a bottom plate is arranged at the bottom of the case body, and four support legs are arranged at the four corners of the bottom of the bottom plate; mountable universal wheels are arranged on the bottoms of the support legs, and the bottom of an inner cavity of the case body is provided with four spring washers; tops of the four spring washers are provided with a placing plate, and the top of the placing plate is provided with the host; two side walls of the inner cavity of the case body are provided with slide blocks. According to the novel computer case device, under the action of the spring washers at the bottom and springs arranged among fixing plates on both sides and a brush, collisions can be effectively prevented, and the brush can be driven to clean ventilation holes, which are formed in side walls of the case body of the host, through the expansion and contraction of a telescopic device; the ventilation effect is good, the effect of dust removal is achieved, and meanwhile the heat is taken away from the case body by the heat dissipating device; the heat dissipating effect is good, and by means of the mountable universal wheels, moving is convenient.

Owner:合肥千奴信息科技有限公司

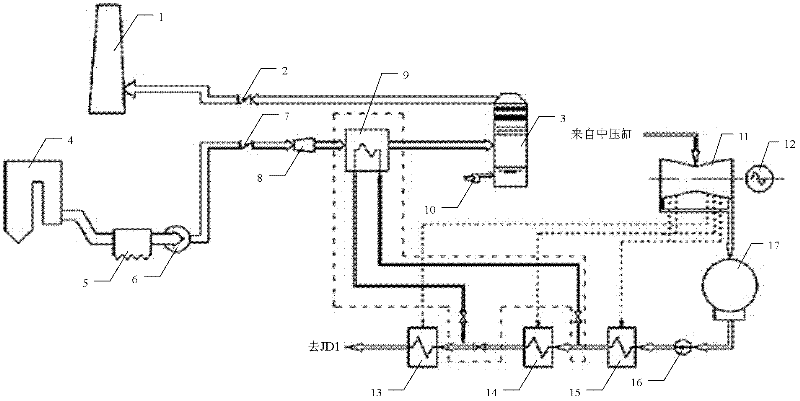

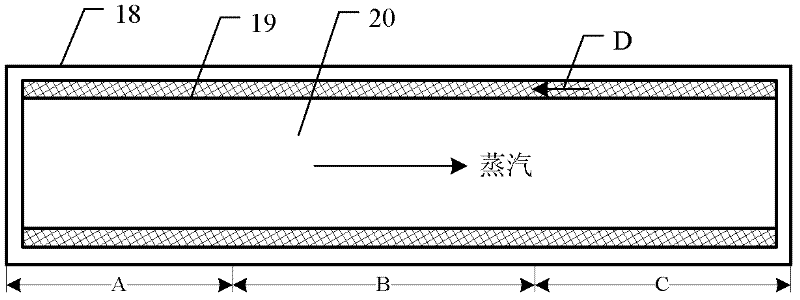

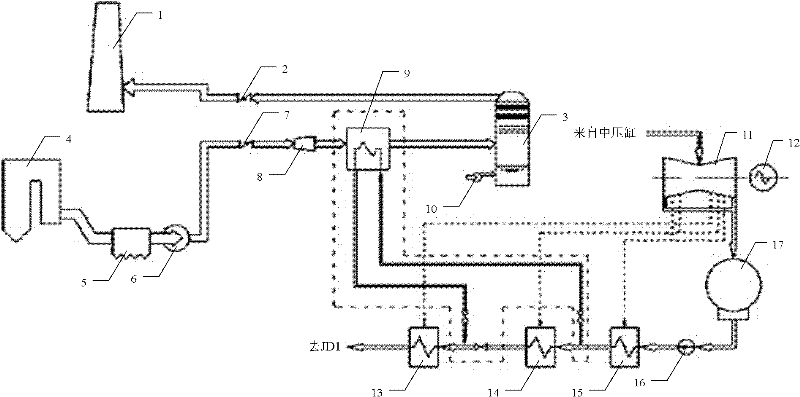

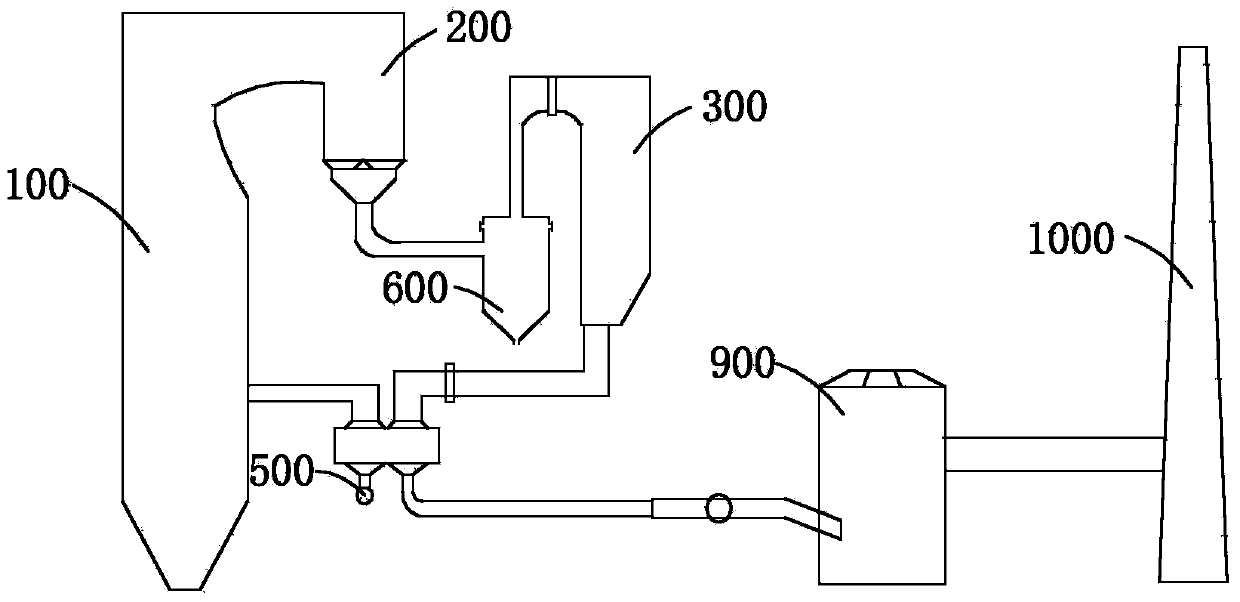

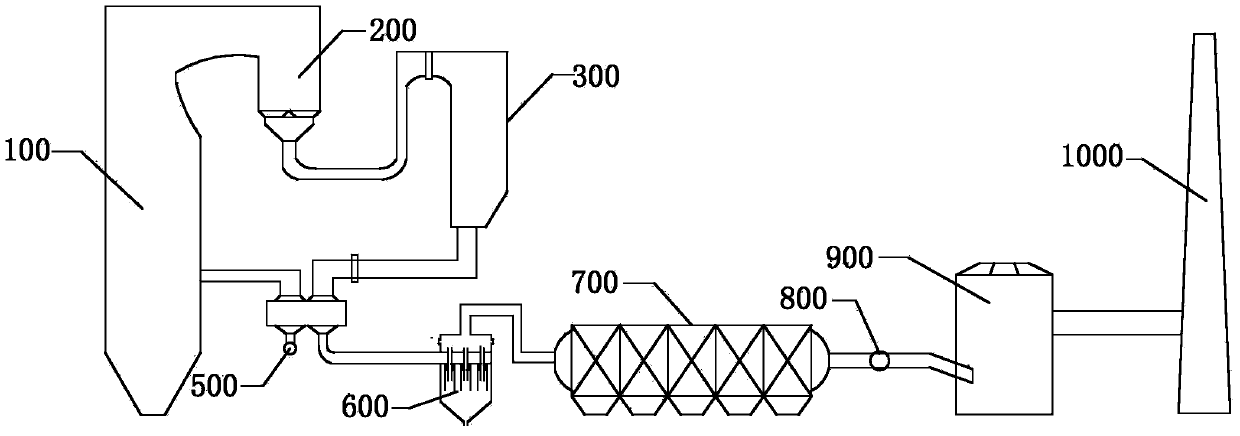

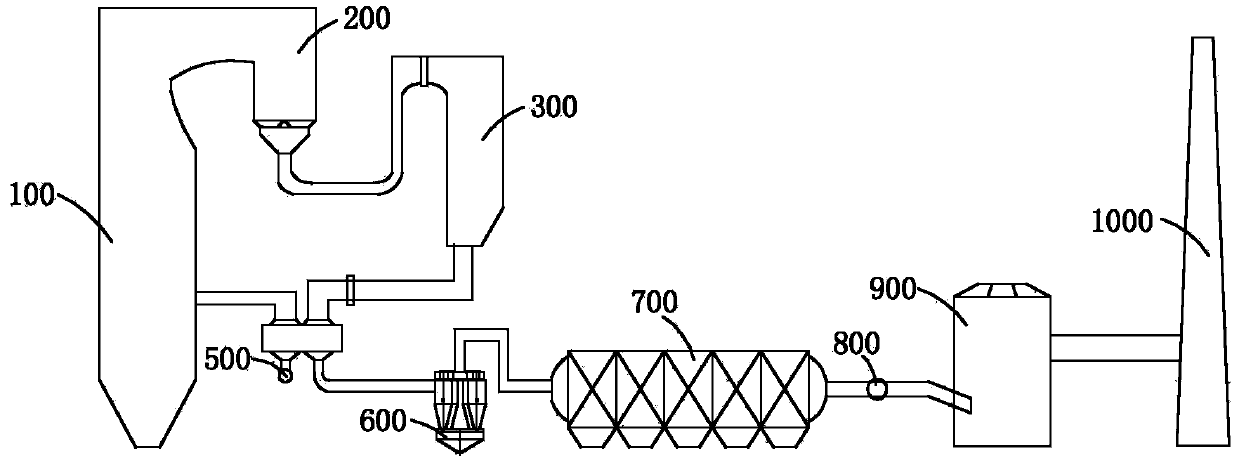

Coal power plant combined type heat pipe flue gas waste heat recovery system and method

ActiveCN102444901AMeet temperature requirementsReduce the amount of waterCombustion processIndirect carbon-dioxide mitigationWater vaporFlue gas

The invention discloses a coal power plant combined type heat pipe flue gas waste heat recovery system and method. The system comprises a boiler, a deduster, a draught fan, a booster fan, a combined type heat pipe heat exchanger component, a desulfurizing tower and a chimney which are sequentially connected in a cooperation mode through pipelines. The method comprises the following steps: additionally arranging the combined type heat pipe heat exchanger component in a gas flue system of a coal power plant, and recycling heat and water vapor of the gas flue system; and a bypass gas flue is led out between the draught fan and the booster fan of the gas flue system and is connected between the desulfurizing tower and the chimney of the gas flue system. The coal power plant controllable type heat pipe flue gas waste heat recovery system and method disclosed by the invention can overcome the defects of poor energy conservation performance, poor environmental protection performance, high cost, poor reliability, large occupation space and the like so as to realize the advantages of good energy conservation performance, good environment protection performance, low cost, good reliability, small occupation space and wide application scope.

Owner:中创清洁能源发展(沈阳)股份有限公司

Power distribution cabinet for electrical engineering

InactiveCN109659821AEasy to moveImprove stabilitySubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsVentilation tubeEngineering

Owner:JIANGXI YAPO ELECTRIC CO LTD

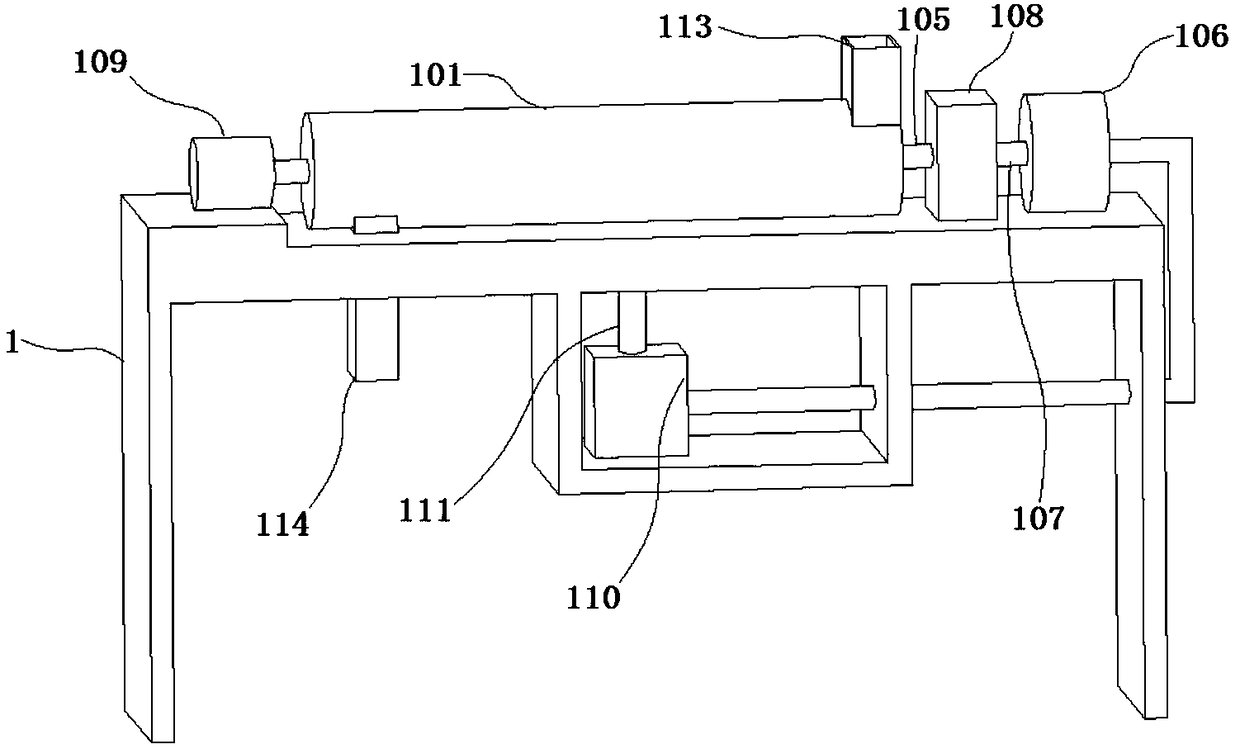

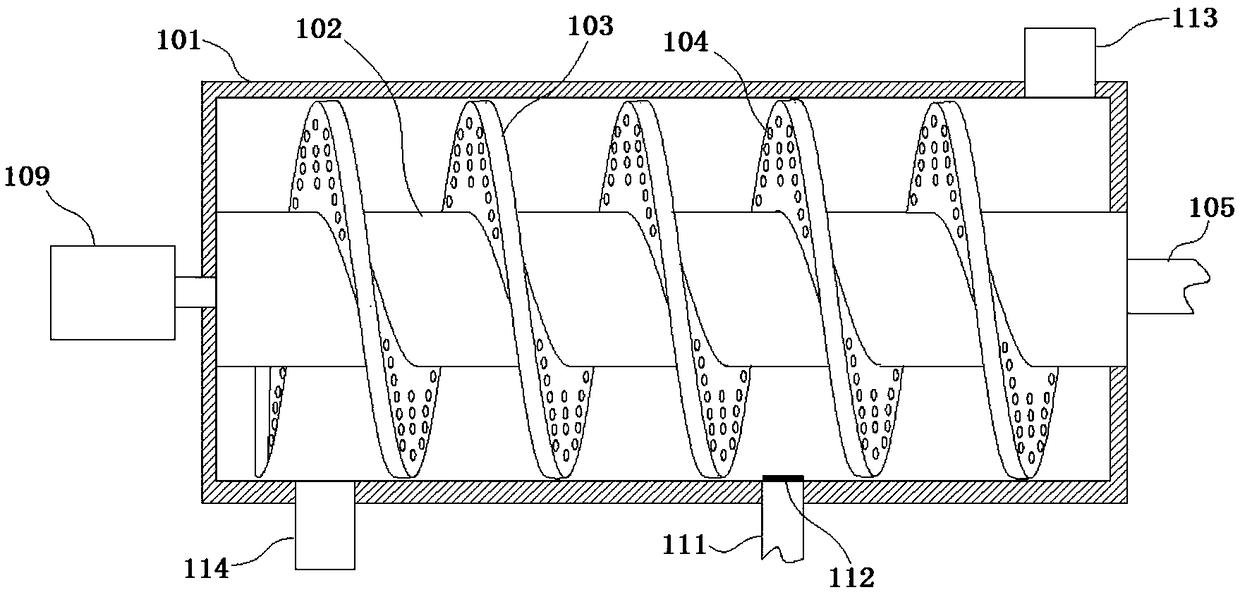

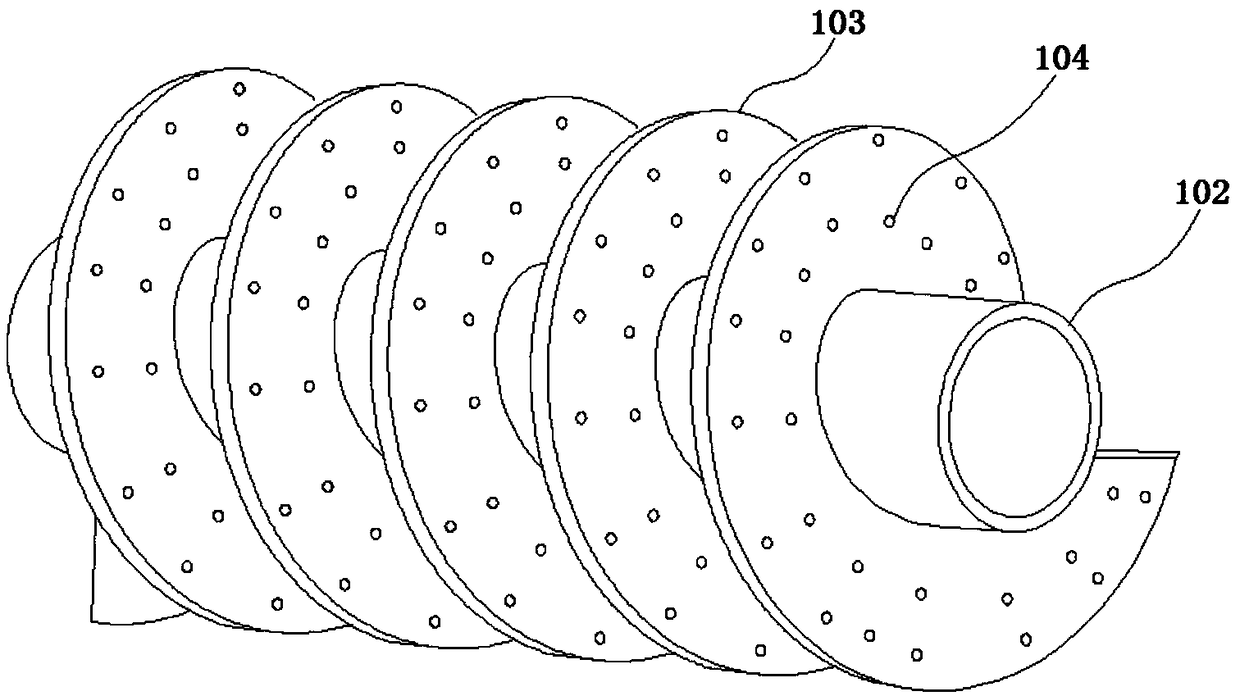

Hot air chamber of efficient grain dryer

InactiveCN109269280AEvenly heatedReduce qualityDrying gas arrangementsDrying solid materialsVacuum cleanerGrain quality

The invention discloses a hot air chamber of an efficient grain dryer and relates to the technical field of grain drying. The hot air chamber comprises a bracket, one surface of the bracket is fixedlyconnected with a cylinder, a hollow roller is rotatably connected to one surface of the cylinder, a spiral hollow baffle is fixedly connected to the circumferential side face of the hollow roller, through holes are formed in one surface of the spiral hollow baffle, one surface of the spiral hollow baffle is communicated with the hollow roller, and one surface of the cylinder is communicated witha hot air pipe. Through the cooperation between the hollow roller and the spiral hollow baffle, the spiral hollow baffle rotates and stirs grains in a hot air chamber body to make the grains heated uniformly, the drying efficiency is improved, and the problems that the grain quality declines and the drying effect is poor since the grains are heated nonuniformly in the drying process are avoided; dust in the hot air chamber body is absorbed, collected, filtered and then discharged by a vacuum cleaner in time, and the problem that the environment is polluted since the dust generated in the process of drying the grains is directly discharged to the outside without disposal is solved.

Owner:合肥三伍机械有限公司

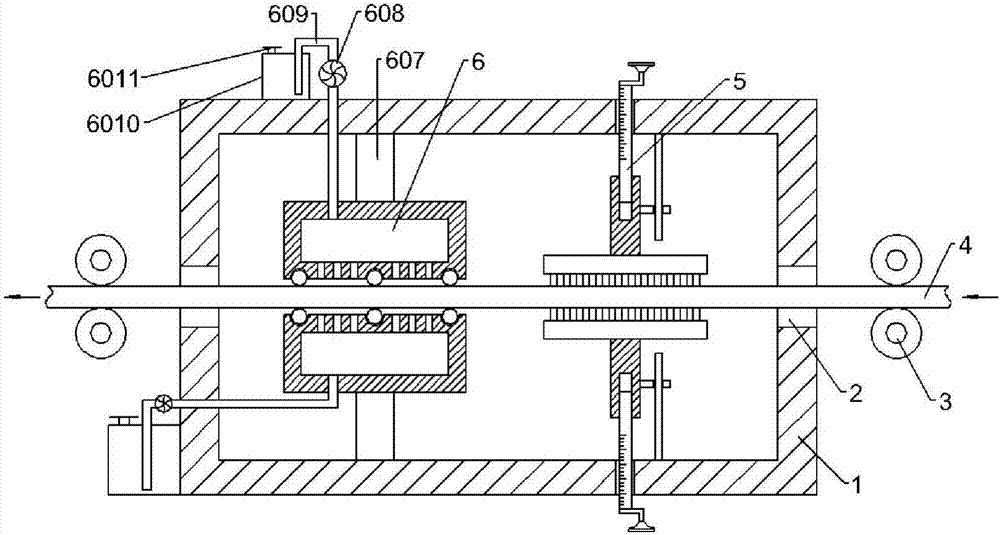

Dedusting device for digital printing machine

InactiveCN106985557AAdjust cleaning strengthWith dust removal effectOther printing apparatusEngineeringDigital printing

The invention provides a dedusting device for a digital printing machine. The device comprises a housing, wherein an inlet and an outlet are symmetrically formed in two sidewalls of the housing; a fabric passes through the housing through the inlet and the outlet; two cleaning devices, each comprising a mounting plate, are symmetrically arranged at the upper side and the lower side of the fabric in the housing; brush hair is arranged at the lower side of each mounting plate; a mounting column is fixedly connected to the middle of the upper side of each mounting plate; a threaded groove of which an opening is upwards formed is formed in the upper part of each mounting groove; a threaded rod is connected into each threaded groove by means of threads; the threaded rods pass through threaded holes in the top part of the housing, and handles are fixedly connected to the top ends of the threaded rods; guide rods are fixedly connected to the inner top part of the housing; guide plates which are provided with through holes are fixedly connected to the sidewalls of the mounting columns; two dedusting device bodies are symmetrically arranged on the fabric at the left side of the cleaning device. The dedusting device for the digital printing machine has the advantages of being reasonable in structure design, convenient to use, and good in fabric dedusting effect, and has a certain popularization and application.

Owner:HAINING KUCAI DIGITAL TECH CO LTD

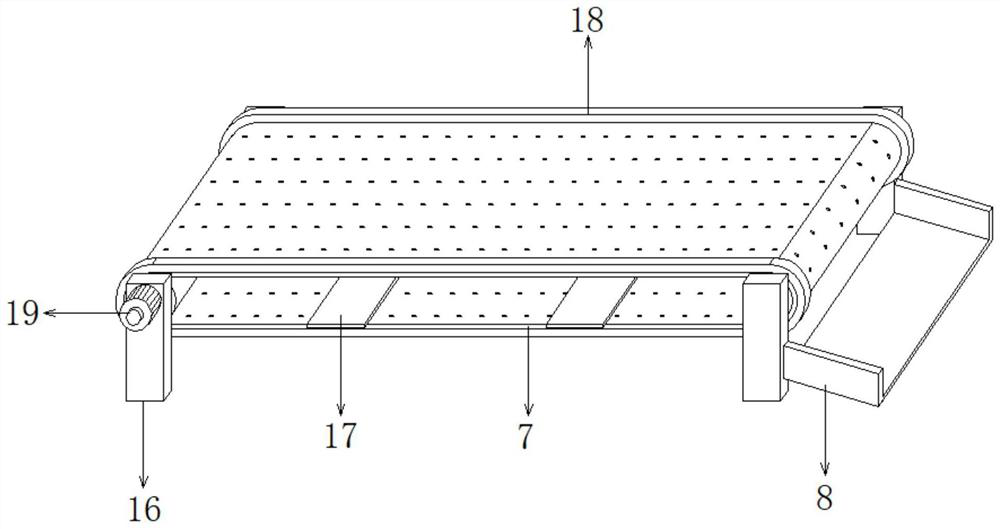

Packaging aluminum-foil paper detection device

InactiveCN111999302AThe time to put paper is the sameExpand coverageOptically investigating flaws/contaminationWebs handlingStructural engineeringMechanical engineering

The invention discloses a packaging aluminum-foil paper detection device comprising a conveying table. A driving belt wheel, a driven belt wheel and a conveying belt are arranged in the conveying table, the conveying belt is connected with the driving belt wheel and the driven belt wheel, a plurality of sets of placing grooves are formed in the conveying belt at equal intervals, steps are arrangedon the peripheries of the inner walls of the placing grooves, and aluminum-foil paper is placed on the steps. The invention relates to a packaging aluminum-foil paper detection device. a feed box isdesigned and aluminum-foil paper is provided automatically and is guided into the placing grooves, and the paper placing time is consistent with the displacement position of each group of placing grooves; a flattening roller rotating in the feeding box is used for flattening the aluminum-foil paper for the first time to eliminate wrinkles; a water supply structure is designed, water is guided outfrom a guide pipe through air pressure and sprayed to the surface of the aluminum-foil paper through a spray head, the spray head is large in coverage range, uniform in spraying and capable of addingwater in time, the spraying time is kept consistent with the displacement position of each set of containing grooves, the device is suitable for different working conditions, and better use prospectsare brought.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

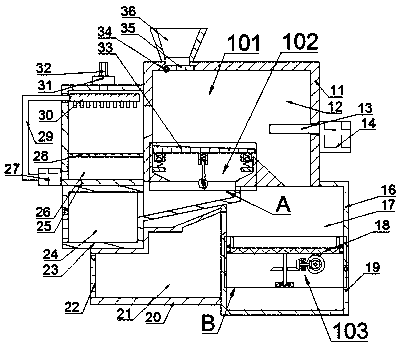

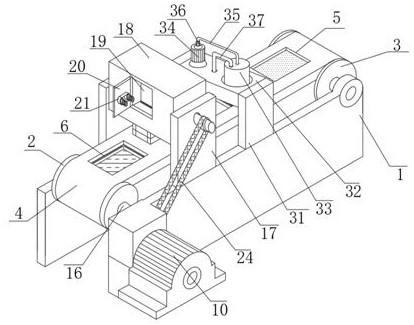

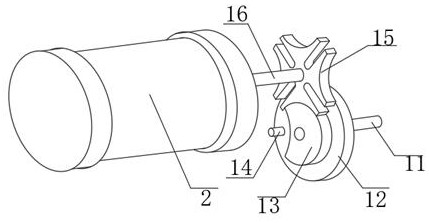

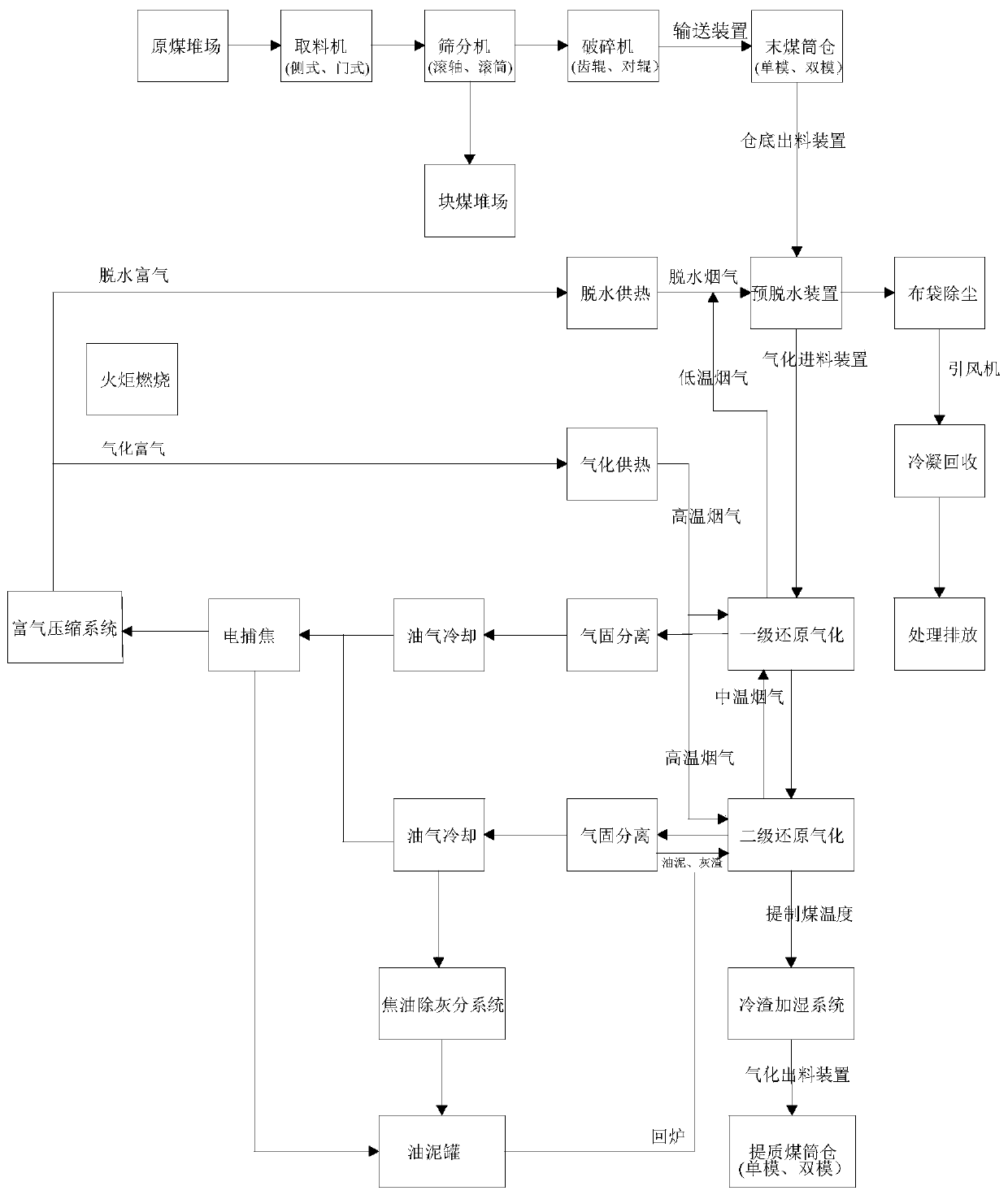

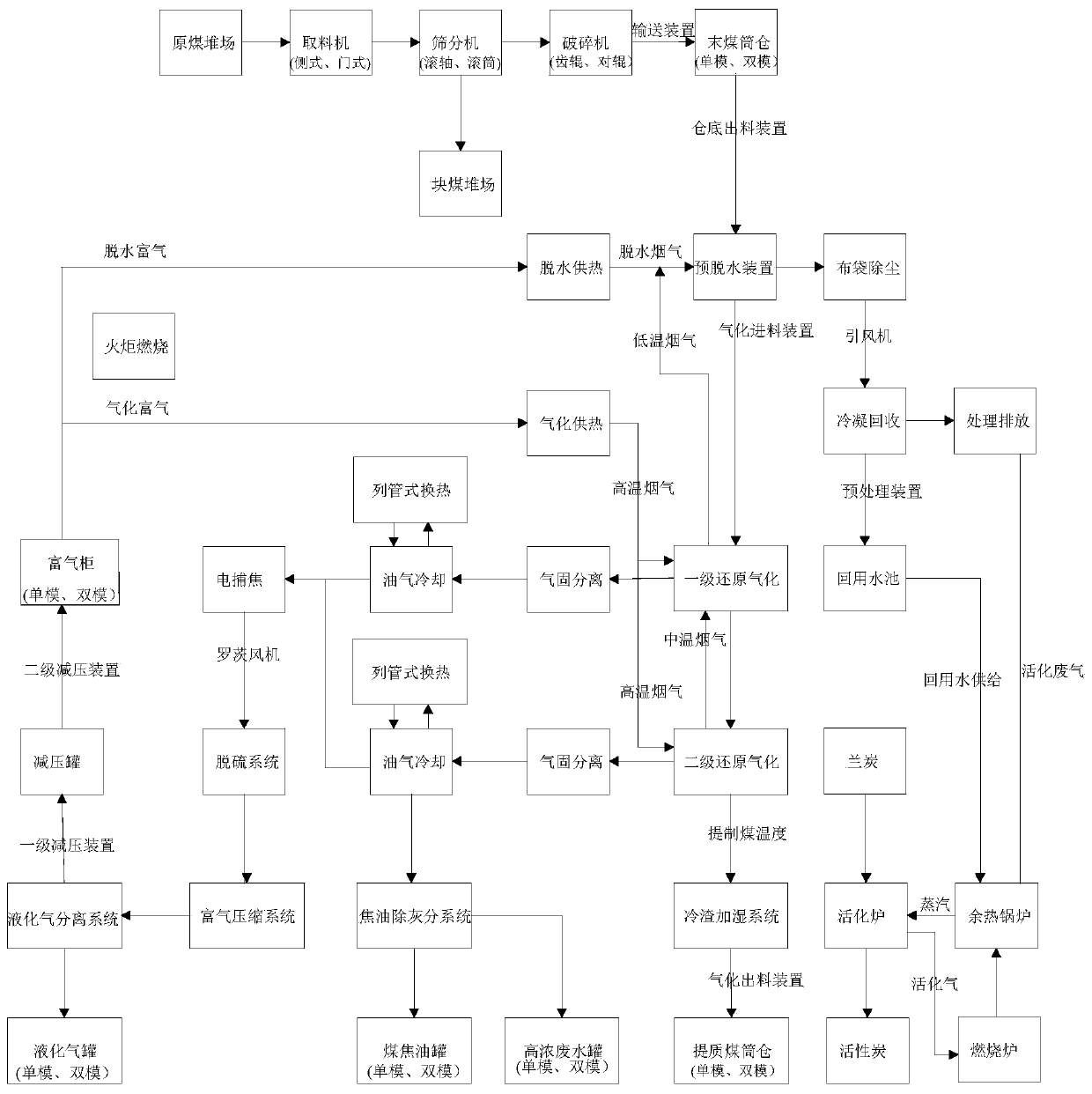

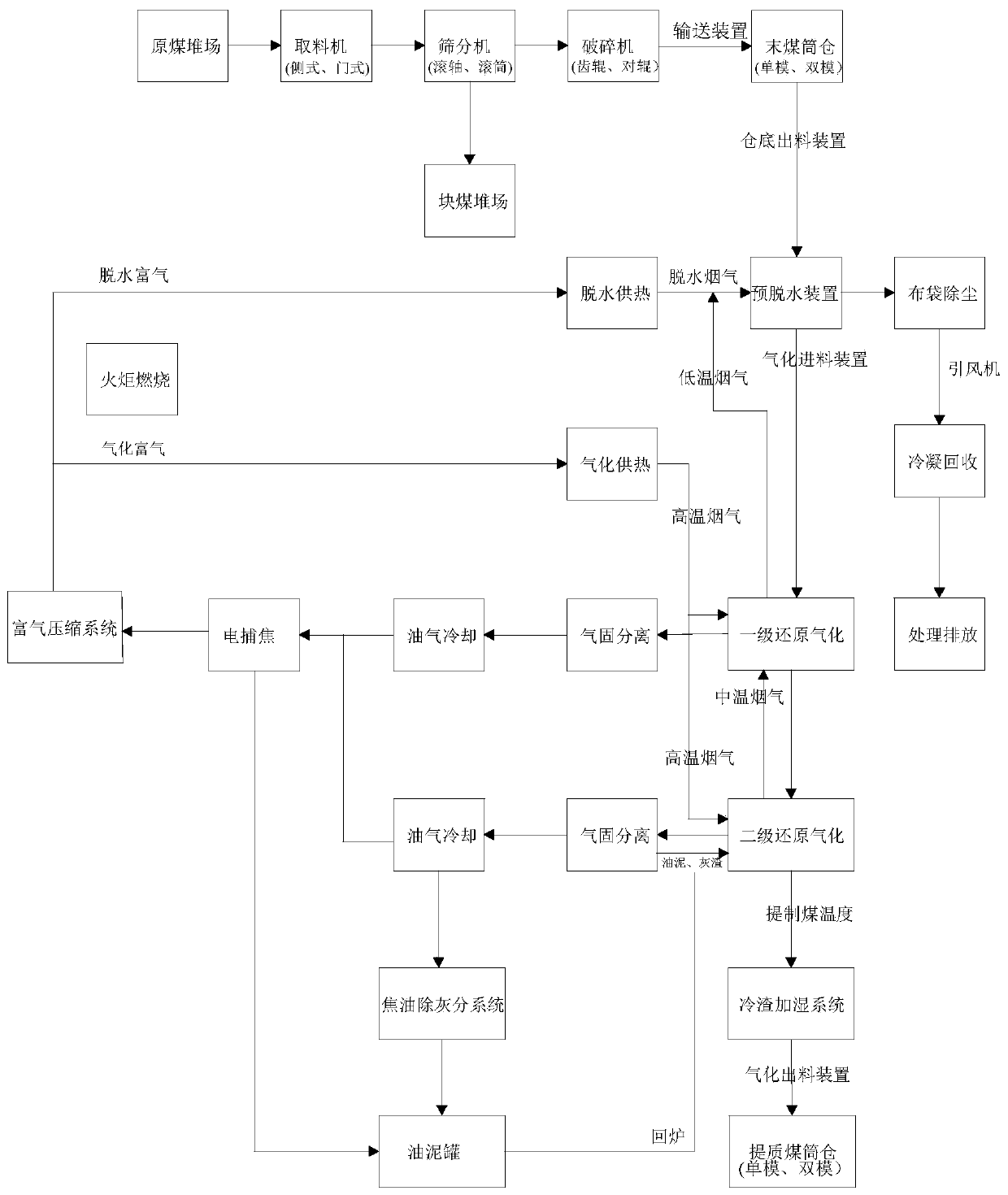

Method for gasification reduction of pulverized coal and separation and recycling of upgraded coal

PendingCN110003929AReduce productionNo lossEnergy inputOven incrustations prevention/removalSlagPulverizer

The invention discloses a method for gasification reduction of pulverized coal and separation and recycling of upgraded coal. The method comprises following steps: 1), raw coal is screened and pulverized by a pulverizer and pulverized coal enters a slack coal silo; 2), the pulverized coal in the slack coal silo is dried, then enters a primary gasification reduction device and a secondary gasification reduction device and is reacted sufficiently, an obtained material enters a cold slag humidification system and then enters an upgraded coal silo through a gasification discharging device, and anupgraded coal product is obtained; 4), ash residues obtained by a gas-solid separation system is conveyed to the secondary gasification reduction device, and oil sludge returns to the a secondary gasification device through an oil sludge conveying device; 5), a non-condensable gas is gasified to supply heat to a reaction system, and dewatered non-condensable gas and flue gas with waste heat supplyheat to a pre-dewatering device to dry a material; 6), flue gas containing dust and steam, which is produced by the pre-dewatering device, is subjected to cloth bag dedusting and condensation recovery successively under the power action of an induced draft fan.

Owner:浙江天禄环境科技有限公司

System and method for efficiently removing dust in flue gas of coal-fired power plant

InactiveCN103994455AReasonable designMeet emission standardsLighting and heating apparatusAir preheaterCyclone

The invention provides a system for efficiently removing dust in flue gas of a coal-fired power plant. The system is arranged between a boiler and a chimney of the coal-fired power plant, and used for removing dust in the flue gas discharged from the coal-fired power plant. The system comprises an economizer, a denitration reactor, an air preheater and a desulfurizing tower which are communicated sequentially, wherein the economizer is communicated with the boiler, and the desulfurizing tower is communicated with the chimney. The system further comprises a multi-tube type cyclone separator, wherein the multi-tube type cyclone separator is arranged between the economizer and the chimney and used for removing dust in the flue gas of the coal-fired power plant. The invention further provides a method for efficiently removing dust in the flue gas of the coal-fired power plant. The system for efficiently removing dust in the flue gas of the coal-fired power plant is reasonable in design, and for the flue gas discharged from the coal-fired power plant, the multi-tube type cyclone separator is arranged between the economizer and the chimney to remove dust from the flue gas; moreover, the multi-tube type cyclone separator can meet the requirement for purification efficiency of the system, and the flue gas discharged from the coal-fired power plant can reach the corresponding discharging standard.

Owner:彭维明

Composite sandstone crushing and dust removal integrated device

ActiveCN109126994AFully brokenImprove crushing efficiencyDispersed particle filtrationTransportation and packagingMechanical engineeringIntegrated devices

The invention discloses a composite sandstone crushing and dust removal integrated device. The device comprises a crushing box body, a first crushing mechanism, a second crushing mechanism and a dustremoval device; feeding ports are formed in the top of the crushing box body in the circumferential direction of the edge, the inner wall of the crushing box body is provided with material guiding plates corresponding to the feeding ports, discharge holes are formed in the middles of the material guiding plates, material guiding rollers driven by a motor for material guiding are arranged on the portions, corresponding to the upper portions of the material guiding plates, of the interior of the crushing box body, and the first crushing mechanism includes a first driving motor, a rotating shaft,multiple crushing rods and multiple crushing hammers. The device adopts a composite crushing mode integrating collision crushing, impact crushing, counterattack crushing and sandstone collision crushing, sandstone can be fully crushed, the crushing efficiency is high, the effect is good, general popularization is facilitated, a dust removal effect is achieved at the same time, and the demands ofclean production are met.

Owner:富平中昊建材有限责任公司

High-temperature waste gas dust collection method

ActiveCN108619842AIncrease contact areaWith dust removal effectCombination devicesGas treatmentFlue gasEngineering

The invention relates to the technical field of flue gas treatment and particularly discloses a high-temperature waste gas dust collection method which comprises the following steps: (1) introducing aflue gas from the bottom of a dust collection tower, and discharging the flue gas from the top of the dust collection tower after passing through a filtering layer in the dust collection tower; (2) while the flue gas is introduced into the dust collection tower, spraying water down from the top of the dust collection tower; (3) collecting water from the bottom of the dust collection tower, wherein the water sprayed down from the top of the dust collection tower is water collected from the bottom of the dust collection tower. Due to the adoption of the filtering layer, the flue gas can be adsorbed, the flue gas has a large contact area with the filtering layer when passing through the filtering layer, and in addition, when the flue gas is introduced from the bottom of the dust collection tower, the water is sprayed down from the top of the dust collection tower, and the water also has a dust collection function when being in contact with the flue gas, so that a dust collection effect can be improved.

Owner:重庆市永川区植成家俱厂

Coal power plant combined type heat pipe flue gas waste heat recovery system and method

ActiveCN102444901BExcessive heatImprove efficiencyCombustion processIndirect carbon-dioxide mitigationWater vaporFlue gas

The invention discloses a coal power plant combined type heat pipe flue gas waste heat recovery system and method. The system comprises a boiler, a deduster, a draught fan, a booster fan, a combined type heat pipe heat exchanger component, a desulfurizing tower and a chimney which are sequentially connected in a cooperation mode through pipelines. The method comprises the following steps: additionally arranging the combined type heat pipe heat exchanger component in a gas flue system of a coal power plant, and recycling heat and water vapor of the gas flue system; and a bypass gas flue is led out between the draught fan and the booster fan of the gas flue system and is connected between the desulfurizing tower and the chimney of the gas flue system. The coal power plant controllable type heat pipe flue gas waste heat recovery system and method disclosed by the invention can overcome the defects of poor energy conservation performance, poor environmental protection performance, high cost, poor reliability, large occupation space and the like so as to realize the advantages of good energy conservation performance, good environment protection performance, low cost, good reliability, small occupation space and wide application scope.

Owner:中创清洁能源发展(沈阳)股份有限公司

Glass spin-drying device

PendingCN109489378AQuick removalEasy to fixDrying solid materials without heatDrying gas arrangementsSpinsEngineering

The invention discloses a glass spin-drying device which comprises a workbench; a transmission mechanism is installed below the workbench; a drive motor is connected to the input end of the transmission mechanism, and a rotary shaft is connected to the output end of the transmission mechanism; one end, far away from the transmission mechanism, of the rotary shaft extends out of the surface of theworkbench; a spin-drying disc is connected to the end, far away from the transmission mechanism, of the rotary shaft; multiple clamping placement tables are distributed at the periphery of the surfaceof the spin-drying disc in a rectangular shape; the clamping placement tables distributed on the two opposite sides of a rectangle are symmetrically arranged two by two; a rectangular region enclosedby multiple clamping placement tables is matched with a glass sheet to be dried in size; each clamping placement table is in a ladder shape; a ladder of each clamping placement table is arranged awayfrom the edge of the spin-drying disc; and the external of each clamping placement table is wrapped with an antiskid damping layer. The glass spin-drying device provided by the invention is reasonable in design, can effectively improve the efficiency of removing water drops on the glass sheet, can ensure the glass sheet not to be damaged at the same time and has certain dust removal effect.

Owner:成都市澳格斯科技有限公司

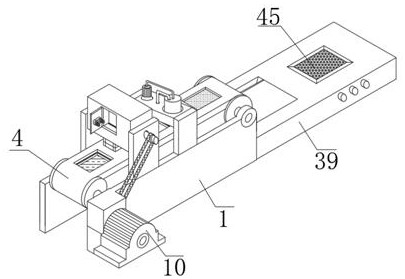

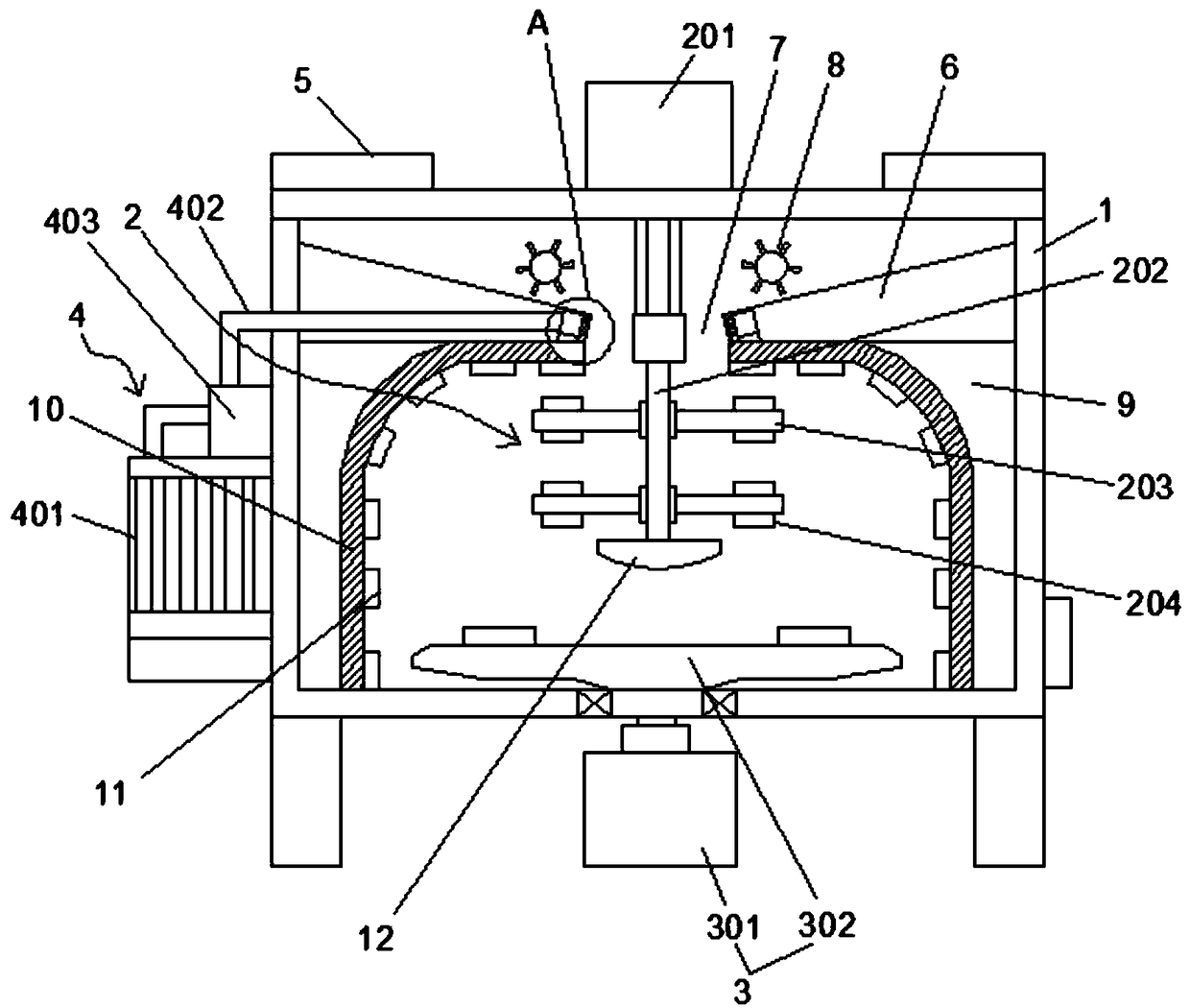

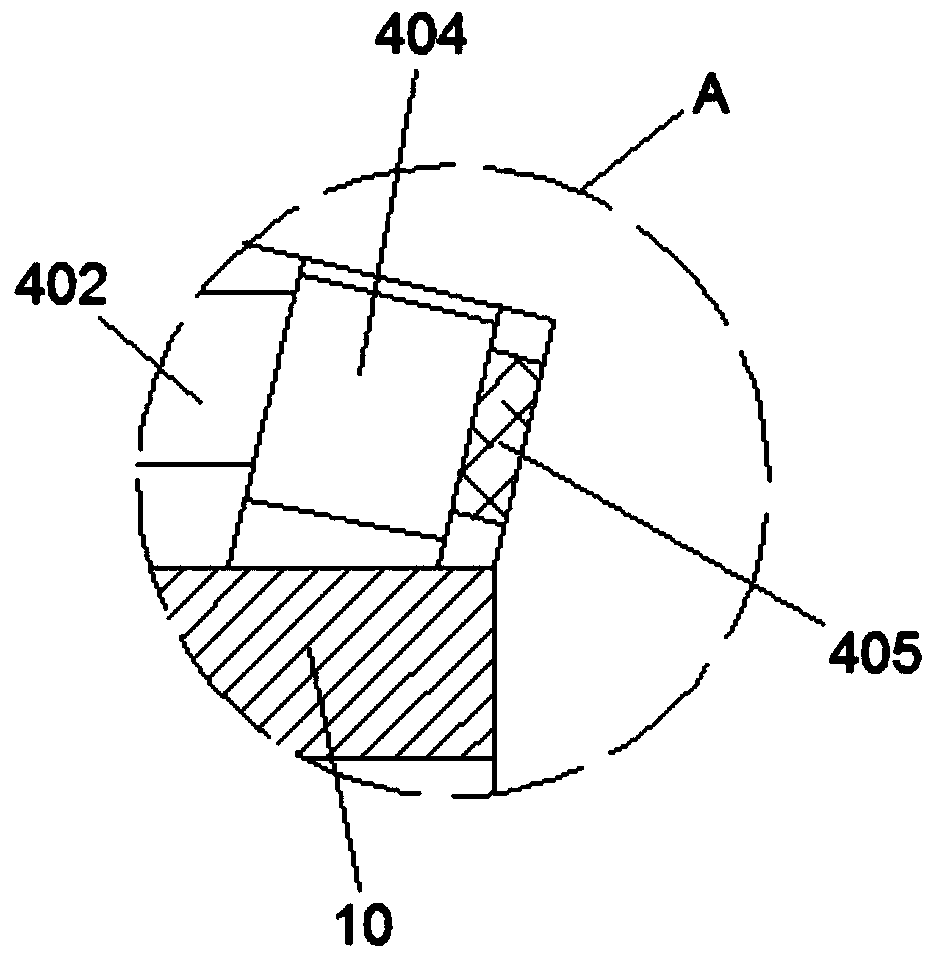

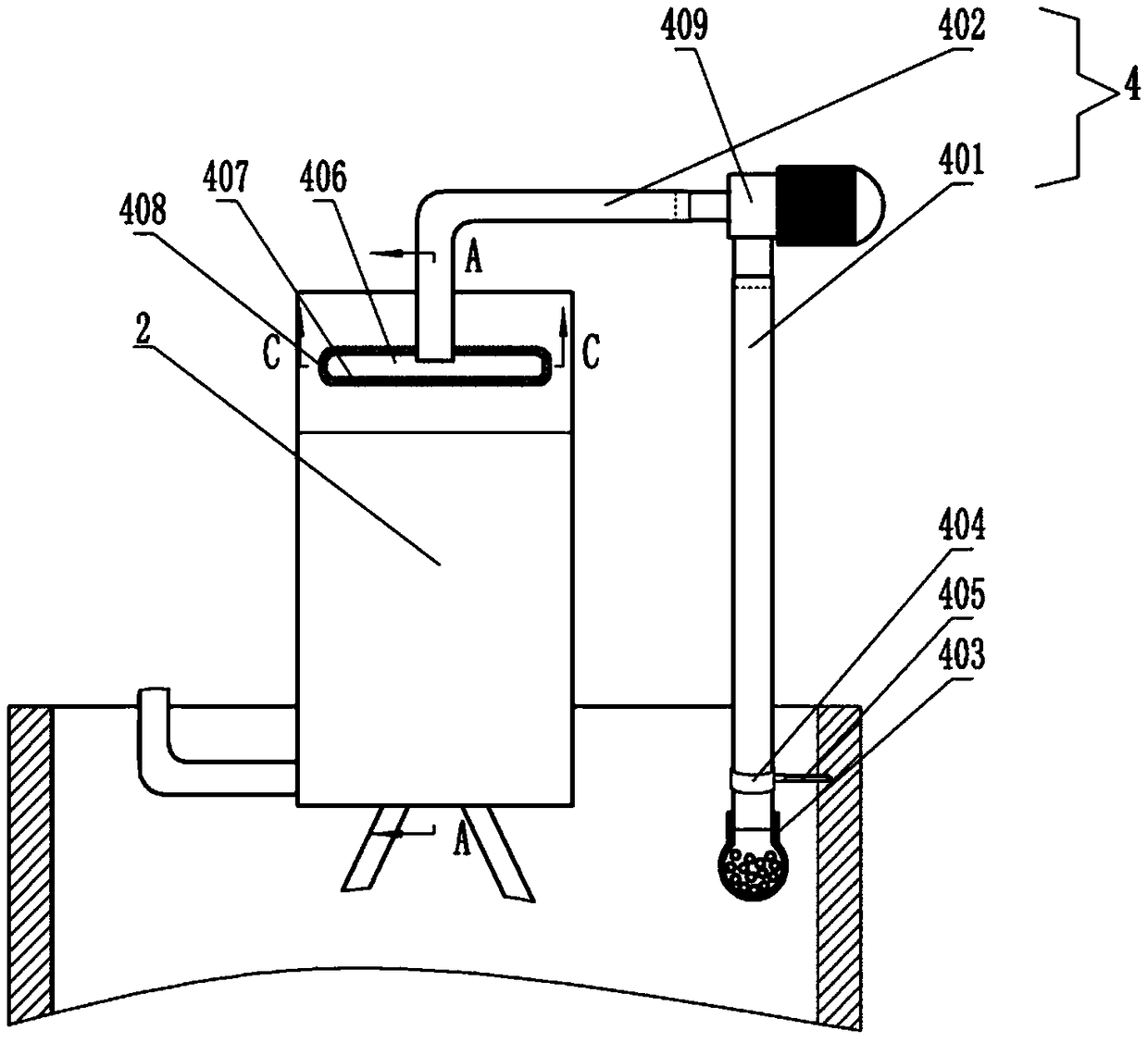

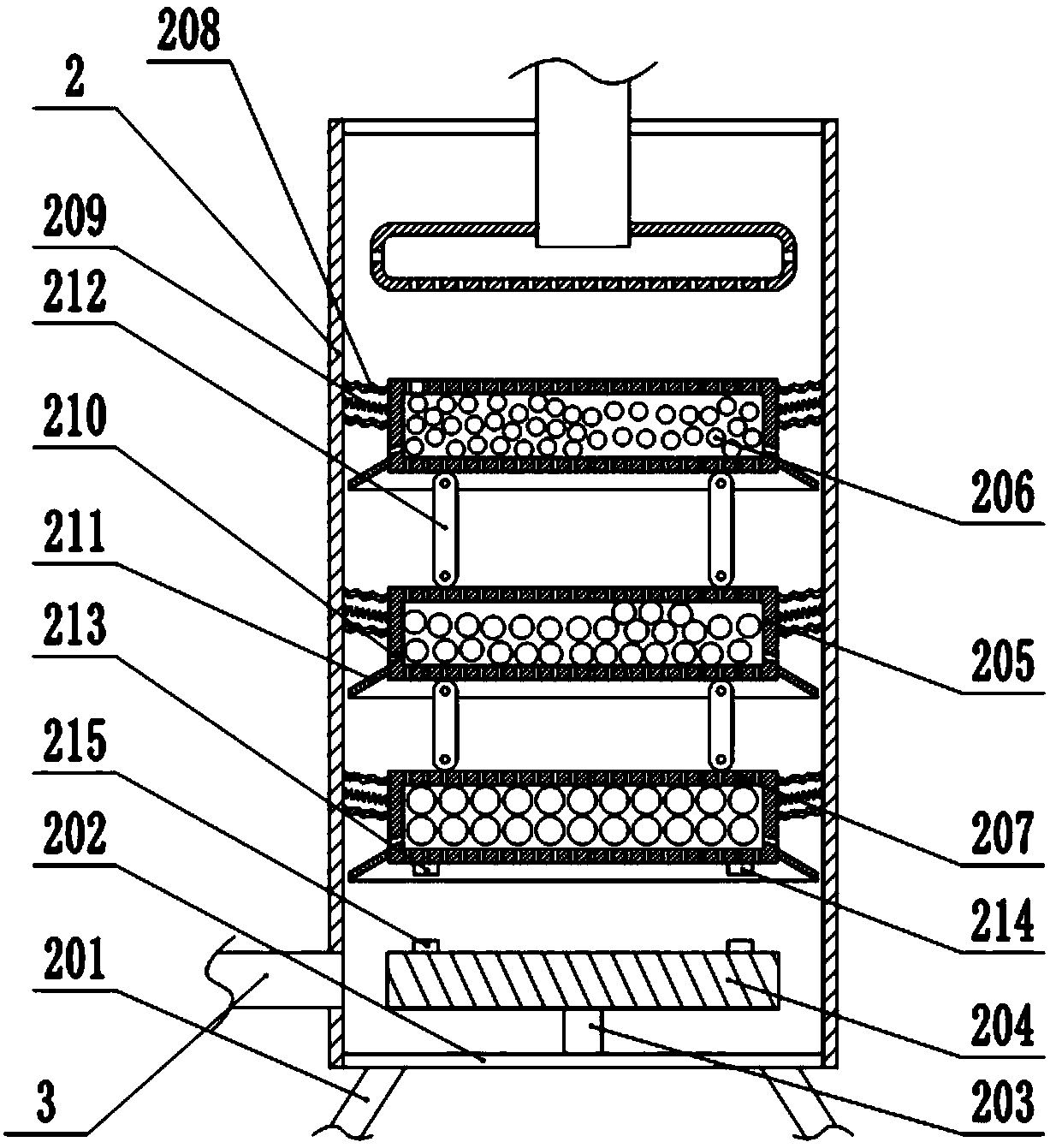

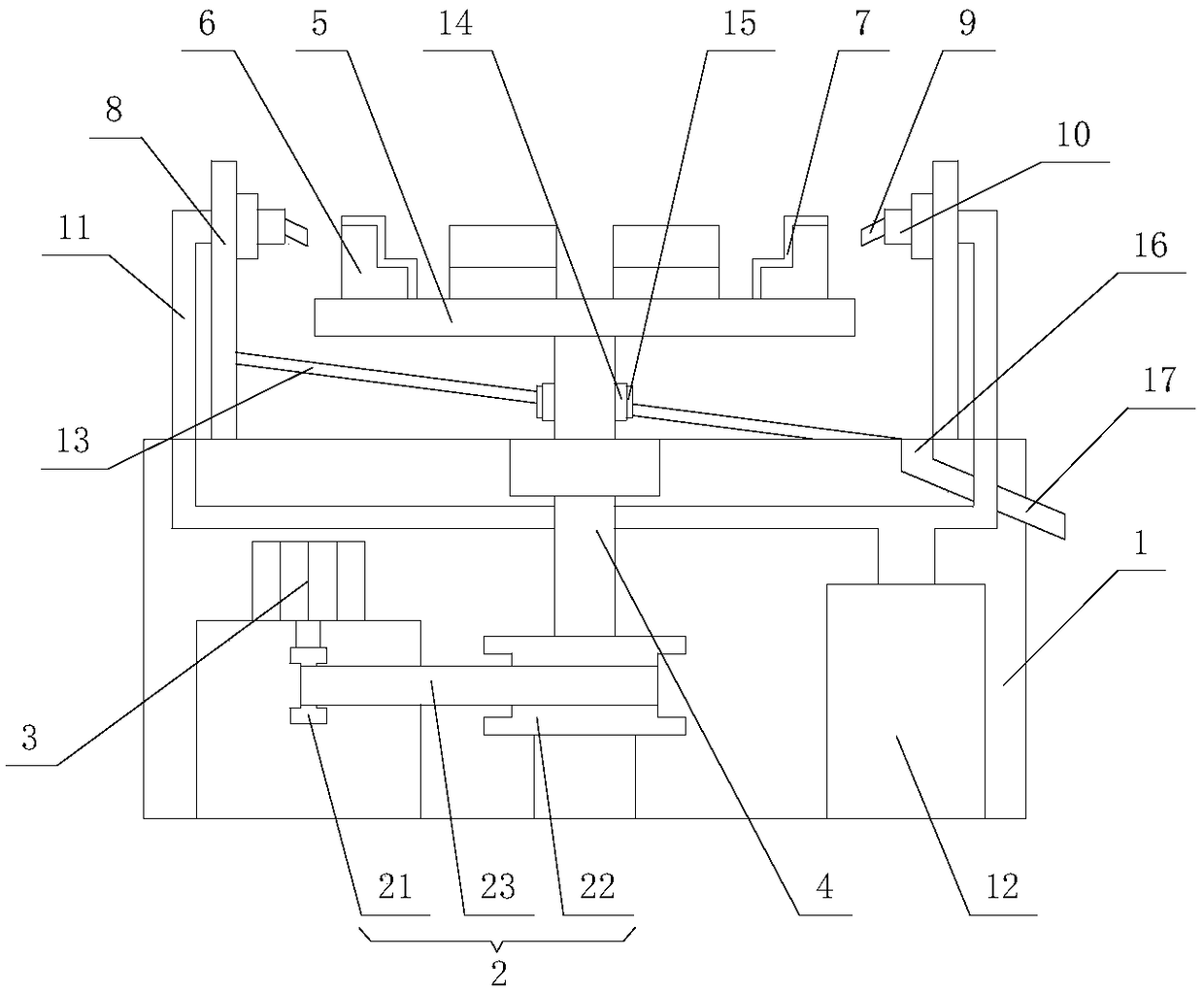

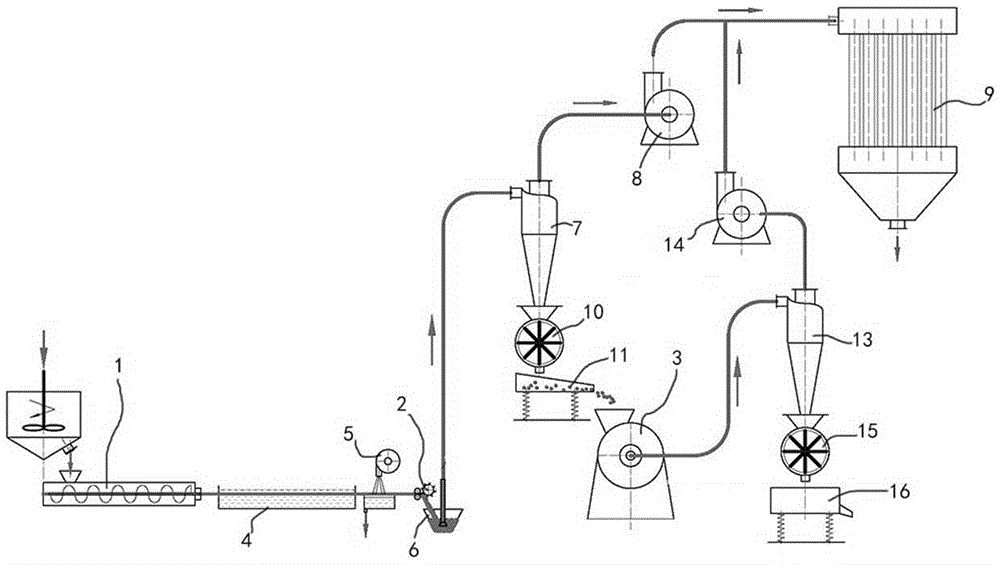

Self-suction balance type rotational-molding raw material processing device

ActiveCN106079148ARealize fully automatic flow operationIncrease productivityCombination devicesBaghouseEngineering

The invention provides a self-suction balance type rotational-molding raw material processing device. The self-suction balance type rotational-molding raw material processing device is characterized in that the self-suction balance type rotational-molding raw material processing device comprises a water cooling tank (4), an airflow drying machine (5), a trough (6), a first cyclone separator (7), a first draught fan (8), a bag-type dust collector (9), a first rotary discharging device (10), a vibrating feeding device (11), a second cyclone separator (13), a second draught fan (14) and a second rotary discharging device (15); an inlet of the first cyclone separator (7) communicates with the interior of the trough (6); the first rotary discharging device (10) is arranged at a bottom outlet of the first cyclone separator (7), and an outlet of the first rotary discharging device (10) is connected with an inlet of the vibrating feeding device (11); an outlet of the vibrating feeding device (11) is connected with an inlet of a plastic mill (3); an outlet of the plastic mill (3) is connected with an inlet of the second cyclone separator (13); and the second rotary discharging device (15) is arranged at a bottom outlet of the second cyclone separator (13).

Owner:安徽爱迪滚塑科技股份有限公司

Air circulation sterilizing panel lamp

PendingCN107300139AShorten the timeImprove the bactericidal effectLighting elementsDeodrantsEngineeringLamp shell

The invention discloses an air circulation sterilizing panel lamp which comprises a lamp shell and a lamp arranged in the lamp shell. A fan is arranged in the lamp shell, an air inlet and an air outlet are formed in the lamp shell, and a fence and a filter sterilizing structure are arranged at the air inlet. The air circulation sterilizing panel lamp with the structure has the advantage of good sterilizing effect.

Owner:湖南中科泰通热能科技发展有限公司

Rabbit-breeding-information showing issuing system

The invention relates to a system for displaying and distributing rabbit breeding information, which includes a dust suction fan. The left and right sides of the dust suction fan are respectively connected with a first dust suction pipe and a second dust suction pipe, and the lower part of the first dust suction pipe is provided with a left dust suction chamber. , the left and right sides of the left dust suction chamber are respectively equipped with a first dust inlet pipe and a second dust inlet pipe; The fourth dust inlet pipe; the first sample display chamber is installed under the dust suction fan, the first sample display chamber is provided with an intermediate isolation plate, and the intermediate isolation plate is provided with a first breeding cage. The inventive system can display rabbit breeding information in multiple ways, and it is convenient to set up multiple areas to display the effect of rabbit breeding, and has a dust removal effect to avoid affecting the display effect, and is convenient to use.

Owner:华蓥市东云生态农业有限公司

Leather spraying dust-removing apparatus

InactiveCN106237787ARemove completelyAvoid pollutionCombination devicesSkins/hides/leather/fur manufacturing apparatusFiltrationEngineering

The present invention discloses a leather spraying dust-removing apparatus, and relates to the technical field of leather processing. The leather spraying dust-removing apparatus comprises a base, wherein the top portion of the base is sequentially provided with a spraying box and a dust removing box from left to right, one side of the base is provided with a controller, a supporting plate and an object placement net plate are sequentially connected inside the spraying box from top to bottom, the top portion of the supporting plate is sequentially provided with a pad block and a fan from left to right, the top portion of the pad block is provided with a high pressure pump, and the input end of the high pressure pump is communicated to a material feeding pipe. According to the present invention, with the use of the first filtration net plate, the electric adsorption plate and the second filtration net plate, and the iron core and the coil arranged in the electric adsorption plate, the apparatus has the dust removing effect, the waste gas produced by the apparatus can be subjected to the dust removing treatment, the dust can be completely removed, and the pollution of the dust contained in the waste gas on air can be avoided.

Owner:WUXI XINDA LIGHT IND MACHINERY

Steel scrap crusher dust removal and impurity removal device based on waterpower and wind power

The invention provides a steel scrap crusher dust removal and impurity removal device based on waterpower and wind power. The device comprises a heavy feeding and conveying crawler belt, and an arc-shaped conveying structure section is arranged at the input end of the heavy feeding and conveying crawler belt. The arc-shaped conveying structure section is soaked in a pool cooperating with the arc-shaped conveying structure section and sinks below the water surface of the pool. An air supply device for supplying air to the water surface capable of allowing floats to float is arranged in front ofthe pool. Multiple spray heads capable of washing the floats on the water surface capable of allowing the floats to float to the rear portion of the pool is arranged on the front pool wall of the pool. The spray heads are connected to a spray head water pump, and the spray head water pump is connected to a water supply system. Front blocking floating balls and rear floating balls are arranged onthe front side and the rear side of the arc-shaped conveying structure section correspondingly. A gap for conveying out the floats between the rear blocking floating balls is formed in the rear pool wall of the pool. The gap is connected to a float collecting pool through a middle channel. The device can achieve the functions of removing dust and removing floatable plastic impurities.

Owner:SHANGHAI CHANAN RENEWABLE RESOURCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com