Electrothermal conversion body coating formula and application method

An electrothermal conversion and coating technology, applied in the direction of heating element materials, etc., can solve the problems of operators and environmental pollution, and achieve the effects of strong adaptability to current and voltage changes, rapid temperature rise, and uniform thermal field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

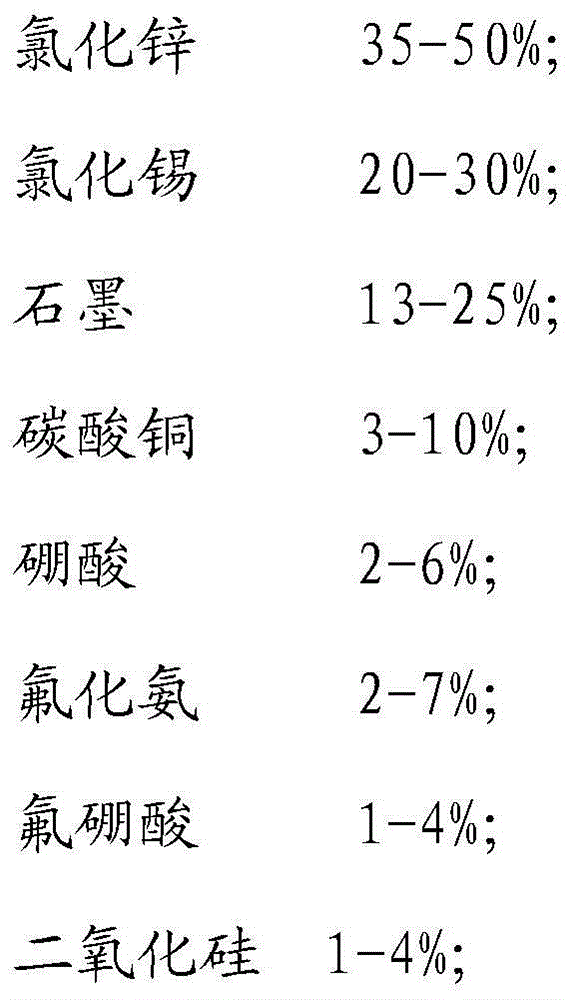

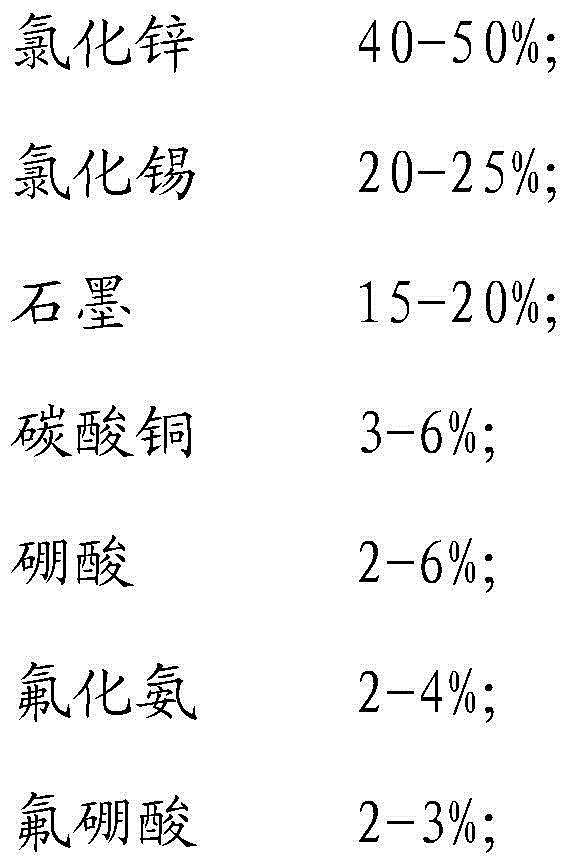

[0047] The electrothermal converter coating in embodiment 1-4, its main solid raw material weight ratio is shown in the following table:

[0048] Example

tin chloride

silica

1

40%

24%

18%

6%

4%

4%

2%

2%

2

45%

22%

15%

5%

6%

2%

2.5%

2.5%

3

48%

20%

16%

5%

5%

3%

2%

1%

4

50%

24%

15%

3%

2%

3%

1%

2%

[0049] Liquid raw material adopts dehydrated alcohol and terpineol in the coating, and the addition of dehydrated alcohol is 30% of each group total solid raw material weight listed in the above table, and the addition of terpineol is 5% of total solid raw material weight. That is, add 30 g of dehydrated alcohol and 5 g of terpineol in every 100 g of uniformly mixed solid raw materials.

[0050] The spec...

example 1

[0065] Quartz electric heating tube for rapid heating water heater, external dimension: 14mm in diameter and 220mm in total length, according to the calculation method for making electrothermal converters for heating liquids, the maximum power that can be processed by components of this size:

[0066] W=S×g1 (S-surface area)

[0067] That is (3.14×0.7×0.7×20)×20=615.4w

[0068] The dose to be sprayed L=W×α1 is 615.4×0.5=307g

[0069] Then remove the oil stains on the surface of the member tubes with acid or lye, after cleaning and drying, take the coating solution calculated in the dosage in Examples 1-4, all spray on the surface of the quartz member, place in a heating furnace, and the temperature Rise to 400-500°C and keep it warm for 20 minutes, then take it out and let it cool naturally.

[0070] Brush the cooled components with silver paste to make electrodes, then dry and solidify in a furnace at 200°C-400°C, and after cooling, lead out the power supply wiring by mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com