Fast air heater

A heater and air technology, applied in the direction of air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of inability to meet the heating requirements of high-humidity gas, low electrothermal conversion efficiency, and unfavorable rapid temperature rise, etc., to achieve high efficiency Energy-saving heat exchange area, high electrothermal conversion efficiency, good air tightness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

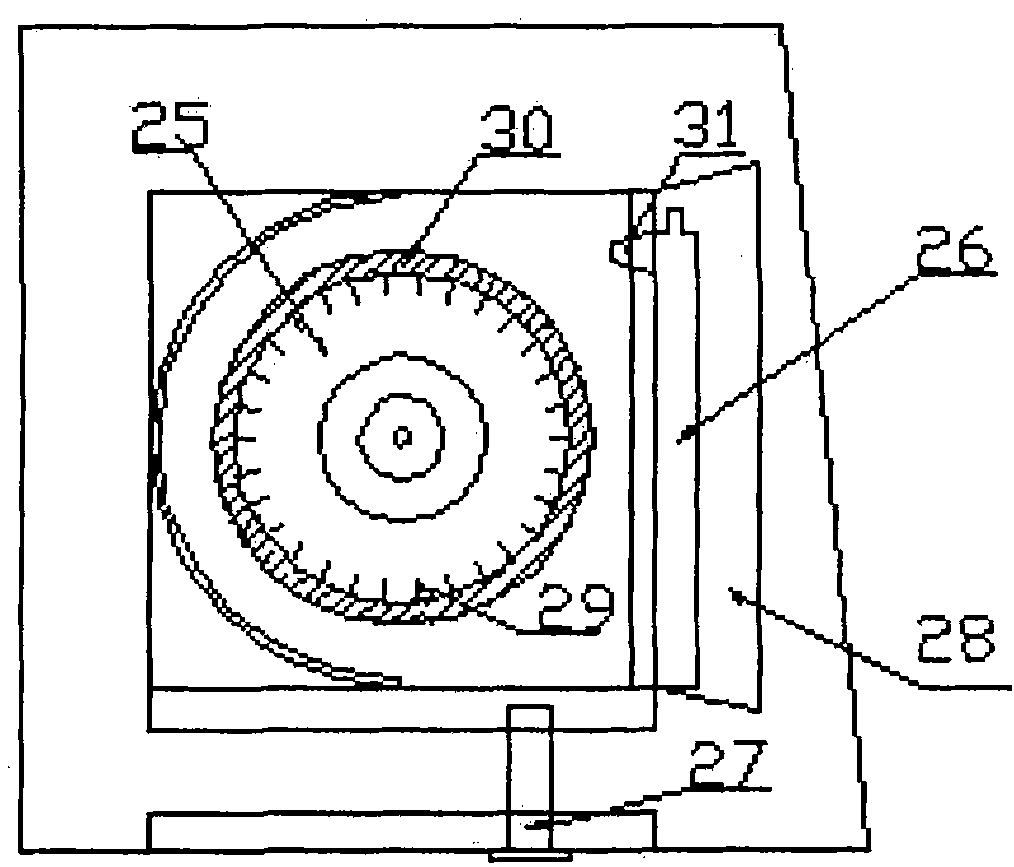

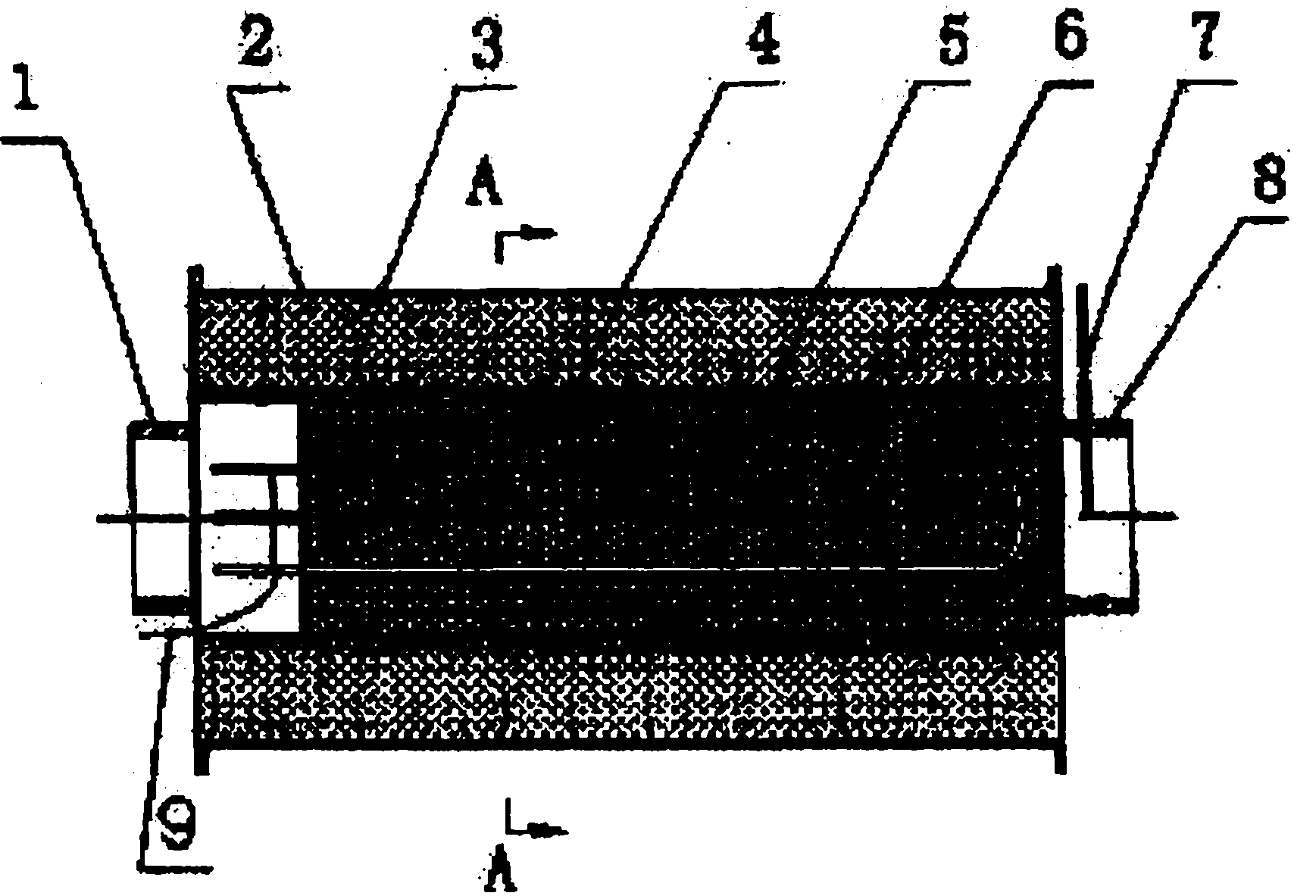

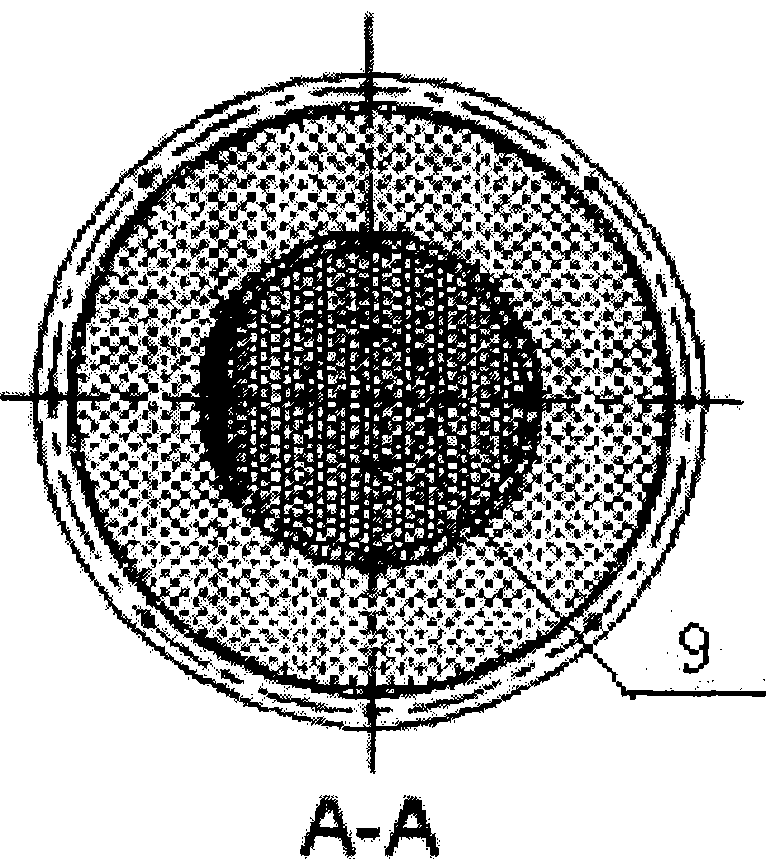

[0052] refer to Figure 4 , This embodiment is a rapid air heater with a wide humidity range. The left dotted line is the flaring section, the right dotted line is the closing section, the middle of the two dotted lines is the heating section, and the air flow direction is as follows: Image 6 . The flared section, the heating section, and the closing section are sealed and connected by a sealing ring and flange 41 (the specification is DN125-PN10 RF (series II) GB / T9119-2000). When the pressure difference between the inside and outside of the heater is ±130KPa, Air leakage rate at flange 41 connection ≤1×10 -6 cm 3 / s. The steel pipe used for the shell of the device is a low temperature resistant non-brittle nickel steel pipe containing more than 3.5% Ni. The inner liner of the heating section adopts ceramic tube 15, and the inner liner of the flaring section and the closing section adopts 250°C high-quality polytetrafluoroethylene material (hereinafter referred to as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com