Composite bed reactor and method for combined production of calcium carbide, gas and tar

A reactor and compound bed technology, applied in the field of compound bed reactors, can solve the problems of small particle raw material gas flow interference loss, high pollution, high energy consumption, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

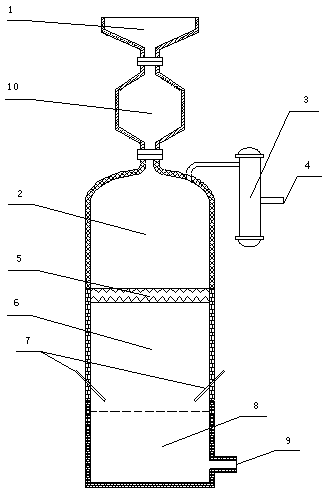

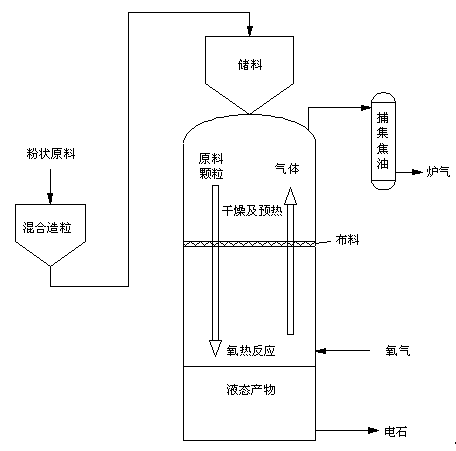

[0032] A composite bed reactor for the co-production of calcium carbide, gas and tar, such as figure 1 shown. The reactor includes a hopper 1, a moving bed preheating chamber 2, a tar trap 3, a gas discharge port 4, a rotary distributor 5, an oxygen hot chamber 6, an oxygen injection burner 7, a product molten pool 8, and a product discharge port. 9 and the gate silo 10, etc., there is one hopper 1, which is located on the top of the central axis of the reactor, the bottom of the hopper 1 is communicated with the gate silo 10, the gate silo 10 is communicated with the moving bed preheating chamber 2, and the moving bed preheating chamber 2 is connected. A tar catcher 3 is provided on the top side of the hot chamber 2, a gas discharge port 4 is provided on the tar catcher 3, a rotary distributor 5 is provided at the bottom of the moving bed preheating chamber 2, and the moving bed preheating chamber 2 passes through the rotary distributor 5 is communicated with the oxygen hot ...

Embodiment 2

[0039] A method for co-producing calcium carbide, coal gas and tar using the reactor described in Example 1, comprising the following steps:

[0040] A. Raw material molding: pulverized coal and carbide slag (containing 90% calcium hydroxide) are used as raw materials, in which the fixed carbon content of the pulverized coal is 70%, the volatile content is 22%, and the ash content is 8%; the C content is 76% %. Grind and sieve the raw materials, select powders below 120 mesh, mix them according to the ratio of C / Ca molar ratio of 16:1, and use a tablet machine to form columnar particles with a diameter of 30mm and a height of 40-60mm after stirring evenly.

[0041] b. Raw material transportation and preheating: the raw material particles obtained in the above step A are sent to the hopper 1, and then sent to the moving bed preheating chamber 2 through the gate silo 10, and the feeding speed and the motor speed of the rotary distributor 5 are adjusted to control the The spee...

Embodiment 3

[0045] A method for co-producing calcium carbide, coal gas and tar using the reactor described in Example 1, comprising the following steps:

[0046] A. Raw material granulation: using coke and calcium oxide as raw materials, the C content in the coke is about 90%, the ash content is about 8%, and the purity of the calcium oxide is about 90%. Grind and sieve the raw materials, select powders below 60 mesh, mix them according to the ratio of C / Ca molar ratio of 9:1, spray and add water after stirring evenly, and finally use a roller extrusion molding machine to form small balls with a particle size of 30mm.

[0047] b. Raw material transportation and preheating: the raw material particles obtained in the above step A are sent to the hopper 1, and then sent to the moving bed preheating chamber 2 through the gate silo 10, and the feeding speed and the motor speed of the rotary distributor 5 are adjusted to control the The speed at which the granular raw material moves down in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com