Vertical-type discharge active carbon regenerating furnace

A regeneration furnace, activated carbon technology, applied in filter regeneration, filtration separation, petroleum industry and other directions, can solve the problems of uneven distribution of the overall thermal field, poor regeneration effect, etc., to avoid uneven heating and local breakdown phenomenon, regeneration Good effect, easy disassembly and maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with accompanying drawing

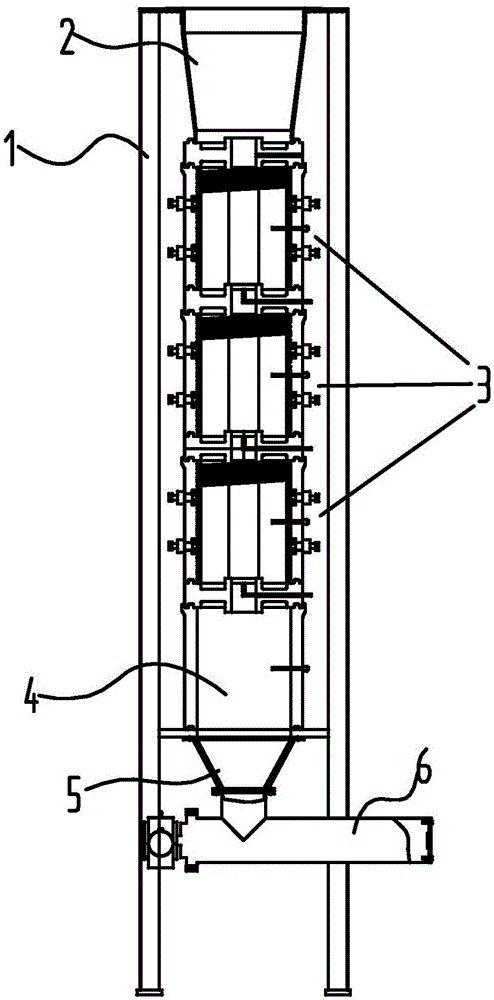

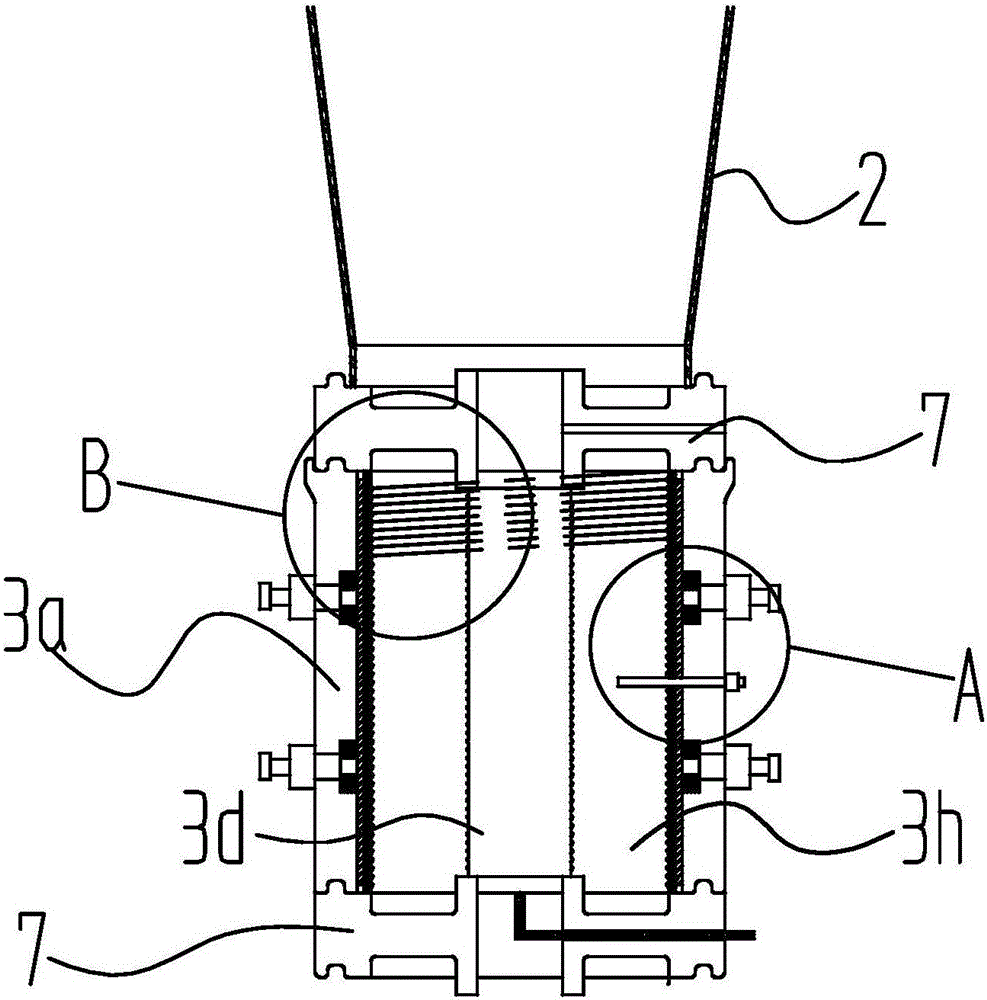

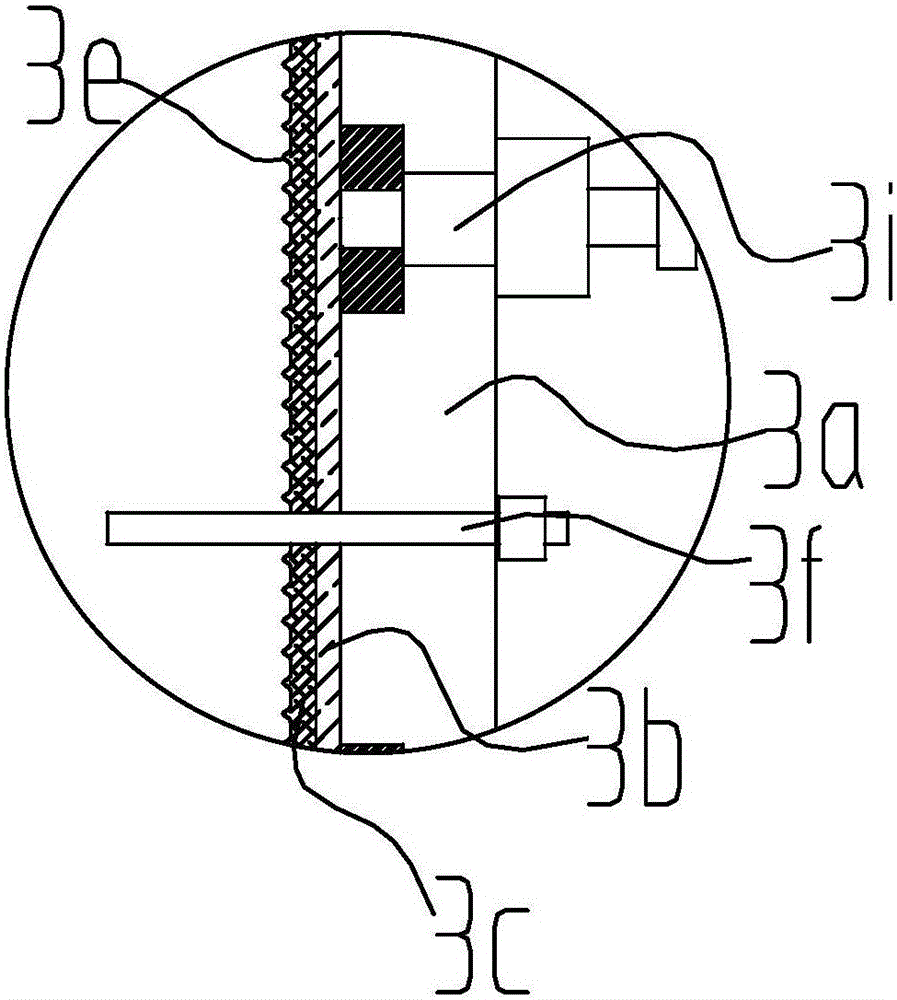

[0038] Such as figure 1 , figure 2 ,Such as figure 1 Shown, the present invention comprises frame, and frame is a vertical frame, and is positioned at frame top to be provided with feed bin inside frame, is positioned at the bottom of frame inside frame and is provided with discharge bin, is positioned at feed bin There is a regeneration furnace group and a transitional insulation bin 4 between the storage bin. Connected, the outlet of the transition insulation bin is connected with the inlet of the outlet bin, and the transition insulation bin is erected in the frame.

[0039] Such as figure 1 and figure 2 As shown, the regeneration furnace group is composed of a plurality of regeneration furnaces, and the plurality of regeneration furnaces are connected sequentially through connecting sleeves from top to bottom. The top of the regeneration furnace group is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com