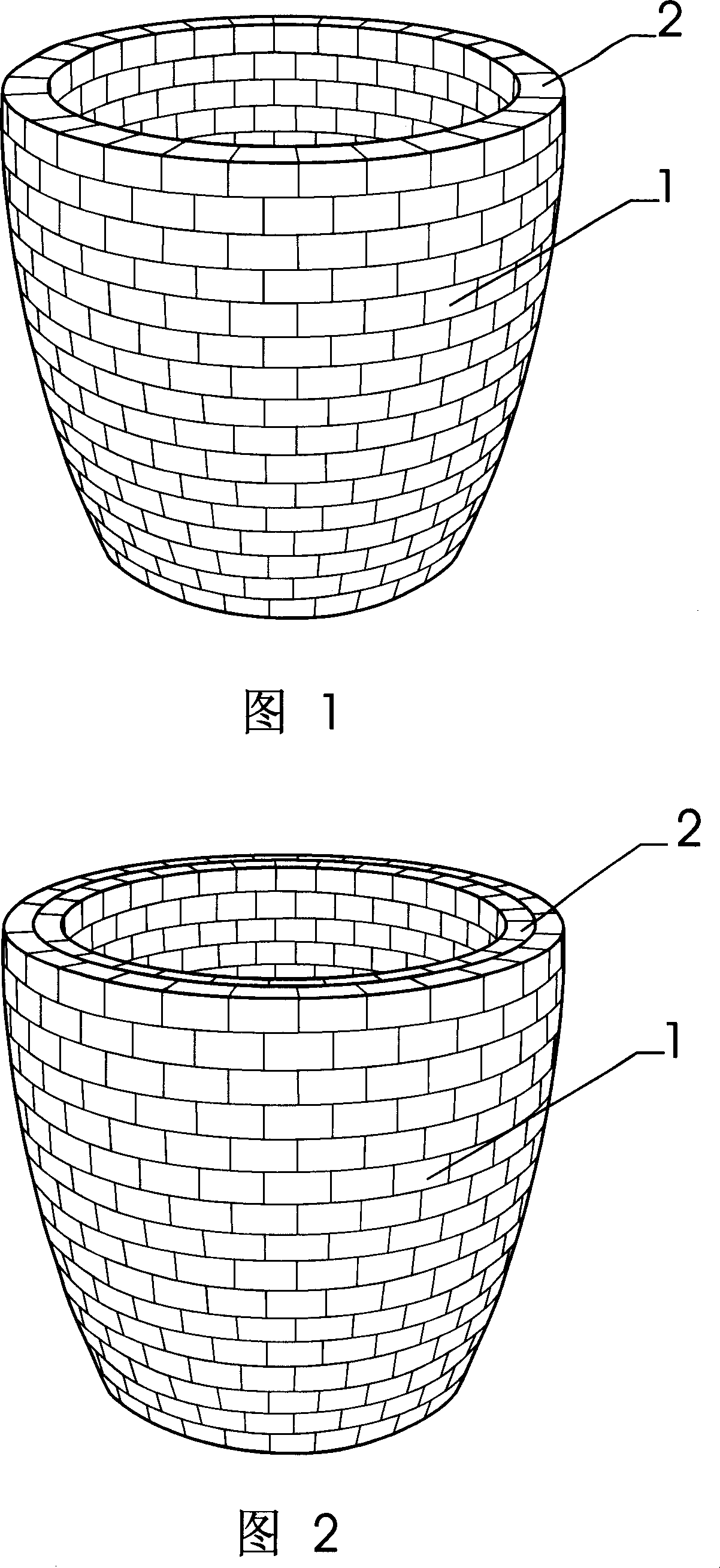

Combined pyrolytic boron nitride crucible lining

A boron nitride crucible and crucible lining technology, which is applied to crucible furnaces, lighting and heating equipment, furnaces, etc., can solve the problems of high price of boron nitride crucibles, uneconomical economic costs, and large volume of melting crucibles. Good chemical and thermal stability, low maintenance cost, and long crucible life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

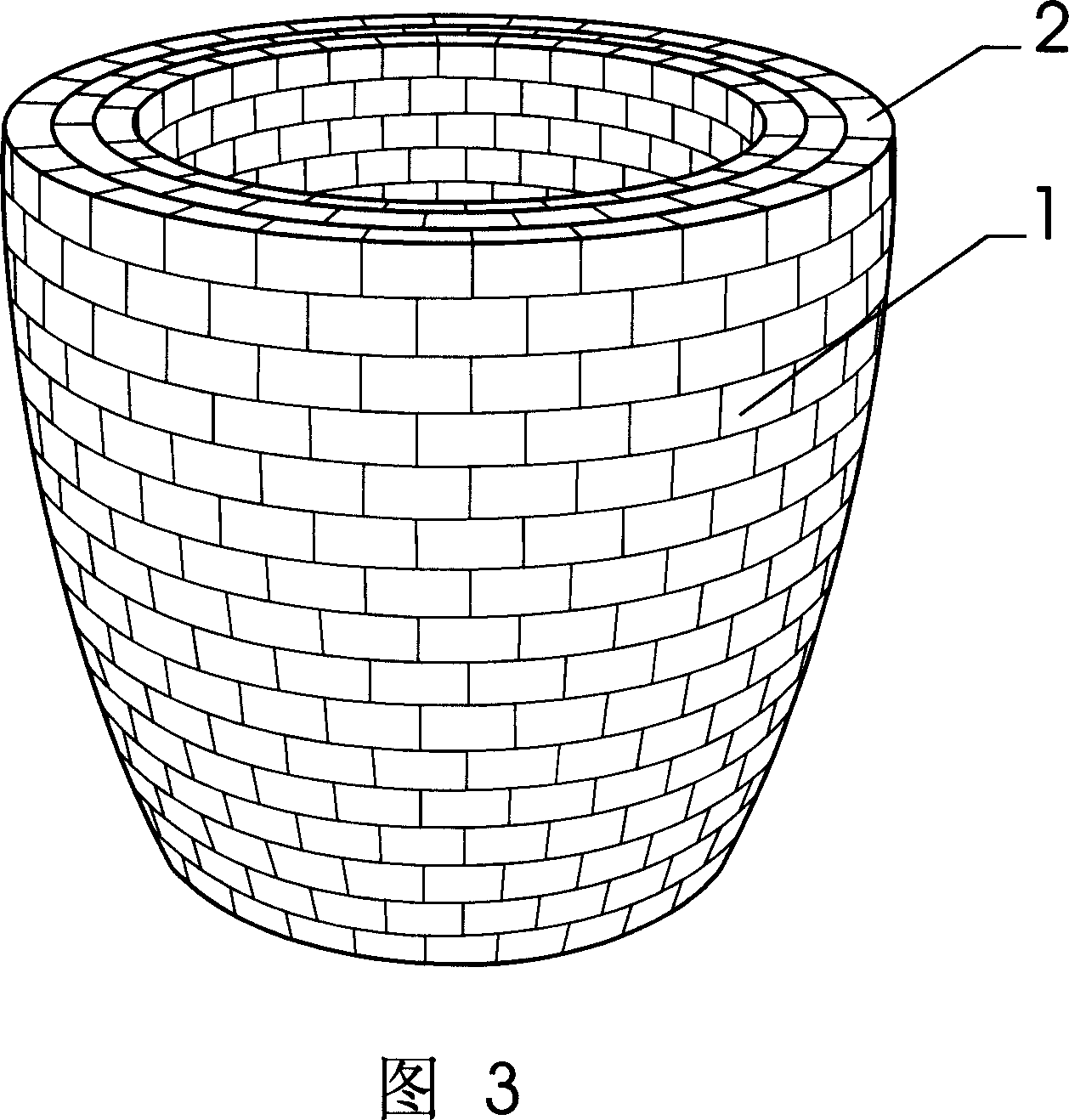

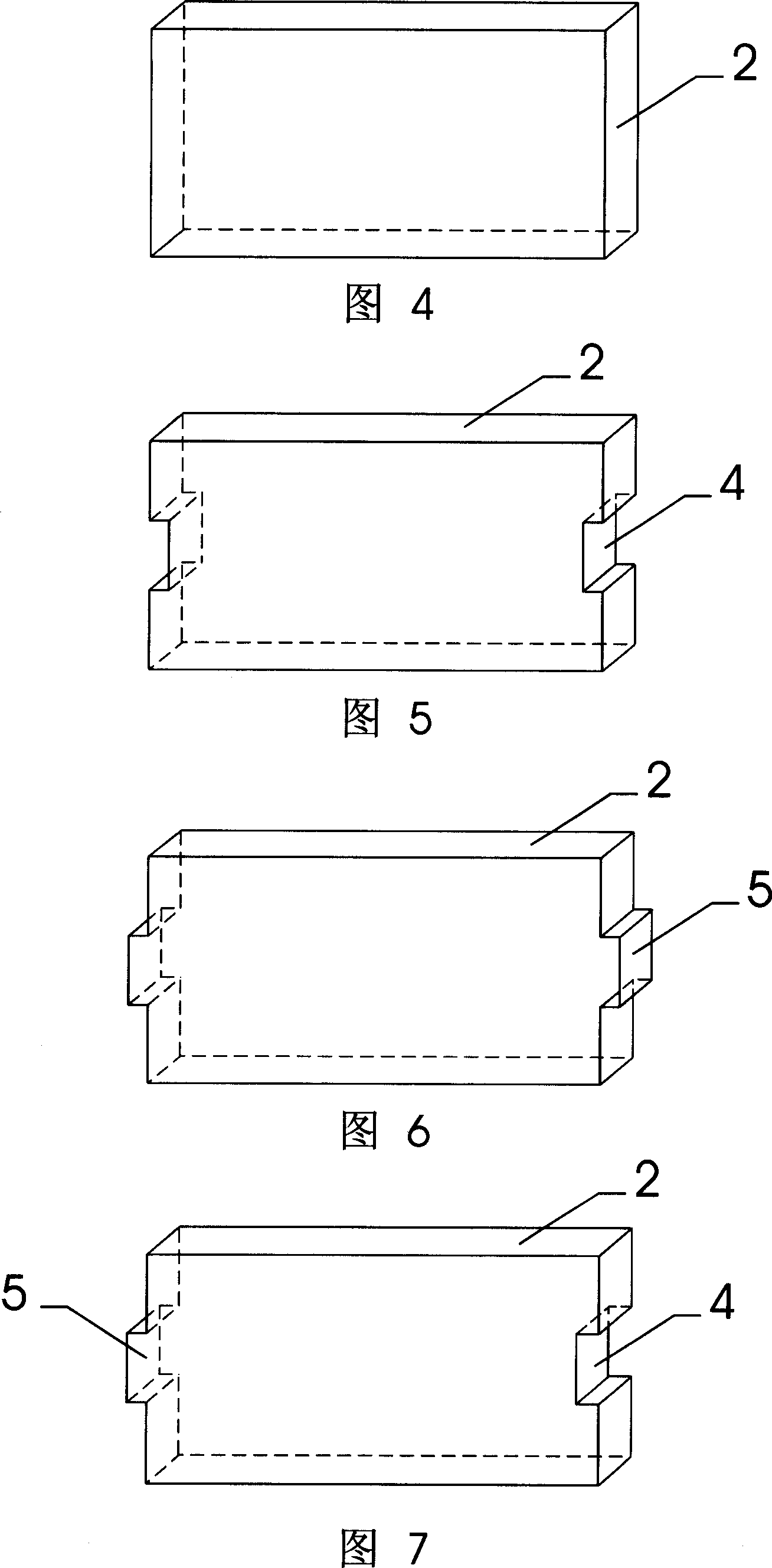

[0032] Manufacture of Pyrolytic Boron Nitride Bricks

[0033] The blank of pyrolytic boron nitride brick manufactured by chemical vapor deposition process is then machined into the required shape and size to obtain pyrolytic boron nitride brick, as follows:

[0034] High-purity raw gas BCl 3 and NH 3 , mixed in a certain proportion and passed into the high-temperature reaction chamber, the temperature of the reaction chamber is as high as 2000 ° C, and the mixed gas is in the reaction chamber, according to the following chemical reaction equation:

[0035] BCl 3 +NH 3 =BN+3HCl

[0036] In the growth process of pyrolytic boron nitride (PBN) materials, people are always used to compare it to falling snow, that is, the hexagonal BN small snow flakes grown in the reaction, which are continuously piled up on the heated graphite substrate (core mold) In fact, with the prolongation of time, the accumulation layer is thickening, that is, the shell of pyrolytic boron nitride is fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com