Method for preparing graphene through electrochemical anode stripping

A graphene and electrochemical technology, applied in the field of electrochemical anode exfoliation to prepare graphene, can solve the problems such as failure to achieve uniform dispersion of graphene, large dispersion concentration of graphene, and the quality of graphene needs to be improved, and achieve good water solubility and Stability, low price, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

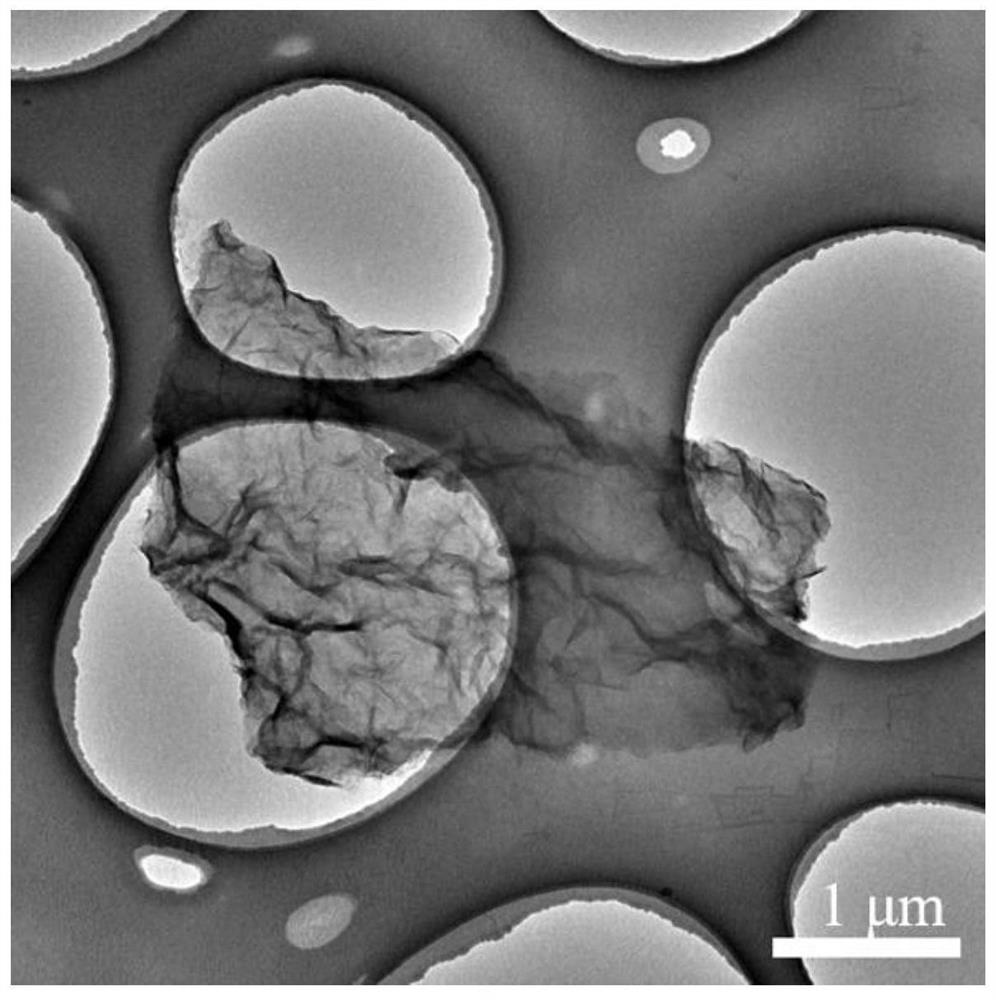

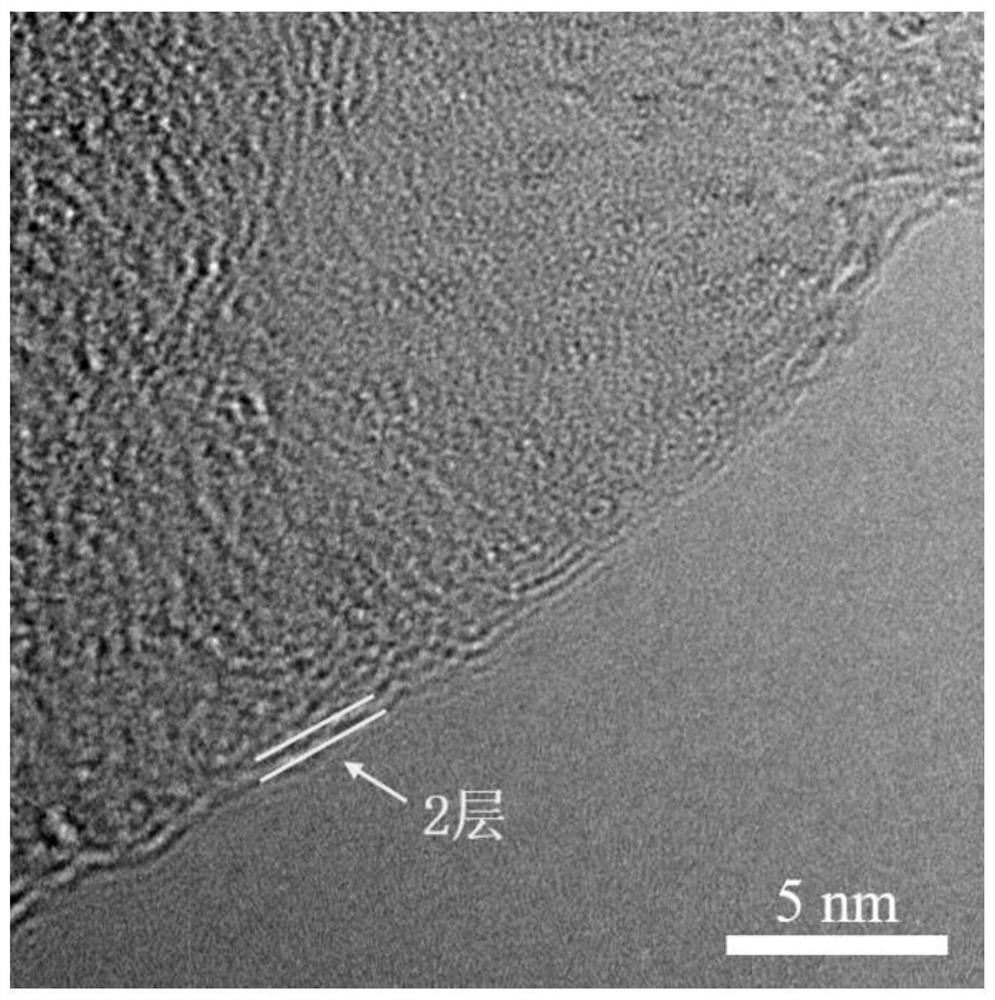

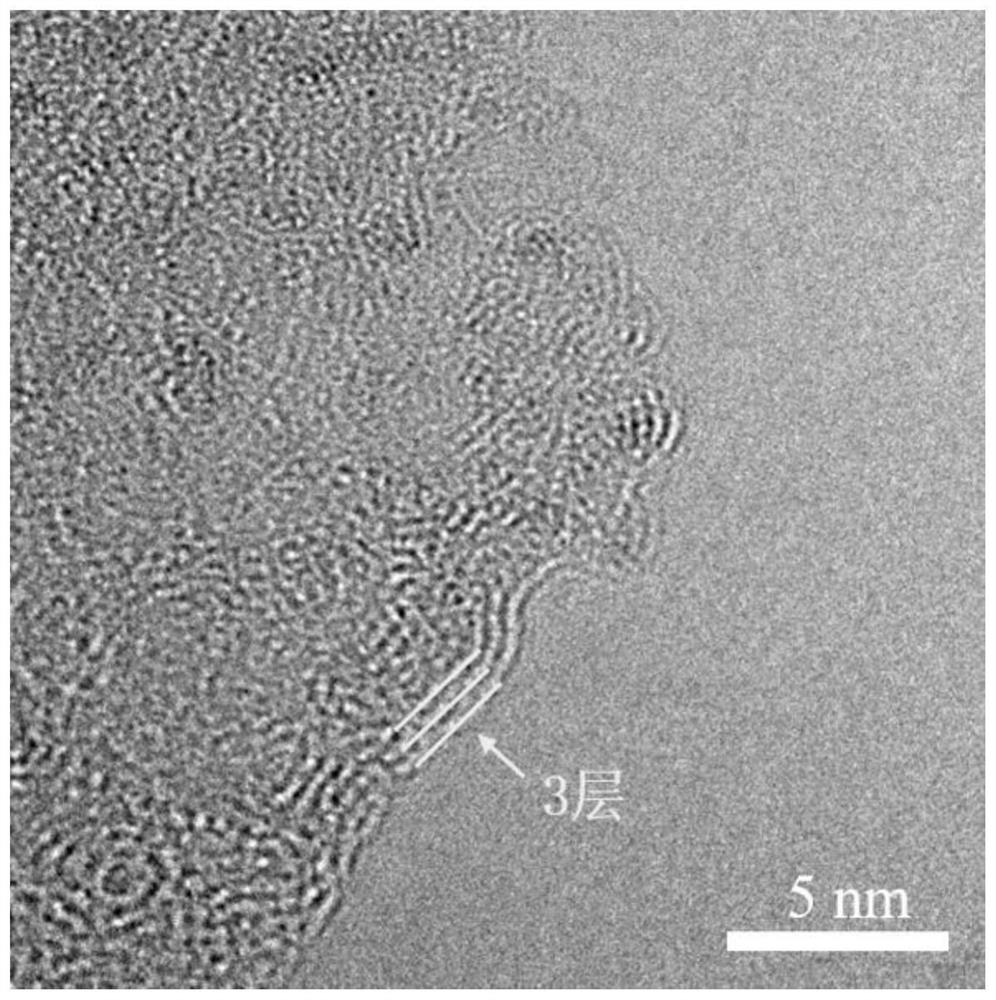

Image

Examples

Embodiment 1

[0046] This embodiment adopts the following steps to prepare graphene by electrochemical exfoliation in turn:

[0047] (1) Weigh 2.4195g of sodium molybdate dihydrate and dissolve it in 100mL of deionized water with stirring to obtain a 0.1M sodium molybdate electrolyte.

[0048] (2) The thickness of the graphite paper used is 0.05cm. Cut out two pieces with a length of 5cm and a width of 2cm. Use anhydrous alcohol to wipe and clean the surface of the graphite paper, and then use it as the anode and cathode respectively, and connect them to the two poles of the DC power supply. Then these two graphite paper electrodes are put into the electrolytic solution of step (1) in parallel, make the distance between two graphite papers be 4cm, and the length that two graphite paper parts are immersed in the electrolytic solution is 4cm, and the width is equal to 4cm. It is 2cm.

[0049] (3) Turn on the DC power supply, the voltage used is +10V, start the electrochemical anode stripping...

Embodiment 2

[0057] This embodiment adopts the following steps to prepare graphene by electrochemical exfoliation in turn:

[0058] (1) Weigh 2.4195g of sodium molybdate dihydrate and dissolve it in 100mL of deionized water with stirring to obtain a 0.1M sodium molybdate electrolyte.

[0059] (2) The thickness of the graphite paper used is 0.05cm. Cut out two pieces with a length of 5cm and a width of 2cm. Use anhydrous alcohol to wipe and clean the surface of the graphite paper, and then use it as the anode and cathode respectively, and connect them to the two poles of the DC power supply. Then these two graphite paper electrodes are put into the electrolytic solution of step (1) in parallel, make the distance between two graphite papers be 4cm, and the length that two graphite paper parts are immersed in the electrolytic solution is 4cm, and the width is equal to 4cm. It is 2cm.

[0060] (3) Turn on the DC power supply, the voltage used is +9V, start the electrochemical anode peeling an...

Embodiment 3

[0063] This embodiment adopts the following steps to prepare graphene by electrochemical exfoliation in turn:

[0064] (1) Weigh 1.2098g of sodium molybdate dihydrate and dissolve it in 100mL of deionized water with stirring to obtain a 0.05M sodium molybdate electrolyte.

[0065] (2) The thickness of the graphite paper used is 0.05cm. Cut out two pieces with a length of 5cm and a width of 2cm. Use anhydrous alcohol to wipe and clean the surface of the graphite paper, and then use it as the anode and cathode respectively, and connect them to the two poles of the DC power supply. Then these two graphite paper electrodes are put into the electrolytic solution of step (1) in parallel, make the distance between two graphite papers be 4cm, and the length that two graphite paper parts are immersed in the electrolytic solution is 4cm, and the width is equal to 4cm. It is 2cm.

[0066] (3) Turn on the DC power supply, the voltage used is +10V, start the electrochemical anode strippin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com