Mica electro-thermal film

A technology of electric heating film and mica, which is applied in the direction of electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of low heat conversion efficiency, not conforming to low-carbon environmental protection, and not suitable for long-term use, etc., to achieve comprehensive heating effect and excellent electrical performance Excellent, strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

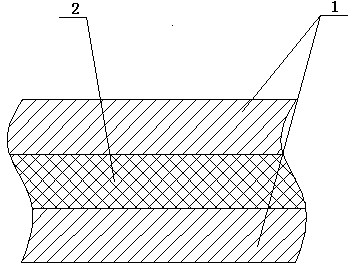

[0025] Such as figure 1 As shown, Embodiment 1 provides a mica electrothermal film, which is a composite three-layer structure, with an alloy foil 2 etched with a heating circuit in the middle, and a mica substrate 1 on both sides of the heating element. The mica substrate 1 is 0.3mm thick mica laminated paper. The alloy foil 2 and the mica substrate 1 are uniformly coated with a high-temperature adhesive and pressed through a high-temperature pressing process to obtain a mica electric heating film. The mica electric heating film of this structure uses the heat transfer method of hot air convection.

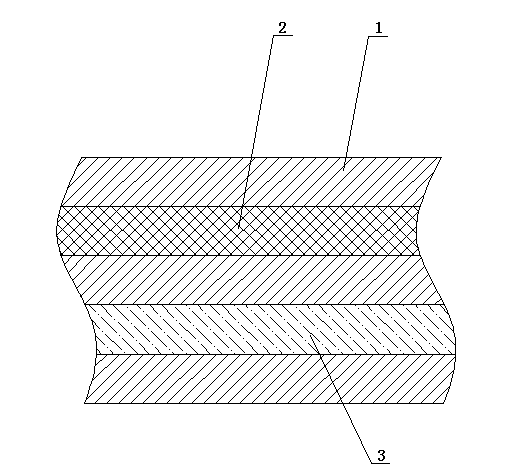

[0026] Such as figure 2 As shown, Embodiment 2 provides a mica electrothermal film, the electrothermal film is a composite five-layer structure, followed by mica substrate 1, alloy foil 2, mica substrate 1, aluminum foil 2, mica substrate 1, the mica s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com