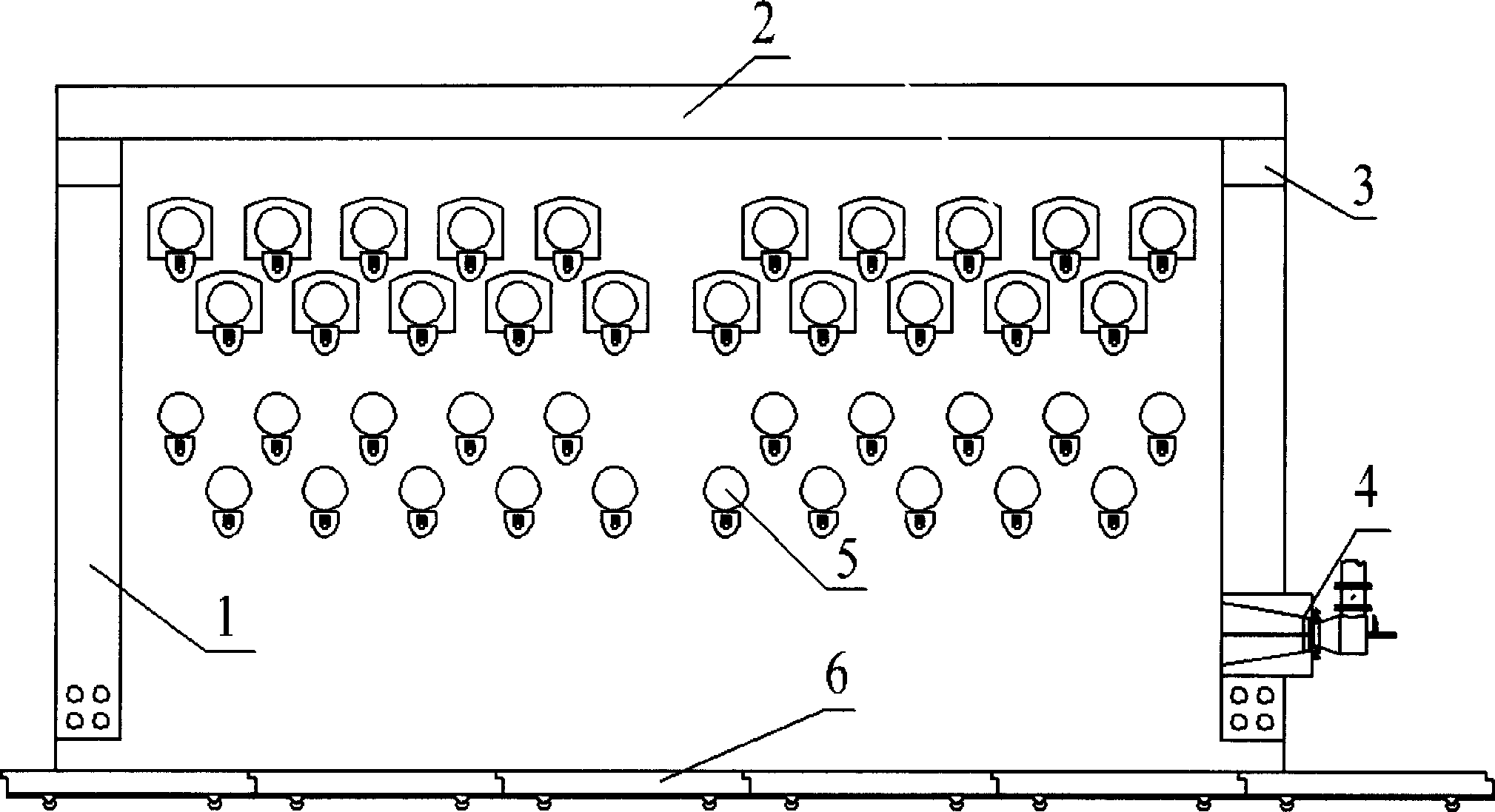

Efficient directly burning sealed metal magnesium reducing smelter

A reduction furnace, a closed-type technology, applied in the field of metal magnesium smelting devices, can solve the problems of low heat utilization rate, poor heat transfer effect, and uncompact arrangement of reduction tanks, and achieves high combustion efficiency, convenient feeding and discharging, and shortening reduction. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] The magnesium smelting reduction furnace was put into industrial application in a magnesium company in Henan. The application shows that the furnace temperature of the reduction furnace is stable, easy to adjust, and the fuel combustion efficiency reaches 98%. Compared with the traditional magnesium smelting reduction furnace, the heat utilization rate is increased by more than 120%, and the product output and quality are significantly improved and improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com