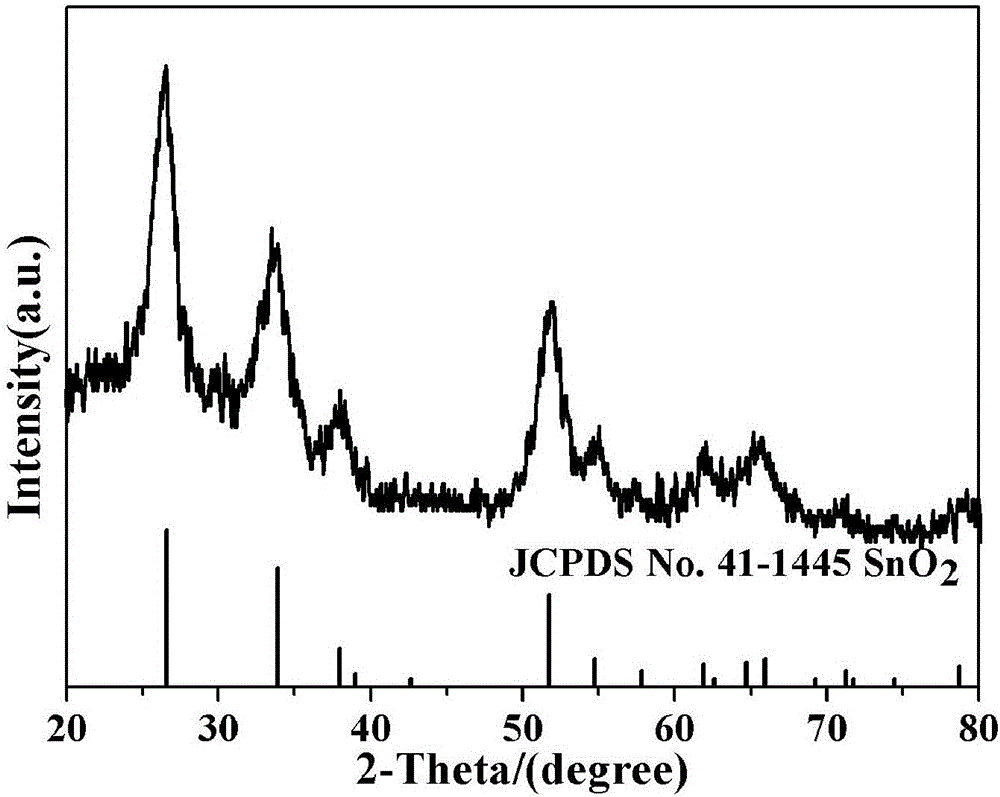

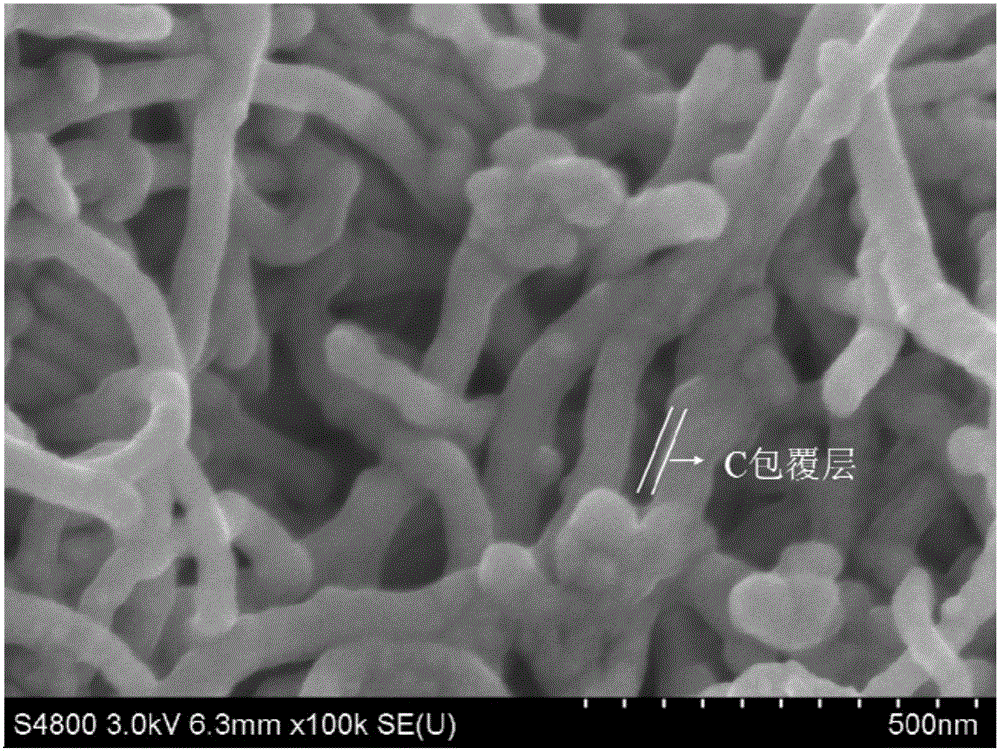

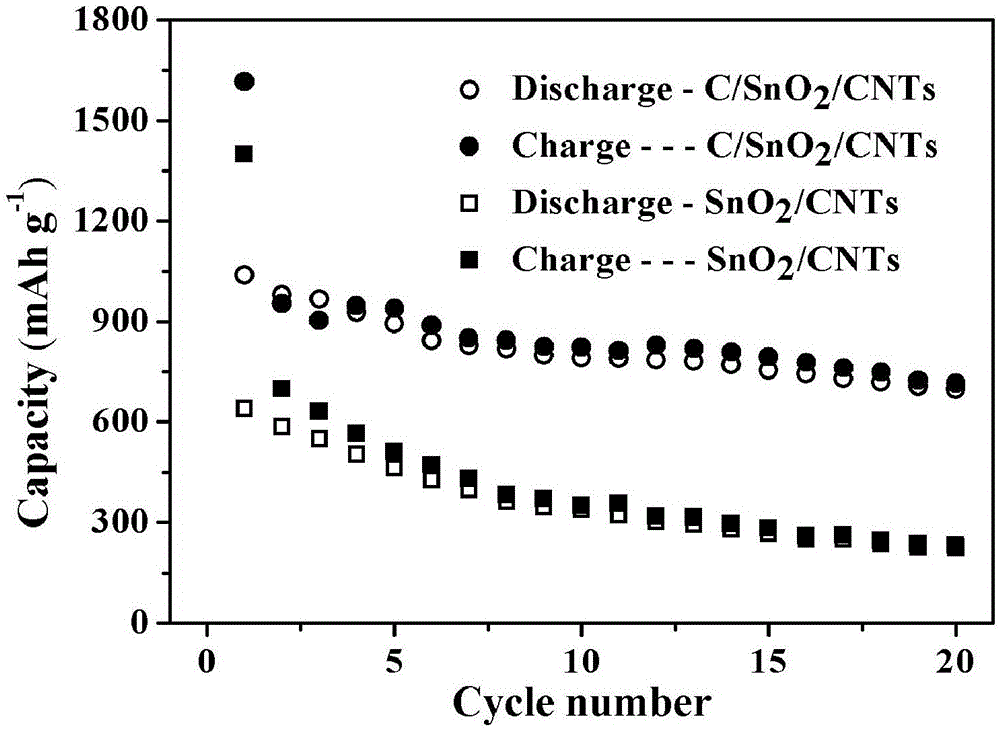

Preparation method of C/SnO2/CNT (carbon nano tube) composite material of core shell structure for lithium ion battery cathode

A lithium-ion battery, core-shell structure technology, applied in nanotechnology for materials and surface science, battery electrodes, secondary batteries, etc., can solve problems such as the volume expansion of SnO2, and achieve short cycle times and excellent morphology Uniformity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Evenly disperse 30 mg of carboxylated carbon nanotubes (CNTs) in 80 mL of deionized water to obtain solution A, the concentration of CNTs in solution A is 0.375 mg·mL -1 ; Add 0.6765 g SnCl to solution A 2 2H 2 O, stir evenly first, then ultrasonically treat (50W) at 40°C for 30min to obtain a uniformly dispersed solution B; then add 0.3g glucose to solution B, and stir to obtain solution C; wherein, the inner diameter of the carboxylated carbon nanotube 8-10nm, the outer diameter is 20-30nm, and the length is 10-30μm.

[0031] 2) Transfer solution C to a polytetrafluoroethylene hydrothermal kettle, control the volume filling ratio to 80%, seal the hydrothermal kettle and place it in a microwave hydrothermal reactor, and set the temperature at 10°C min -1The heating rate was increased to 150 ° C for 2 hours of hydrothermal reaction, after the reaction was completed, it was cooled to room temperature with the furnace, and then the C / SnO 2 / CNTs powder, washed three...

Embodiment 2

[0036] 1) Evenly disperse 50 mg of carboxylated carbon nanotubes (CNTs) in 80 mL of deionized water to obtain solution A, the concentration of CNTs in solution A is 0.625 mg·mL -1 ; Add 0.86 g SnCl to Solution A 4 , first stir evenly, and then obtain a uniformly dispersed solution B at 60° C. by ultrasonic treatment (80W) for 60 minutes; then add 0.5 g of glucose to solution B, and stir well to obtain solution C; wherein, the inner diameter of the carboxylated carbon nanotubes is 8-10nm, the outer diameter is 20-30nm, and the length is 10-30μm.

[0037] 2) Transfer solution C to a polytetrafluoroethylene hydrothermal kettle, control the volume filling ratio to 80%, seal the hydrothermal kettle and place it in a microwave hydrothermal reactor, and set the temperature at 10°C min -1 The heating rate was raised to 120°C for hydrothermal reaction for 5 hours. After the reaction was completed, it was cooled to room temperature with the furnace, and then the C / SnO 2 / CNTs powder, ...

Embodiment 3

[0039] 1) Evenly disperse 60 mg of carboxylated carbon nanotubes (CNTs) in 60 mL of deionized water to obtain solution A, the concentration of CNTs in solution A is 1 mg·mL -1 ; Add 1.353 g SnCl to Solution A 2 2H 2 O, stir evenly first, then ultrasonically treat (100W) at 50°C for 120min to obtain uniformly dispersed solution B; then add 0.2g fructose to solution B, and stir uniformly to obtain solution C; wherein, the inner diameter of the carboxylated carbon nanotube 8-10nm, the outer diameter is 20-30nm, and the length is 10-30μm.

[0040] 2) Transfer the solution C to a polytetrafluoroethylene hydrothermal kettle, control the volume filling ratio to 60%, seal the hydrothermal kettle and place it in a microwave hydrothermal reactor, and set the temperature at 10°C min -1 The heating rate was increased to 180 ° C for 2 hours of hydrothermal reaction, and after the reaction was completed, it was cooled to room temperature with the furnace, and then the C / SnO 2 / CNTs powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com