Process for removing sulfur dioxide for smoke using papermaking white mud

A paper-making white mud and sulfur dioxide technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of wasting calcium carbonate resources, high recovery costs, etc., and achieve low cost, high desulfurization efficiency, and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

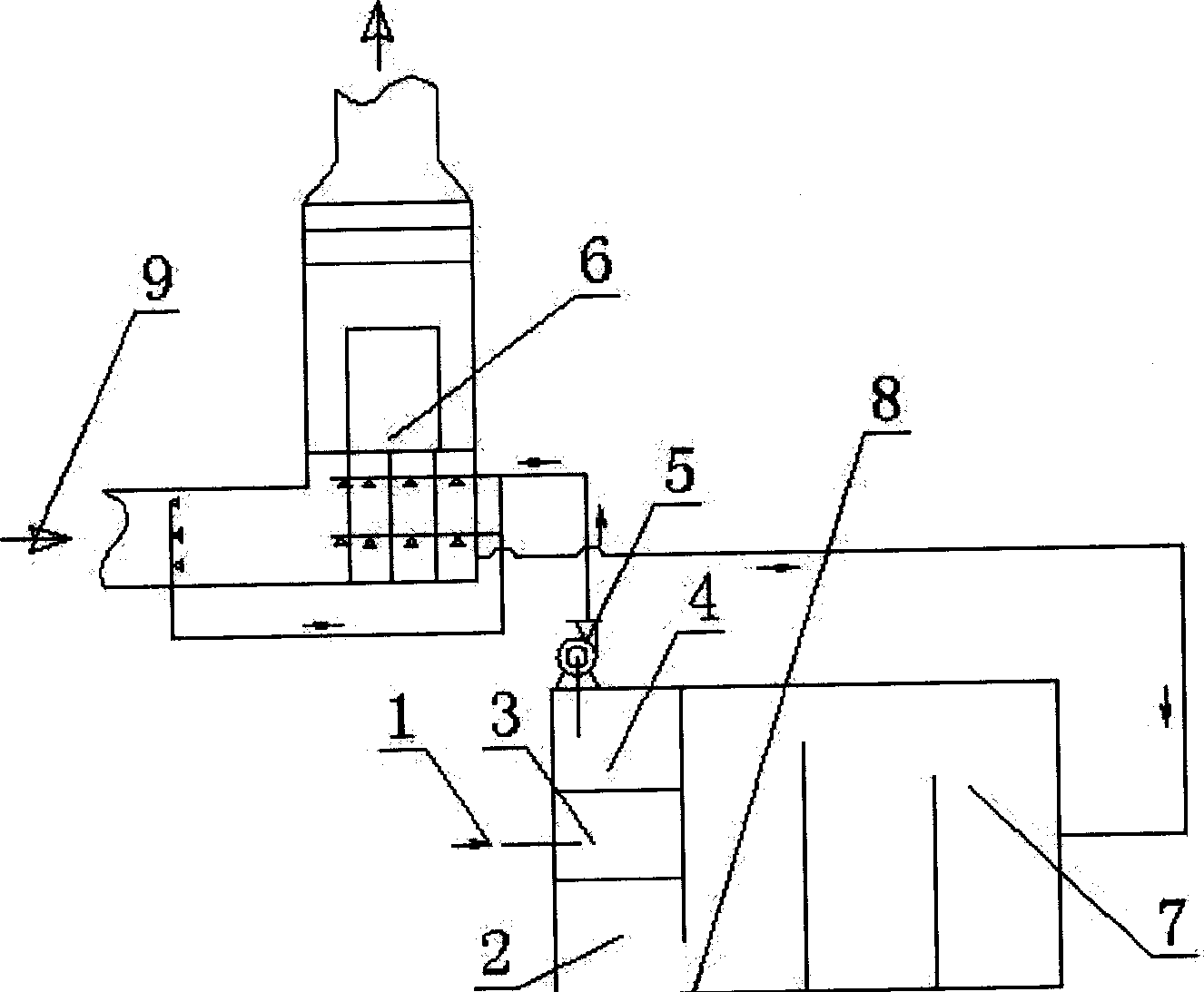

[0019] This embodiment is realized in the following way: the white mud 1 and the circulating water 2 from the clarification tank 8 are added to the slurry mixing tank 3, the stirred slurry enters the slurry tank 4, and is pumped into the desulfurization tower 6 by the booster pump 5 Contacting with the flue gas, the reacted solution flows out from the bottom of the desulfurization tower 6 and enters the sedimentation tank 7, and the circulating water after the precipitation is removed enters the clarification tank 8 to participate in recycling. Wherein, the concentration of the white mud slurry in the slurry mixing tank 3 is 0.5%-2%.

[0020] The equipment used in this embodiment is a sedimentation tank 7, a clarification tank 8, a slurry mixing tank 3, a slurry tank 4, a booster pump 5 and a desulfurization tower 6, and the connection method is: from the entrance 9 of the desulfurization tower 6, to the sedimentation tank 7 , the clarifier 8, the pulp mixing tank 3 with the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com