A method and device for recovering n-methylpyrrolidone waste gas from lithium battery production by membrane separation

A technology of methylpyrrolidone and membrane separation method, which is applied in the direction of separation method, semipermeable membrane separation, and dispersed particle separation, etc. It can solve the problems that the waste gas recovery method cannot recover NMP solvent well, mix it in, and reduce energy consumption , improve the recovery quality and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

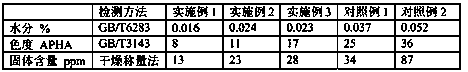

Embodiment 1

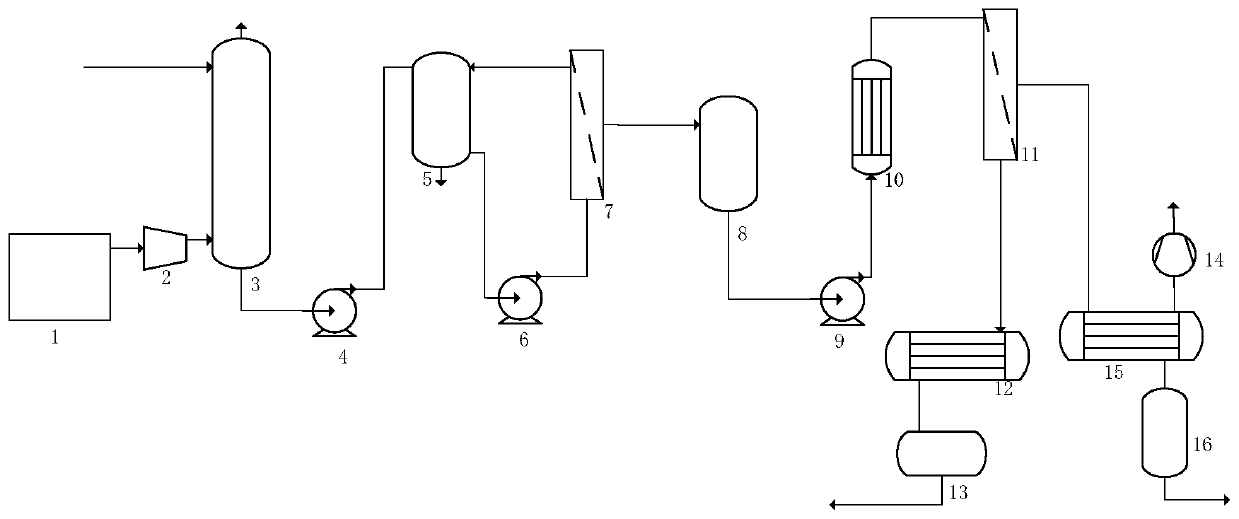

[0039] The NMP waste gas from the lithium battery pole piece drying box 1 is sent to the absorption tower 3 by the blower device 2, and water is used as a solvent to absorb the waste gas. The temperature of the absorption liquid is controlled between 35 and 45°C, and the water is continuously circulated. When the NMP concentration in the absorption liquid at the bottom of the tower reached 80wt%, the NMP waste liquid at the bottom of the absorption tower 3 entered the circulation tank 5 through the infusion pump 4, and entered the porous ceramic membrane 7 through the circulation pump 6. The average pore size is 5nm, the operation mode is cross-flow filtration, the operating pressure is 0.5MPa, and the operating temperature is 40°C. The intercepted liquid is returned to the circulation tank 5, and the filtered NMP-water clear liquid is stored in the clear liquid tank 8, and is fed to the feed liquid pump 9 The NMP-clear water is heated to 90°C and enters the water-permeable NaA...

Embodiment 2

[0041] The NMP waste gas from the lithium battery pole piece drying box 1 is sent to the absorption tower 3 by the blower device 2, and water is used as a solvent to absorb the waste gas. The temperature of the absorption liquid is controlled between 35 and 45°C, and the water is continuously circulated. When the NMP concentration in the absorption liquid at the bottom of the tower reaches 75wt%, the NMP waste liquid at the bottom of the absorption tower enters the circulation tank 5 through the infusion pump 4, and enters the porous ceramic membrane 7 through the circulation pump 6. The pore size is 10nm, the operation mode is cross-flow filtration, the operating pressure is 0.4MPa, and the operating temperature is 35°C. The intercepted liquid is returned to the circulation tank 5, and the filtered NMP-water clear liquid is stored in the clear liquid tank 8, and is fed into the feed liquid pump 9. Under the action, it enters the heater 10, and the NMP-clear water is heated to ...

Embodiment 3

[0043] The NMP waste gas from the lithium battery pole piece drying box 1 is sent to the absorption tower 3 by the blower device 2, and water is used as a solvent to absorb the waste gas. The temperature of the absorption liquid is controlled between 35 and 45°C, and the water is continuously circulated. When the NMP concentration in the absorption liquid at the bottom of the tower reaches 80wt%, the NMP waste liquid at the bottom of the absorption tower enters the circulation tank 5 through the infusion pump 4, and enters the porous ceramic membrane 7 through the circulation pump 6, and the average of the porous ceramic membrane 7 The pore size is 20nm, the operation mode is cross-flow filtration, the operating pressure is 0.2MPa, and the operating temperature is 30°C. The intercepted liquid is returned to the circulation tank 5, and the filtered NMP-water clear liquid is stored in the clear liquid tank 8, and in the feed liquid pump 9 Under the action, it enters the heater 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com