Warp knitting machine production data acquisition and management system

A production data and management system technology, applied in general control system, control/adjustment system, comprehensive factory control, etc., can solve the problems of low level of informatization, process management, machine working status monitoring, personnel performance assessment, order delivery ability Control and other information management is backward and real-time is not strong, etc., to achieve the effect of convenient employee management, standardized operation process, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in detail below in conjunction with accompanying drawing description:

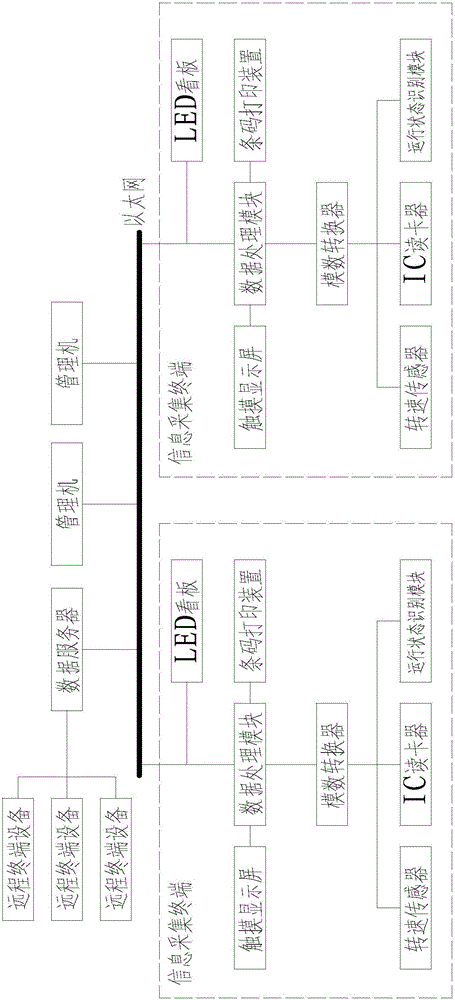

[0026] Such as figure 1 As shown, the present invention includes a data server and at least one group of information collection terminals;

[0027] The data server is used to analyze, count and store data, provide data query and generate production task data;

[0028] The database server is usually composed of one or more computers and database management system software (SQL, Oracle), which can be connected with the enterprise's ERP to achieve data sharing.

[0029] Each group of information collection terminals includes:

[0030] The rotational speed sensor is connected with the main motor shaft of the warp knitting machine for collecting the rotational speed data of the main motor of the warp knitting machine;

[0031] The rotational speed sensor adopts an incremental encoder, which is connected with the main motor shaft of the warp knitting machine, and conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com