Patents

Literature

51results about How to "Uniform thermal field" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

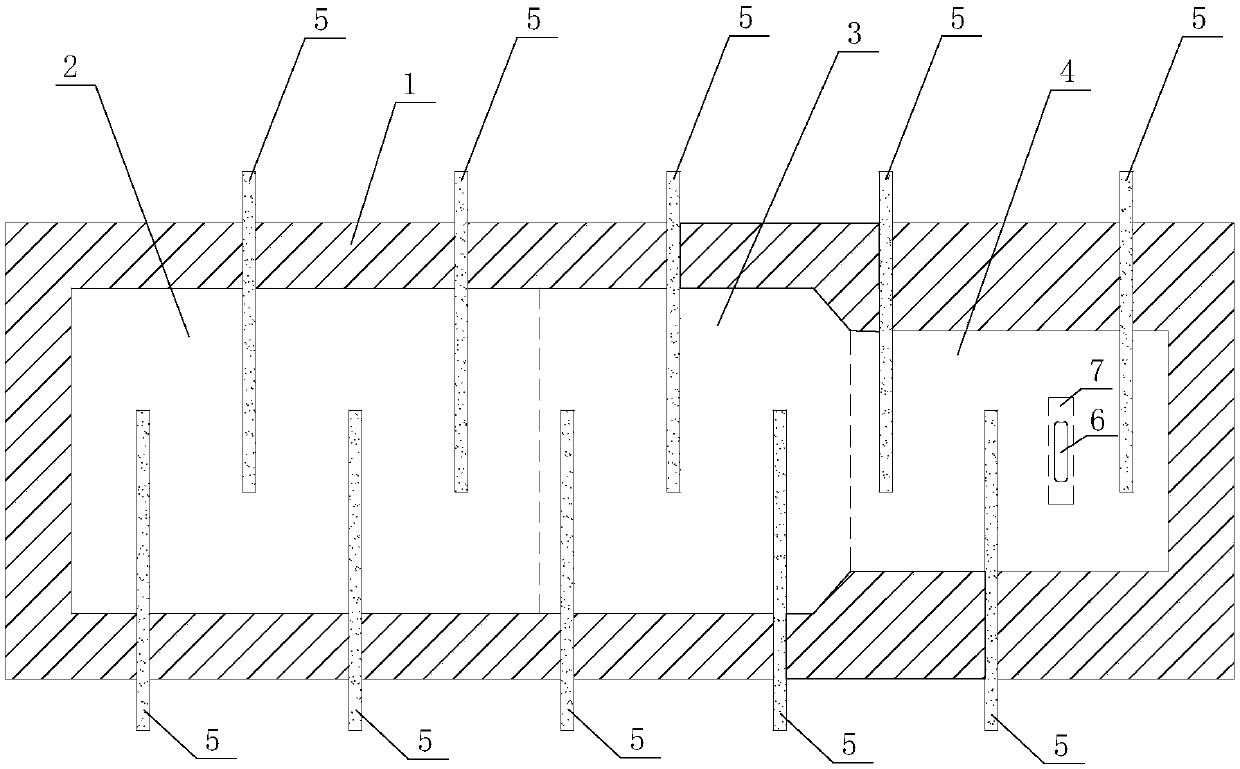

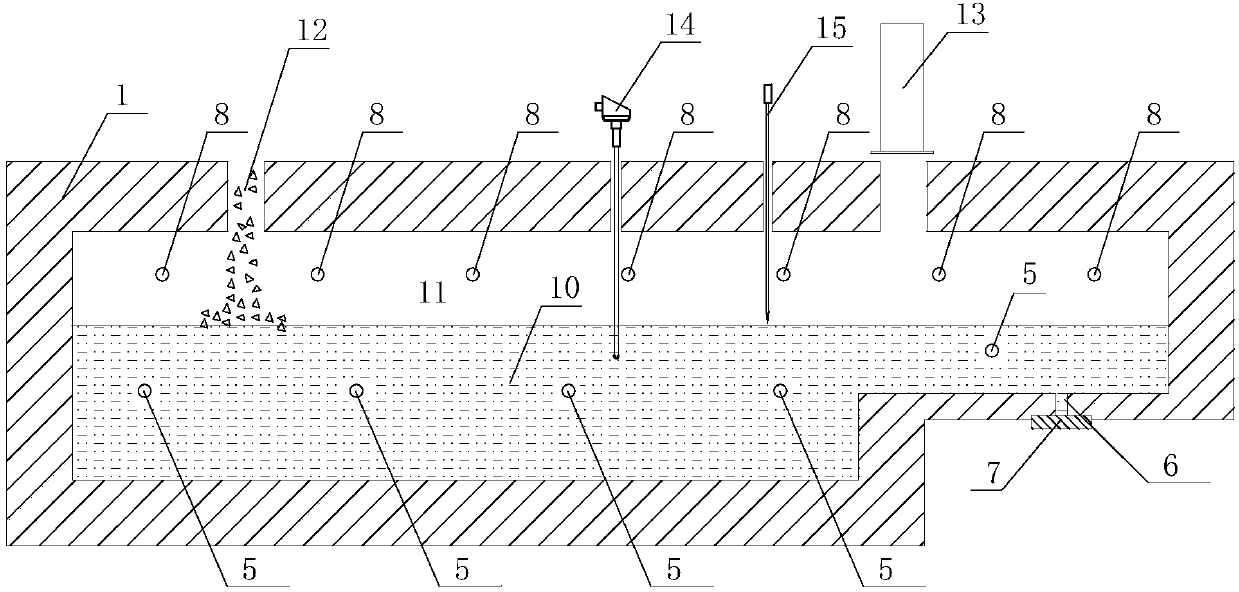

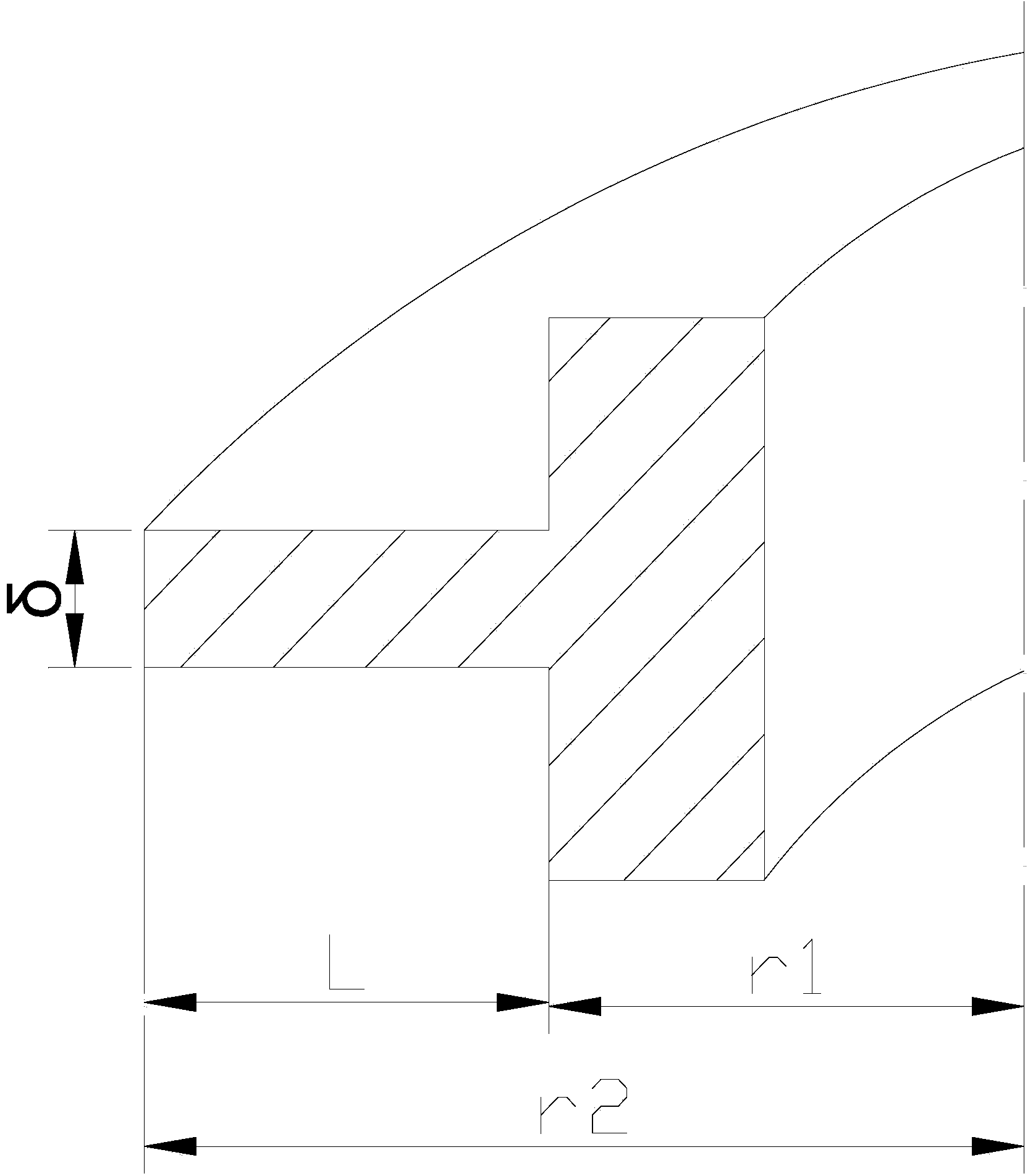

Gas-electric kiln for producing basalt continuous fiber

PendingCN107857462AUniform temperatureUniform compositionGlass furnace apparatusElectric furnaceFiberCombustor

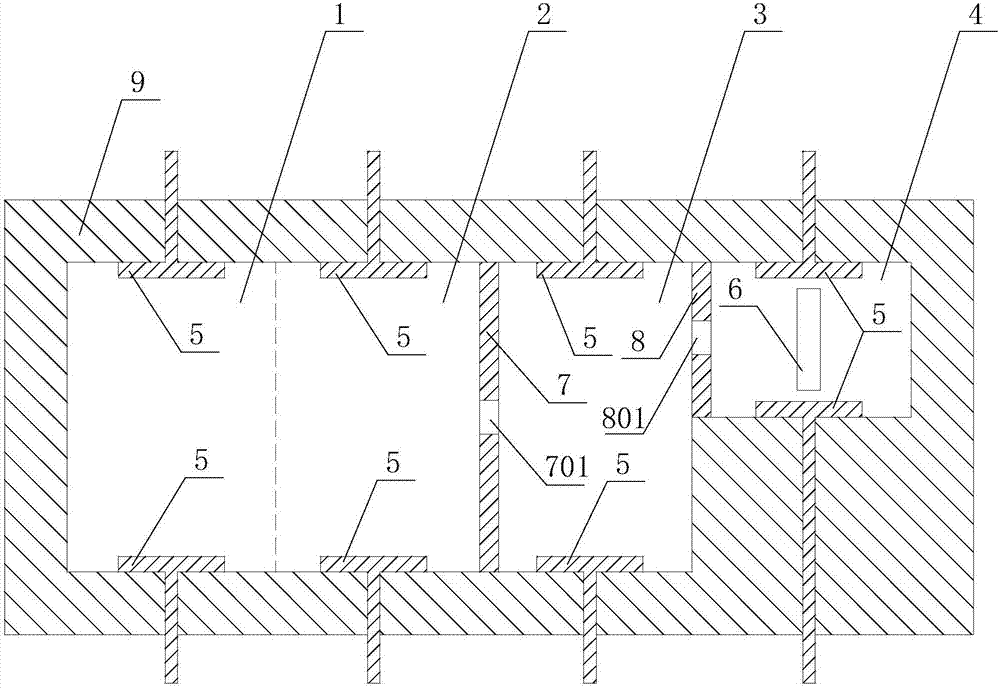

The invention provides a gas-electric kiln for producing basalt continuous fiber. A cavity in a kiln body comprises a melting region, a clarification homogenizing region and a work region; two long high side walls of the melting region, two long high side walls of the clarification homogenizing region and two long high side walls of the work region are each provided with at least one electrode; all electrodes on the two long high side walls of the kiln body are distributed in a staggered mode in the length direction of the kiln body; combustors are arranged on the two long high side walls of the melting region, the two long high side walls of the clarification homogenizing region and the two long high side walls of the work region; the electrified electrodes are immersed in basalt molten liquid, and a heating mode belongs to internal heating; the combustors conduct heating above the basalt molten liquid, and a heating mode belongs to external radiation heating; the two heating modes are combined to form internal and external integrated heating, so that a thermal field in the kiln is more uniform, the melting rate of basalt stone is increased, the temperature and components of the basalt molten liquid are more uniform, the yield and quality of the basalt continuous fiber produced by the single kiln are improved, and the kiln is more beneficial to achieving large-scale industrialproduction of the basalt continuous fiber.

Owner:山东聚源玄武岩纤维股份有限公司

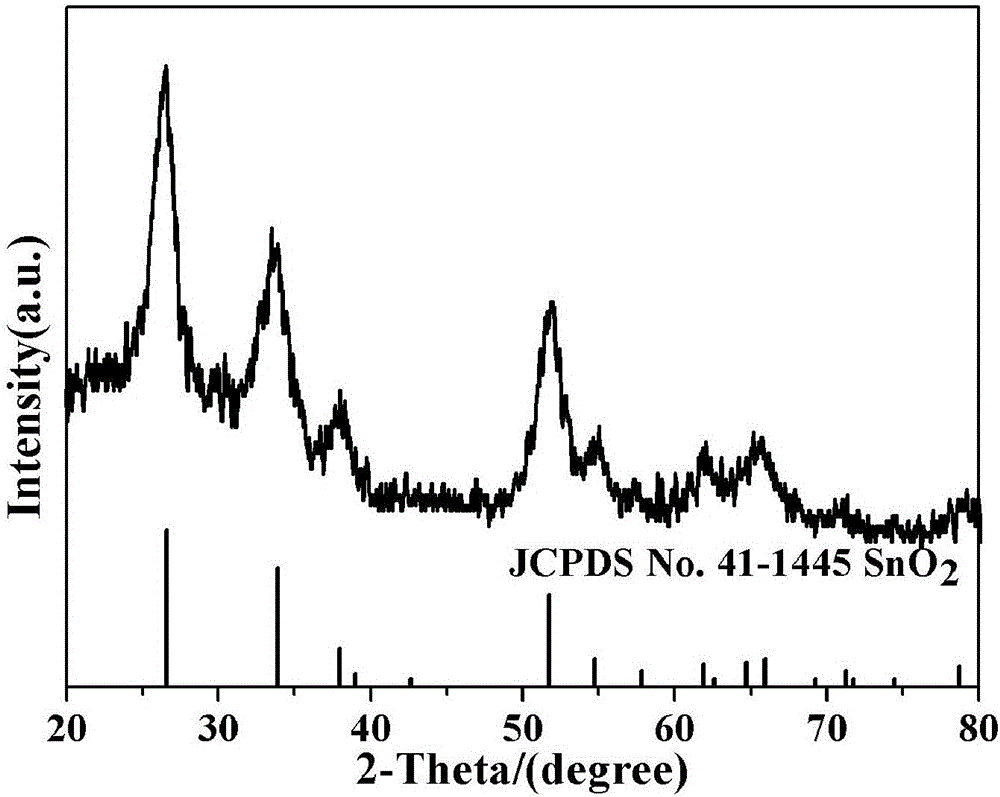

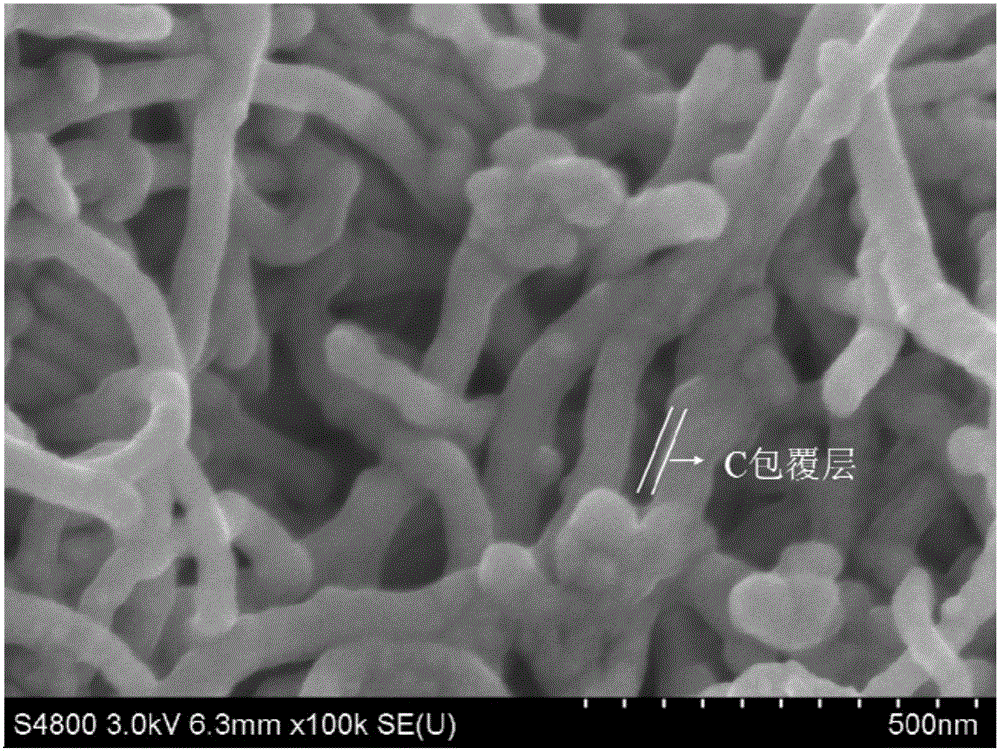

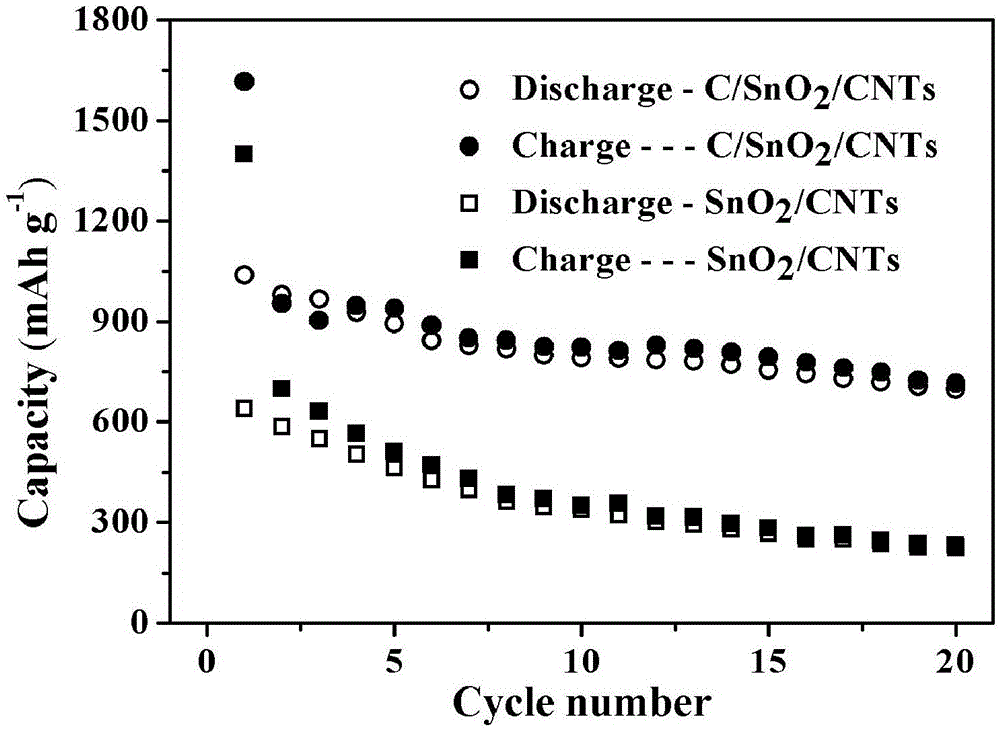

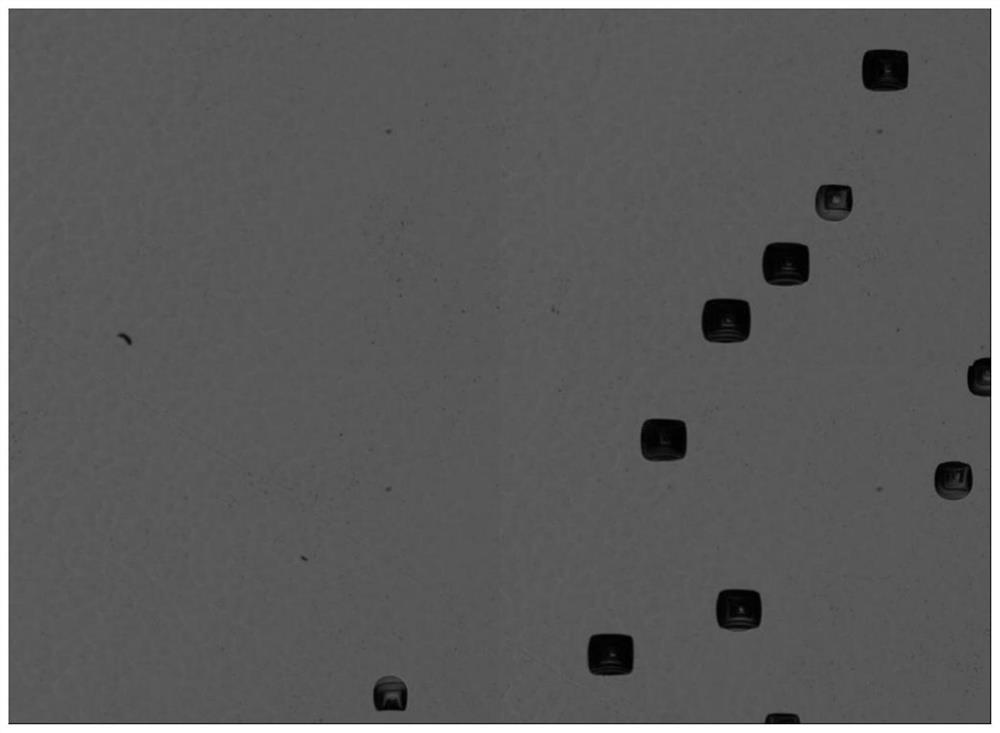

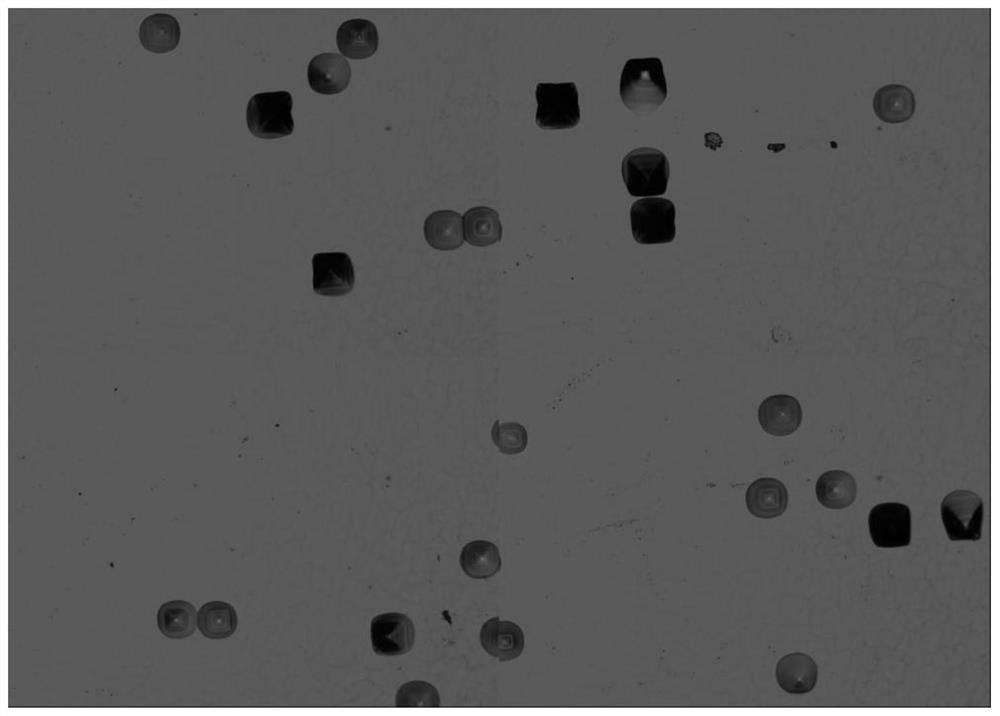

Preparation method of C/SnO2/CNT (carbon nano tube) composite material of core shell structure for lithium ion battery cathode

InactiveCN106025240AGood repeatabilityEasy to prepareMaterial nanotechnologyCell electrodesMass ratioCarbon nanotube

The invention relates to a preparation method of a C / SnO2 / CNT (carbon nano tube) composite material of a core shell structure for a lithium ion battery cathode. According to the method, carboxylated CNTs are uniformly dispersed in deionized water to obtain a solution A; a tin source is added into the solution A to obtain a uniformly dispersed solution B; a sugar type carbon source is added into the solution B; after the uniform stirring is performed, a solution C is obtained, wherein the mass ratio of the carboxylated CNTs to the tin source to the sugar type carbon source is (10-200mg):(0.36-3.1g):(0.1-1.5g); the solution C is transferred into a hydrothermal kettle; hydrothermal reaction is performed for 1 to 6h at the temperature being 120 to 210 DEG C; after the reaction is completed, the mixture is cooled to the room temperature; then, powder is separated out; washing and drying are performed; the C / SnO2 / CNT composite material of the core shell structure for the lithium ion battery cathode is obtained. The preparation method has the advantages that the process is simple; the preparation period is short; the repeatability is high; the reaction temperature is low; the energy consumption is low; the production cost is reduced; the preparation method is suitable for large-scale production and preparation.

Owner:SHAANXI UNIV OF SCI & TECH

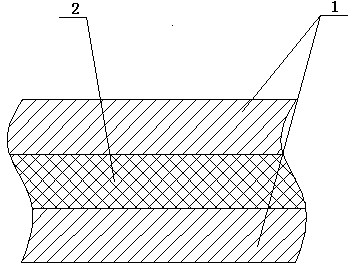

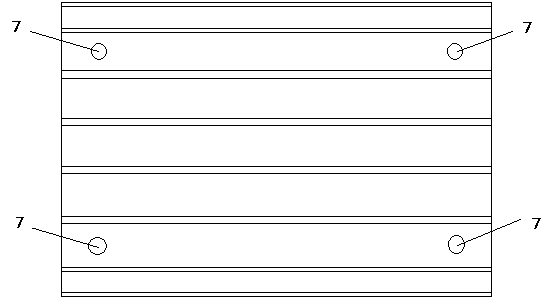

Mica electro-thermal film

InactiveCN103002608AHigh temperature resistanceGood electrical performanceHeating element materialsAdhesiveAlloy

The invention relates to the field of mica material processing, in particular to mica electro-thermal film. The mica electro-thermal film is in a composite multilayer structure, the middle layer is a heating element, and two sides attached to the heating element are mica substrates. The heating element is an alloy foil sheet with a heating circuit etched, the mica substrates are mica laminated paper, and the electro-thermal film is formed by pressing the alloy foil sheet and the mica substrates through high-temperature adhesives and a high temperature pressing process. The mica electro-thermal film is simple in structure and high in thermal conversion efficiency; and heating equipment produced through the mica electro-thermal film meets utilization requirements of being safe and comfortable and environment friendly and energy saving.

Owner:湖北平安电工材料有限公司

Multiple heat resources-electric warming magnesium smelting apparatus and process

The present invention relates to multiple heat source-electrothermal magnesium smelting apparatus and process. The magnesium smelting apparatus includes one vertical vacuum furnace with reactor, hot slag bin, furnace body heat isolator, feeding bin, one material, heater and electrodes inside the reactor; one magnesium crystallizer on the furnace; one cold slag bin blow the hot slag bin; and several vacuum valves. The present invention has high heating speed, high production efficiency, no pollution, high production adaptability, low labor strength, low production cost and high magnesium yield.

Owner:咸阳新能源材料产业技术研究院有限责任公司

Semiconductor gas sensor

ActiveCN103698359AReduce power consumptionIncrease resistanceMaterial analysis by electric/magnetic meansElectrical resistance and conductanceEngineering

The invention discloses a semiconductor gas sensor, comprising a base, a heating electrode, and a signal sensing electrode, wherein the base comprises a surface; the heating electrode is arranged on the surface; the signal sensing electrode is arranged inside a heat field formed by the heating electrode; the heating electrode is insulated with the signal sensing electrode; the heating electrode comprises a primary heating section and a secondary heating section; the primary heating section is adjacent to the signal sensing electrode; the secondary heating section is relatively far away from the signal sensing electrode; the resistance of the main heating section is greater than that of the secondary heating section. By adopting the semiconductor gas sensor disclosed by the invention, more effective utilization of the heat generated by the heating electrode is ensured by setting the primary heating section near the signal sensing electrode in the heating electrode to have the resistance greater than that of the secondary heating section which is relatively far away from the signal sensing electrode, and the surface power loss is reduced. Thus, power consumption of the sensor is reduced.

Owner:SUZHOU NANOGRID TECH

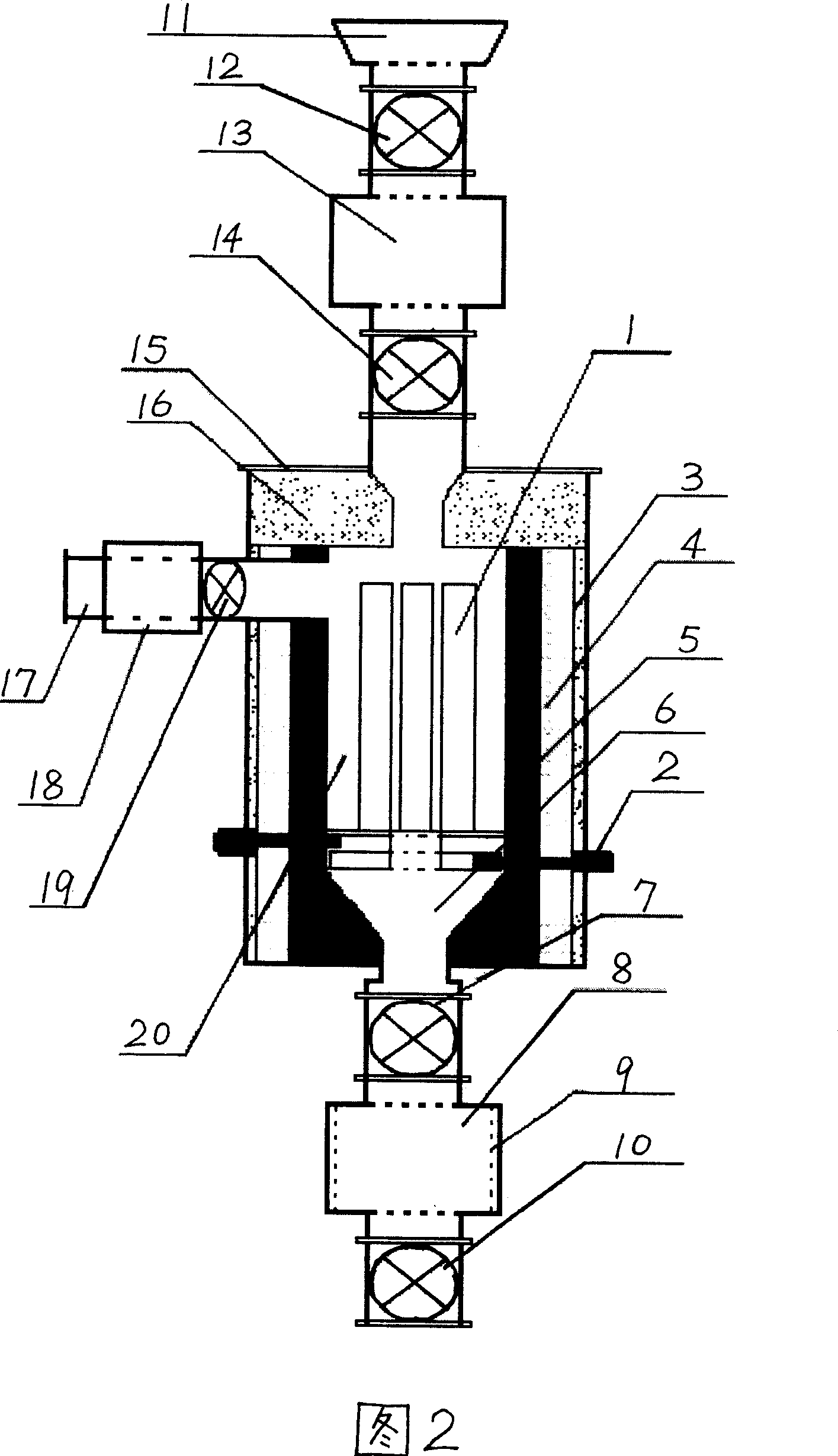

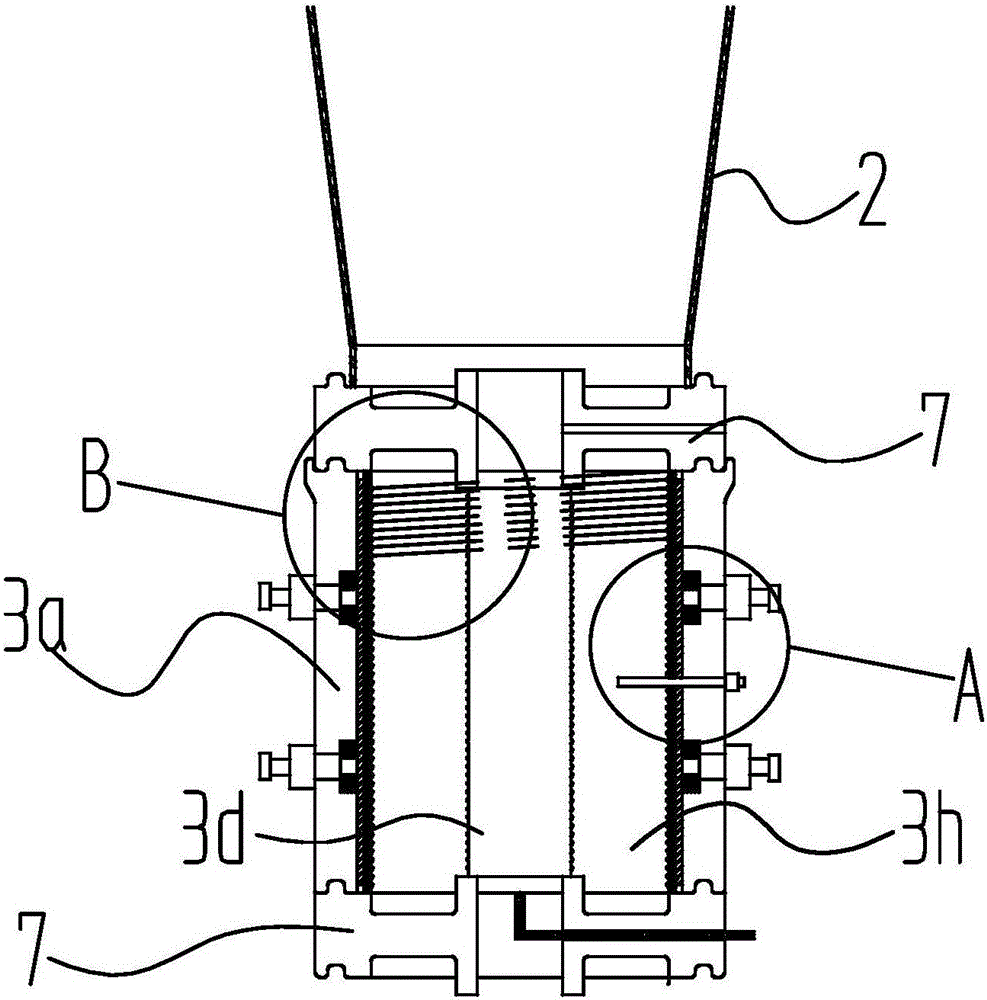

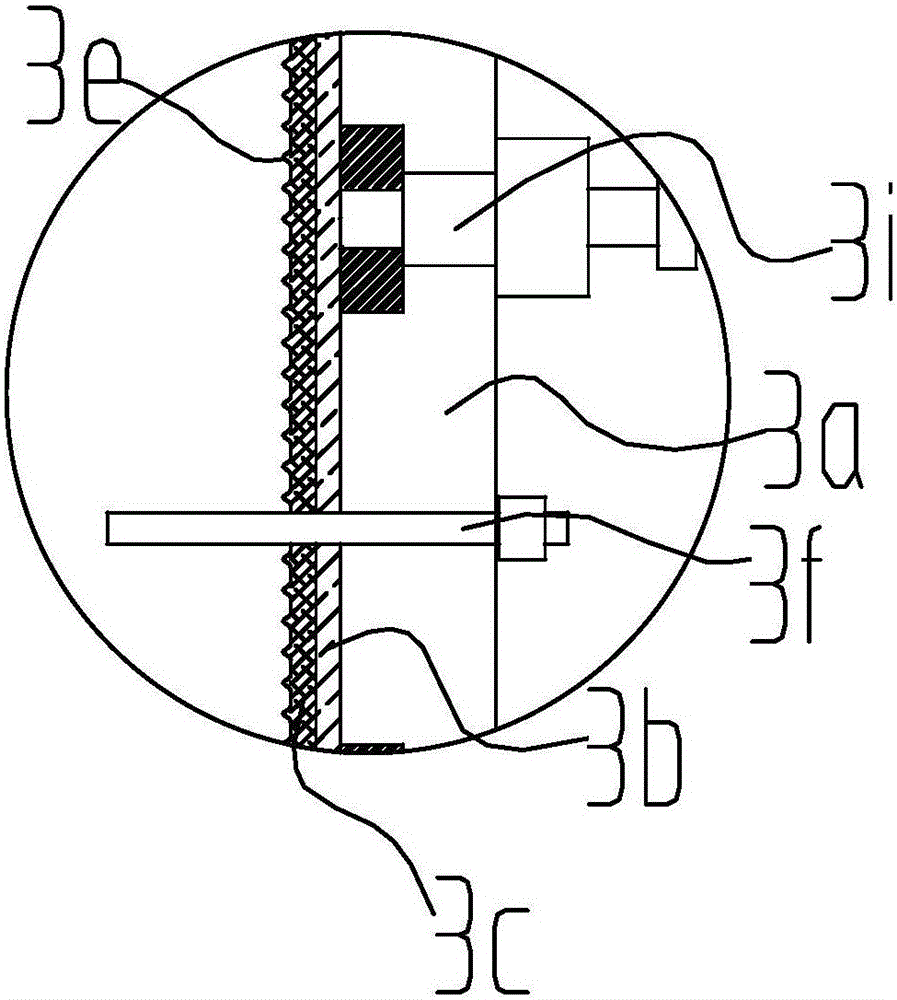

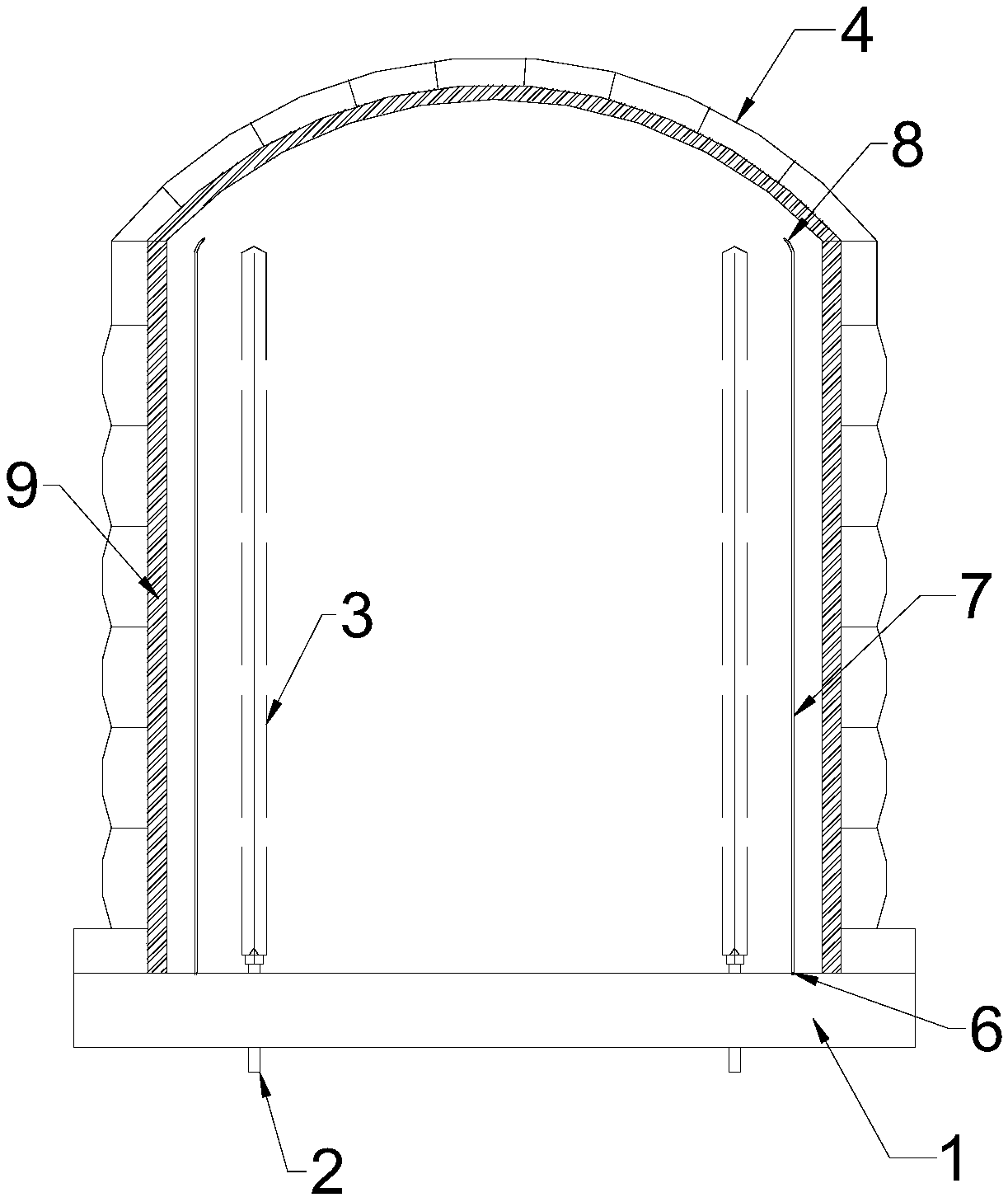

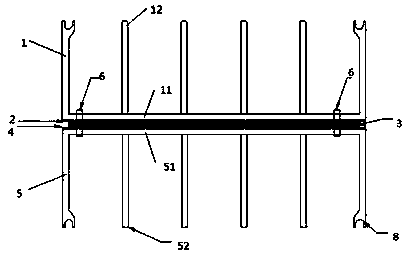

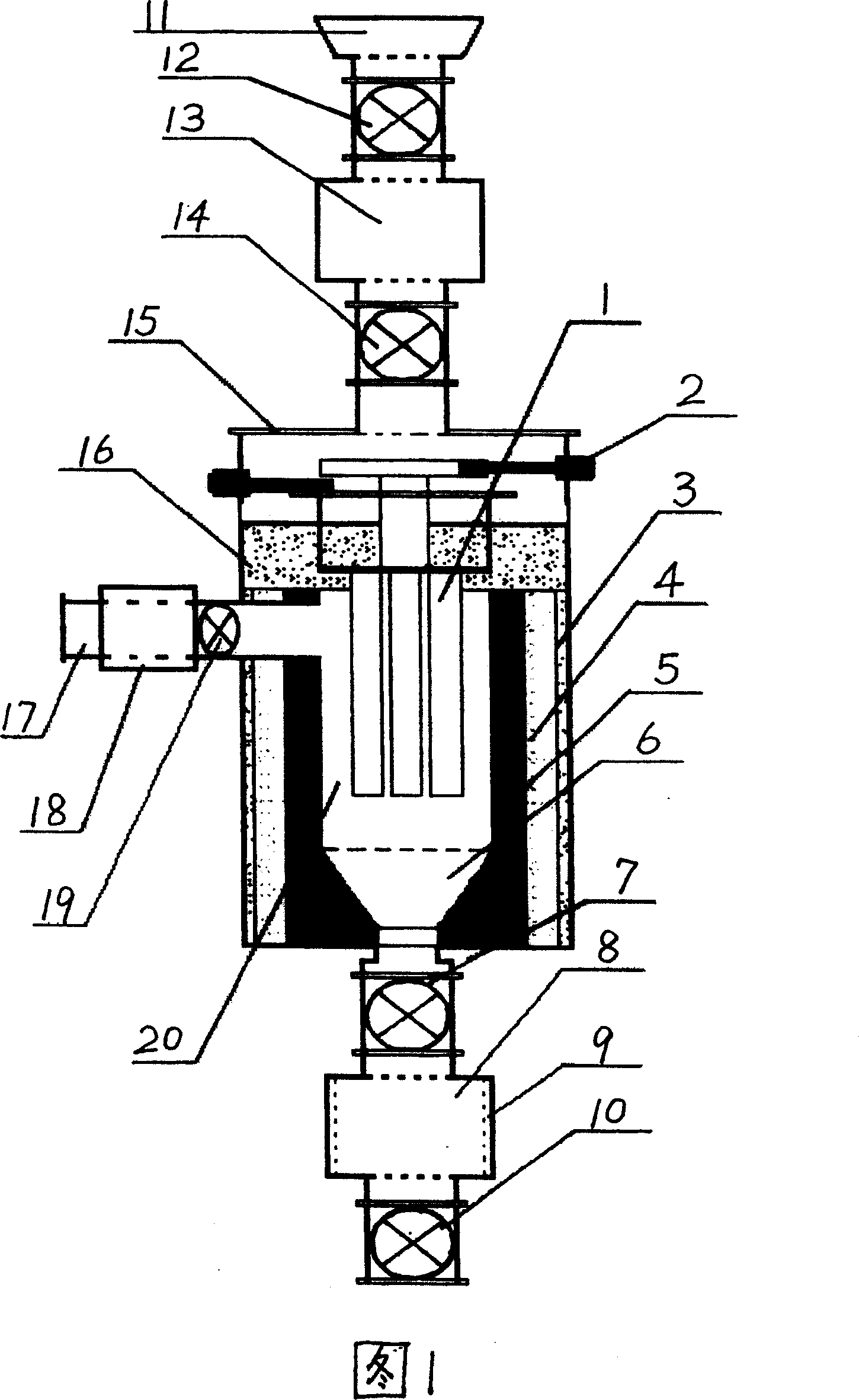

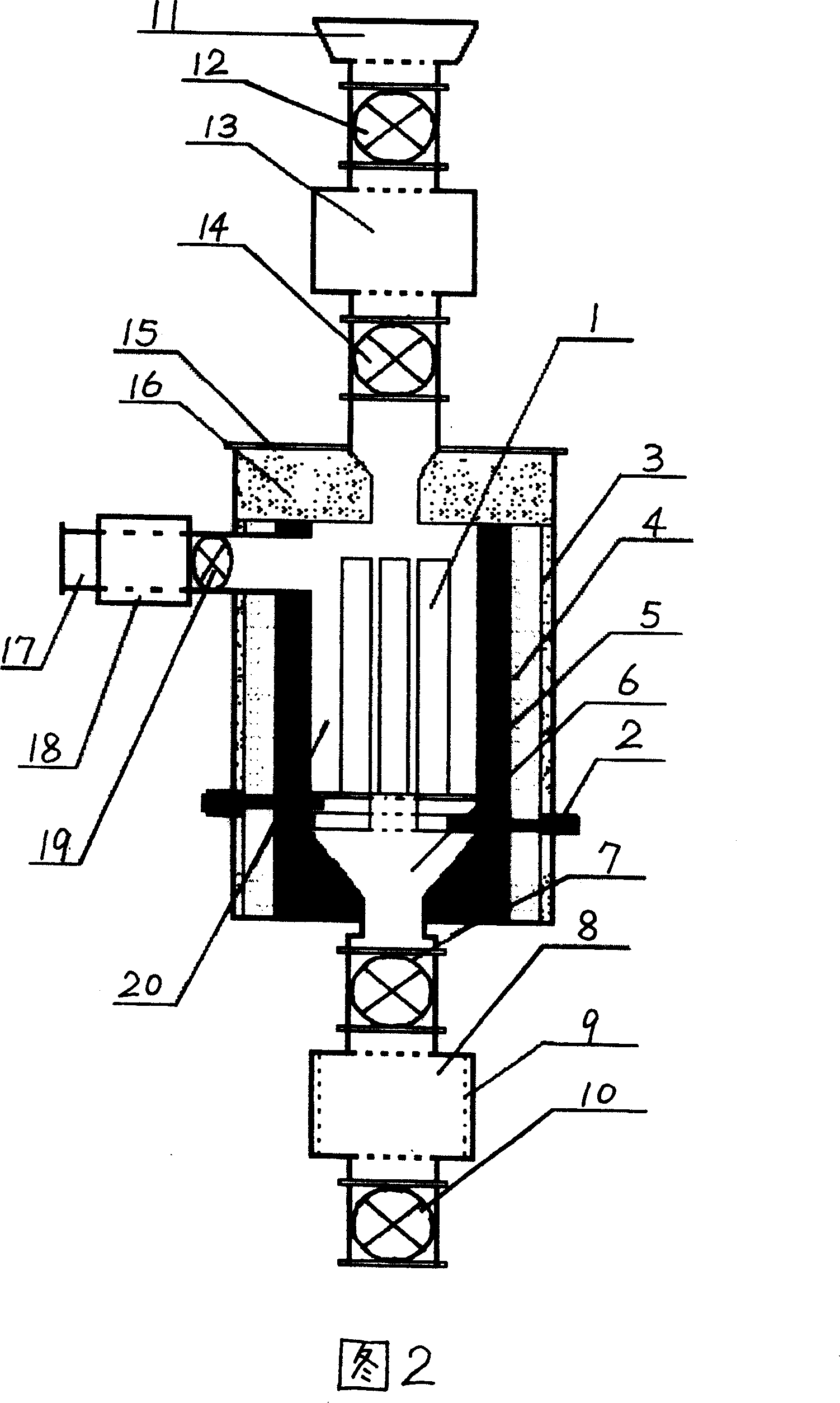

Pneumoelectric kiln for producing basalt continuous fibers

PendingCN107399901AIncrease production capacityQuality improvementElectric furnaceGlass productionFiberOperating point

The invention provides a pneumoelectric kiln for producing basalt continuous fibers. A cavity in a furnace body includes a melting zone, a clarifying zone, a homogenizing zone and an operating zone; the wall, positioned below the designed height of the upper light level of a melt in the kiln, of the lateral wall of each of the melting zone, the clarifying zone, the homogenizing zone and the operating zone is provided with at least one pair of electrodes, and the wall, positioned above the designed height of the upper liquid level of the melt in the kiln is provided with a natural gas lance. Energized electrodes are immersed in the basalt melt to realize internal heating, the natural gas lances heat the electrodes above the basalt melt to realize external radiation heating, and the internal heating and the external radiation heating are combined to form internal and external co-heating, so the thermal field in the kiln is uniform, and the melting rate of basalt rocks is improved to make the temperature and the components of the basalt melt uniform, thereby the productivity and the quality of the basalt continuous fibers produced by a single kiln are improved, and the large-scale industrial production of the basalt continuous fibers is facilitated.

Owner:山东聚源玄武岩纤维股份有限公司

Efficient directly burning sealed metal magnesium reducing smelter

InactiveCN1811313AImprove productivityImprove combustion efficiencyFurnace typesProduction rateHigh density

The efficient directly burning sealed metal magnesium reducing smelter is superior to traditional metal magnesium reducing smelter, which has the demerits of poor heat transmission, low heat utilization rate, etc. The present invention has directly burning high density arranged reducing pots, homogeneous heat field, mechanical ash discharging, high production efficiency, high heat utilization rate, high yield and high product quality.

Owner:维恩克材料技术(北京)有限公司

Conductive heating ceramic tube and preparation method

InactiveCN1499898AGood waterproof and insulation performanceStrong securityHeating element shapesElectric heatingChina clay

Two or more electric heating electrodes are arranged orderly and in interval along axial line or in annular along cross section inside ceramic tube. Material of the ceramic tube is evenly mixed china clay and stuffing of current conducting fine particle. Preparing an insulated surface according to conventional method for manufacturing ceramic tube and embedding bus bar in advance or posting bus bar after makes electric heater unit. The electric heater unit could be solid rod shaped. The invention has advantages of good water resistance and insurability, high safety and high conversion efficiency of electric heating.

Owner:黄加玉 +1

Crucible for titanium alloy smelting

The invention belongs to the technical field of fireproof materials and in particular relates to a crucible for titanium alloy smelting. The crucible for titanium alloy smelting is characterized by being prepared from the following raw materials in percentages by weight: 30-50% of zirconium diboride, 20-40% of electric smelted zirconium oxide, 10-20% of yttrium oxide and 5-10% of titanium nitride, wherein a binding agent accounting for 5% of the total weight of the raw materials is further added. According to the crucible provided by the invention, the energy consumption is reduced greatly, the alloy yield is increased, and meanwhile, molten metal is not polluted.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

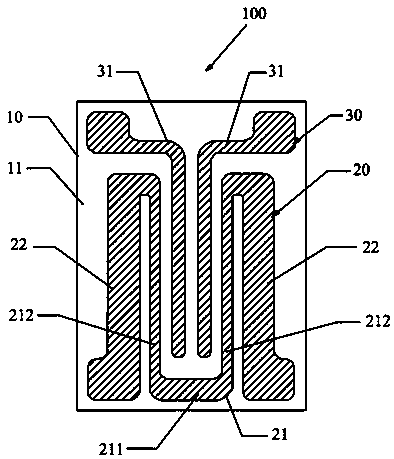

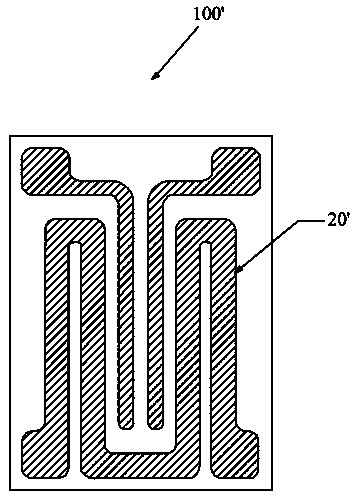

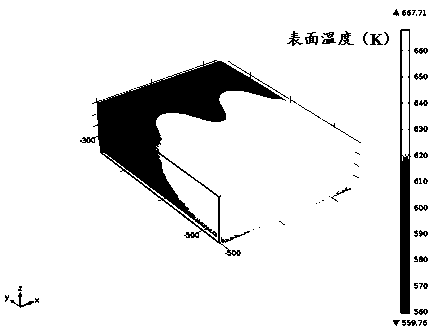

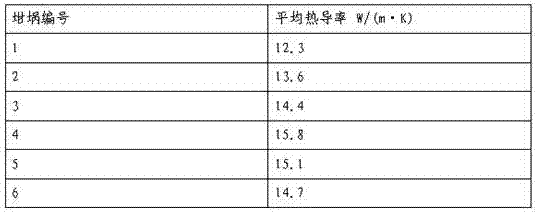

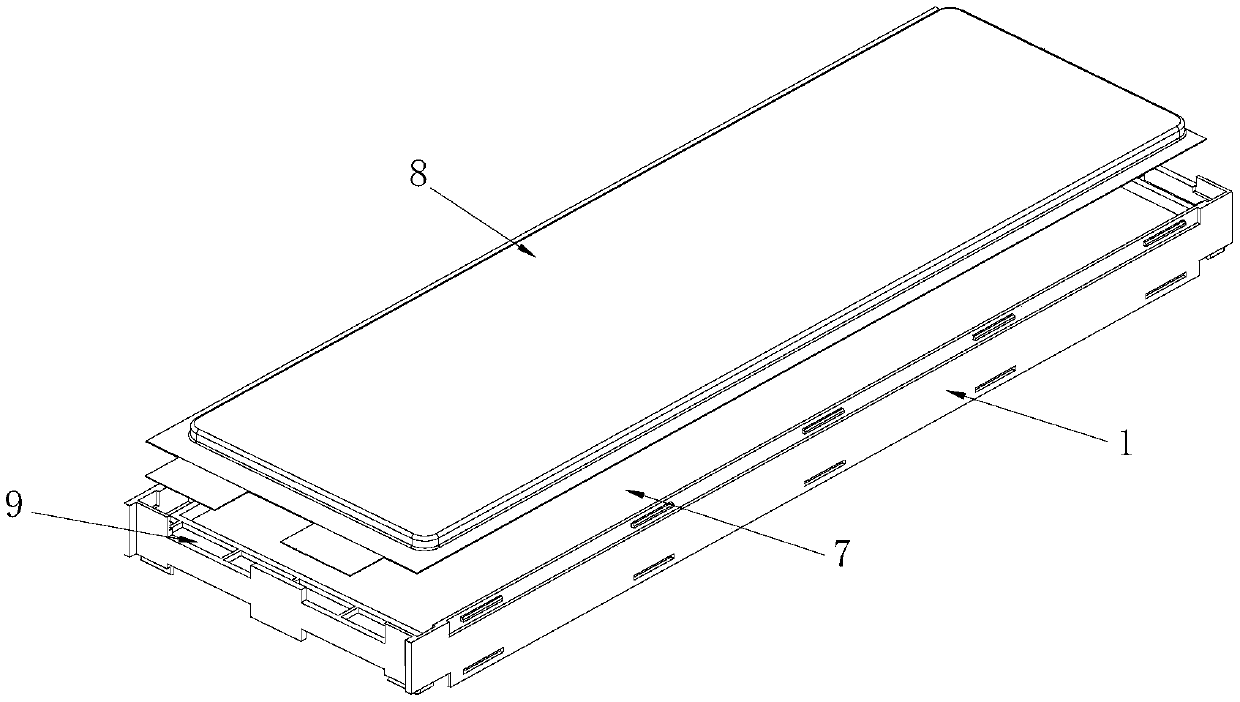

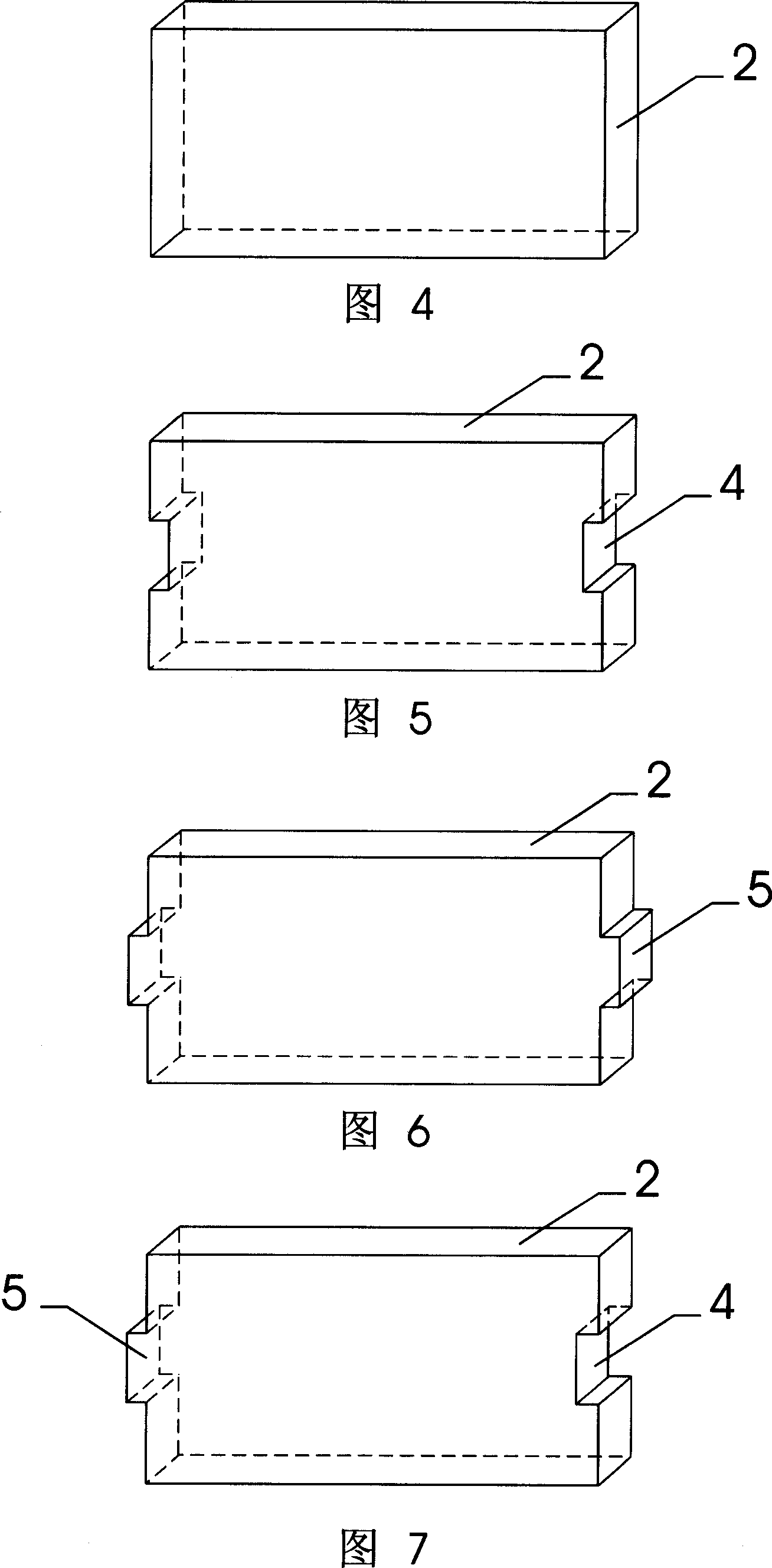

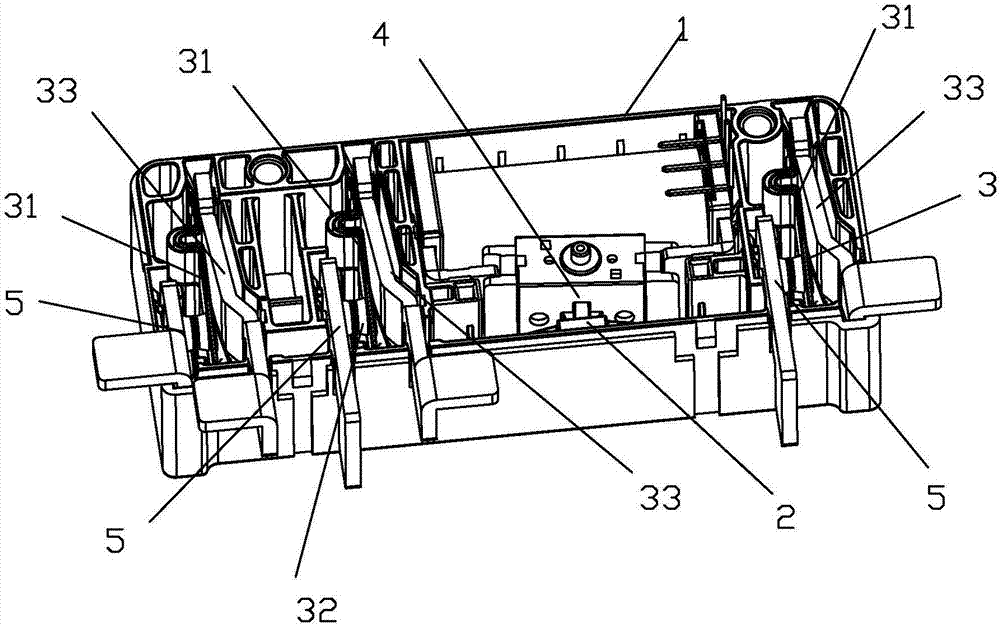

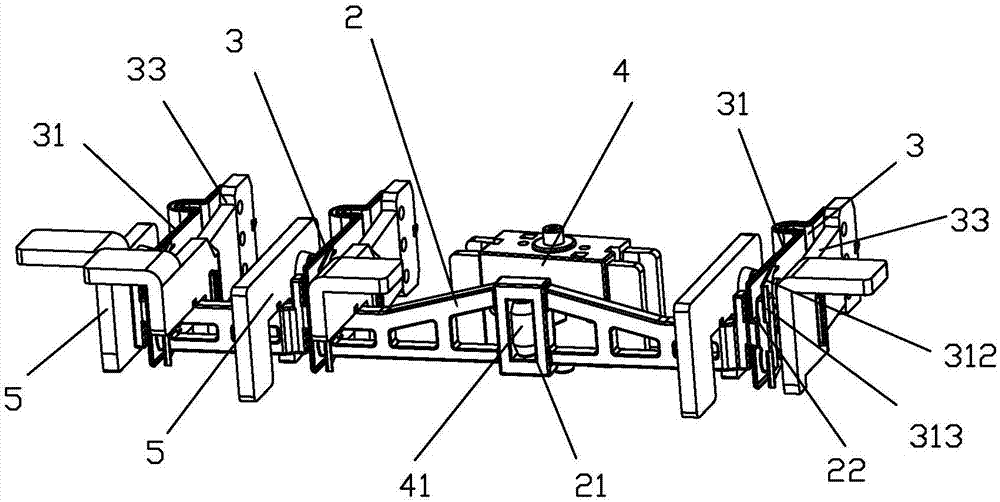

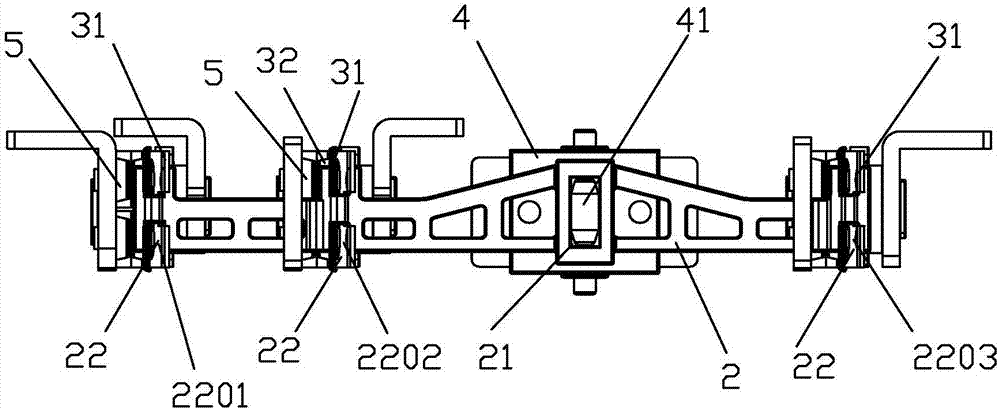

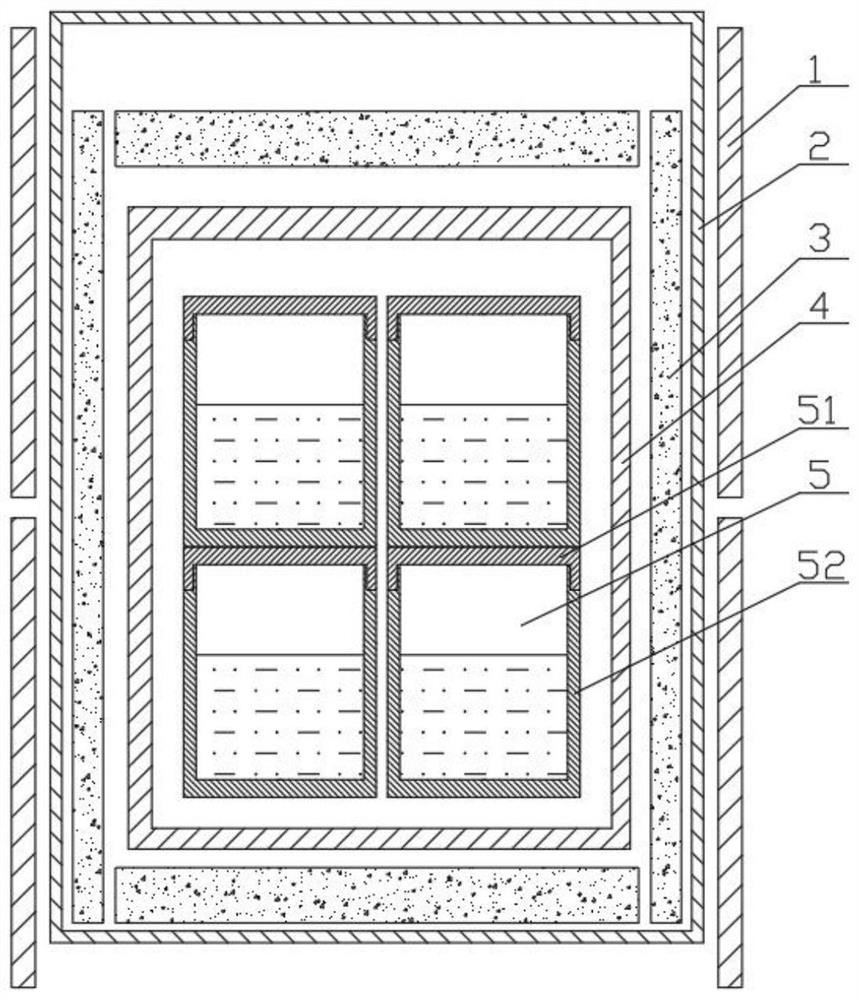

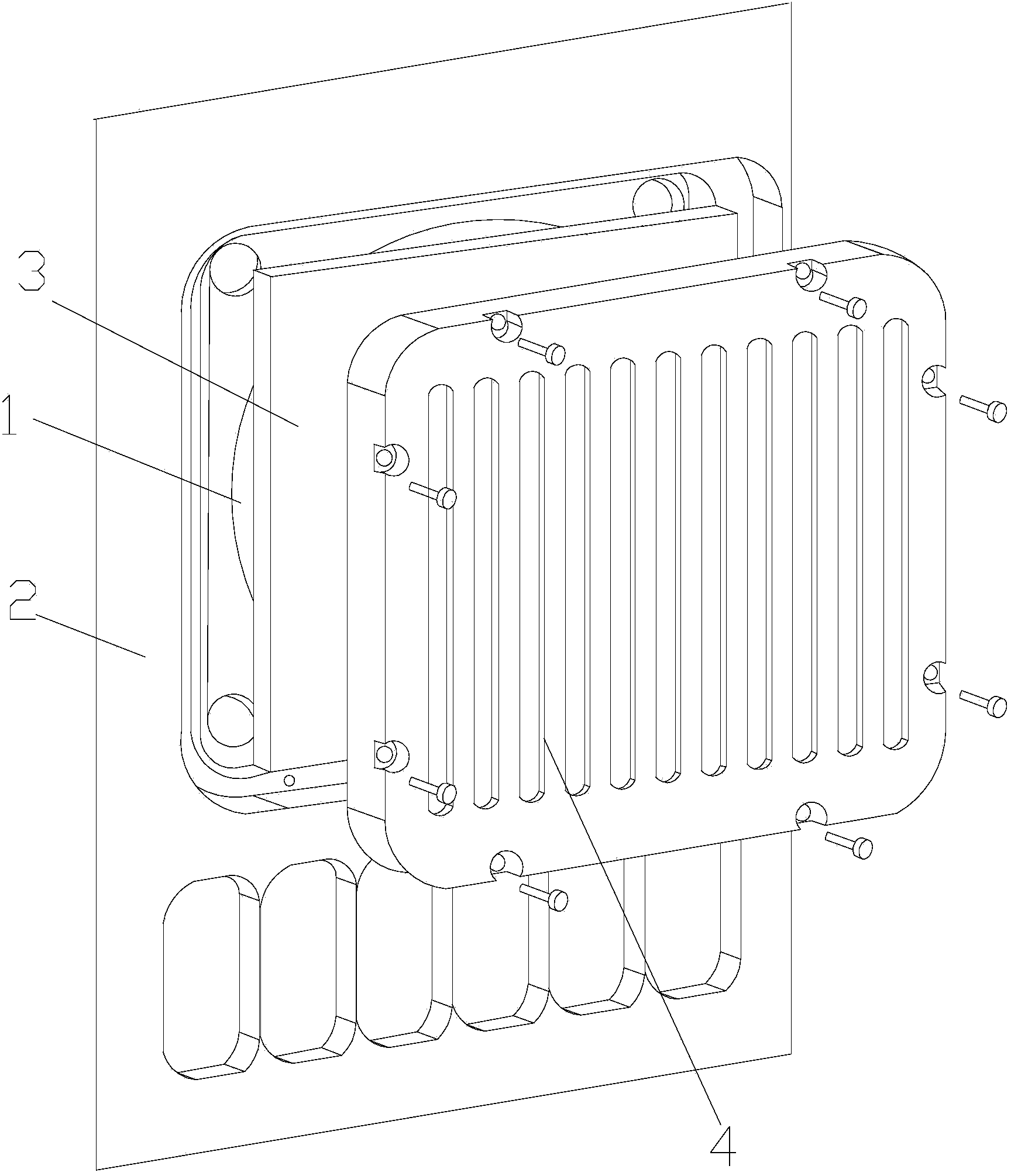

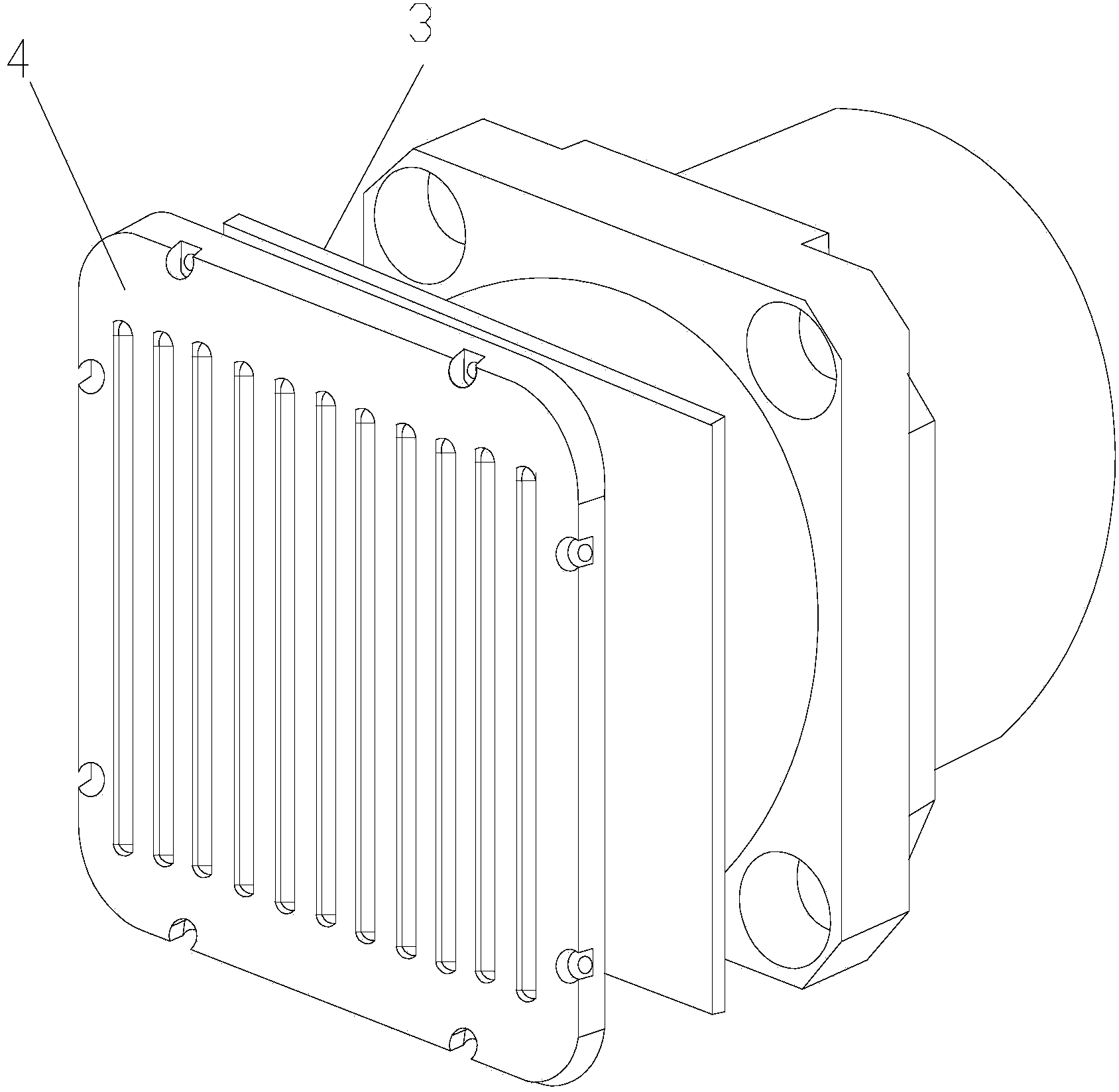

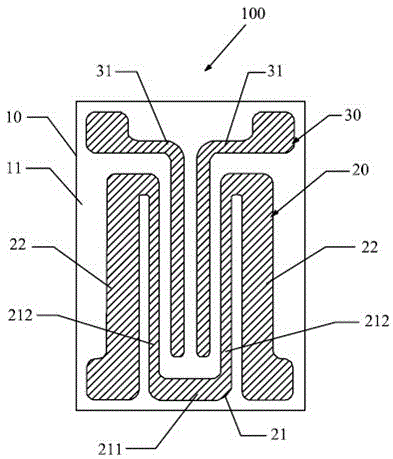

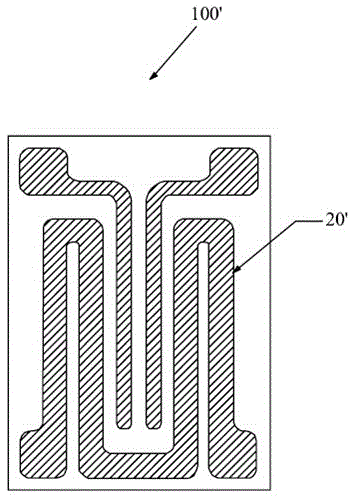

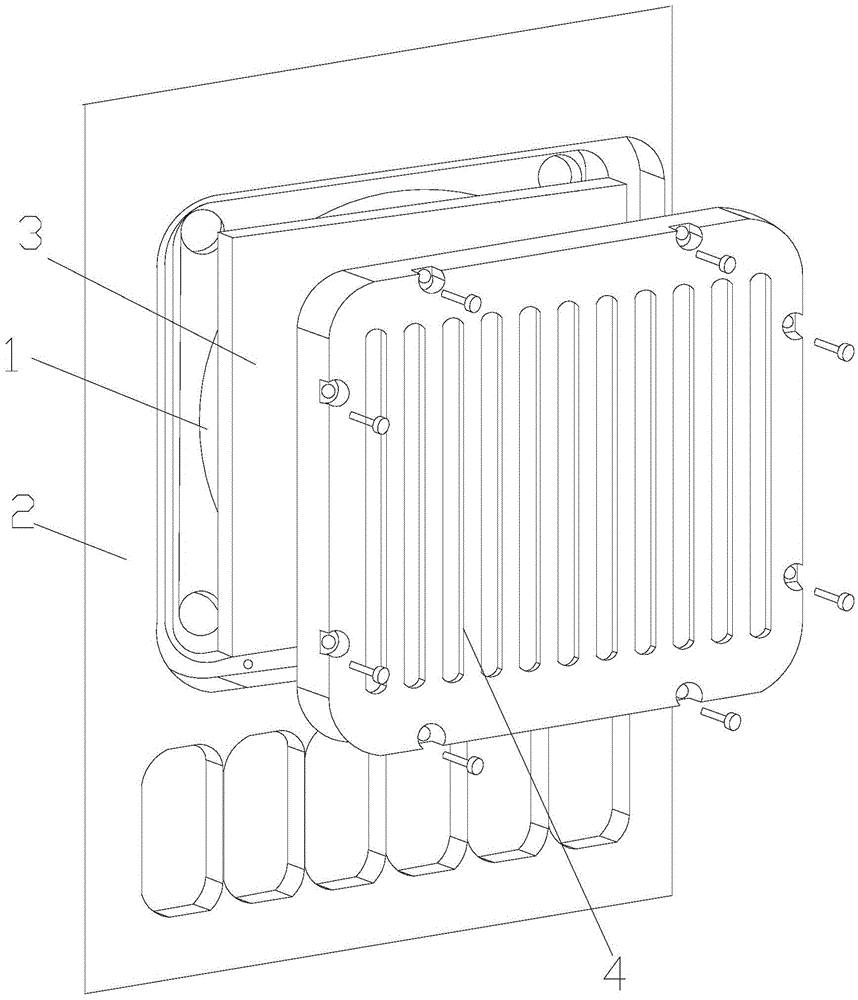

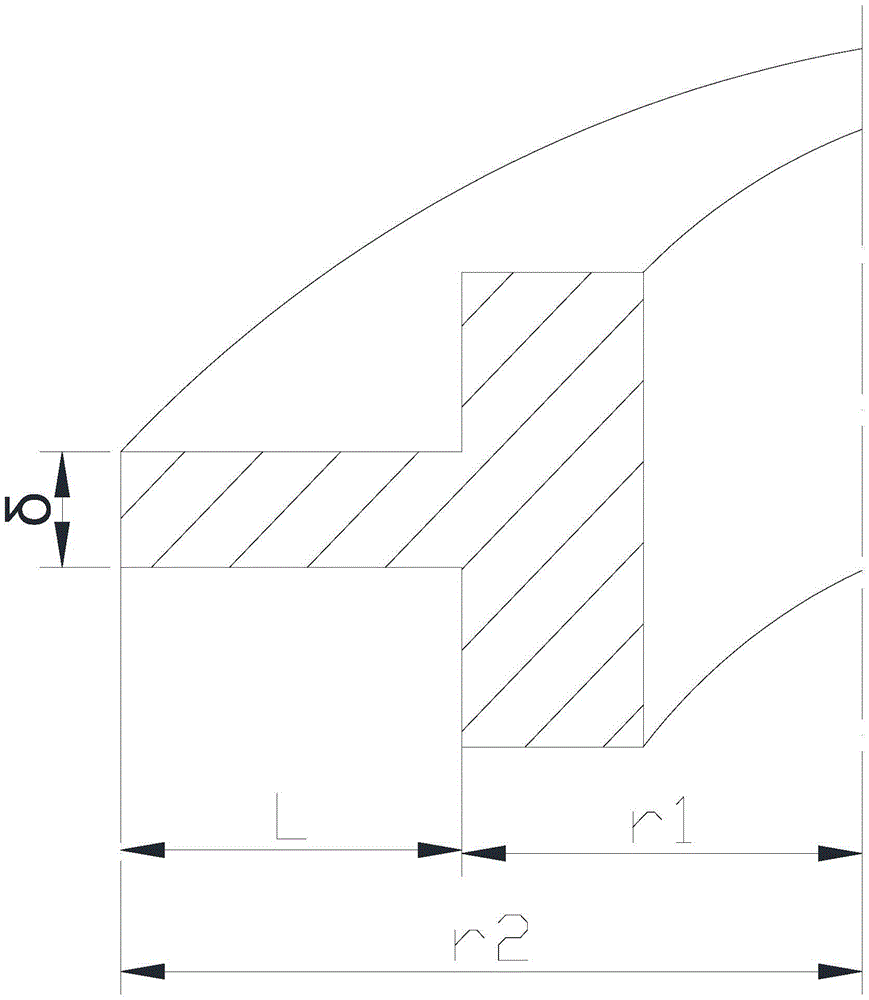

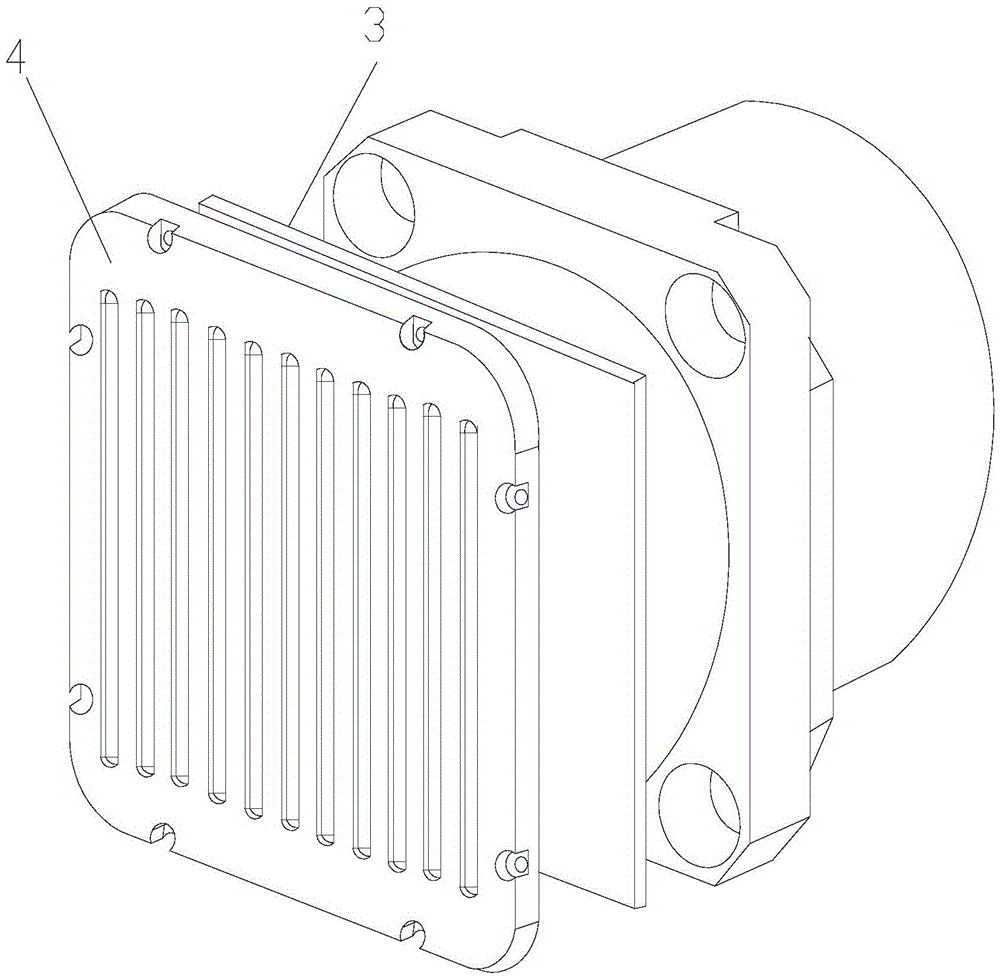

Bracket for core module and solid state battery module structure

PendingCN109638188ASpeed up heat transferIncrease the areaSecondary cellsCell component detailsCooling effectEngineering

The invention discloses a bracket for a core module. In particular, the bracket comprises a frame main body, wherein a through hole is formed in the frame main body; a heat sink is arranged inside theframe main body; a core heat dissipation region exposed via the through hole is formed on the heat sink; the bottom of the frame main body is also provided with heat dissipation slots with slot widthextending to both sides of the heat sink; the heat sink is communicated into the heat dissipation slots and extends to the inner walls of the heat dissipation slots to form a radiation rib covering the whole heat dissipation slots; and the frame body is also provided with polar earholes around the through hole. The invention also discloses a solid-state battery module structure using the bracketfor the core module. The bracket has the advantages of excellent core heating and cooling effects, uniform thermal field of the battery module, convenience in assembly, and easy assembly of the solid-state battery module.

Owner:WM MOTOR TECH GRP CO LTD

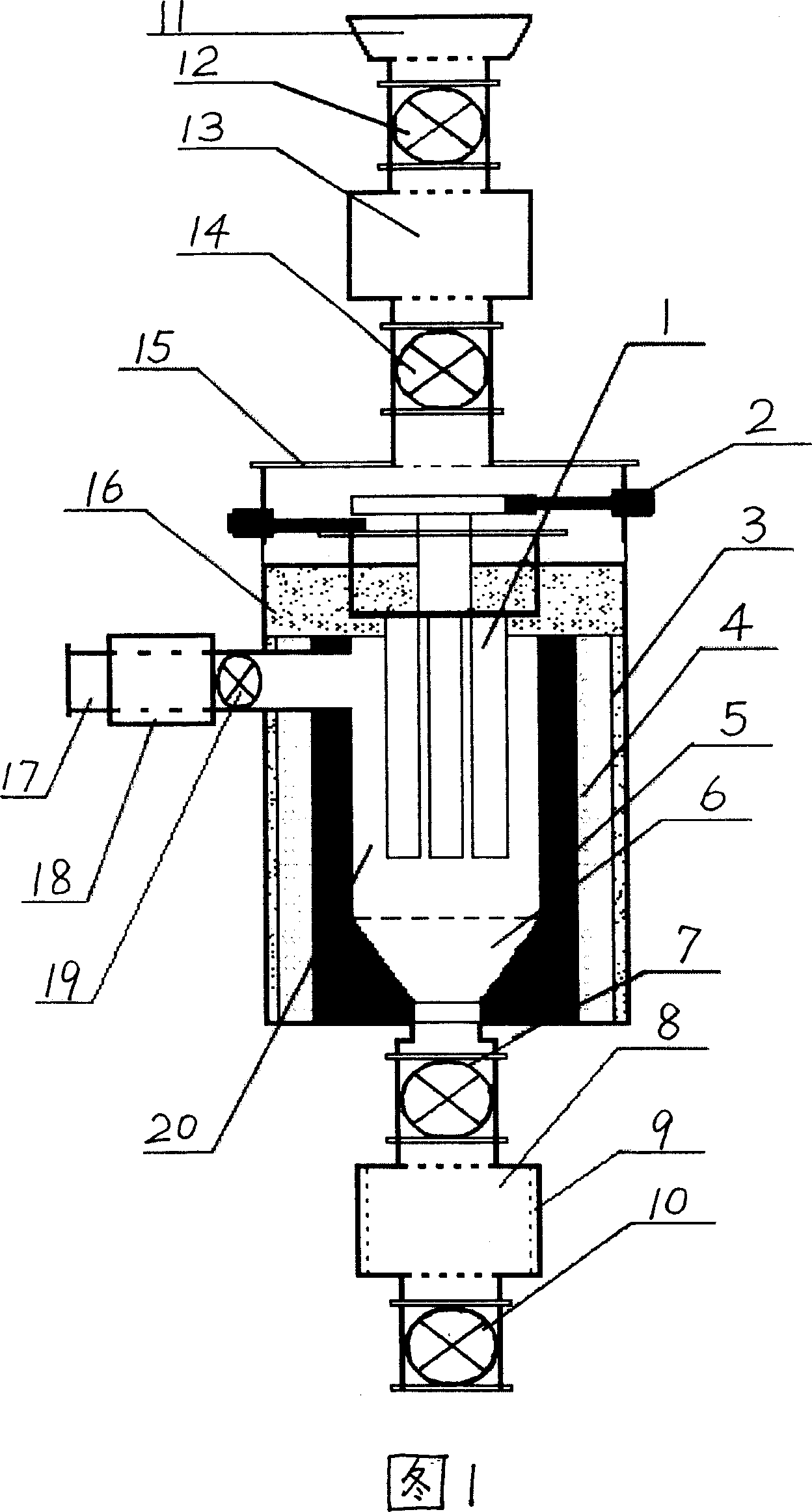

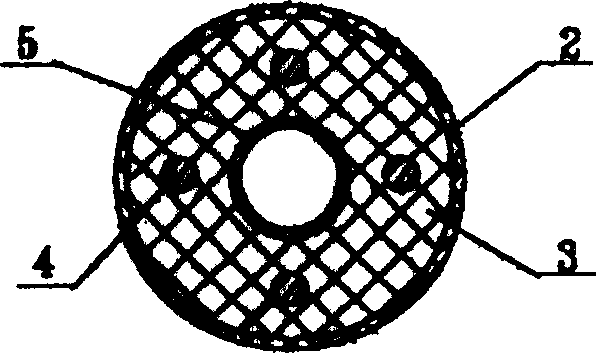

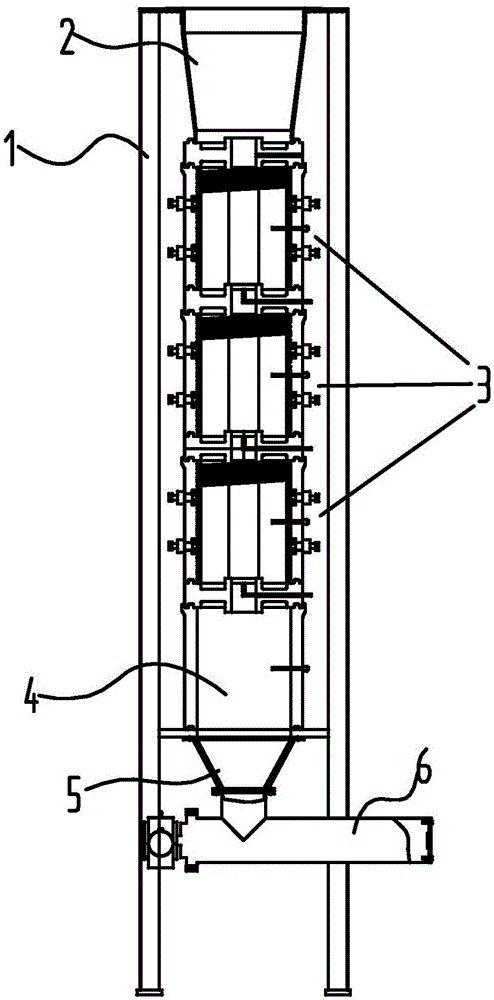

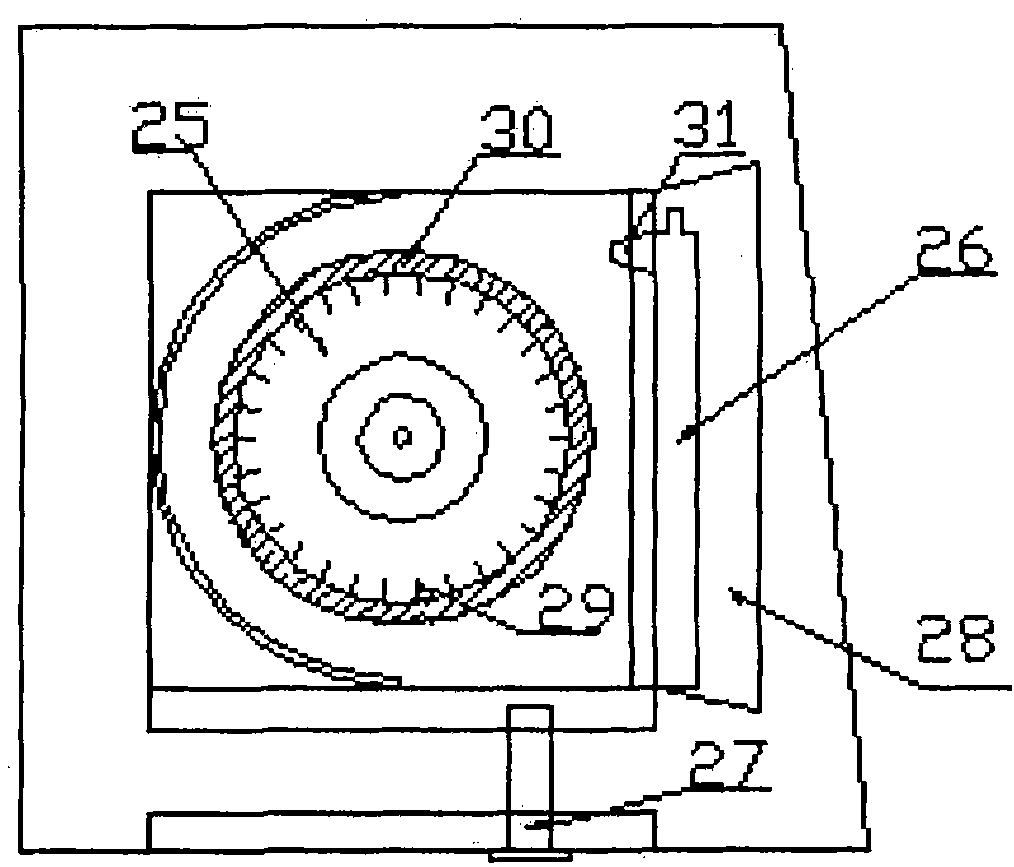

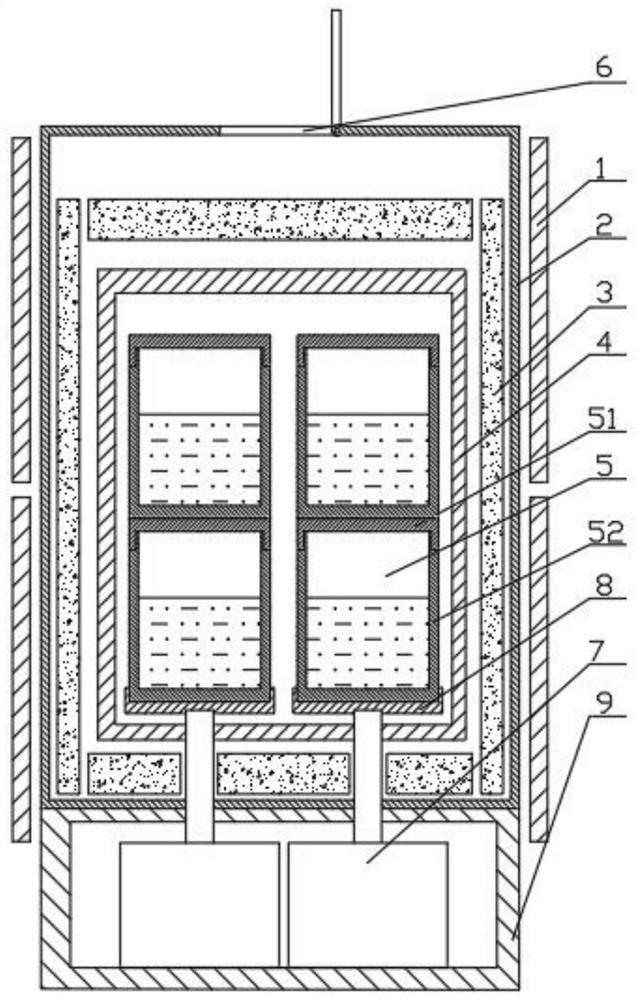

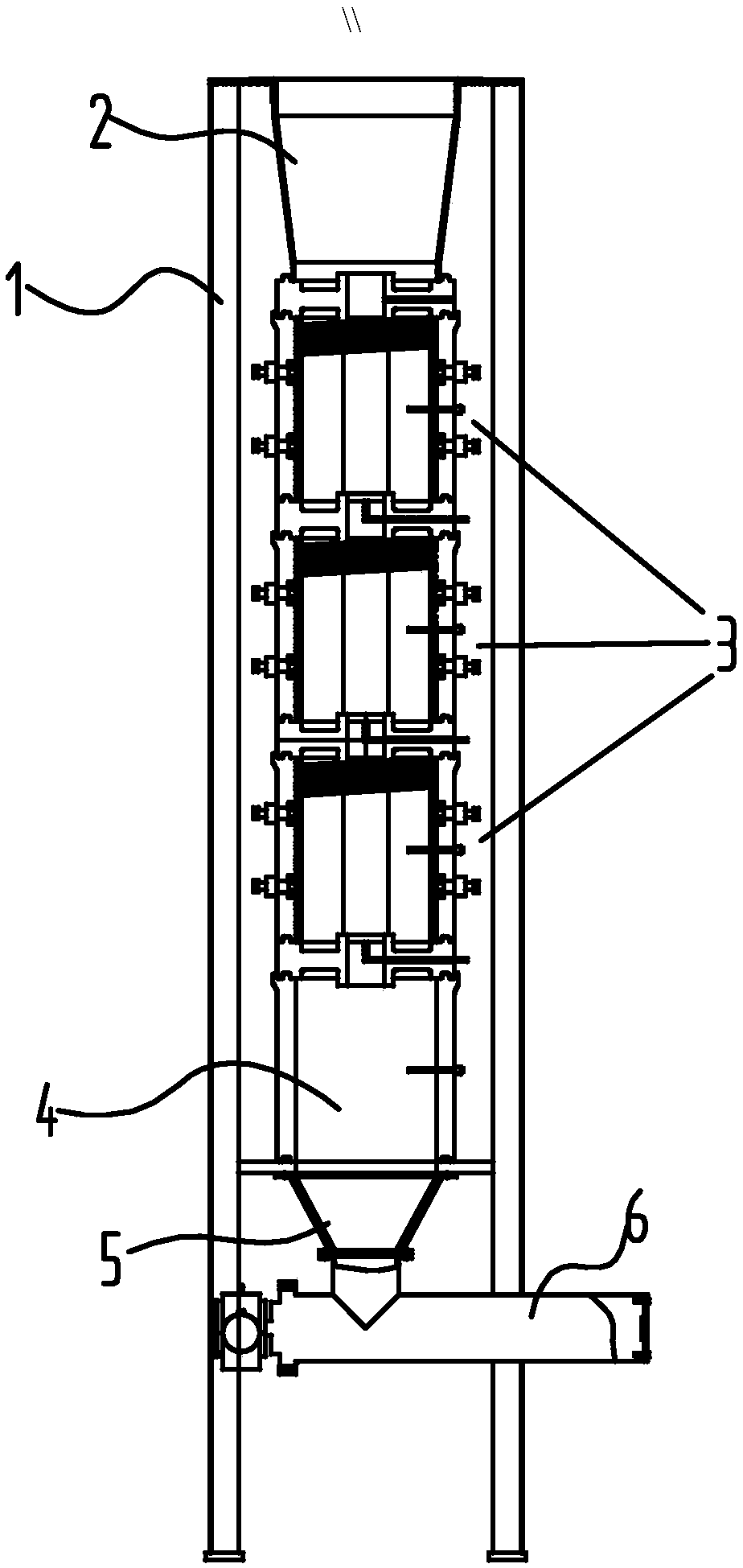

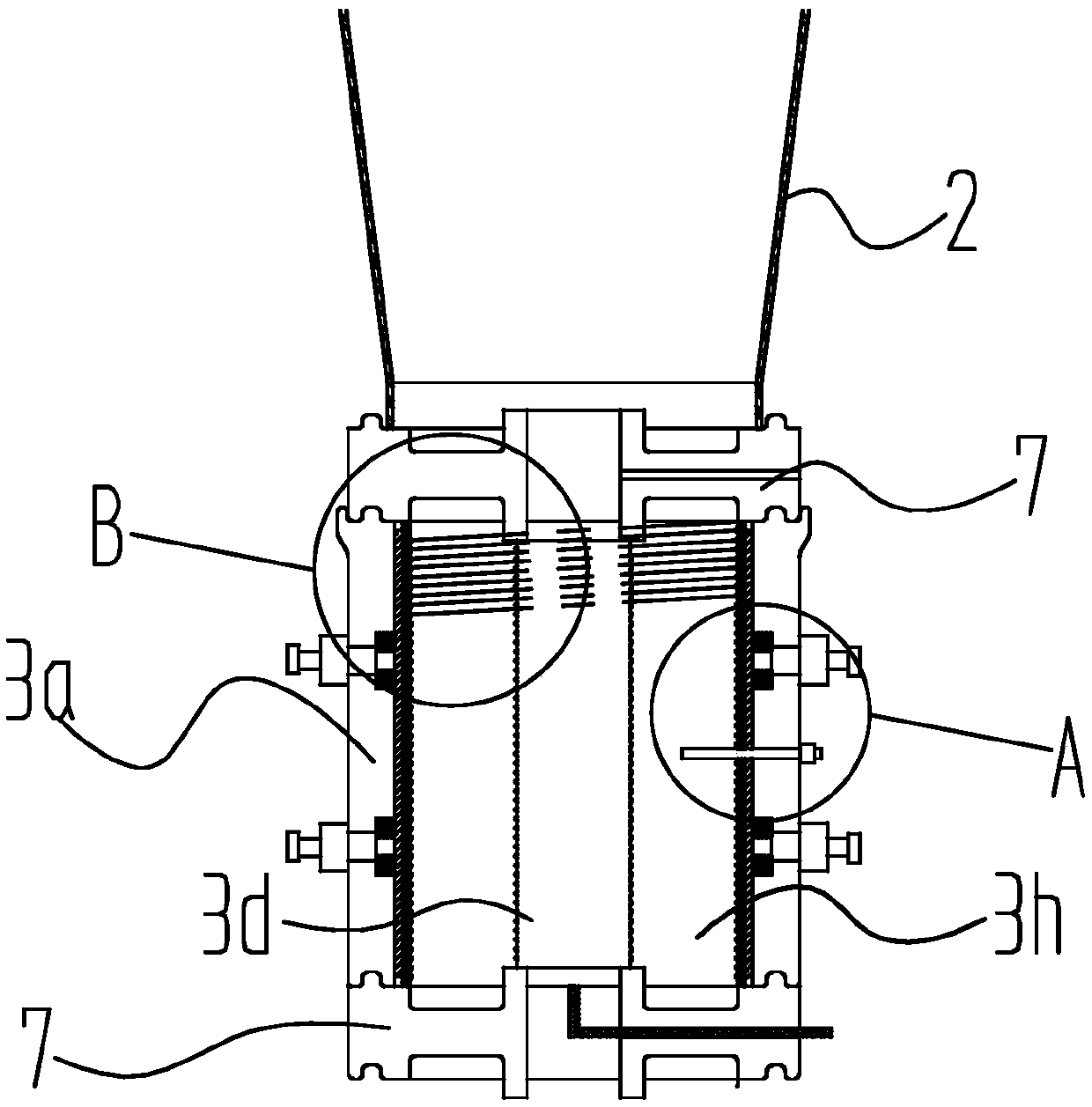

Vertical-type discharge active carbon regenerating furnace

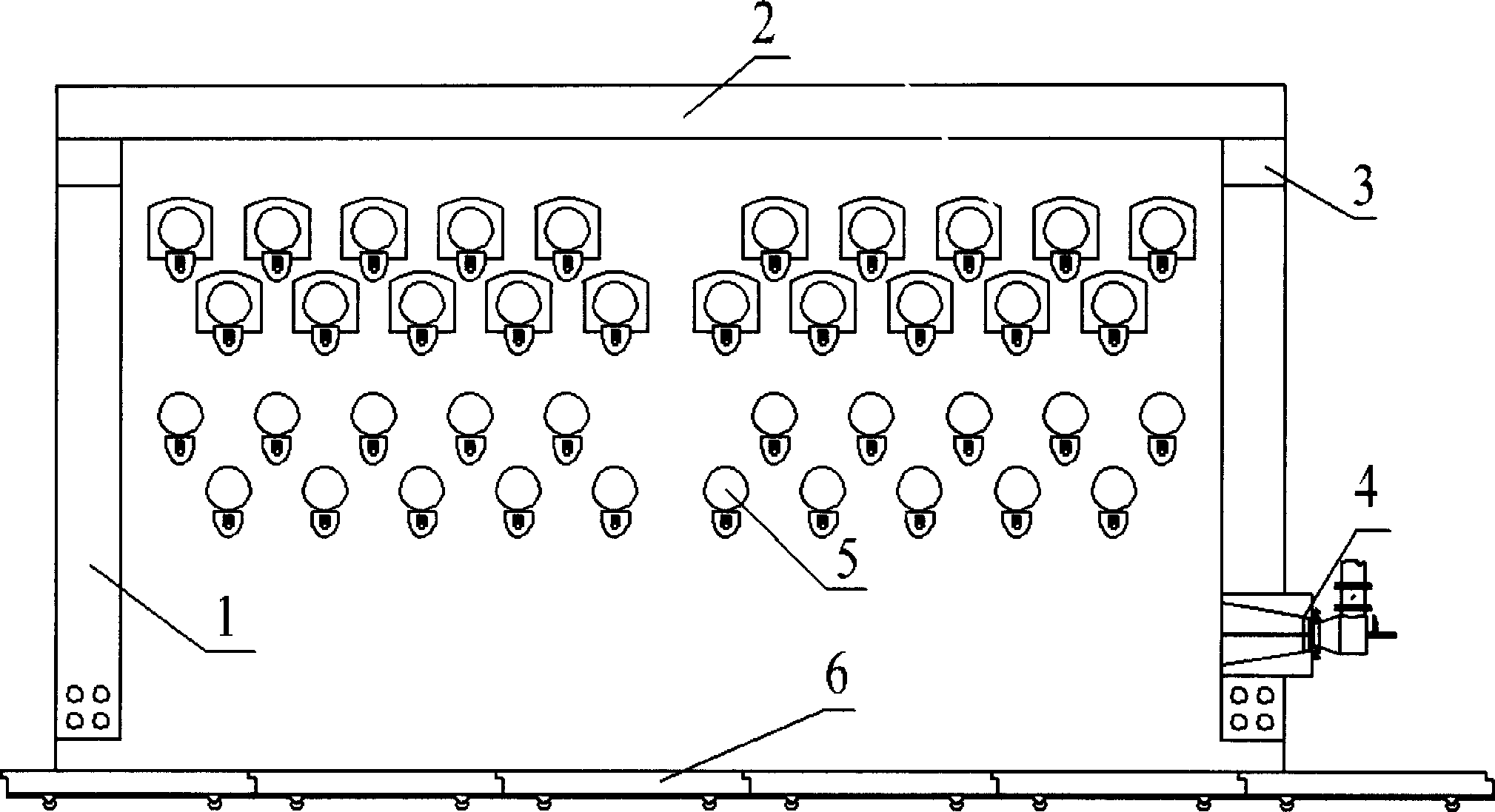

ActiveCN106040209AEvenly heatedReduce wearOther chemical processesCombustible gas purificationActivated carbonGraphite electrode

The invention discloses a vertical-type discharge active carbon regenerating furnace. The vertical-type discharge active carbon regenerating furnace comprises a stander, wherein the top end of the stander is provided with a feeding cabin, the bottom end of the stander is provided with a discharging cabin, a regenerating furnace group is arranged between the feeding cabin and the discharging cabin, the regenerating furnace group consists of a plurality of regenerating furnaces which are successively arranged from top to bottom, each regenerating furnace comprises an insulation sleeve, an annular graphite electrode and a central electrode, the central electrode is fixed at the center of the insulation sleeve, the annular graphite electrode is coaxially assembled in a cavity of the insulation sleeve, a conductive plate is embedded between the annular graphite electrode and the inner wall of the insulation sleeve, the outer wall of the central electrode is provided with threaded projections, the inner wall of the annular graphite electrode is correspondently provided with threaded projections, and an annular regenerating cavity is formed between the outer wall of the central electrode and the inner wall of the annular graphite electrode. By adopting an annular furnace body and the central electrode structure, the active carbon is uniformly heated; and by adopting a multi-sectional independent furnace body structure, the temperature requirement for the activation of the active carbon can be met.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

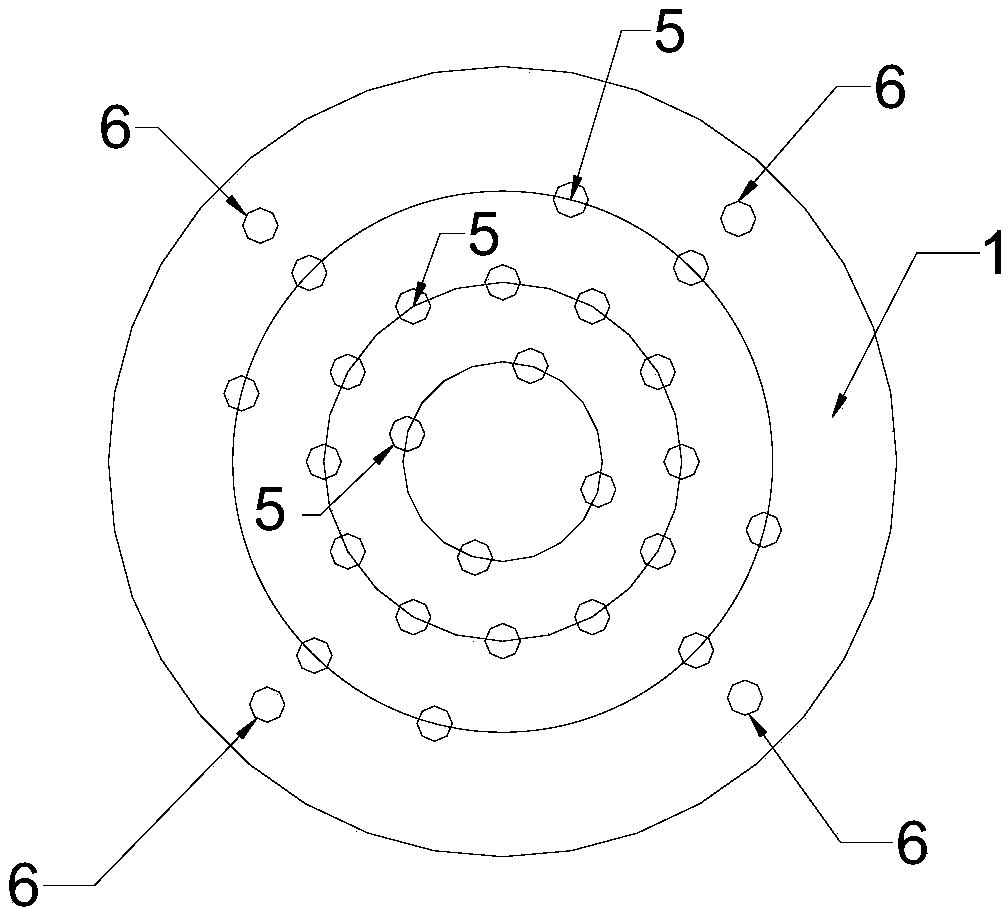

Polycrystalline silicon reducing furnace

InactiveCN108675304ASolve the problem of uneven reaction temperatureQuality improvementSilicon compoundsReaction temperatureEngineering

The invention discloses a polycrystalline silicon reducing furnace which comprises a chassis, an electrode arranged on the chassis and a bell jar arranged above the chassis, wherein silicon core rodsare mounted, in one-to-one correspondence, on the electrode; multiple bottom air inlet nozzles are formed in the chassis while multiple top air inlets are formed in the chassis; the top air inlets areconnected with top air inlet extension pipes; the top end of the top air inlet extension pipes are connected with top air inlet nozzles. According to the polycrystalline silicon reducing furnace disclosed by the invention, the chassis is directly connected to the top of the reducing furnace through a pipeline, then the problem of non-uniform reaction temperature in the reducing furnace is solved,an effect of balancing material distribution in the reducing furnace is realized, and the product quality is improved; meanwhile, additional workload on the furnace assembly / disassembly is avoided, and the disassembly is easy, convenient and practical.

Owner:SICHUAN YONGXIANG NEW ENERGY CO LTD

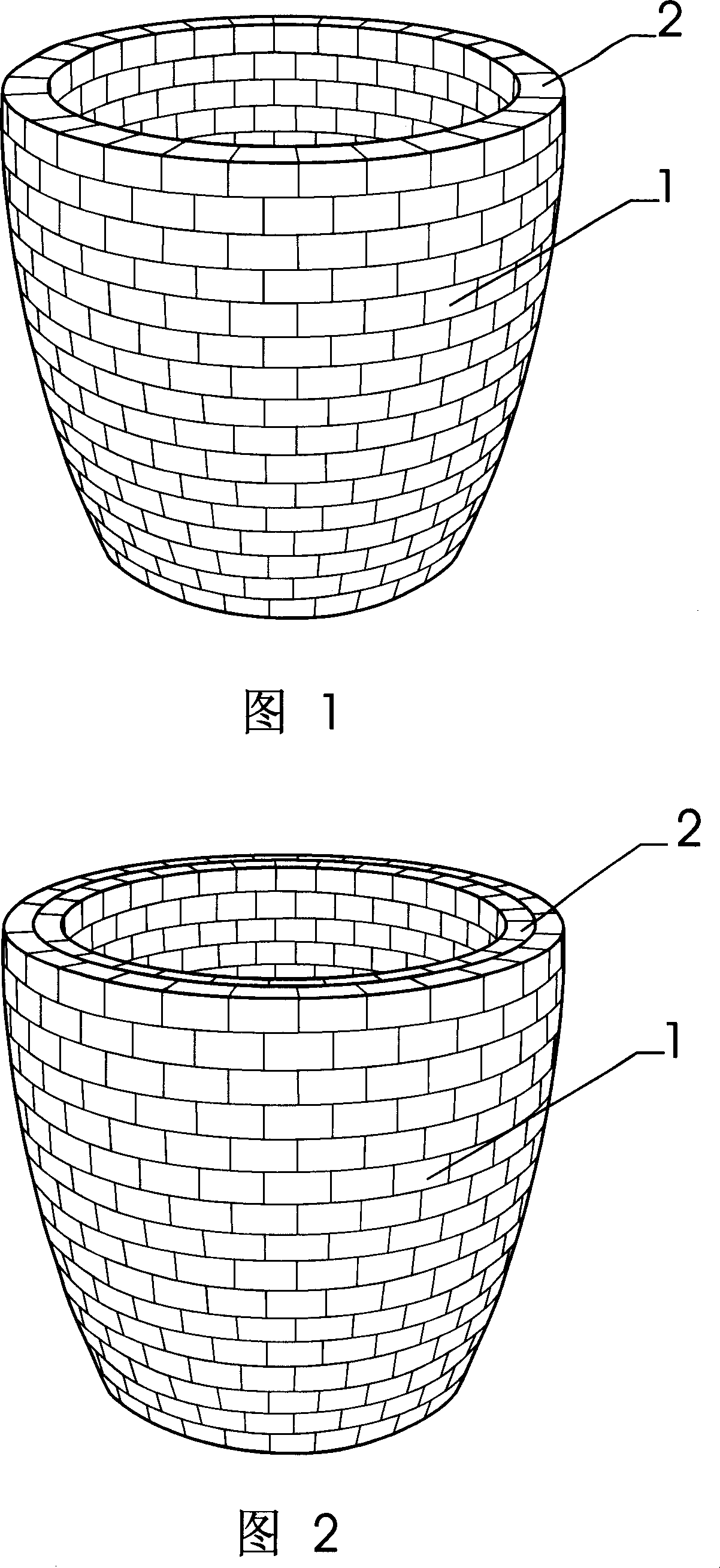

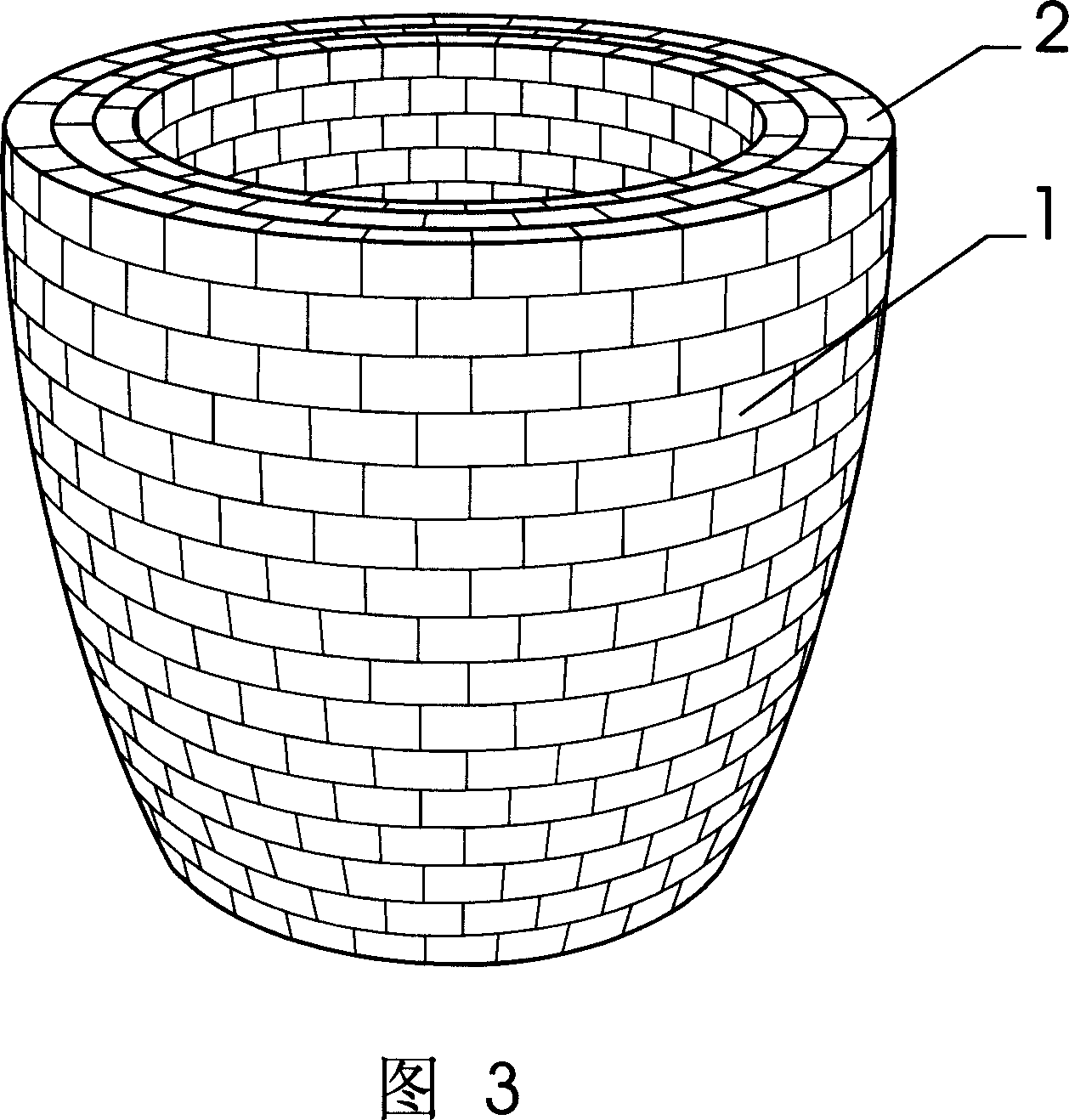

Combined pyrolytic boron nitride crucible lining

The invention relates to a combined pyrolytic boron nitride crucible lining, belonging to the titanium and titanium alloy melting crucible lining, especially the pyrolytic boron nitride crucible lining. Said crucible lining is cup shape piled by pyrolytic boron nitride brick, which can accommodate titanium and titanium alloy fluid. The crucible lining in invention can be installed in the shell with insulation, heat conservation and support performances and can satisfy demands in industrial production such as big cubage, low cost, easy maintenance and long service life. It is provided with mature producing process, simple equipment, stable performance, easy maintenance. When titanium and titanium alloy are melted, the crucible lining can not be bonded, and big melting pool can be formed in the crucible lining in favor of diffusing alloy element. Components of the alloy melted and cast is even and stable performance.

Owner:朱明 +1

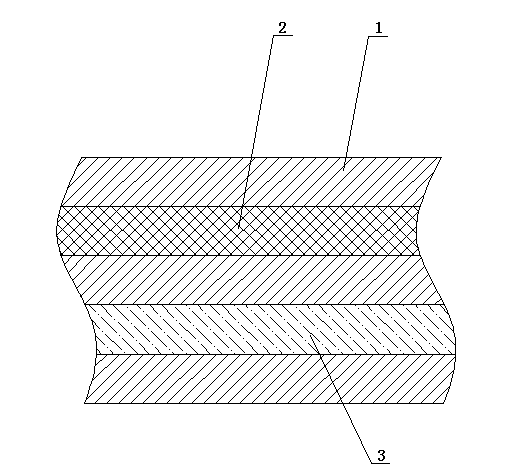

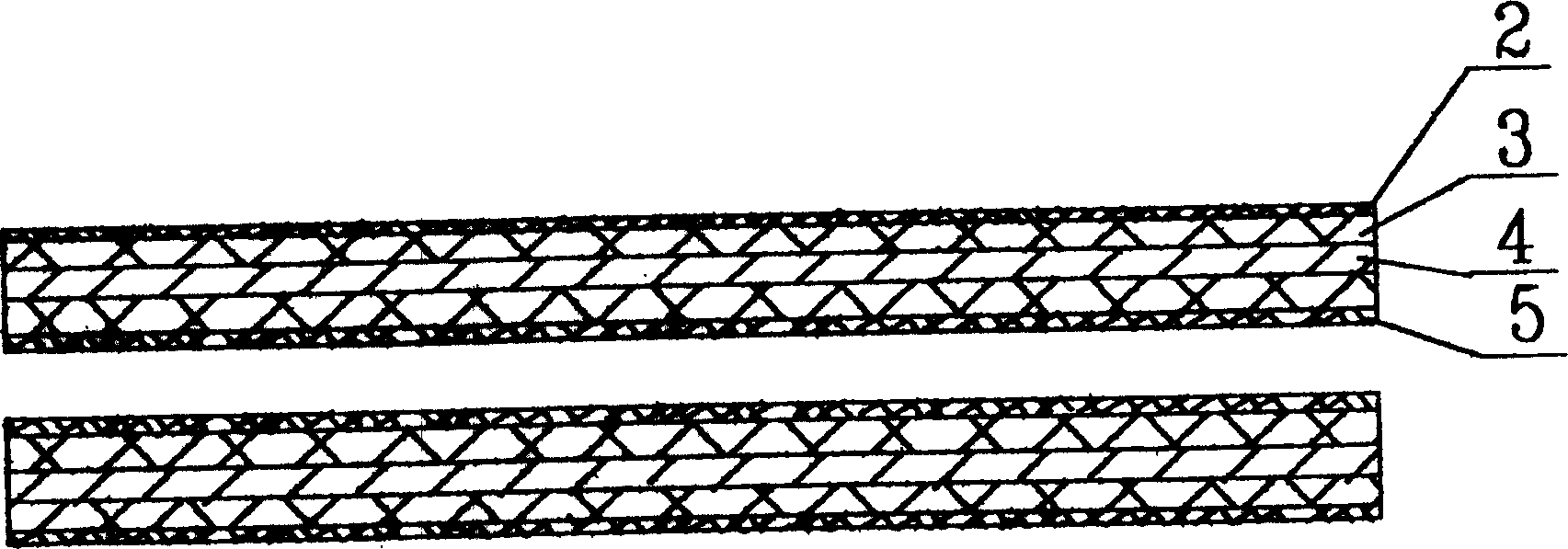

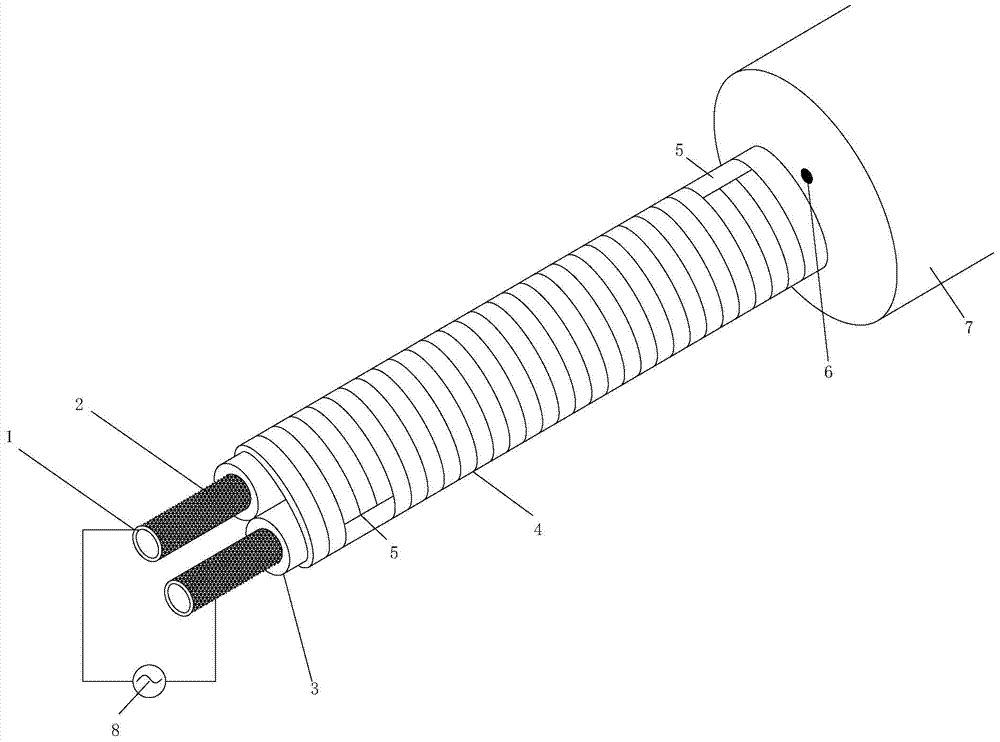

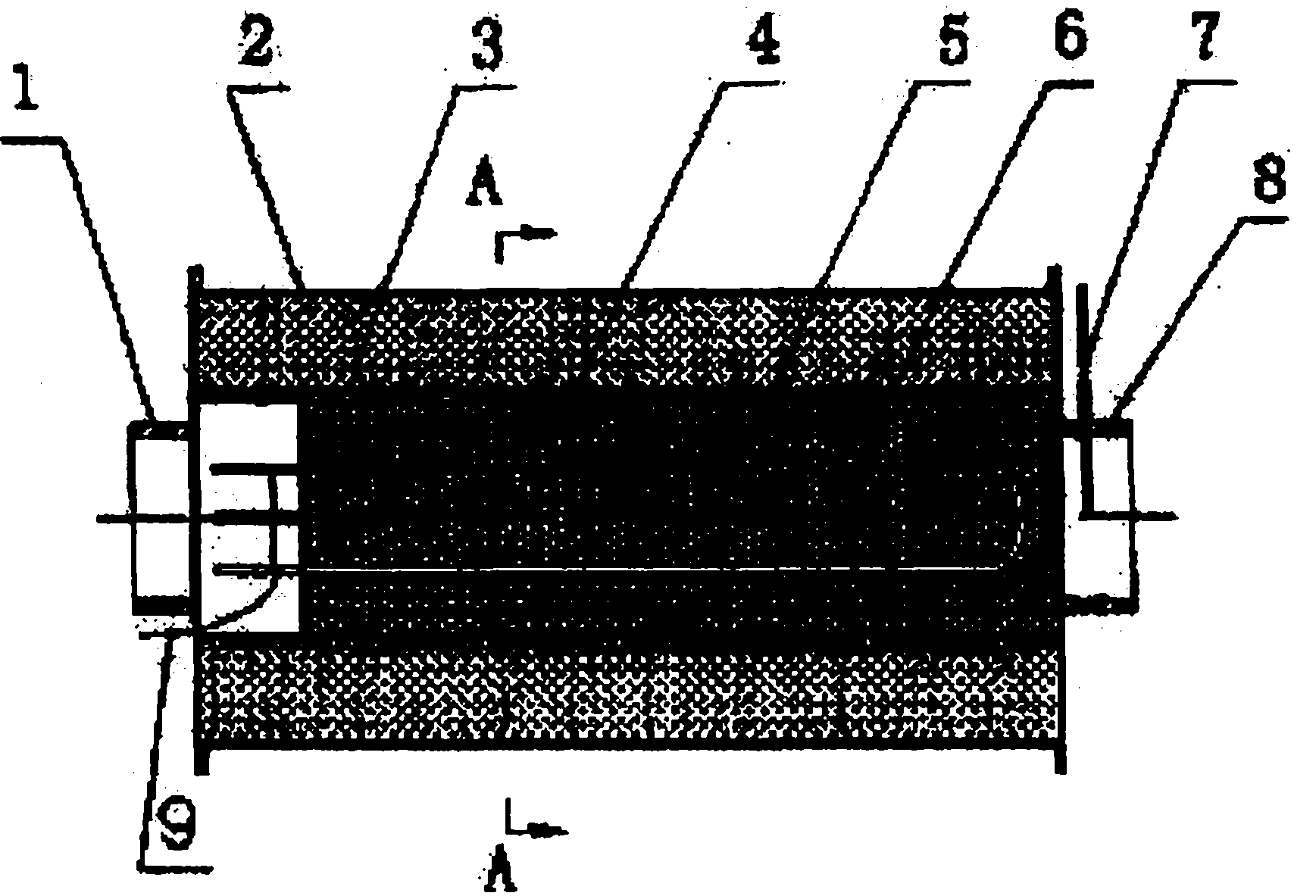

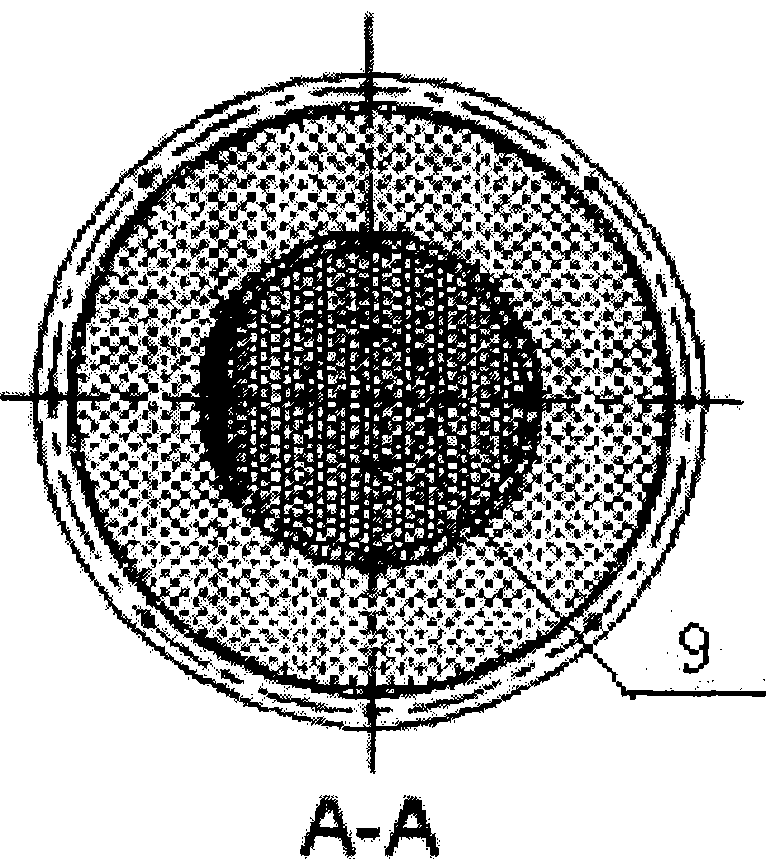

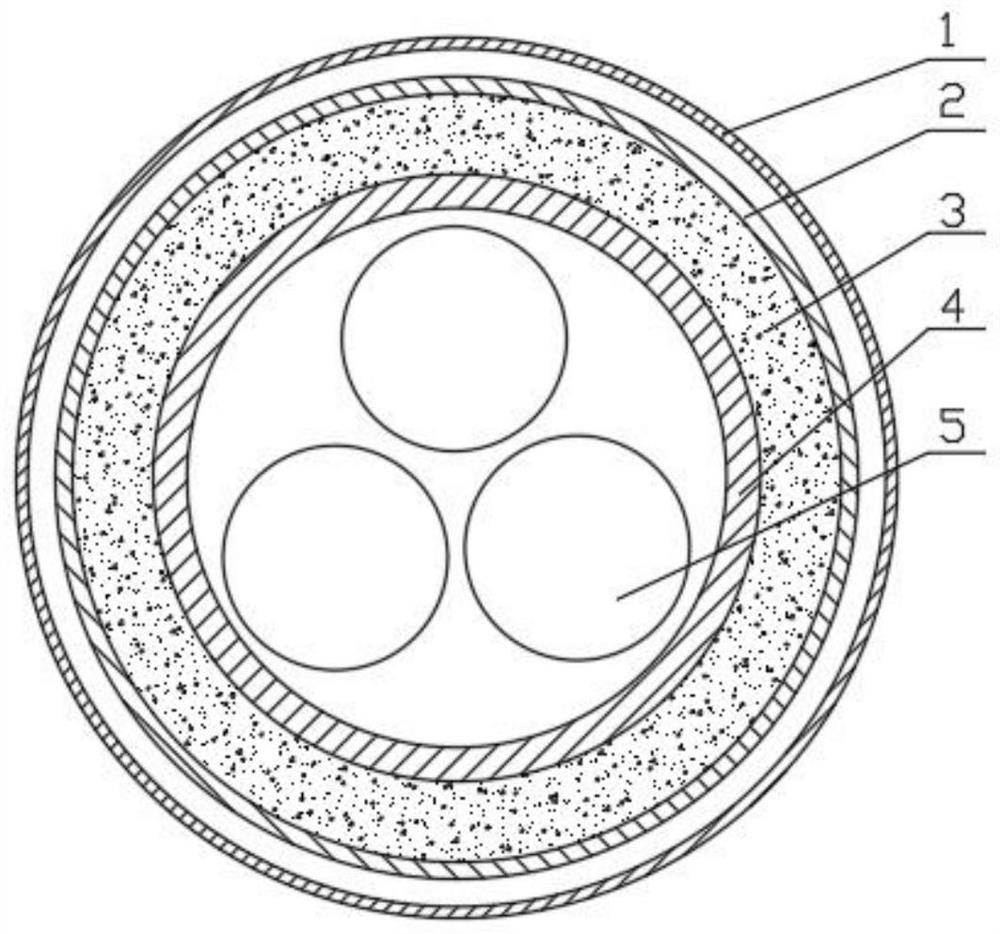

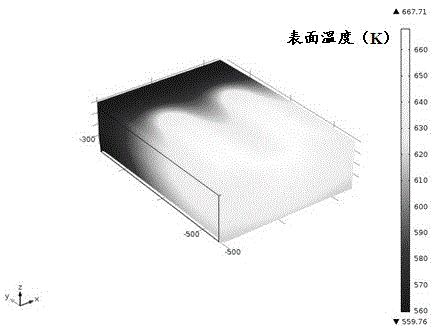

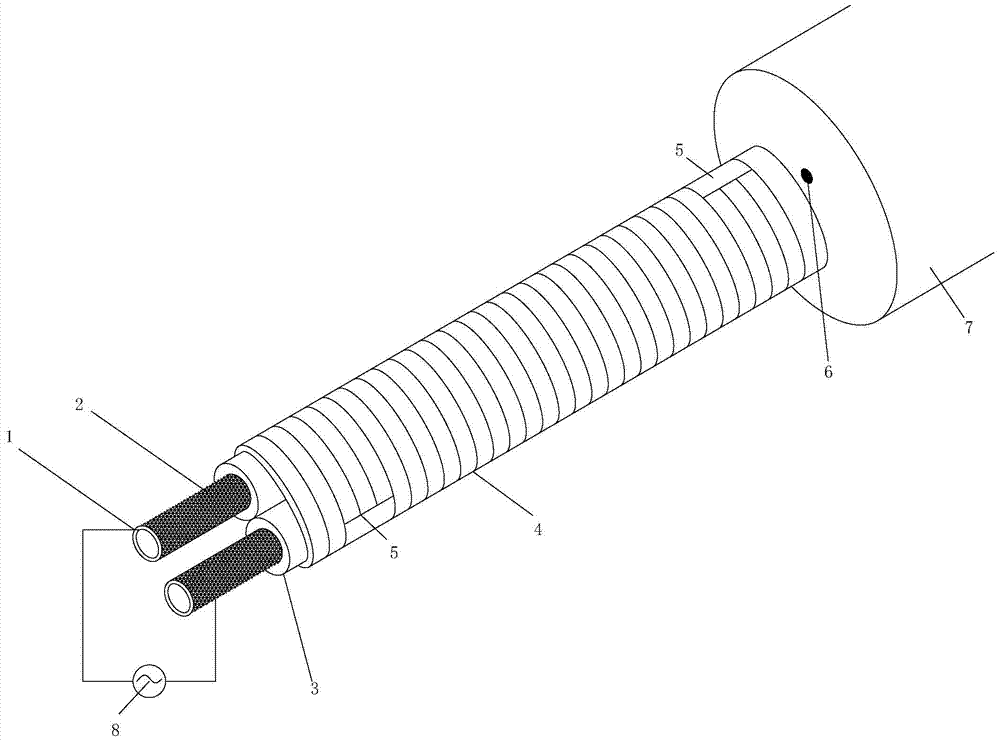

High-temperature flue gas sampling line with constant-power heating and tracing functions

ActiveCN104764630AHigh tensile strengthReduce loadWithdrawing sample devicesConstant powerWhole body

The invention relates to the technical field of sampling detection, in particular to a high-temperature flue gas sampling line with constant-power heating and tracing functions. The high-temperature flue gas sampling line comprises a plurality of sampling pipelines, wherein metal braid layers wrap the outer walls of the sampling pipelines; the metal braid layers on two sampling pipelines are respectively connected with a power supply; an insulating layer wraps the outside of each metal braid layer; all sampling pipelines are lapped into a whole body by a heater strip; the heater strip is respectively connected with the metal braid layers of the power supply; a heat-preservation layer also wraps the outer side of the heater strip; a temperature sensor is also arranged on the surface of the heater strip; and an insulating tape is arranged between the temperature sensor and the heater strip. The high-temperature flue gas sampling line is very even in thermal field, large in heated area and low in load of the heater strip, and can be applied to a high-temperature occasion at about 170 DEG C.

Owner:JIANGYIN HUILONG ELECTRIC HEATING APPLIANCE

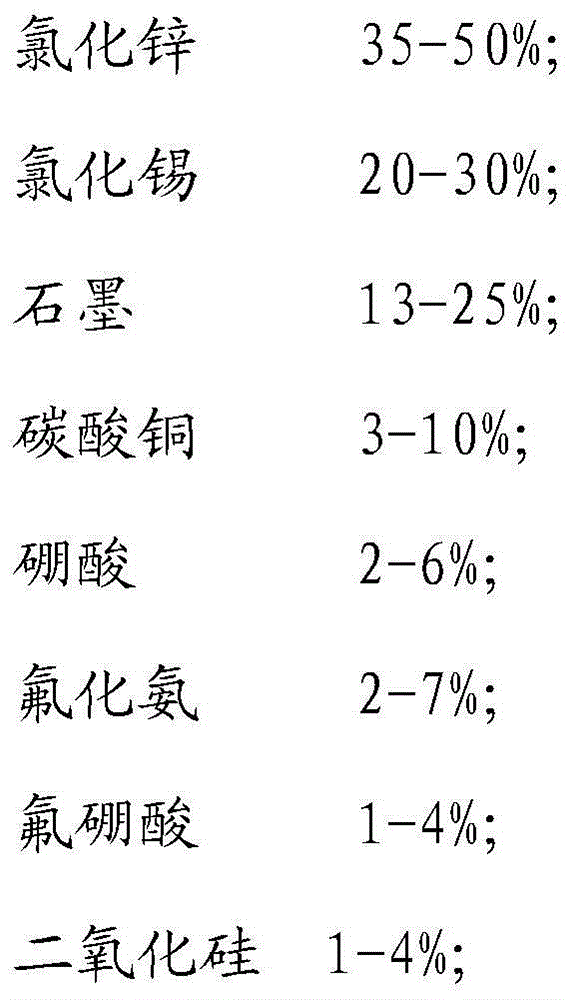

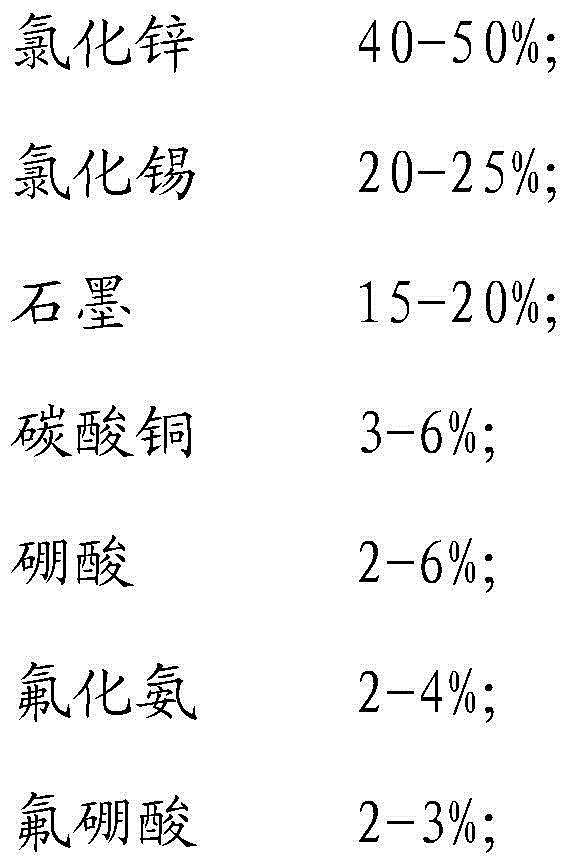

Electrothermal conversion body coating formula and application method

ActiveCN102843793BFast heatingUniform thermal fieldHeating element materialsPotassium dioxideFluoboric acid

The invention relates to an electrothermal conversion body coating formulation and an application method. The electrothermal conversion body coating formulation mainly comprises the following raw materials by weight percent: 35-50 percent of zinc chloride, 20-30 percent of tin chloride, 13-25 percent of graphite, 3-10 percent of copper carbonate, 2-6 percent of boric acid, 2-7 percent of ammonium fluoride, 1-4 percent of fluoboric acid and 1-4 percent of potassium dioxide silicon. The electrothermal conversion body coating formulation disclosed by the invention can be used for manufacturing various electrothermal conversion body heating elements on insulating materials in different shapes, such as silicon wafer electrothermal plates, mica electrothermal pieces, borosilicate glass electrothermal tubes, ceramic electrothermal tubes and the like, and can be widely applied to products and equipment, such as household appliances, industrial appliances and the like. The electrothermal conversion body coating formulation has the advantages of high electrothermal conversion rate, long service life, high heating power, low attenuation, simplicity in manufacturing and little pollution, and is suitable to be popularized and applied.

Owner:华夏万众创新(北京)科技有限公司

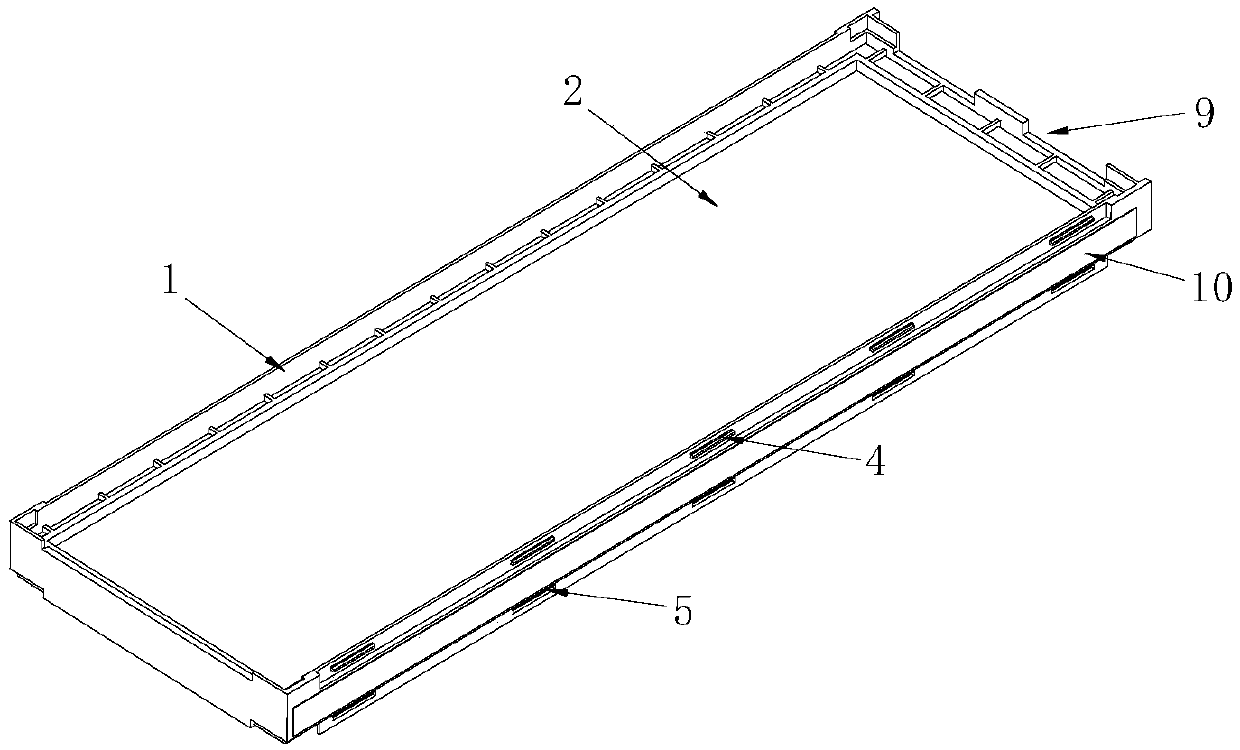

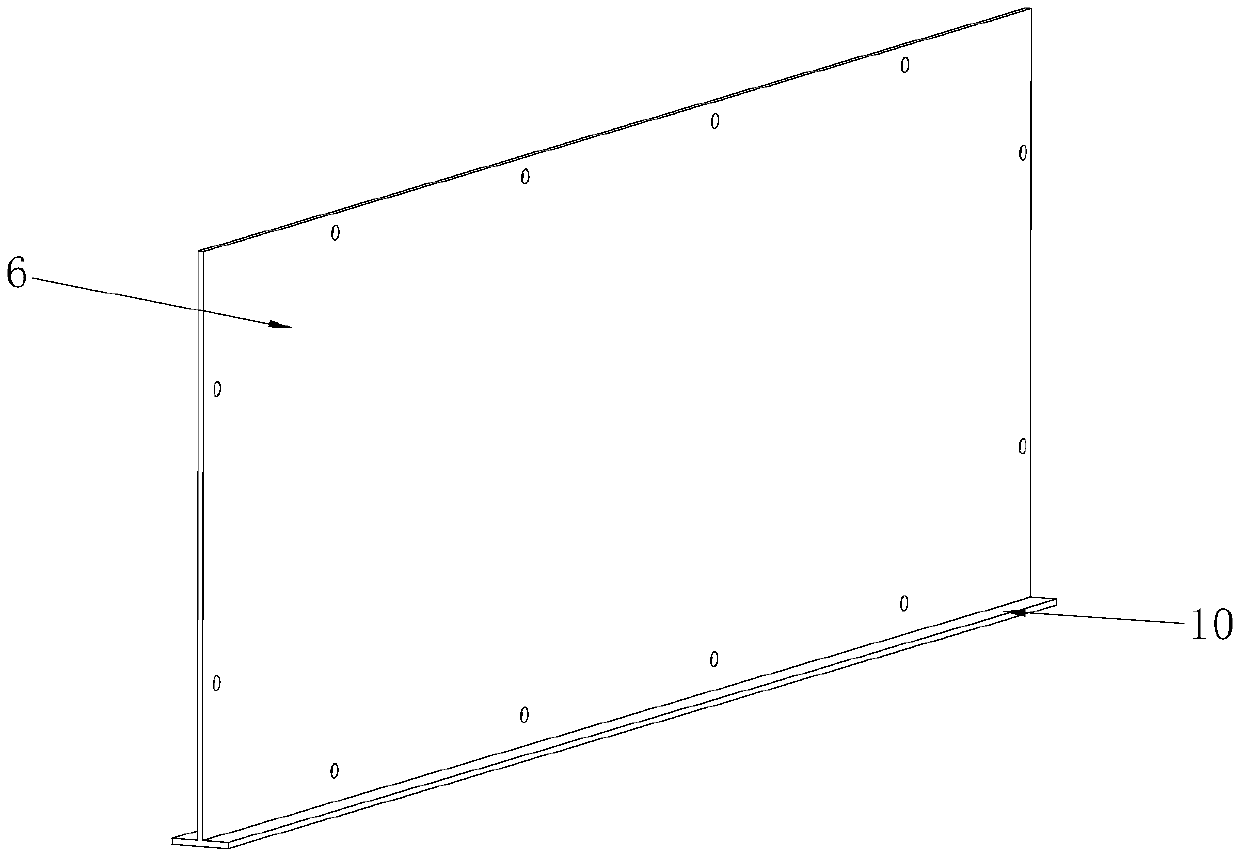

Preparation method of carbon/carbon hot-pressing mold for high-pressure hot-pressing sintering furnace

The invention discloses a preparation method of a carbon / carbon hot-pressing mold for a high-pressure hot-pressing sintering furnace, which comprises the following steps of: 1, presetting continuous carbon fibers along the radial direction of a hot-pressing mold paving layer, and paving the carbon fibers along the circumferential direction and the longitudinal direction to obtain a three-dimensional structure prefabricated body; 2, high-temperature pretreatment; 3, performing chemical vapor deposition to obtain a hot-pressing die blank; 4, dipping-carbonizing to obtain a compact hot-pressing die blank; 5, processing to a final size; and 6, dipping-carbonizing to obtain the carbon / carbon hot-pressing mold. The continuous carbon fibers are introduced in the radial direction in advance, then the circumferential carbon fibers and the longitudinal carbon fibers are laid, the damage effect of the radial carbon fibers is avoided, the circumferential carbon fibers and the longitudinal carbon fibers are kept complete and continuous, the reinforcing effect is achieved, the overall structural strength is improved, the radial heat conductivity coefficient of the carbon / carbon hot-pressing die is increased, and the service life of the carbon / carbon hot-pressing die is prolonged. Therefore, the carbon / carbon hot-pressing die is stable in structure, excellent in mechanical property, uniform in thermal field, long in service life and suitable for a high-pressure hot-pressing furnace.

Owner:XIAN CHAOMA SCI TECH

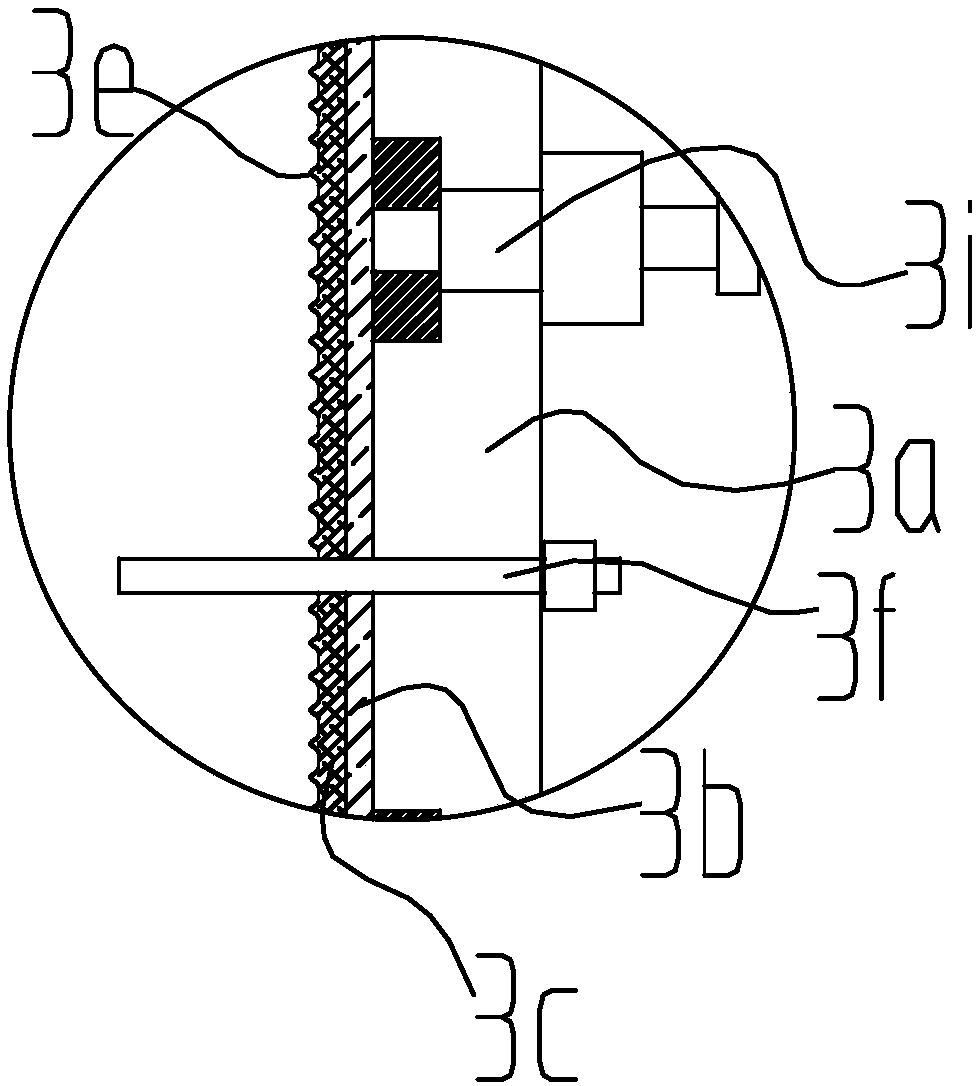

Three-phase magnetic latching relay

ActiveCN106920716AImprove motor flexibilityHigh movement reliabilityElectromagnetic relay detailsNon-polarised relaysEngineeringThree-phase

The invention discloses a three-phase magnetic latching relay which comprises a pushing clamp, an armature part, movable spring parts and a base, wherein the movable spring parts consist of an A-phase movable spring part, a B-phase movable spring part and a C-phase movable spring part; a pushing rod of the armature part is arranged between the B-phase movable spring part and the C-phase movable spring part; the pushing clamp is provided with a first clamp groove matched with the pushing rod of the armature part and three second clamp grooves respectively matched with the A-phase movable spring part, the B-phase movable spring part and the C-phase movable spring part; a head of the pushing rod of the armature part is completely suspended in the first clamp groove of the pushing clamp without limiting; and mutual limiting is arranged between the B-phase second clamp groove and the B-phase movable spring part and between the C-phase second clamp groove and the C-phase movable spring part in a width direction of the pushing clamp. According to the three-phase magnetic latching relay, a thermal field of a product can be equalized; temperature rise can be reduced; the motion flexibility and the reliability of a mechanism can be further improved; and powerful disjunction can be achieved during on-load operation of contacts.

Owner:XIAMEN HONGFA ELECTRIC POWER CONTROLS

Fast air heater

InactiveCN101403529BIncrease the heat exchange areaHigh electrothermal conversion efficiencyAir heatersMiddle linePressure reduction

The invention discloses a quick air heater, mechanical parts thereof adopt waterproof and high-temperature resistant materials, and a core heating part adopts electrothermal film heating pipes, thus achieving ultrahigh electrothermal transfer efficiency which is over 95 percent and ultra-quick response; the electrothermal film heating pipes are distributed in the form of an isoperimetric polygon,thus ensuring even air heating; the quick air heater takes the shape of a cylinder with two thinner ends and a thicker middle part integrally and consists of three parts which are an expanding section, a heating section and a shrinking section, the expanding section and the shrinking section are approximately completely symmetric relative to the midline of the heating section in structure; the design that the whole quick air heater is divided into three sections takes consideration that the electrothermal film heating pipes and adapter sleeves thereof need to be placed in the heating section and both parts occupy certain cross section areas. In order to reduce pressure reduction loss and optimally keep flow speed unchanged in a process that airflow passes through the heater, the core heating part of the heating section adopts the ultra-thin electrothermal film heating pipes, the axial direction of which is the same as the airflow direction, and the effective cross section area of highwet air that passes through the heating section is ensured to be approximately the same as the cross section area of the original pipe.

Owner:BEIHANG UNIV

PVT method raw material batch purification device and method

InactiveCN111809232AUniform heating and purificationUniform thermal fieldCrucible furnacesFrom condensed vaporsThermal insulationSingle crystal

The invention discloses a PVT method raw material batch purification device and method, and belongs to the field of PVT method preparation. The device comprises an induction coil, a furnace body, a heater and crucibles, wherein the induction coil is arranged on the outer wall of the furnace body, the heater is installed in the furnace body, the crucibles are arranged in the heater, and the purification method comprises the steps of loading the crucibles with the reaction raw materials; putting a plurality of crucibles filled with reaction raw materials into the heater; placing a thermal insulation material between the furnace body and the heater; vacuumizing the interior of the furnace body to 10E<-6> torr or below; heating the heater by the induction coil to 1300 DEG C; introducing Ar until the pressure is 100 to 500 torr; heating to a specified temperature in a range of 1700-2000 DEG C by the heater; maintaining for 10 to 30 hours and then cooling; taking out the crucibles in the step b, and putting the crucibles into a PVT method crystal growth furnace; starting crystal growth. The research and development aim is to solve the problem that the industrialization and large-scale production of single crystals are seriously influenced due to the fact that purification of raw materials of a PVT process needs a long growth period, the identity of raw material treatment can be better guaranteed, and a crystal growth process is optimized in a more targeted mode.

Owner:哈尔滨科友半导体产业装备与技术研究院有限公司

Heat dissipation optimizing structure for precise device in inertial navigation product

ActiveCN103687451AReduce thermal contact resistanceFacilitate conductionCooling/ventilation/heating modificationsEngineeringPerformance index

The invention provides a heat dissipation optimizing structure for a precise device in an inertial navigation product. The precise device is contained in an installation hole of a box body and a gap between the precise device and the box body is filled with a soft silica gel heat-conductive fin. One face of the soft silica gel heat-conductive fin makes tight contact with the surface of the precise device and the other face of the soft silica gel heat-conductive fin makes tight contact with the rear surface of a heat dissipation device fixedly connected with the box body. The soft silica gel heat-conductive fin is arranged in the gap between the precise device and the box body so that the air gap can be eliminated, thermal contact resistance between the precise device and the box body can be reduced, heat generated by the precise device can be rapidly conducted to the surface of the box body, a thermal field inside the product can be balanced rapidly, and influence on performance indexes of the precise device by the environment temperature can be reduced. Meanwhile, heat is dissipated in a conductive mode, a convective mode and a radiant mode, so that the heat dissipation effect is good, the reliability of the product is improved, the service life of the product is prolonged, the structure is easy to obtain, and the usability is high.

Owner:SHAANXI BAOCHENG AVIATION INSTR

Preparation method of high-density platinum-rhodium alloy ingot for TFT platinum channel

The invention relates to a preparation method of a high-density platinum-rhodium alloy ingot for a TFT platinum channel, and belongs to the technical field of metal materials. The platinum-rhodium alloy ingot with low porosity, no shrinkage porosity and high density is obtained by a smelting exhaust method of vacuuming, induction melting, deoxidizer adding, slowly solidifying, argon filling, vacuuming, induction melting and multiple cycles under the condition of only providing an ordinary mechanical pump. The preparation method effectively improves the density of a platinum-iridium product, thereby avoiding the uneven heating due to pores of the platinum-iridium product when the platinum-iridium product is electrified and heated.

Owner:英特派铂业股份有限公司

Electrothermal conversion body coating formula and application method

ActiveCN102843793AFast heatingUniform thermal fieldHeating element materialsPotassium dioxideFluoboric acid

The invention relates to an electrothermal conversion body coating formulation and an application method. The electrothermal conversion body coating formulation mainly comprises the following raw materials by weight percent: 35-50 percent of zinc chloride, 20-30 percent of tin chloride, 13-25 percent of graphite, 3-10 percent of copper carbonate, 2-6 percent of boric acid, 2-7 percent of ammonium fluoride, 1-4 percent of fluoboric acid and 1-4 percent of potassium dioxide silicon. The electrothermal conversion body coating formulation disclosed by the invention can be used for manufacturing various electrothermal conversion body heating elements on insulating materials in different shapes, such as silicon wafer electrothermal plates, mica electrothermal pieces, borosilicate glass electrothermal tubes, ceramic electrothermal tubes and the like, and can be widely applied to products and equipment, such as household appliances, industrial appliances and the like. The electrothermal conversion body coating formulation has the advantages of high electrothermal conversion rate, long service life, high heating power, low attenuation, simplicity in manufacturing and little pollution, and is suitable to be popularized and applied.

Owner:华夏万众创新(北京)科技有限公司

Method for growing indium phosphide single crystal by VGF method

ActiveCN113638048AVertically oriented crystallizationImprove pass ratePolycrystalline material growthFrom frozen solutionsDirected crystallizationCrucible

The invention belongs to the field of preparation of indium phosphide single crystals, and particularly discloses a method for growing indium phosphide single crystal by a VGF method. The method comprises the steps of putting raw materials into a crucible and assembling a single crystal growth furnace by adopting the VGF method, and carrying out high-temperature annealing treatment; raising the temperature of the melt, and setting a heating target value in a heating control program for heating and pressurizing; carrying out seed melting growth, setting a growth temperature, when the melting length of the seed crystal reaches 10-15mm and the rotating shoulder growth is carried out, enabling the position of the crucible to begin to descend with the descending speed being not greater than 2.5 mm / h, and automatically stopping the descending of the crucible position after the growth is finished; and conducting cooling and annealing, specifically, automatically conducting cooling and annealing after growth is finished, emptying air pressure in the furnace after the temperature is reduced to 350 DEG C, opening a furnace door after the temperature in the furnace is reduced to about 150 DEG C, and obtaining the single crystal. According to the invention, the pulling speed method is added, so that the thermal field of the indium phosphide single crystal in the growth process is more uniform, vertical orientation crystallization is more stable, more indium phosphide single crystals grow, and the qualified rate of the crystal is higher.

Owner:YUNNAN XINYAO SEMICON MATERIAL CO LTD

Structure of semiconductor heating component

InactiveCN104010390AReasonable designSimple structureOhmic-resistance heating detailsRubber ringSemiconductor

The invention discloses a structure of a semiconductor heating component. The structure comprises an upper heat dissipation unit, an upper insulating material base body, an insulating rubber ring, a lower insulating material base body, a lower heat dissipation unit and a fixing device. The insulating rubber ring is even in thickness. The upper insulating material base body is arranged above the insulating rubber ring. The lower insulating material base body is arranged below the insulating rubber ring. The upper heat dissipation unit is arranged above the upper insulating material base body. The lower heat dissipation unit is arranged below the lower insulating material base body. The corresponding position of the upper heat dissipation unit, the corresponding position of the upper insulating material base body, the corresponding position of the insulating rubber ring, the corresponding position of the lower insulating material base body and the corresponding position of the lower heat dissipation unit are provided with a through hole. Internal threads are arranged in the through hole and evenly distributed around the upper heat dissipation unit and the lower heat dissipation unit. The fixing device penetrates through the through hole so that the through hole can be fixed. The structure has the advantages of being simple in structure, efficient, capable of saving energy, long in service life, high in comfort level, rapid in heating, gentle in heat source, high in safety, healthy, environmentally friendly, capable of conducting low-temperature heat dissipation and capable of maintaining the humidity. The structure is mainly used for indoor heating.

Owner:梁卫兵

Preparation method of high-density platinum-rhodium alloy ingot for tft platinum channel

The invention relates to a preparation method of a high-density platinum-rhodium alloy ingot for a TFT platinum channel, and belongs to the technical field of metal materials. The platinum-rhodium alloy ingot with low porosity, no shrinkage porosity and high density is obtained by a smelting exhaust method of vacuuming, induction melting, deoxidizer adding, slowly solidifying, argon filling, vacuuming, induction melting and multiple cycles under the condition of only providing an ordinary mechanical pump. The preparation method effectively improves the density of a platinum-iridium product, thereby avoiding the uneven heating due to pores of the platinum-iridium product when the platinum-iridium product is electrified and heated.

Owner:英特派铂业股份有限公司

Semiconductor gas sensor

ActiveCN103698359BReduce power consumptionIncrease resistanceMaterial analysis by electric/magnetic meansElectrical resistance and conductanceEngineering

The invention discloses a semiconductor gas sensor, comprising a base, a heating electrode, and a signal sensing electrode, wherein the base comprises a surface; the heating electrode is arranged on the surface; the signal sensing electrode is arranged inside a heat field formed by the heating electrode; the heating electrode is insulated with the signal sensing electrode; the heating electrode comprises a primary heating section and a secondary heating section; the primary heating section is adjacent to the signal sensing electrode; the secondary heating section is relatively far away from the signal sensing electrode; the resistance of the main heating section is greater than that of the secondary heating section. By adopting the semiconductor gas sensor disclosed by the invention, more effective utilization of the heat generated by the heating electrode is ensured by setting the primary heating section near the signal sensing electrode in the heating electrode to have the resistance greater than that of the secondary heating section which is relatively far away from the signal sensing electrode, and the surface power loss is reduced. Thus, power consumption of the sensor is reduced.

Owner:SUZHOU NANOGRID TECH

High temperature flue gas sampling line with constant power heating and heat tracing function

The present invention relates to the technical field of sampling and detection, in particular to a high-temperature flue gas sampling line with constant power heating and heat tracing function. It includes several sampling pipes, the outer wall of the sampling pipes is wrapped with a metal braid, and the metal braids on the two sampling pipes are respectively connected to the power supply. Wrapped as a whole, the heating wires are respectively connected to the metal braiding layer connected to the power supply, the outer side of the heating wires is also wrapped with a thermal insulation layer, and the surface of the heating wires is also provided with a temperature sensor, between the temperature sensor and the heating wires Provided with insulating tape. The heat field of the invention is very uniform, the heating area is large, the load of the heating wire is very low, and it can be used in high temperature occasions of about 170 degrees.

Owner:JIANGYIN HUILONG ELECTRIC HEATING APPLIANCE

A vertical discharge activated carbon regeneration furnace

ActiveCN106040209BEvenly heatedReduce wearOther chemical processesCombustible gas purificationActivated carbonGraphite electrode

The invention discloses a vertical-type discharge active carbon regenerating furnace. The vertical-type discharge active carbon regenerating furnace comprises a stander, wherein the top end of the stander is provided with a feeding cabin, the bottom end of the stander is provided with a discharging cabin, a regenerating furnace group is arranged between the feeding cabin and the discharging cabin, the regenerating furnace group consists of a plurality of regenerating furnaces which are successively arranged from top to bottom, each regenerating furnace comprises an insulation sleeve, an annular graphite electrode and a central electrode, the central electrode is fixed at the center of the insulation sleeve, the annular graphite electrode is coaxially assembled in a cavity of the insulation sleeve, a conductive plate is embedded between the annular graphite electrode and the inner wall of the insulation sleeve, the outer wall of the central electrode is provided with threaded projections, the inner wall of the annular graphite electrode is correspondently provided with threaded projections, and an annular regenerating cavity is formed between the outer wall of the central electrode and the inner wall of the annular graphite electrode. By adopting an annular furnace body and the central electrode structure, the active carbon is uniformly heated; and by adopting a multi-sectional independent furnace body structure, the temperature requirement for the activation of the active carbon can be met.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

Multiple heat resources-electric warming magnesium smelting apparatus and process

The present invention relates to multiple heat source-electrothermal magnesium smelting apparatus and process. The magnesium smelting apparatus includes one vertical vacuum furnace with reactor, hot slag bin, furnace body heat isolator, feeding bin, one material, heater and electrodes inside the reactor; one magnesium crystallizer on the furnace; one cold slag bin blow the hot slag bin; and several vacuum valves. The present invention has high heating speed, high production efficiency, no pollution, high production adaptability, low labor strength, low production cost and high magnesium yield.

Owner:咸阳新能源材料产业技术研究院有限责任公司

Heat dissipation optimization structure for precision devices in inertial navigation products

ActiveCN103687451BReduce thermal contact resistanceFacilitate conductionCooling/ventilation/heating modificationsEngineeringUsability

The invention provides a heat dissipation optimizing structure for a precise device in an inertial navigation product. The precise device is contained in an installation hole of a box body and a gap between the precise device and the box body is filled with a soft silica gel heat-conductive fin. One face of the soft silica gel heat-conductive fin makes tight contact with the surface of the precise device and the other face of the soft silica gel heat-conductive fin makes tight contact with the rear surface of a heat dissipation device fixedly connected with the box body. The soft silica gel heat-conductive fin is arranged in the gap between the precise device and the box body so that the air gap can be eliminated, thermal contact resistance between the precise device and the box body can be reduced, heat generated by the precise device can be rapidly conducted to the surface of the box body, a thermal field inside the product can be balanced rapidly, and influence on performance indexes of the precise device by the environment temperature can be reduced. Meanwhile, heat is dissipated in a conductive mode, a convective mode and a radiant mode, so that the heat dissipation effect is good, the reliability of the product is improved, the service life of the product is prolonged, the structure is easy to obtain, and the usability is high.

Owner:SHAANXI BAOCHENG AVIATION INSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com