Bracket for core module and solid state battery module structure

A battery module and battery module technology, applied to battery pack parts, secondary batteries, structural parts, etc., can solve problems such as difficulty in meeting market needs, volumetric energy density and volume density limitations, and improve thermal management Efficiency, enhanced heat transfer effect, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

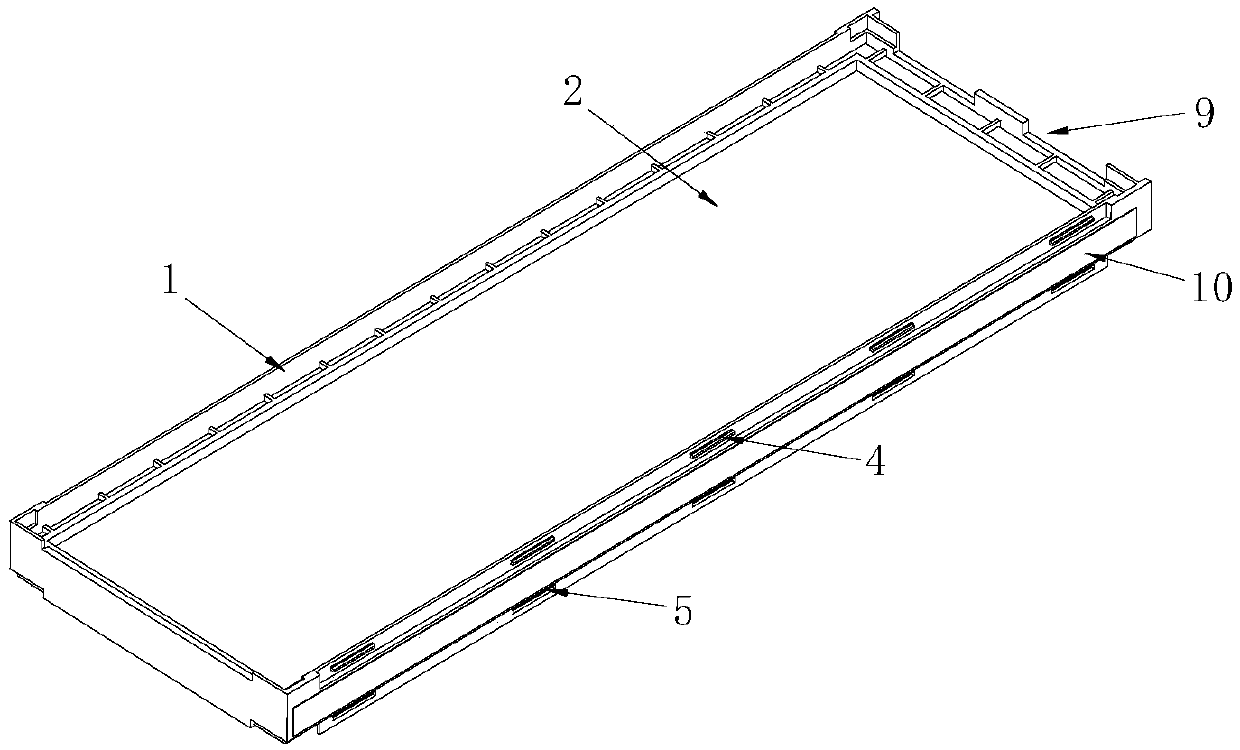

[0031] Such as Figure 1~5 The shown bracket for the cell module includes a frame body 1 made of plastic. The outer contour of the frame body 1 is rectangular, and a through hole 2 with a rectangular shape is formed in the middle of the frame body 1. The through hole 2 It runs through the entire frame body 1 along the thickness direction of the frame body 1 . The bottom of the frame main body 1 is provided with a cooling groove 3, and on both sides of the frame main body 1, a number of bracket buckles 4 and bracket snap holes 5 that can form mutual cooperation are provided on the bottom frame of the frame main body 1. 4 and bracket clamping holes 5 are respectively arranged on both sides of the heat sink 3 . In addition, a number of bracket buckles 4 and bracket buckle holes that can be formed to cooperate with each other are also arranged on the frame at the top of the frame body 1 .

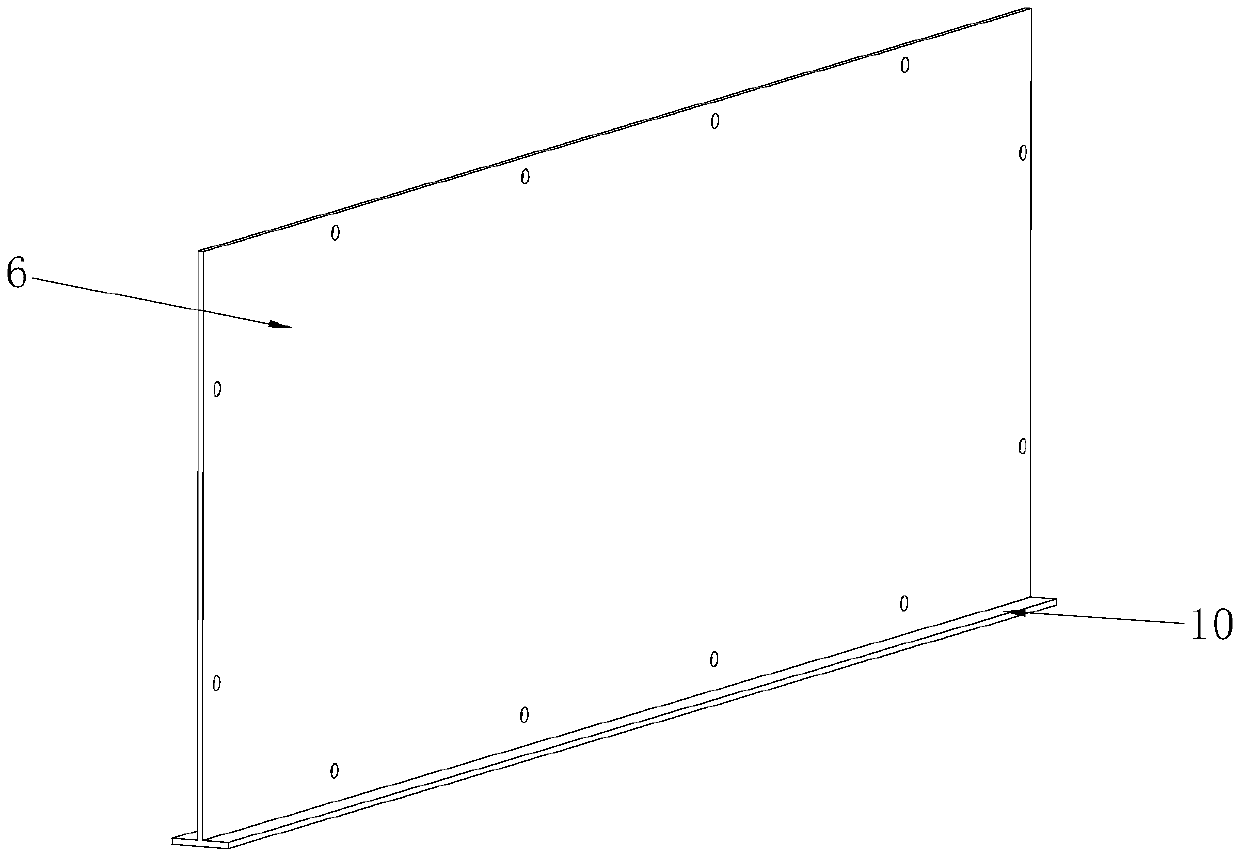

[0032] A heat dissipation aluminum sheet 6 as a heat dissipation fin is integrally formed...

Embodiment 2

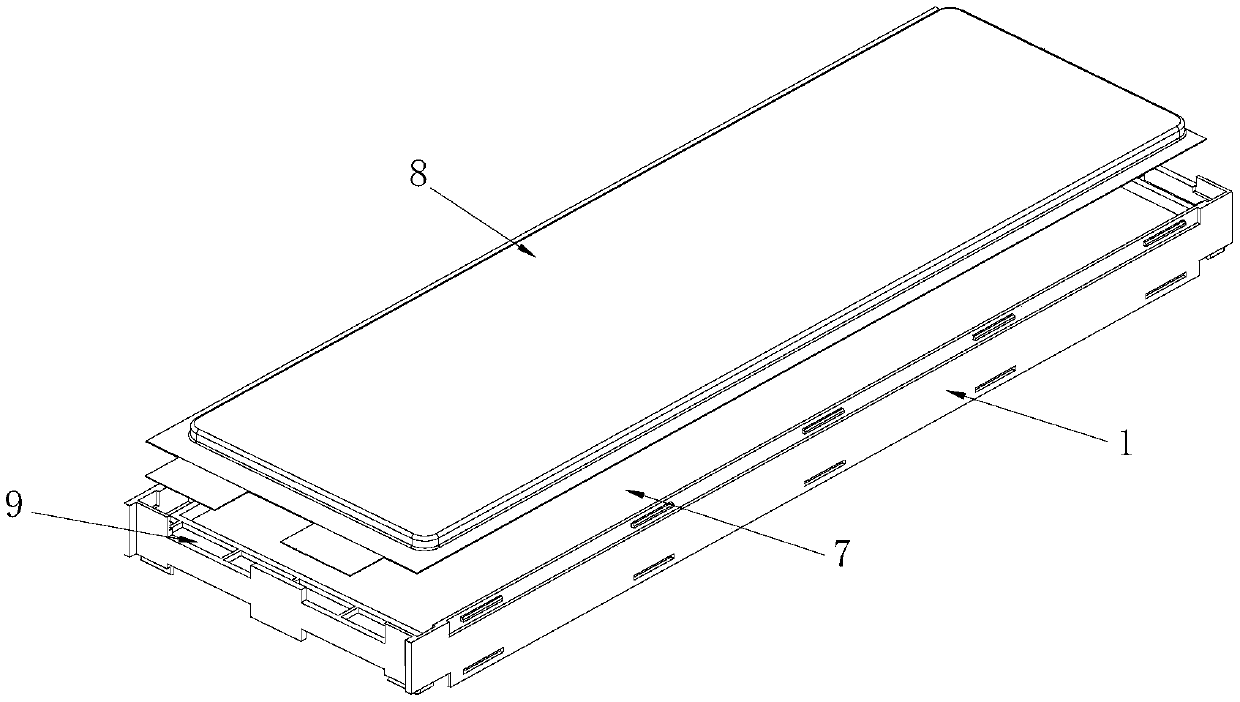

[0037] Such as Figure 6-8 The solid-state battery module structure shown includes an upper case 11 and a lower case 12. The upper case 11 and the lower case 12 are mutually covered to form a cavity in which several cell modules 13 are installed. The cell module body formed by splicing each other is provided with a thermally conductive rubber pad 14 between the lower case 12 and the battery module body. The cell module 13 includes a cell bracket 15, the cell bracket 15 is designed to use the bracket for the cell module in Embodiment 1, the bracket buckle 4 of the cell bracket 15 is connected to the bracket button hole of the adjacent cell bracket 15 In combination, multiple cell modules 13 can be spliced together. In the cell support 15 , the cell 8 is attached to the cell heat dissipation area 7 , and the heat dissipation rib portion 10 is attached to the rubber pad 14 . On both sides of the cell module body, side brackets 16 are installed on the cell module body to fix t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com