Automatic copper bar transplanting warehouse

A warehouse and automatic technology, applied in the field of intelligent warehouse, can solve the problems of large storage area and space, chaotic warehouse management, unfavorable humanized management, etc., to achieve high warehouse accuracy, improved warehouse rhythm, and easy adjustment. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention are described below through specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

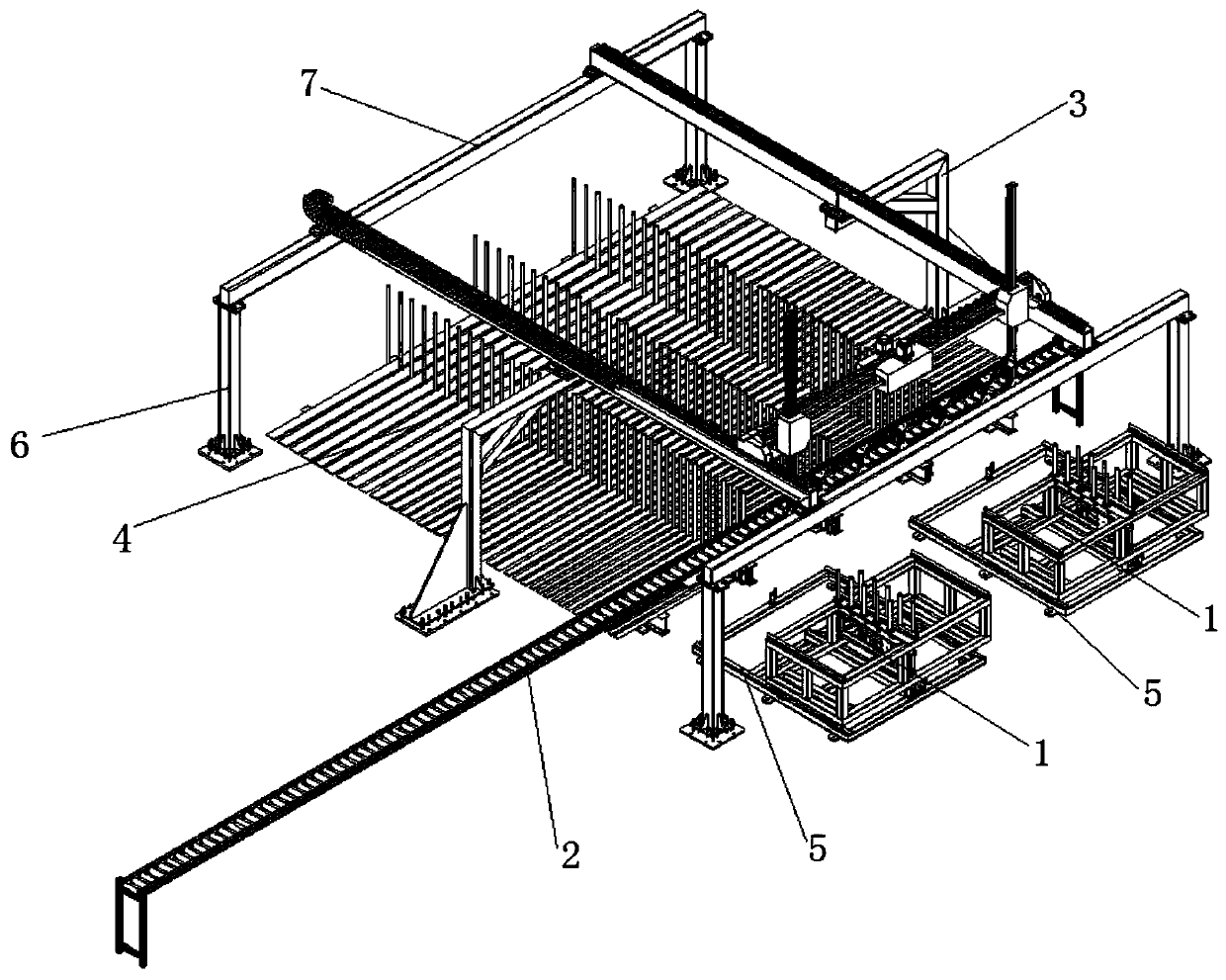

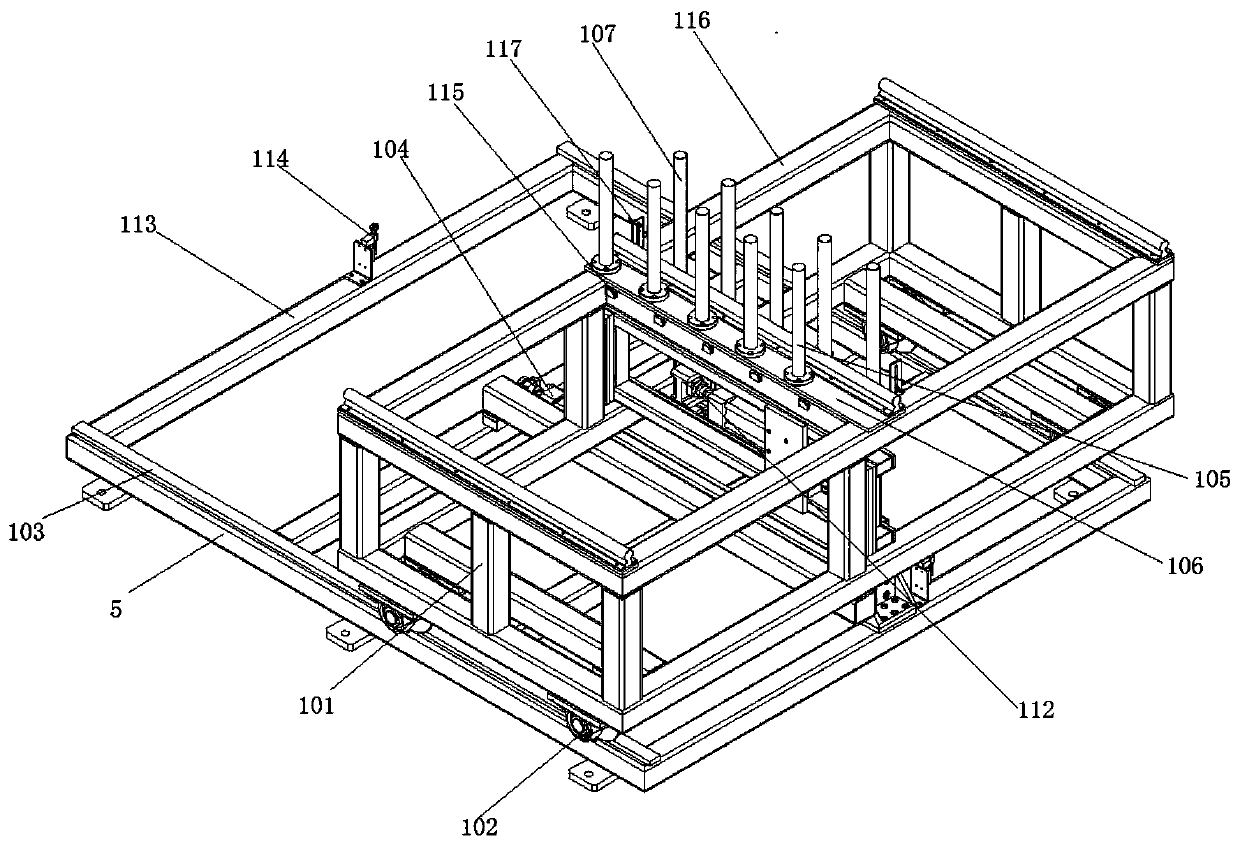

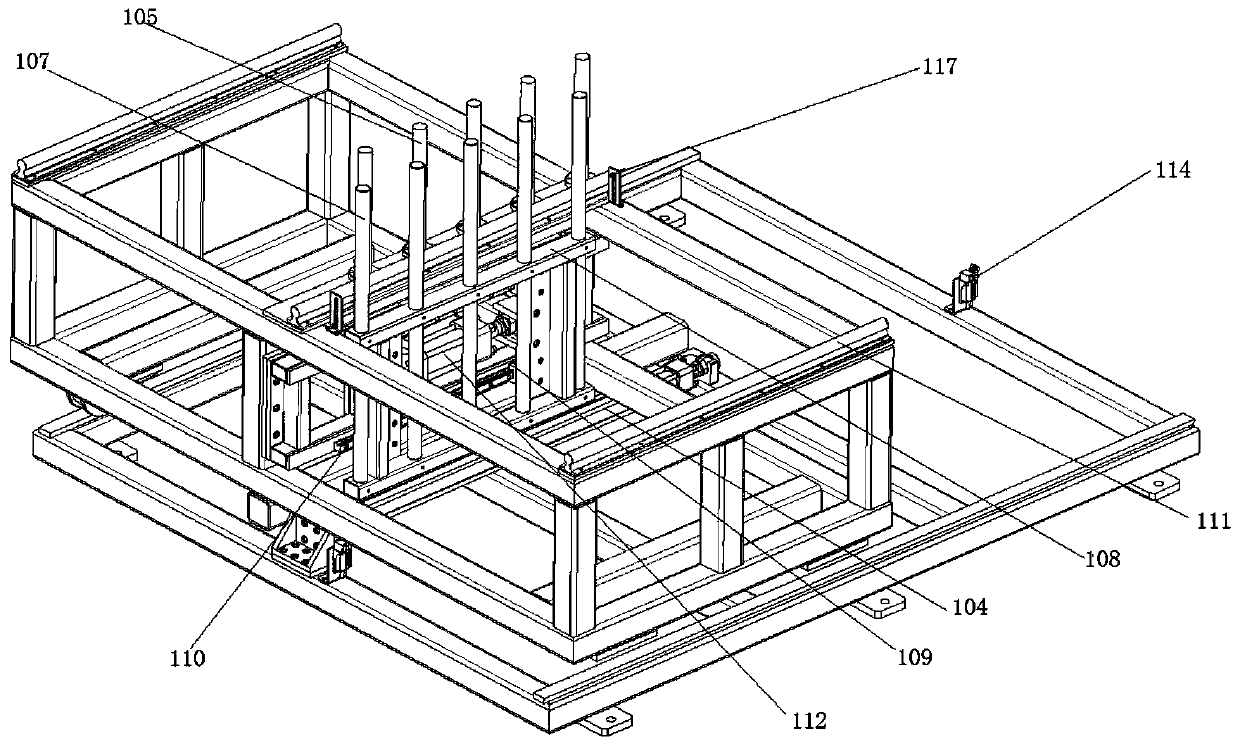

[0028] Such as figure 1 As shown in the figure, an automatic copper bar transplanting warehouse is used to carry out storage and outbound processing of copper bar workpieces. The transplanting warehouse includes a feeding and pushing platform 1, a roller conveyor line 2, a truss manipulator 3 and a copper bar Storage location 4, the loading and pushing platform 1 is located at the feeding end of the truss manipulator 3, the bottom frame 5 of the feeding and pushing platform 1 is connected to the ground by expansion bolts and fixed on the ground, and the roller conveyor line 2 is located at the truss manipulator The feeding end of 3 is used for positioning the copper bar workpiece. The truss manipulator 3 includes a steel structure ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com