Process and equipment forsolar energy gasification of plant stalk and comprehensive utilization of waste slag

The technology of plant straw and solar energy is applied in the field of technology and equipment of straw solar energy gasification and comprehensive utilization of straw waste residue after gasification. and social benefits, eliminate air pollution, and produce high calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

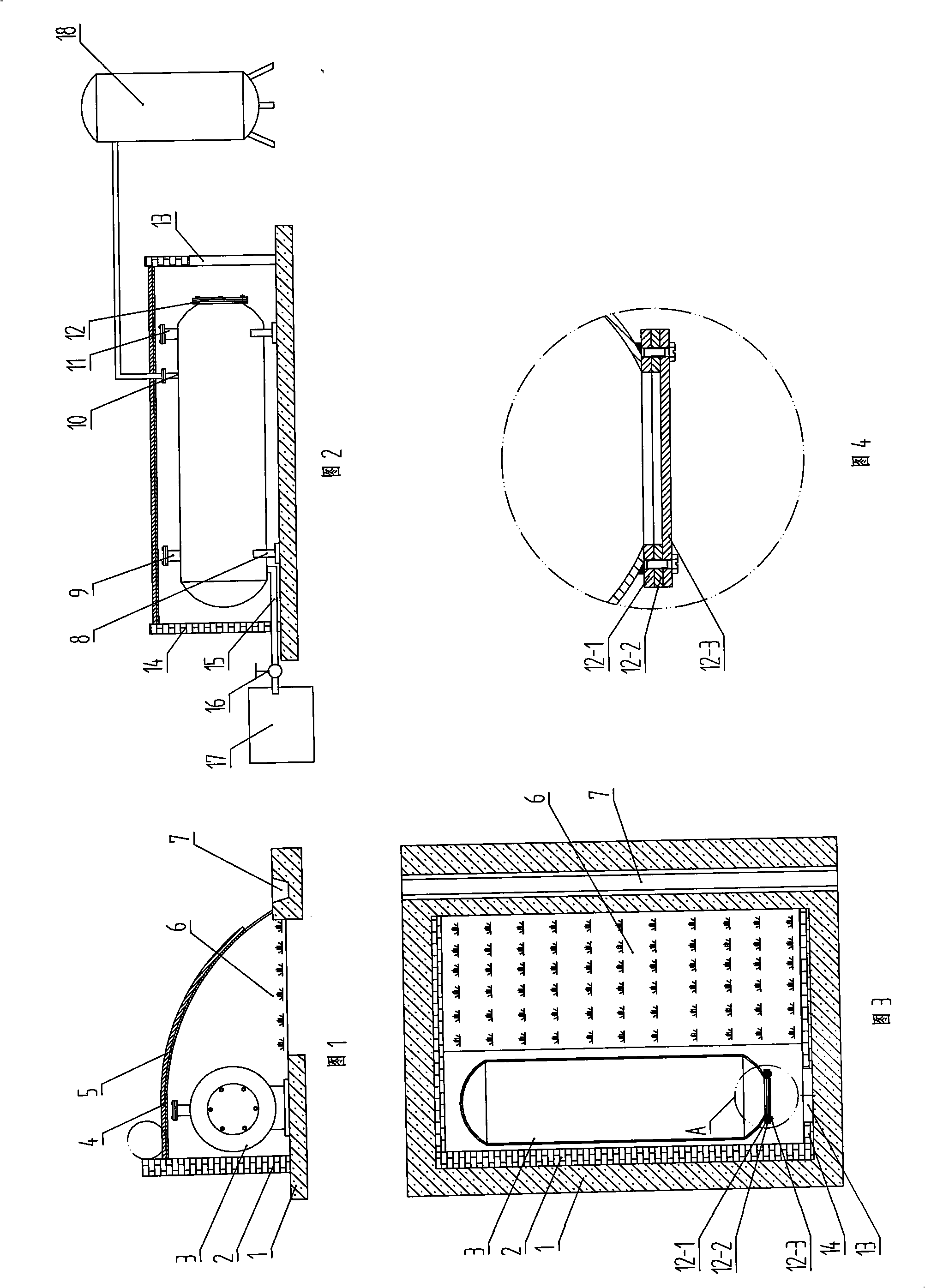

[0021] A plant straw solar energy gasification and waste residue comprehensive utilization process, the process flow is: process step 1, pre-fermentation, process step 2, gasification, process step 3, slag removal, process step 4, waste residue planting edible fungus, process step 5. Mushroom dregs are fertilized into the field;

[0022] The pre-fermentation step is as follows: mix plant straw, water, and ammonium bicarbonate in a weight ratio of 1:2:0.01, stack them on flat ground, seal them with plastic cloth, and carry out pre-fermentation for 5-7 days.

[0023] The gasification step is as follows: mix the pre-fermented stalks, ammonia bicarbonate, and human and animal excrement in a weight ratio of 1:0.02:4, put them into the gasification tank 3 from the manhole 12, and then use the feed The mouth 11 is filled with water, and the straw and feces are gasified in the tank for 100-120 days; the biogas generated in the gasification process is sent to the gas storage tank 18 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com