Separate two-phase anaerobic fermentation fermentation device

An anaerobic fermentation and fermentation device technology, which is applied in the field of separate two-phase anaerobic fermentation and fermentation devices, can solve the problems of difficulty in feeding and discharging materials, high labor costs, secondary pollution, etc., so as to reduce the risk of methane leakage, maintain and manage The effect of convenience and reduction of project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

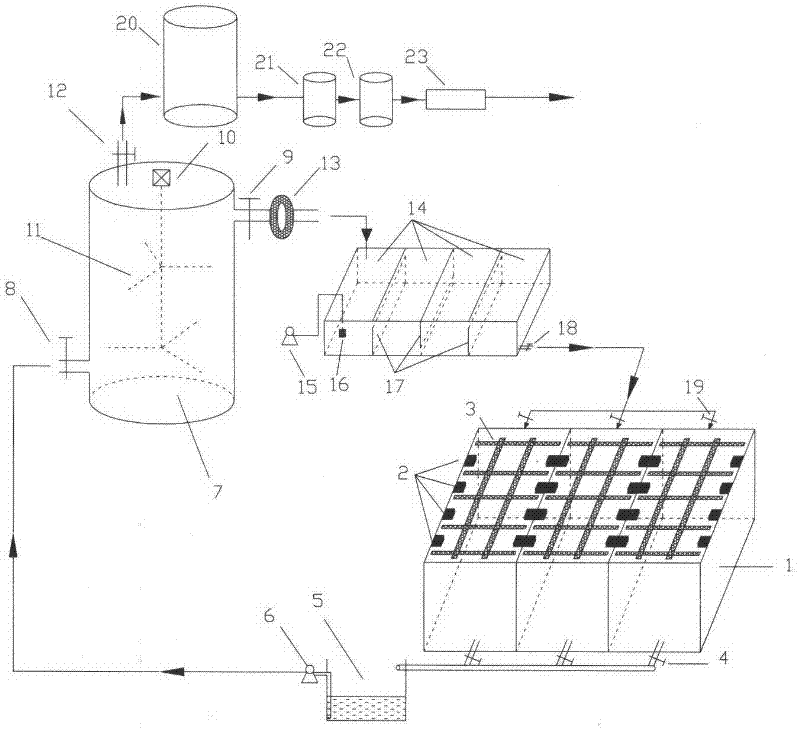

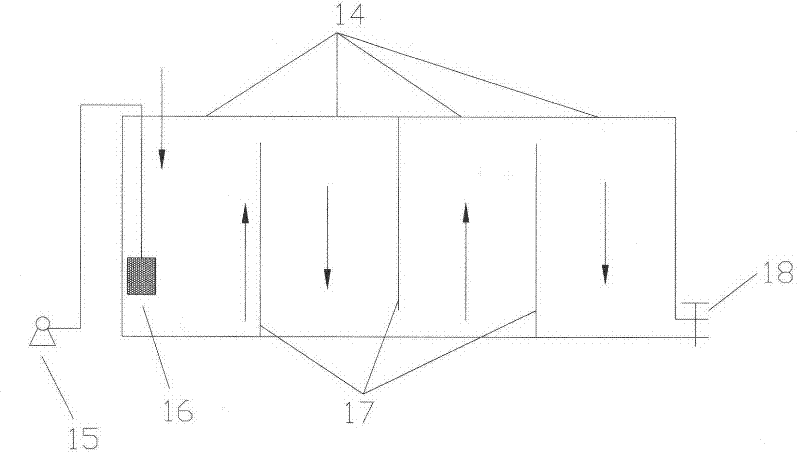

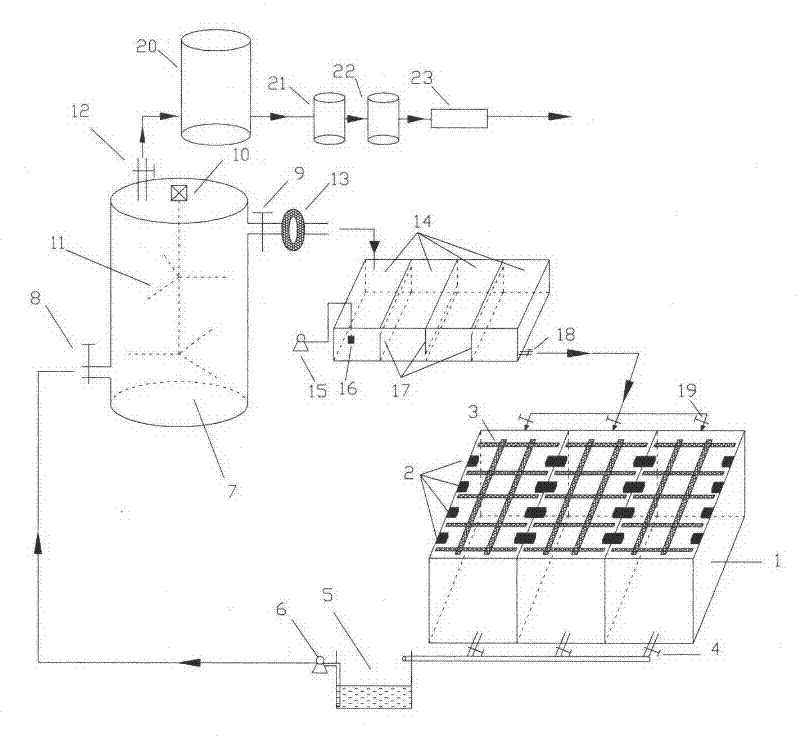

[0028] The accompanying drawings disclose the specific structure of the embodiment of the present invention without limitation, and this embodiment will be further described below in conjunction with the accompanying drawings.

[0029] Depend on figure 1 and figure 2 It can be seen that the separated two-phase anaerobic fermentation fermentation device includes a hydrolysis acidification reaction device, anaerobic fermentation device and biogas slurry oxidation device, of which:

[0030] The hydrolysis acidification reaction device includes 2 to 6 parallel hydrolysis acidification basic units of hydrolysis acidification reaction tank 1 and hydrolyzate collection tank 5, each basic unit is an open material accumulation tank, and the material accumulation tank is equipped with a hydrolysis acidification liquid outlet 4 and the reuse inlet 19 of the biogas slurry after oxidation. The outlet 4 of the hydrolysis acidification solution is located at the bottom of the material accu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com