Multiple heat resources-electric warming magnesium smelting apparatus and process

An electrothermal method and multi-heat source technology, applied in lighting and heating equipment, furnace types, furnaces, etc., can solve the problems of low heating thermal efficiency, low production efficiency, high production cost, etc., to reduce pollution, strong production adaptability, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

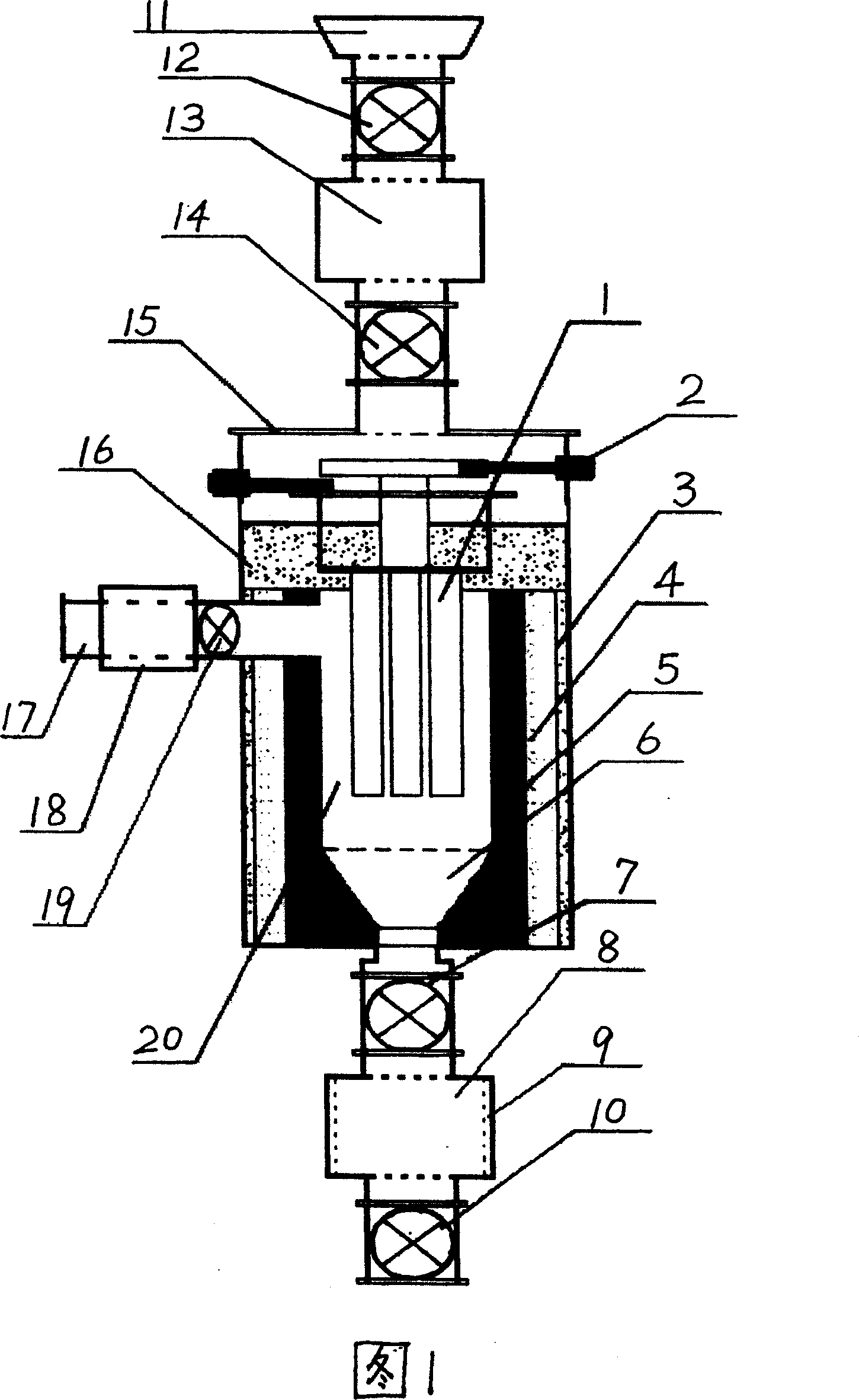

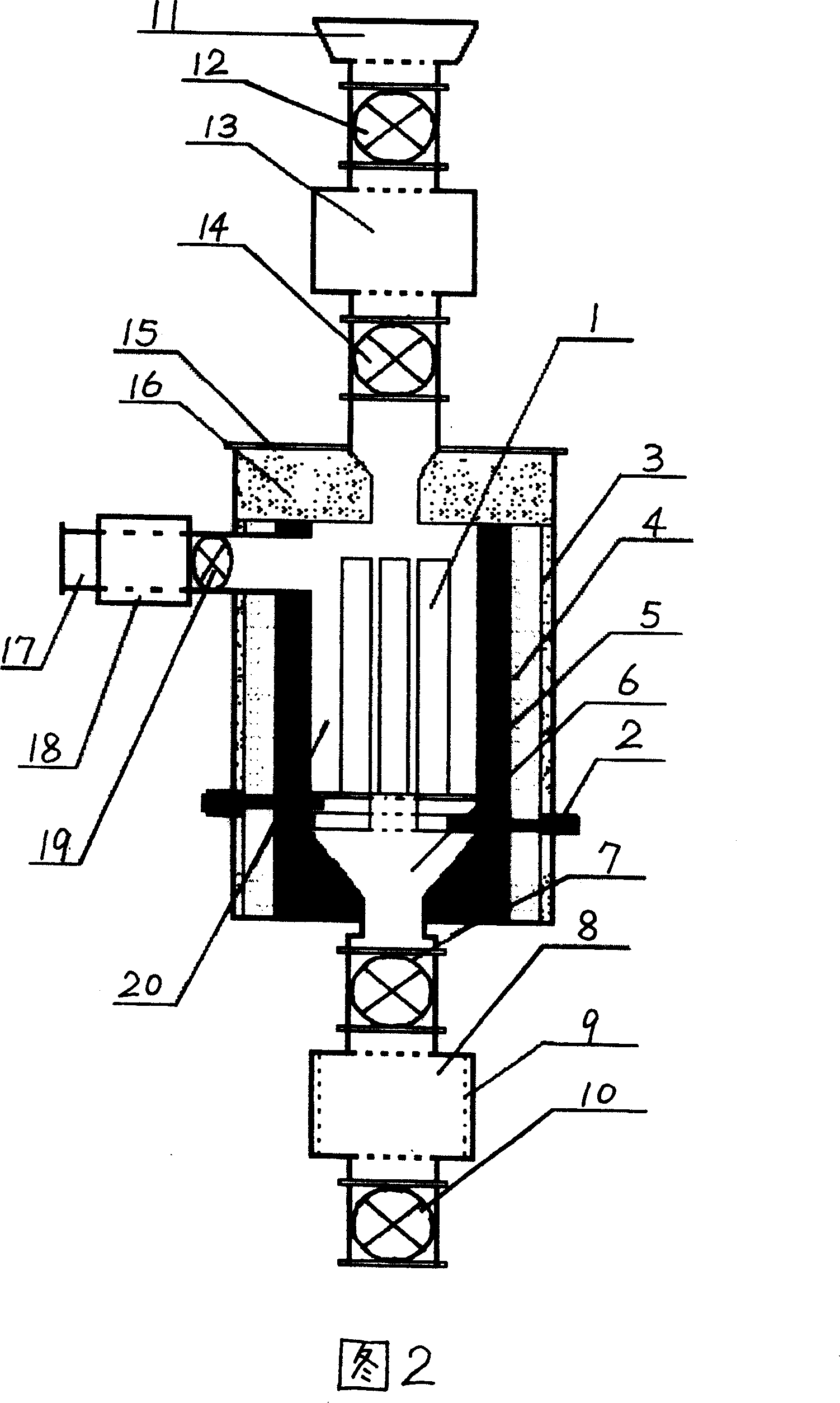

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] As shown in Figure 1, the multi-heat source-electrothermal method smelting magnesium device of the present invention adopts a circular vertical vacuum furnace body, which is mainly composed of a steel furnace shell 3, a refractory layer 5 and a thermal insulation layer 4 inner lining arranged in the furnace shell 3 , such as the combination of magnesia refractory material and insulation cotton. The furnace body is provided with a reaction bin 20 and a hot slag bin 6 which communicate with each other. The upper part of the furnace body is provided with a heat insulation layer 16 and a furnace cover 15. The upper part of the furnace body inlet is provided with a feed bin 11 and a storage bin 13. A primary feed vacuum valve 12 is installed between the bin 11 and the storage bin 13, a secondary feed vacuum valve 14 is installed between the storage bin 13 and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com