PVT method raw material batch purification device and method

A purification method and raw material technology, which is applied in the field of PVT method raw material batch purification equipment, can solve the problems of long growth cycle, affecting single crystal industrialization and large-scale production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

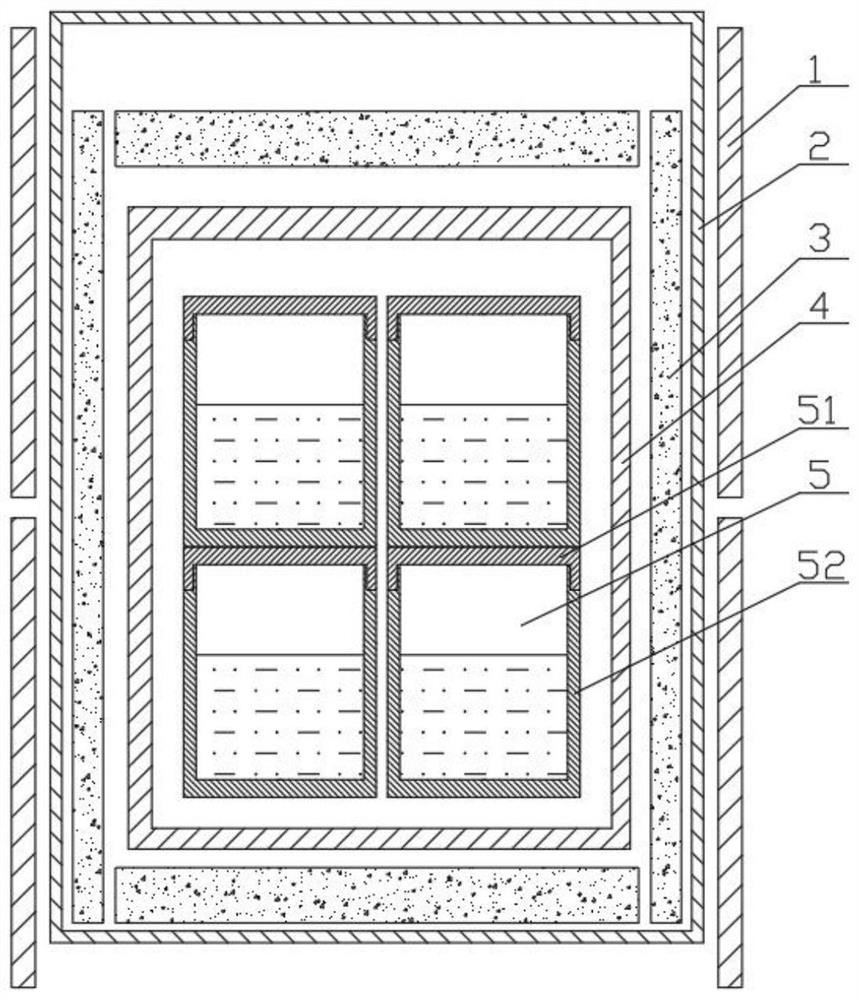

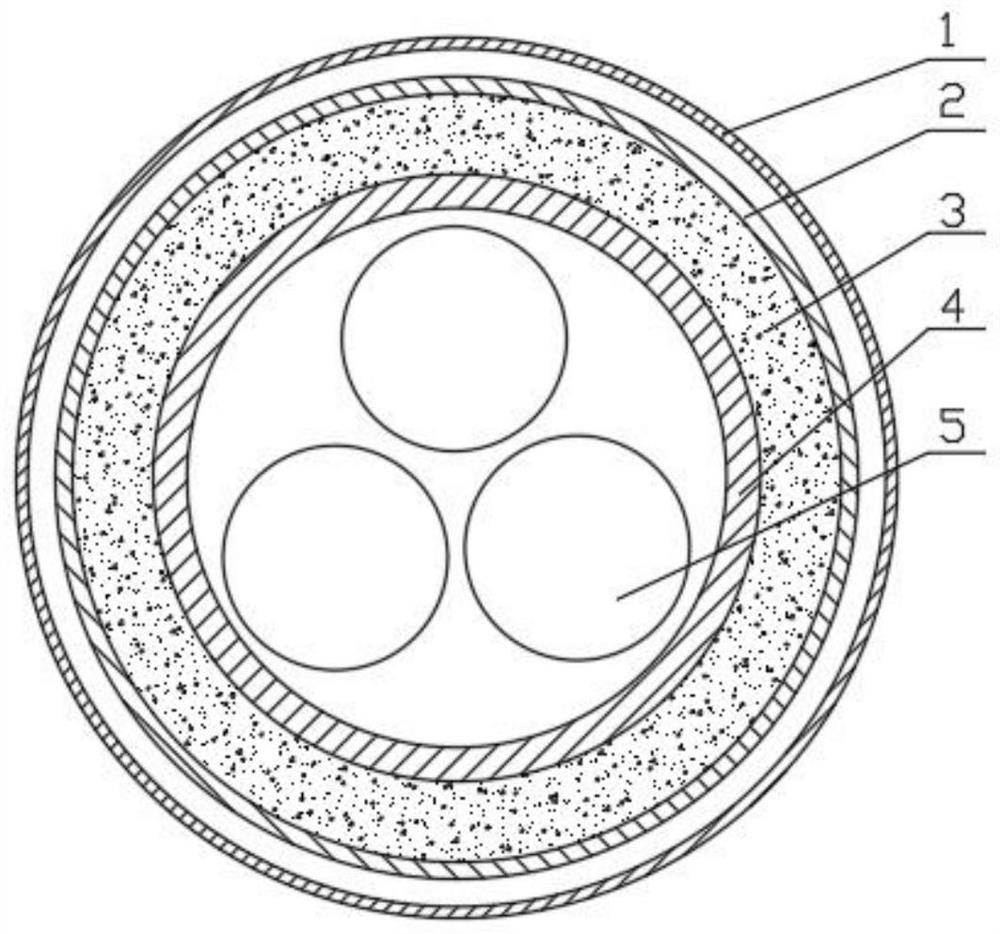

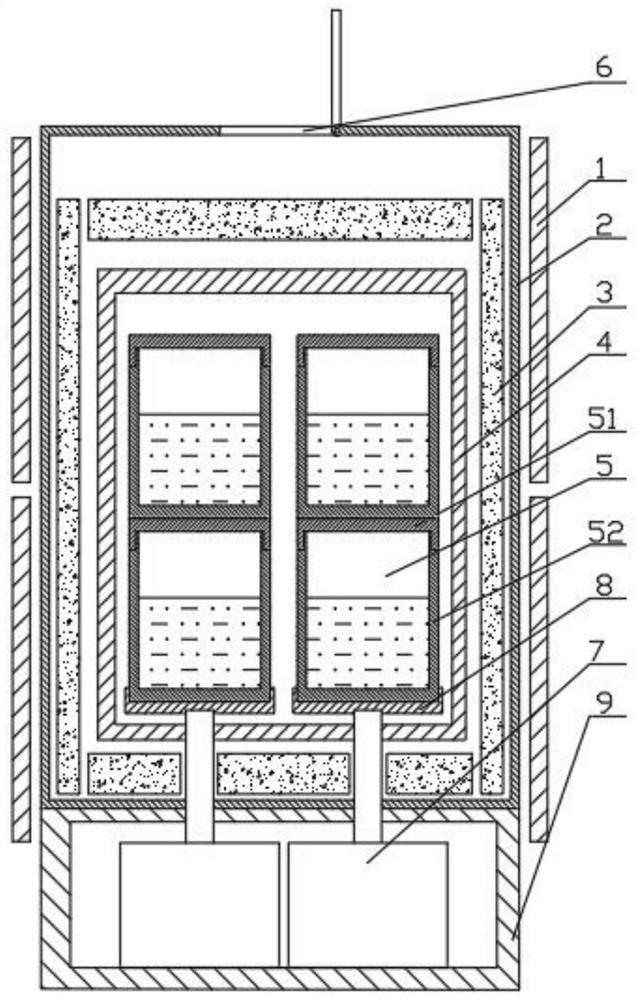

[0037] Specific implementation mode one: combine Figure 1-Figure 3 Describe this embodiment, a kind of PVT raw material batch purification device of this embodiment, comprise induction coil 1, furnace body 2, heater 4 and crucible 5, induction coil 1 is arranged on furnace body 2 outer walls, furnace body 2 is installed The heater 4 and the crucible 5 are arranged inside the heater 4, and the induction coil 1 is used for inductively heating the inside of the furnace body 2. The crucible 5 is arranged in an equilateral triangle in the horizontal direction inside the heater 4, and the triangular arrangement can make the inside of the crucible 5 more heated. Evenly, according to the aspect ratio of the furnace body, 2-3 layers of crucibles 5 can be placed, and the crucibles 5 are loaded with reaction raw materials.

specific Embodiment approach 2

[0038] Specific implementation mode two: combination Figure 1-Figure 3 Describe this embodiment, based on specific embodiment 1, a kind of PVT raw material batch purification device of this embodiment, the furnace body 2 is provided with a temperature measuring window 6, and the temperature measuring window 6 allows the light of the thermometer to pass through, which is convenient to use A pyrometer is used to monitor the temperature of the crucible lid.

specific Embodiment approach 3

[0039] Specific implementation mode three: combination Figure 1-Figure 3 Describe this embodiment, based on specific embodiment one, a kind of PVT method raw material batch purification device of this embodiment, described crucible 5 comprises upper cover 51 and crucible body 52, upper cover 51 is installed on the top of crucible body 52, upper cover 51 It is mounted on the crucible body 52 through threads or buckles.

[0040] Specific implementation mode four: combination Figure 1-Figure 3 Illustrate this embodiment, a kind of PVT raw material batch purification device of this embodiment, also comprise insulation material 3, be provided with insulation material 3 between described furnace body 2 and heater 4, heat insulation material 3 is to furnace body 2 interior To the heat preservation effect, making the device more energy-saving, green and environmentally friendly.

[0041] Specific implementation mode five: combination Figure 1-Figure 3 Describe this embodiment, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com