Preparation method of atom-level active site composite nanocatalytic fiber used for degrading indoor VOCs

An active site and nano-catalysis technology, which is applied in the field of catalyst technology and VOCs pollution control, to achieve the effect of large specific surface area, high porosity, and improved catalytic degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

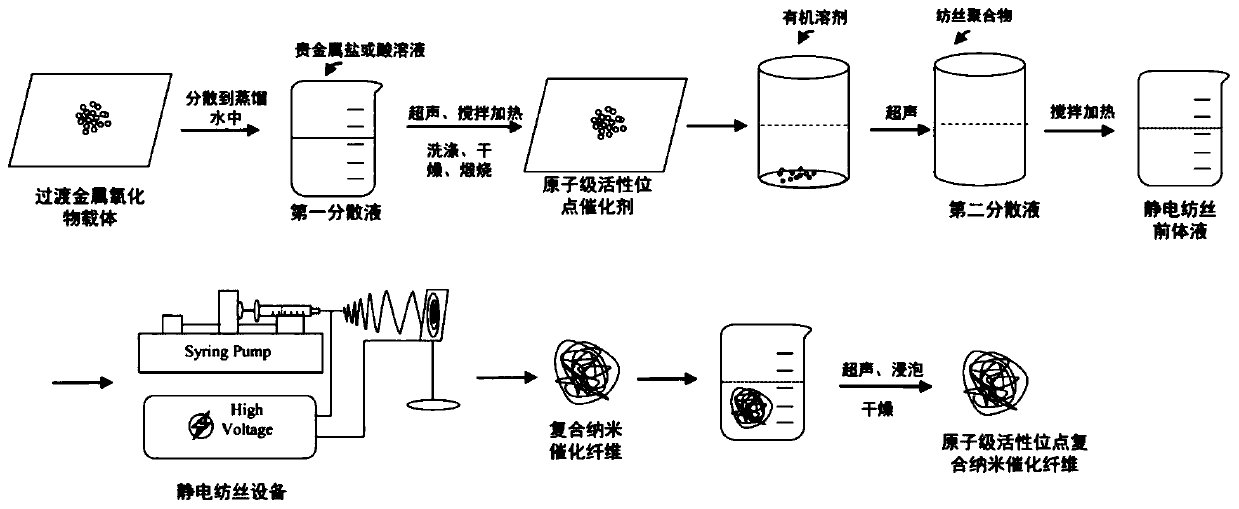

[0040] As shown in the accompanying drawings, a method for preparing an atomic-level active site composite nano-catalytic fiber for degrading indoor VOCs of the present invention comprises the following steps:

[0041] 1) Preparation of noble metal-based atomic-level active site catalysts:

[0042] Disperse the rare earth metal oxide powder used as a catalyst carrier in distilled water, add a salt or acid solution containing the active component of the noble metal, and mix to form the first dispersion; then, ultrasonically adjust the pH with sodium carbonate solution, stir and heat until All the water is evaporated to dryness, and the active atoms of the noble metal in the obtained precipitate are evenly loaded on the rare earth metal oxide carrier; the obtained precipitate is washed with distilled water and absolute ethanol in sequence, dried in an oven, and finally calcined in a horse boiling furnace. Obtain atomic-level active site catalysts;

[0043] 2) Preparation of ele...

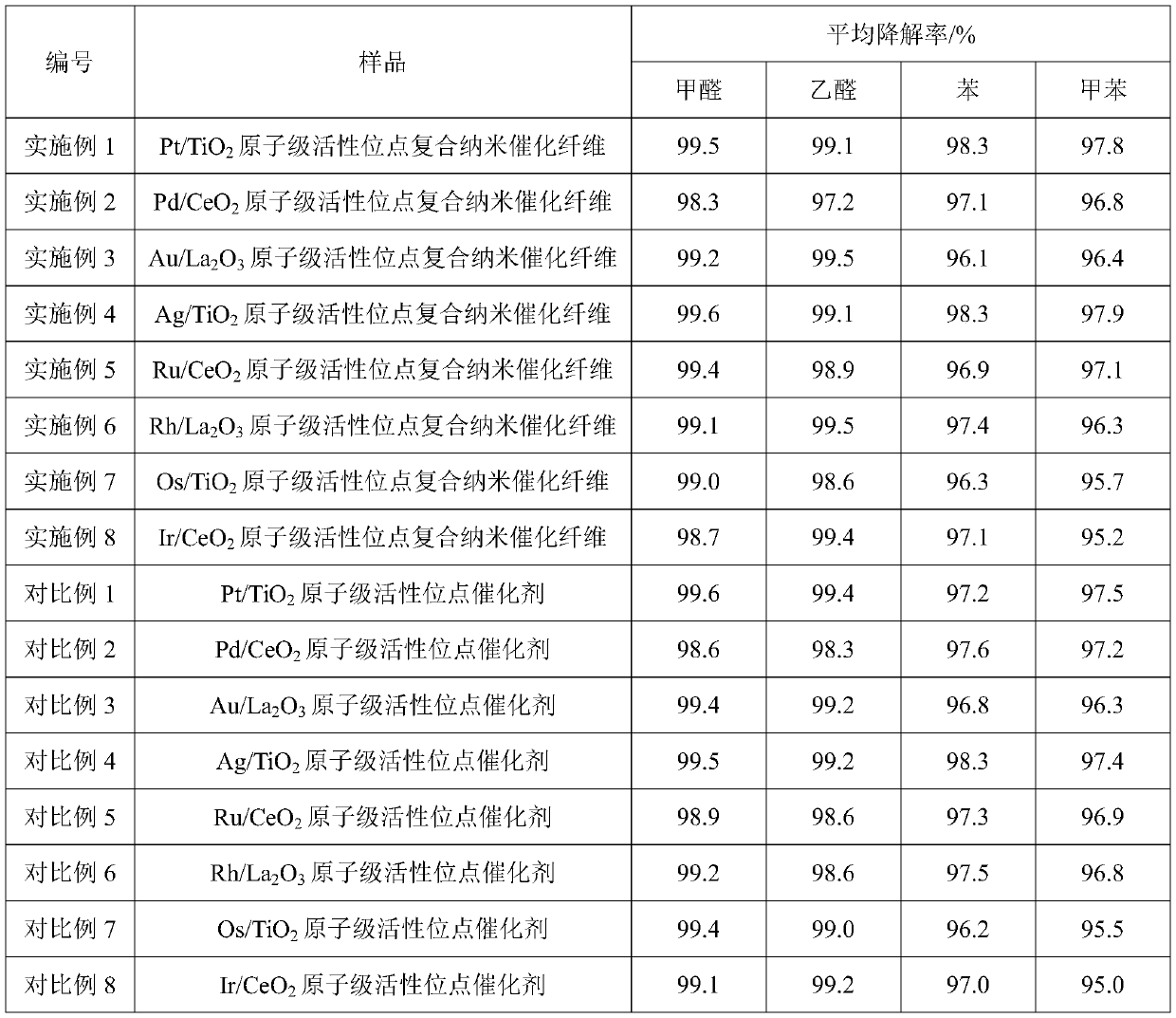

Embodiment 1

[0060] Pt / TiO 2 Preparation of Atomic Scale Active Site Composite Nanocatalytic Fibers

[0061] 1) Preparation of Pt / TiO 2 Atomic level active site catalysts:

[0062] TiO will be used as catalyst support 2 The powder was dispersed in distilled water, adding H 2 PtCl 6 Solution, mixed to form the first dispersion; then, ultrasonic 20min, adjust the pH to 6 with sodium carbonate solution, stir and heat at 50°C for 6h, until all the water is evaporated to dryness, at this time the Pt atoms in the obtained precipitate are evenly loaded on the TiO 2 on the carrier; the obtained precipitate is washed with distilled water and absolute ethanol in sequence, dried in an oven, and finally calcined in a horse boiling furnace to obtain an atomic-level active site catalyst.

[0063] In the step 1), in the first dispersion liquid, TiO 2 The mass concentration is 0.04kg·L -1 , Pt and TiO 2 The mass ratio is 1:200;

[0064] The precipitate in step 1) was washed three times with disti...

Embodiment 2

[0076] Pd / CeO 2 Preparation of Atomic Scale Active Site Composite Nanocatalytic Fibers

[0077] 1) Preparation of Pd / CeO 2 Atomic level active site catalysts:

[0078] CeO to be used as catalyst support 2 The powder was dispersed in distilled water and PdSO was added 4 solution, mixed to form the first dispersion; then, ultrasonicated for 50 min, adjusted to pH 9 with sodium carbonate solution, stirred and heated at 100°C for 2 h, until all the water was evaporated to dryness, at this time the Pd atoms in the obtained precipitate were evenly loaded on the CeO 2 on the carrier; the resulting precipitate is washed with distilled water and absolute ethanol in sequence, dried in an oven, and finally calcined in a horse boiling furnace to obtain an atomic-level active site catalyst.

[0079] In the step 1), in the first dispersion liquid, CeO 2 The mass concentration is 0.4kg·L -1 , Pd and CeO 2 The mass ratio is 1:20;

[0080] The precipitate in step 1) was washed 4 times ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com