Aerobic compost reactor

A composting reactor and sensor technology, applied in application, organic fertilizer, fertilization device, etc., can solve problems such as unbalanced ventilation, poor material uniformity, and incomplete fermentation of materials, so as to improve aeration, easy feeding and discharging, and full fermentation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

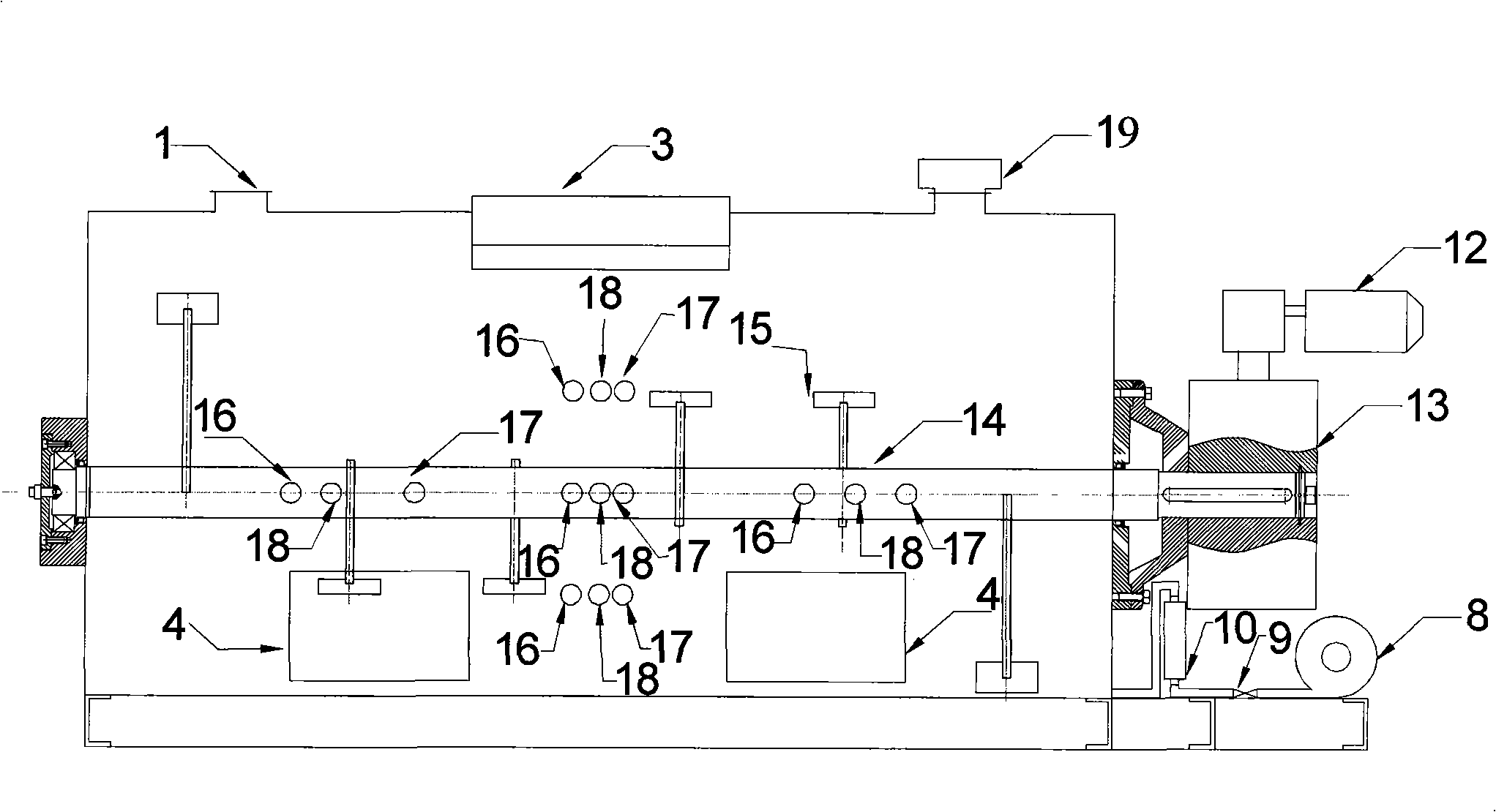

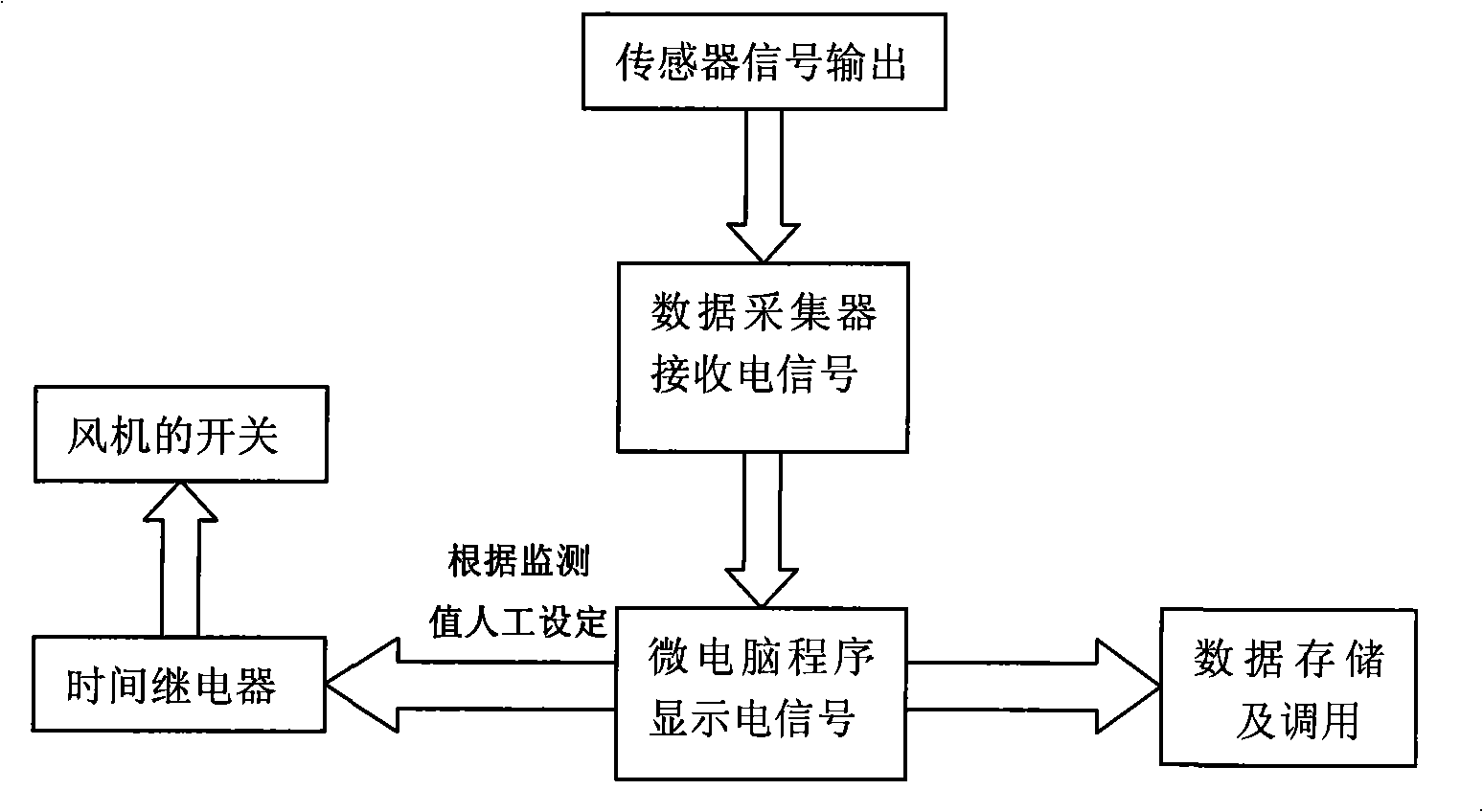

[0019] see figure 1 and figure 2 , The reactor of the present invention includes a compost tank, a ventilation system, a stirring system and various sensors. In this example, the tank body is cylindrical and horizontal.

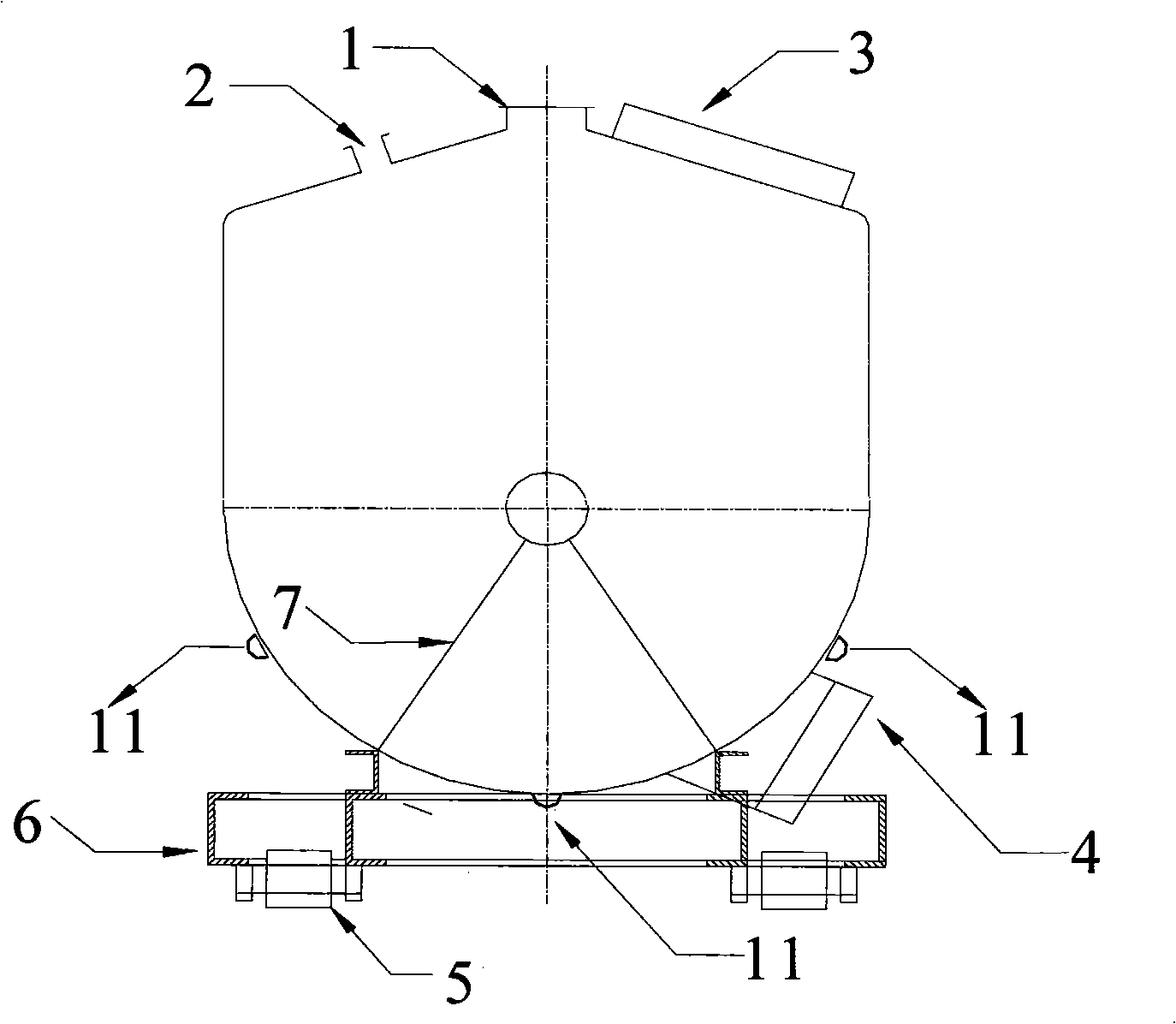

[0020] The top of the tank is provided with a sampling port 1 (two, located at both ends of the top of the tank), an exhaust port 2 and a feeding port 3, and a discharge port 4 is provided at the bottom of the tank. A base 6 is arranged under the tank, and a tank support 7 is installed on the base 6. The tank support 7 is supported on the central axis at both ends of the tank, and the tank is fixed by the base 6 and the support 7. On the bottom surface of the base 6 Casters 5 are installed to increase its mobility.

[0021] The ventilation system is composed of fan 8, valve 9, flowmeter 10 (glass rotameter can be used) and ventilation pipe 11 connected successively with conduits. There are three ventilation pipes, which are respectively located at the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com