Heat dissipation optimization structure for precision devices in inertial navigation products

A technology of inertial navigation and structure optimization, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of precision device performance, life and reliability decrease, precision device surface and environment temperature rise, precision device performance, life reduction and other problems , to achieve the effect of rapid equilibrium of thermal field, improvement of working environment temperature, and improvement of temperature rise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

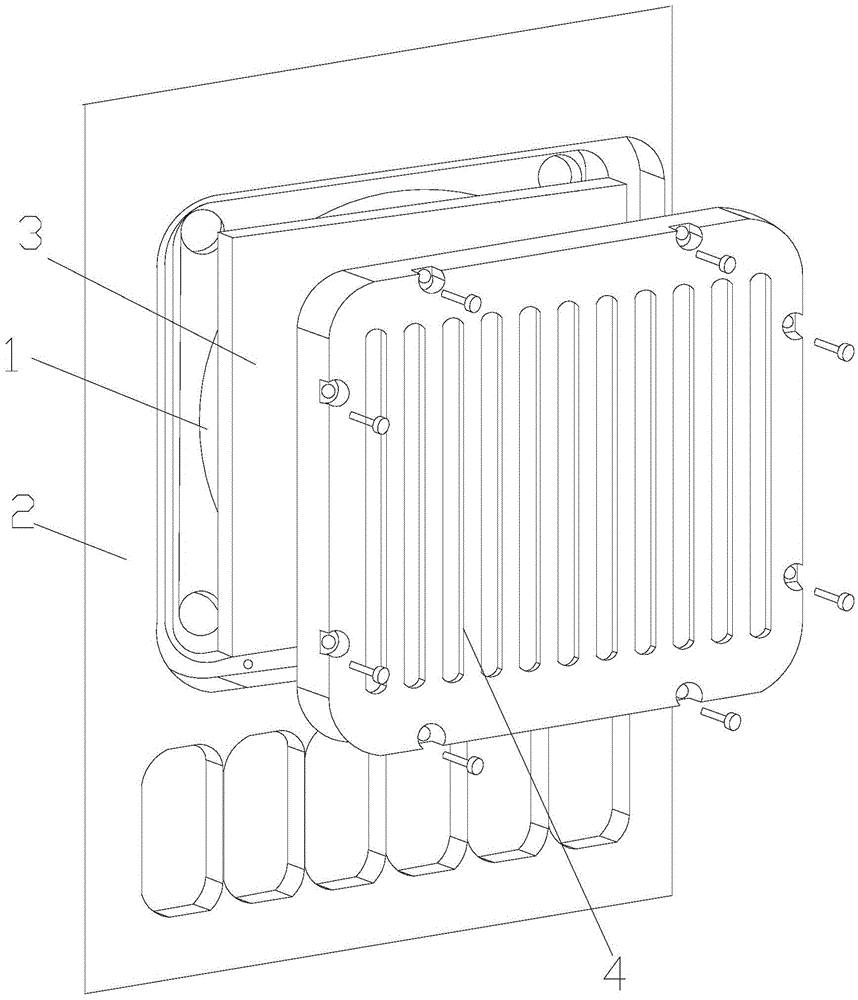

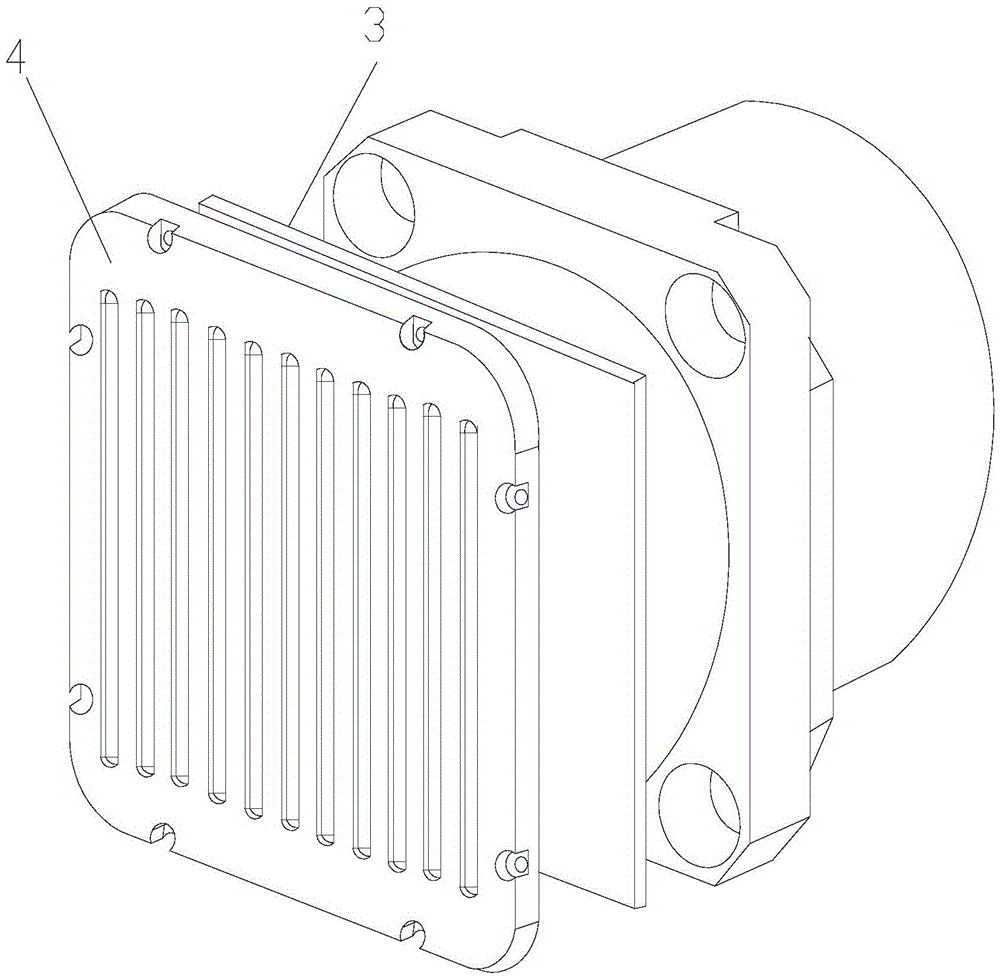

[0018] Attached below Figure 1-4 An embodiment of the present invention is described.

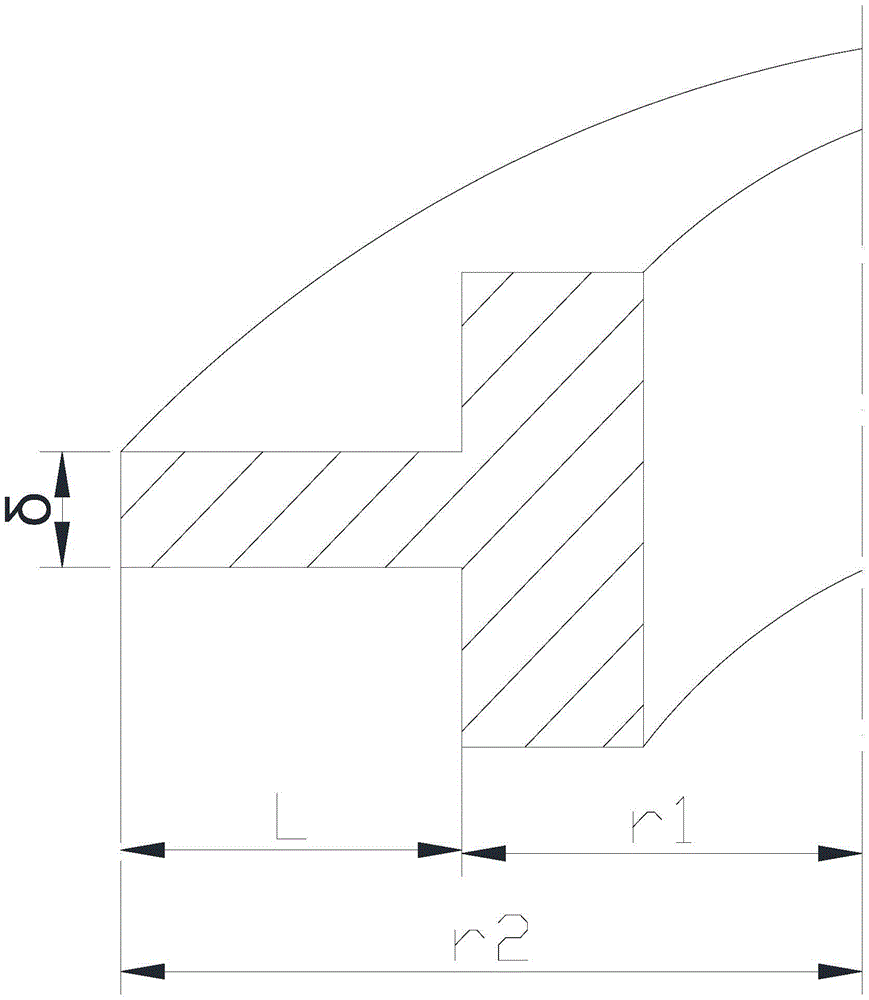

[0019] It is used for the heat dissipation optimization structure of precision devices in inertial navigation products. The precision device 1 is put into the installation hole of the box body 2 and the gap between the two is filled with a soft silicone heat conduction sheet 3. One side of the soft silicone heat conduction sheet 3 and the precision The surface of the device 1 is in close contact, and the other side of the soft silicone heat-conducting sheet 3 is in close contact with the rear surface of the heat sink 4 fixedly connected to the box body 2 . Specifically, the heat dissipation device 4 is a fin radiator, and the fin radiator is fixedly connected with the box body 2 as a whole through mounting screws, and the fin radiator is made of aluminum.

[0020] As we all know, the structure design of inertial navigation electronic products is a fully sealed structure. The internal heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com