Process and equipment for preparing biogas by continuous mode dry fermentation

A dry fermentation and biogas technology, applied in the fields of energy utilization and environmental protection, can solve the problems of multiple storage shifts, large floor space, and high requirements for the manufacture of airtight doors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

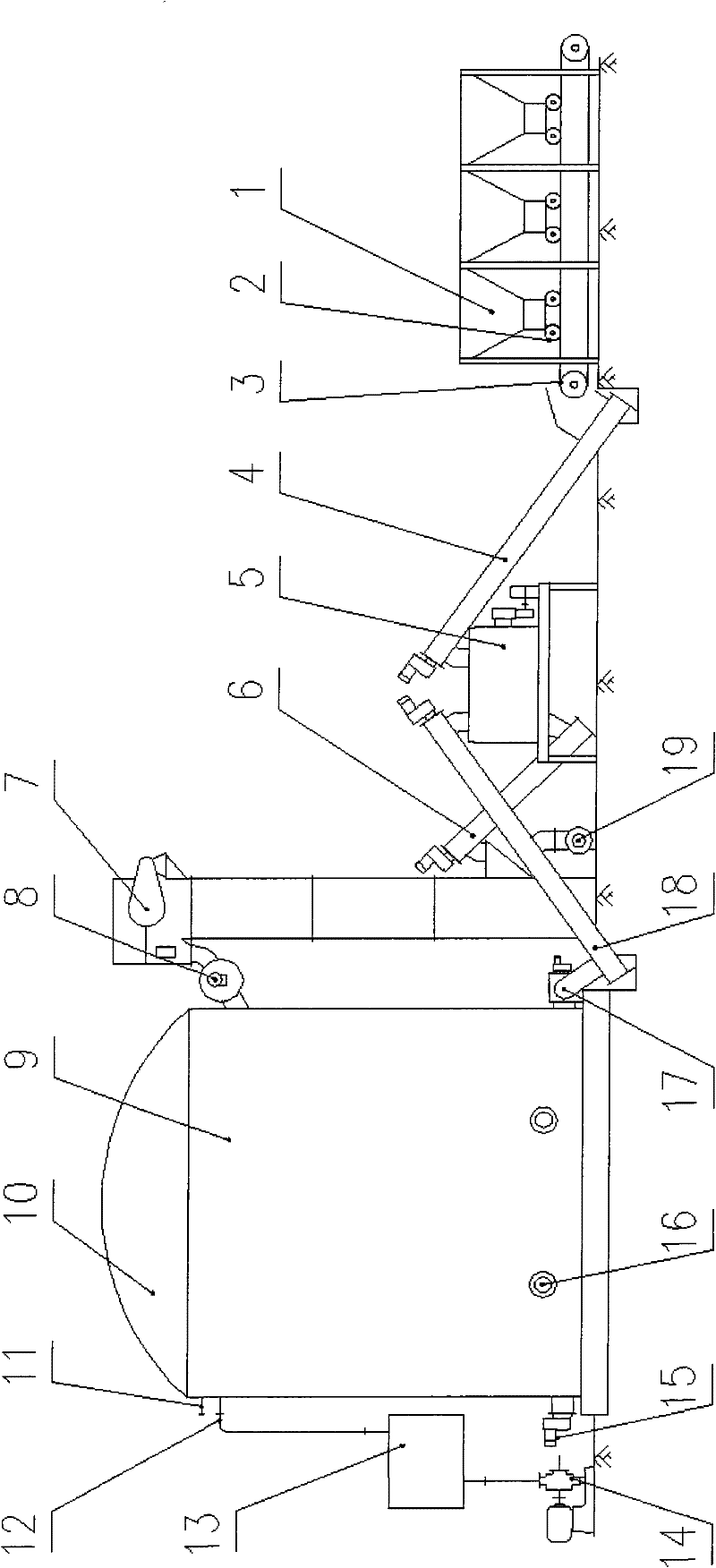

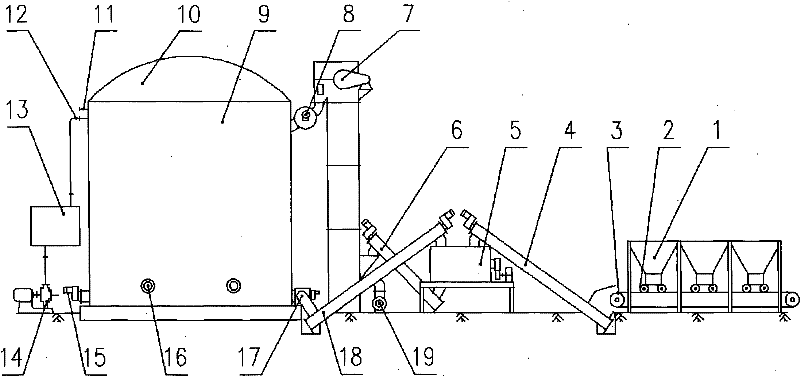

[0007] According to the types of fermentation raw materials, a corresponding number of storage bins are equipped, and various fermentation raw materials are loaded into the storage bin 1 by the loader, and the speed of the corresponding metering belt 2 is adjusted according to the mixing ratio of the raw materials, and various raw materials fall to the collection belt. 3. The raw materials are conveyed to the mixer 5 through the feeding screw 4, and the raw materials mixed uniformly by the mixer fall to the feeding screw 6, and then go to the hoist 7 to lift to the feeding machine 8 located on the upper part of the fermentation tank 9, and the feeding machine 8 will The raw materials are pressed into the fermentation tank 9 for anaerobic fermentation; the generated biogas is output from the biogas outlet pipe 11, and the leachate of the raw materials in the tank is pumped out by the spray pump 14, heated to a suitable temperature by the heat exchanger 13, and then sent to the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com