Locking device of electric appliance

A technology for locking devices and electrical equipment, applied in the direction of coupling devices, components of connecting devices, circuits, etc., can solve the problems of affecting the use of electrical equipment, plugs of electrical equipment are knocked open, and no locking device is installed, so as to achieve convenient entry and exit, Avoid electric shock, convenient plug-in fastening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

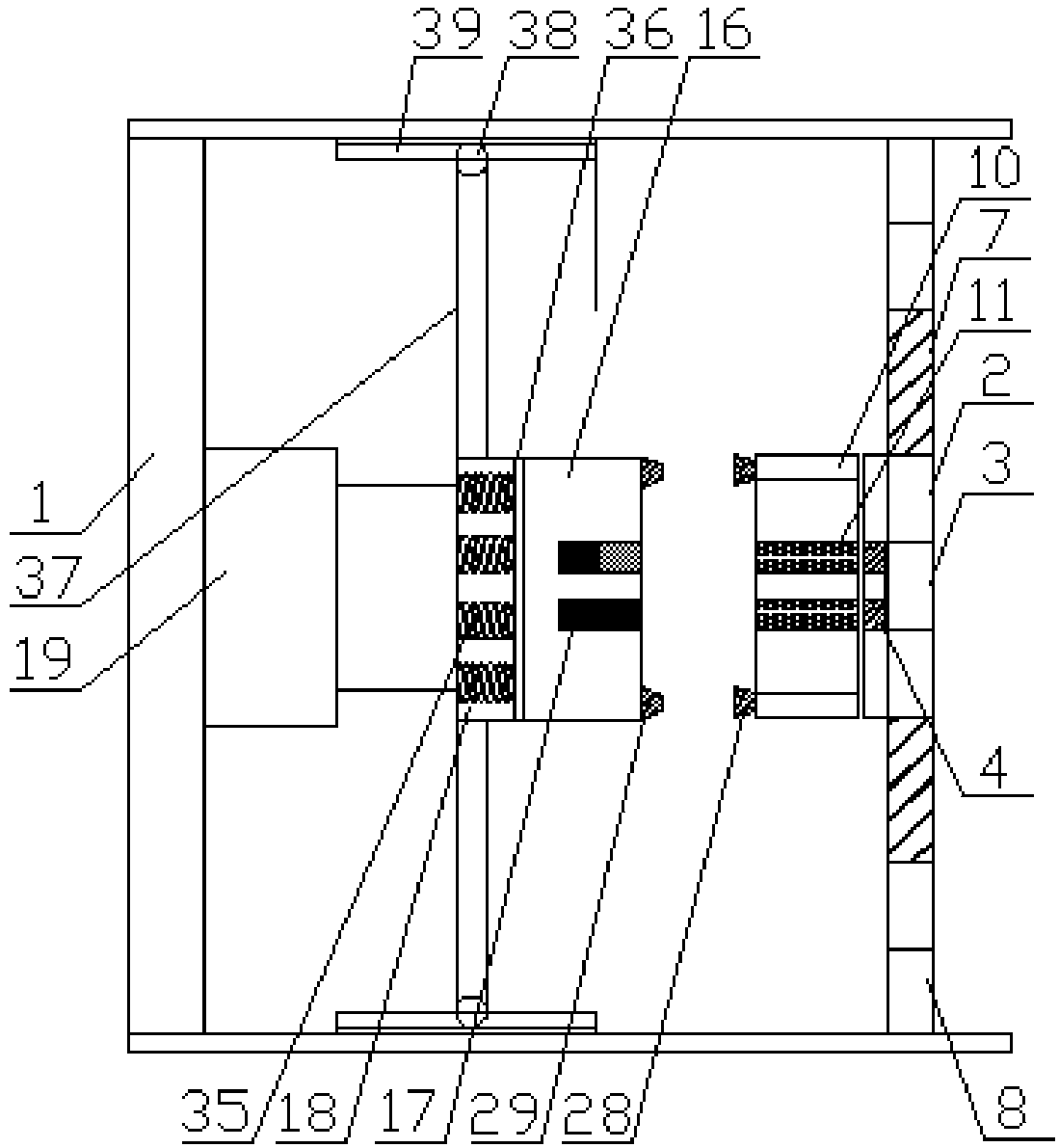

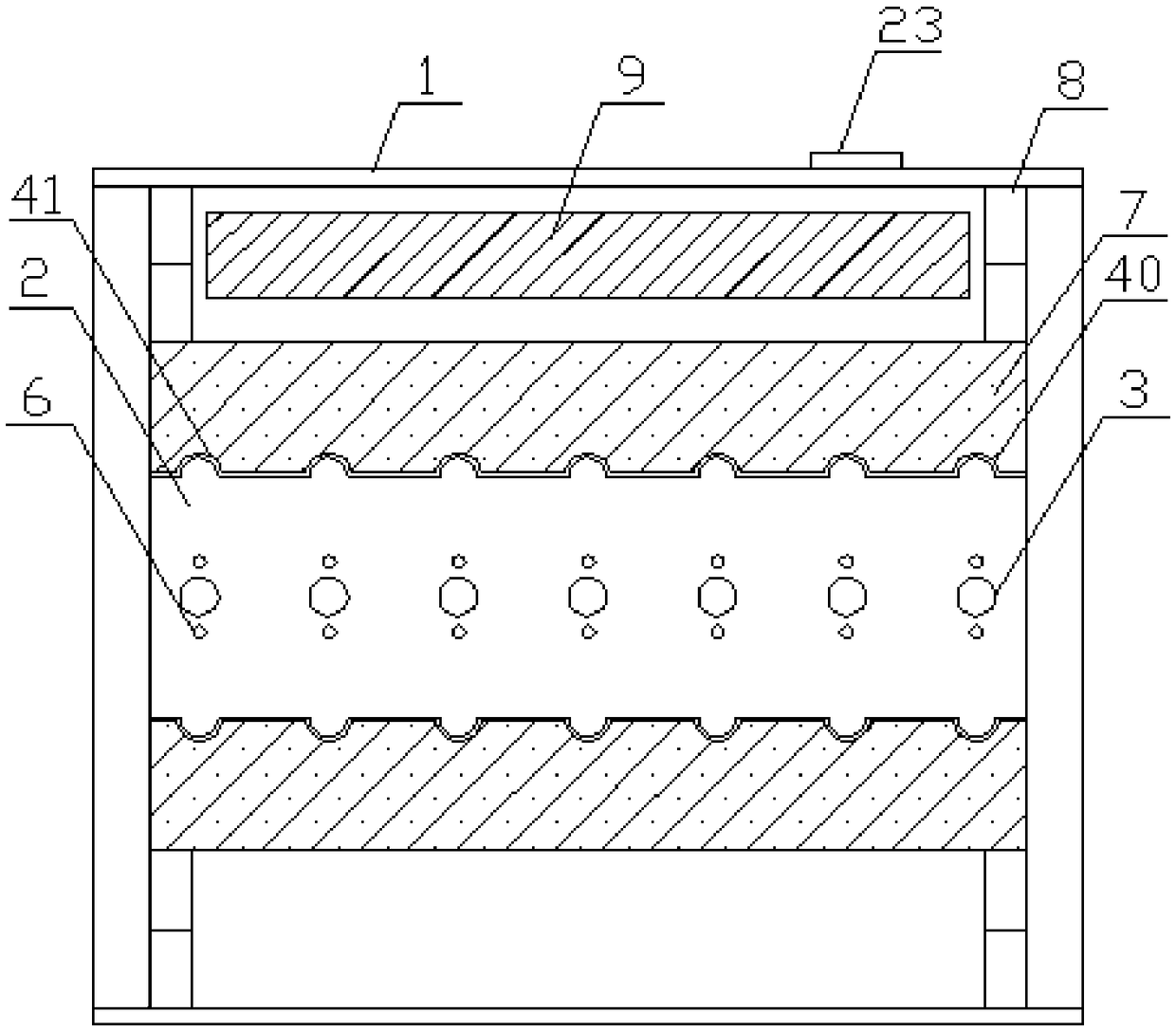

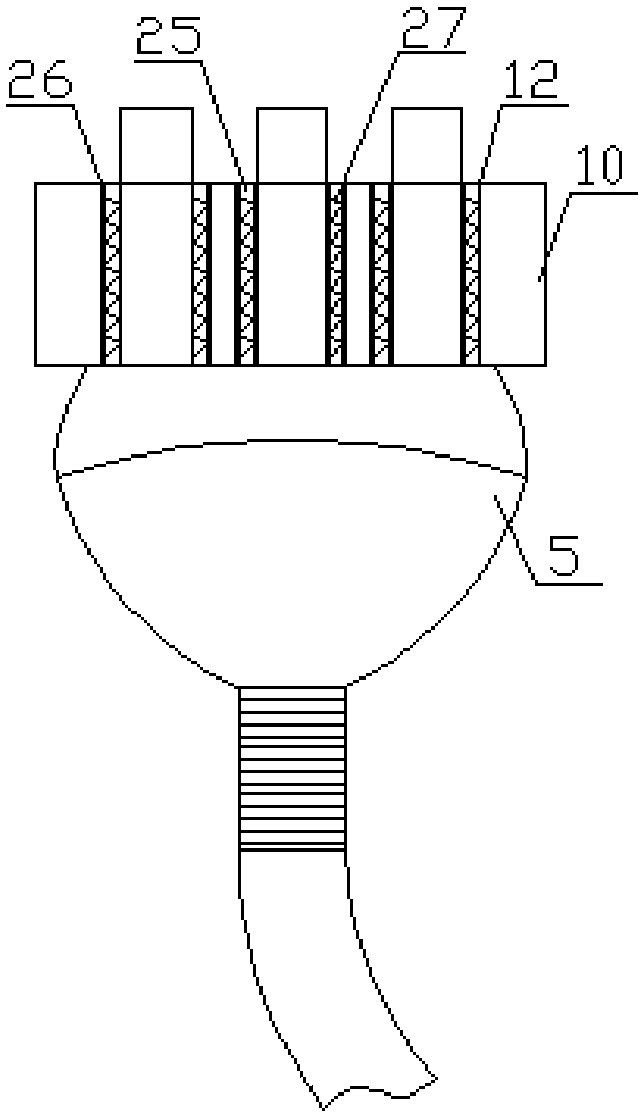

[0020] Embodiment 1: refer to Figure 1-3 , a locking device for electrical equipment, including a box body 1, a working panel 2 is arranged on the front side of the box body 1, a groove 3 is arranged on the working panel 2, and a socket 4 is arranged inside the groove 3 , the outer side of the groove 3 is provided with a plug 5, the groove 3 and the bottom are provided with an infrared sensor 6, the top and bottom of the working panel 2 are provided with a movable clamp 7, and one end of the movable clamp 7 is provided with Buckle groove 40, the edge of the movable clamp 7 and the buckle groove 40 is provided with a rubber sealing strip 41, which is conducive to clamping the plug 5, preventing the plug 5 from being easily knocked off and causing equipment shutdown and damage, and preventing water or dust from The groove 3 enters the box body 1, which affects the service life of the device and the safety of power supply. One end of the movable clamp 7 is provided with a first ...

Embodiment 2

[0023] Embodiment 2: refer to Figure 3-6 , the present invention is applied to a bridge construction equipment, comprising a box body 1, the front side of the box body 1 is provided with a working panel 2, the working panel 2 is provided with a groove 3, and the inside of the groove 3 is provided with Jack 4, the outer side of the groove 3 is provided with a plug 5, the groove 3 and the bottom are provided with an infrared sensor 6, the top and bottom of the working panel 2 are provided with a movable clamp 7, and the movable clamp 7 One end is provided with a buckle groove 40, and the edge of the movable clamp 7 and the buckle groove 40 is provided with a rubber sealing strip 41, which is conducive to clamping the plug 5, preventing the plug 5 from being easily knocked off and causing equipment shutdown and damage, and avoiding water Or dust enters the box body 1 from the groove 3, which affects the service life of the device and the safety of power supply. The first air pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com