High-temperature flue gas sampling line with constant-power heating and tracing functions

A constant-power heating, high-temperature flue gas technology, applied in the sampling device and other directions, can solve the problems of easy damage, difficult use, uneven thermal field, etc., and achieve the effects of uniform thermal field, increased tensile strength, and large heating area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The embodiments listed in the present invention are only used to help understand the present invention, and should not be interpreted as limiting the protection scope of the present invention. For those of ordinary skill in the art, they can also Improvements and modifications are made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

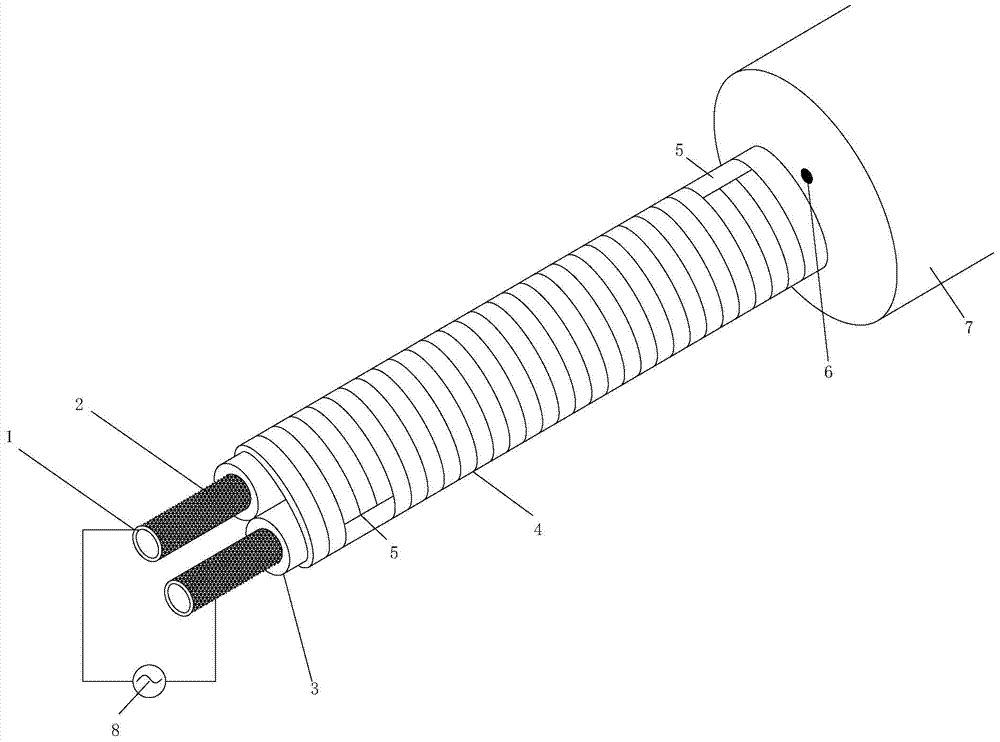

[0013] The present invention includes several sampling pipelines 1, as an embodiment of the present invention, as figure 1 As shown, there are two pipelines used. The outer wall of the sampling pipeline 1 is wrapped with a metal braiding layer 2, the metal braiding layer 2 is a nickel-plated copper wire braiding layer, and the metal braiding layer 2 on the two sampling pipelines 1 is respectively connected to a power supply 8, on the one hand as a heating wire bus bar; on the other hand, the tensile strength of pipeline 1 is increased. The me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com