Carboxylic acid ligand modified hydrothermal carbon material and method for removing heavy metal ions in wastewater

A technology of heavy metal ions and hydrothermal carbon, which is applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problem of low efficiency of heavy metal ions, achieve improved removal efficiency, low price, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] In the embodiment of the present invention, the preparation method of the hydrothermal charcoal powder that adopts comprises:

[0054] Wash, dry, and pulverize the biomass material, pass through a 200-mesh sieve, and retain the biomass material with a particle size of ≤200 mesh, then put the biomass material and water in the liner of a polytetrafluoroethylene reactor, and stir it magnetically for 2 hours. Then the mixture was transferred to an autoclave and reacted at 200 °C for 6 h. After the reaction, the solid was washed with water and ethanol to remove ash, and dried at 60° C. to obtain hydrothermal carbon powder.

[0055] Among them, in Examples 1-8, the biomass materials for preparing hydrothermal charcoal powder are respectively straw (Example 1), fallen leaves (Example 2), walnut shells (Example 3), rice husks (Example 4), Barley hulls (Example 5), rice bran (Example 6), corncobs (Example 7), straw (Example 8).

[0056] In the examples of the present invention...

Embodiment 1

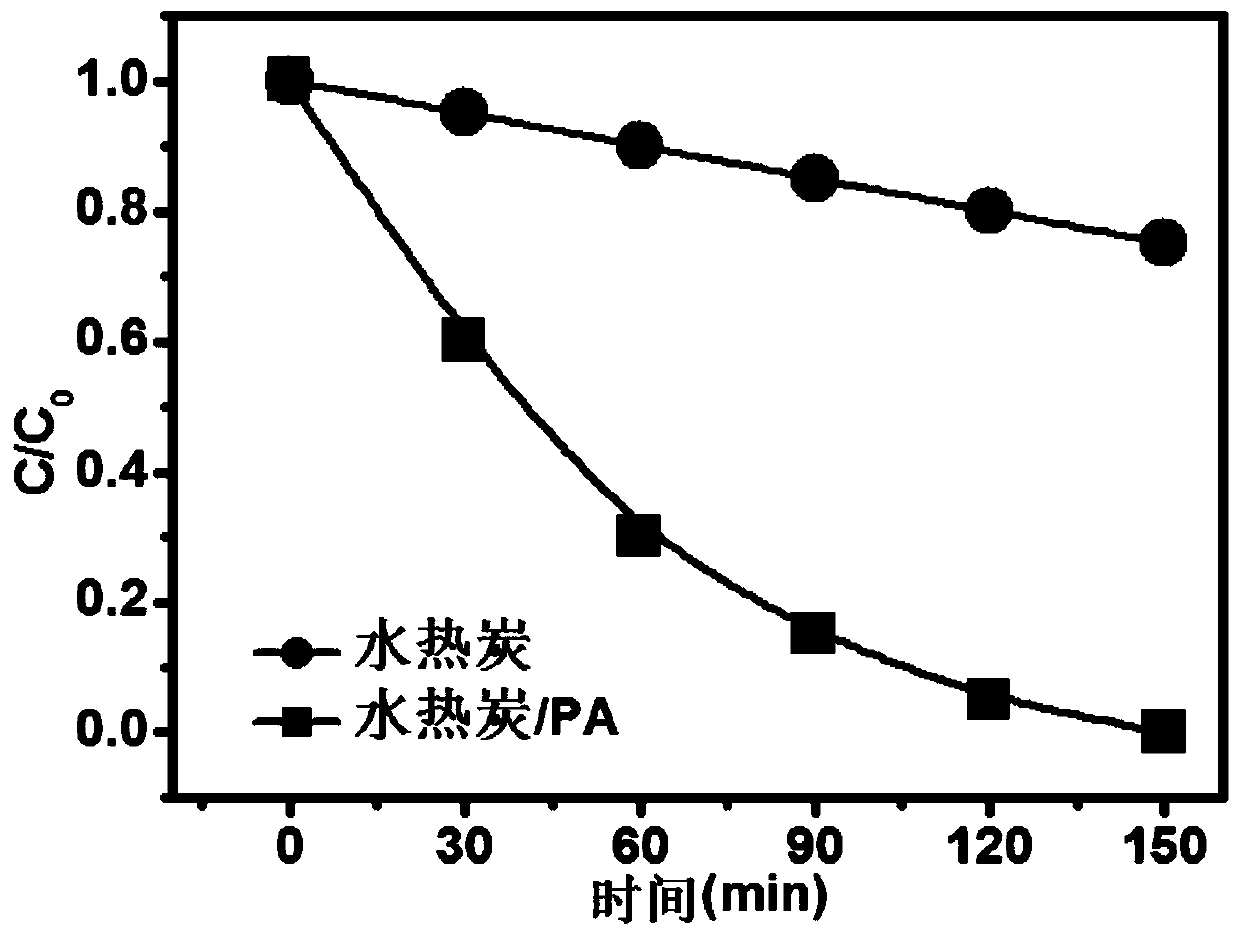

[0060] This example verifies the effect of hydrothermal carbon modified with malonic acid (PA) on removing divalent nickel.

[0061] Preparation of malonate-modified hydrothermal charcoal:

[0062] Weigh malonic acid and hydrothermal charcoal powder according to the mass ratio of malonic acid and hydrothermal charcoal as 1:200, add them into an agate jar with a volume of 100mL, and then use a planetary ball mill to perform ball milling with a rotation speed of 400rpm and a ball milling time of 2h. The solid powder after ball milling was washed with distilled water and ethanol respectively, and then the sample was dried at 60°C to obtain malonate-modified hydrothermal carbon.

[0063] For the remediation of wastewater containing heavy metal divalent nickel, the divalent nickel aqueous solution with a concentration of 20mg / L was used as the simulated wastewater. Take 50mL of simulated wastewater, and add 50mg of malonic acid-modified hydrothermal carbon material into it. Shak...

Embodiment 2

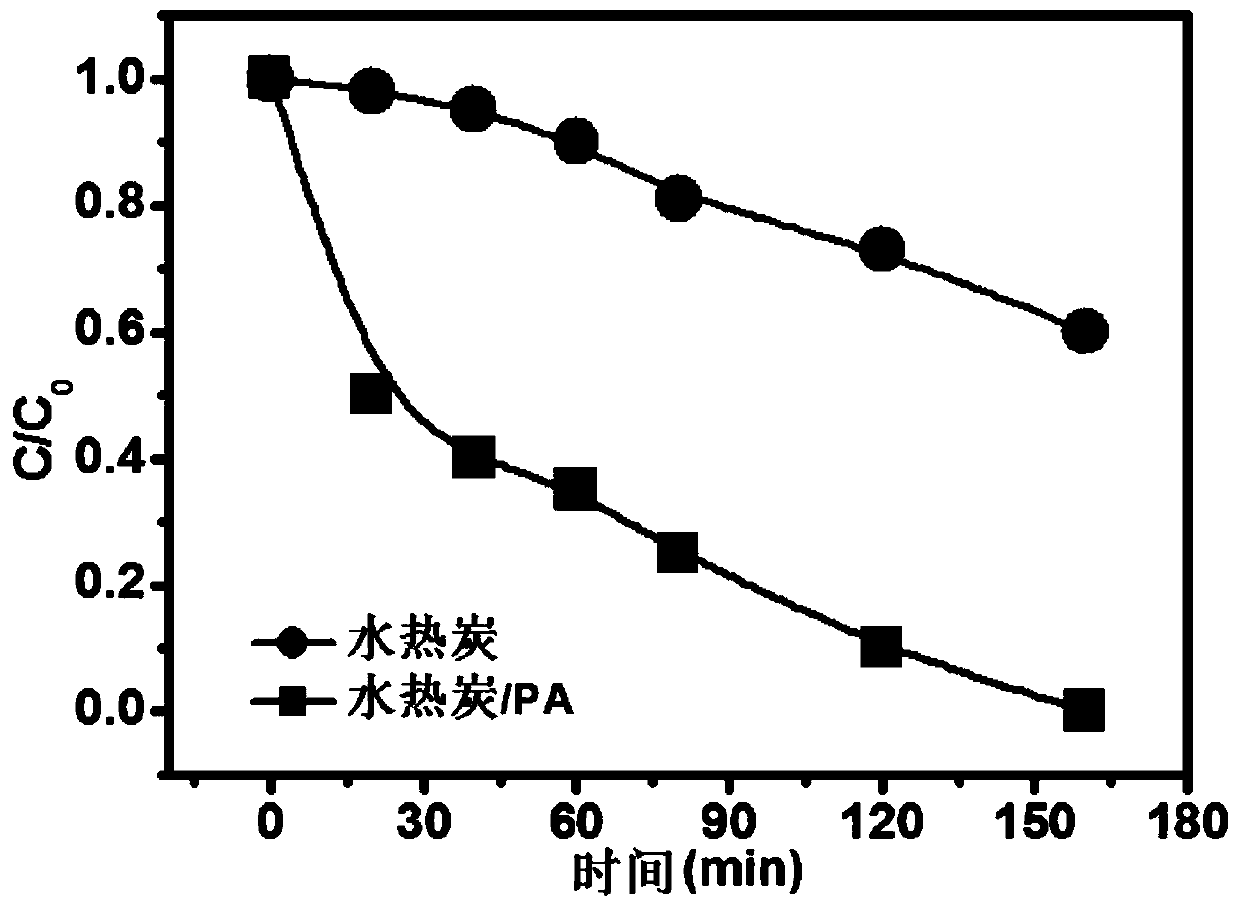

[0065] This example verifies the effect of hydrothermal charcoal modified with malonic acid (PA) on removing divalent copper.

[0066] The preparation method of the hydrothermal charcoal modified by malonic acid is the same as that in Example 1.

[0067] For the remediation of wastewater containing heavy metal divalent copper, the divalent copper aqueous solution with a concentration of 20mg / L was used as the simulated wastewater. Take 50mL of simulated wastewater, and add 50mg of malonic acid-modified hydrothermal carbon material into it. Shake the reaction solution on a shaker to make the hydrothermal charcoal fully contact with the solution. Such as figure 2 As shown, after reacting for 160 minutes, the removal rate of divalent copper in water can reach 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com