Small flat-bottom drying machine

A dryer and flat-bottom technology, applied in non-progressive dryers, dryers, drying solid materials, etc., can solve the problems of inconvenient feeding and discharging, large volume, high cost, etc., and achieve convenient feeding and discharging, high drying efficiency, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

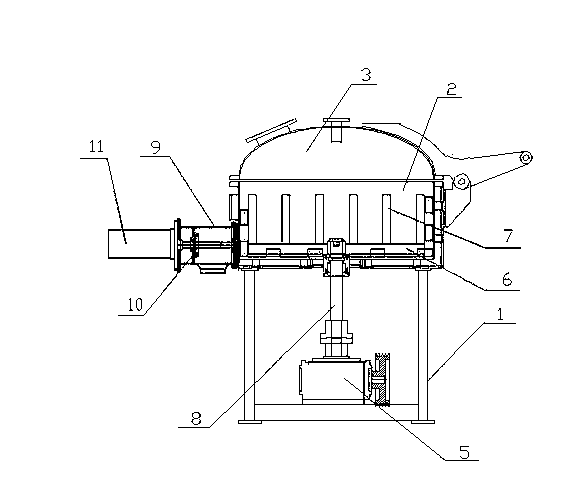

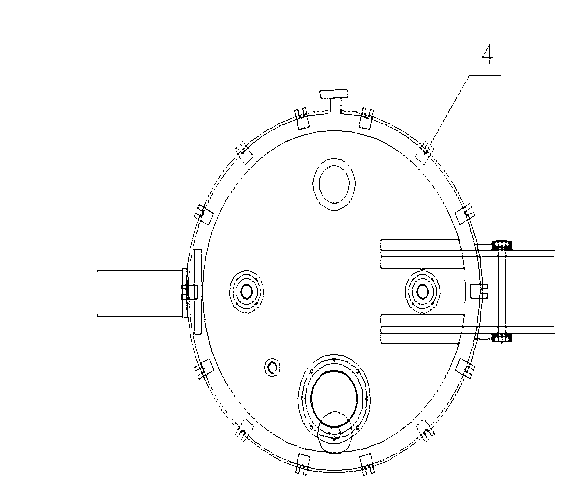

[0018] Such as figure 1 or figure 2 As shown, the flat-bottomed dryer of the present invention includes a frame 1, a drying chamber 2 for drying materials, and an agitator for stirring materials so as to accelerate the drying of materials. The drying cavity 2 is fixed on the upper side of the frame 1 , and the agitator is arranged in the drying cavity 2 . The materials in the drying cavity 2 are stirred and heated by the agitator, and the materials are dried.

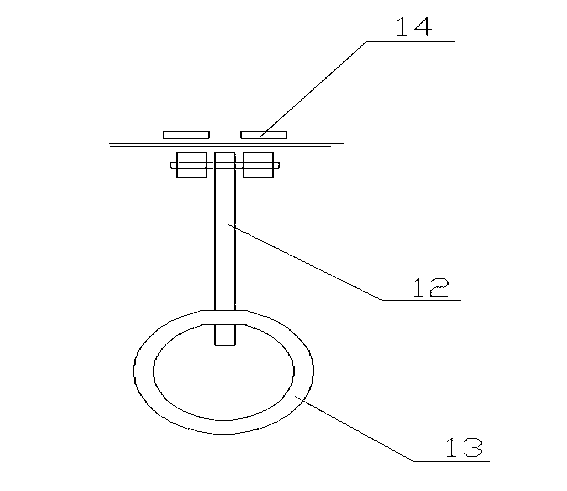

[0019] The drying chamber 2 is a cylinder, and the upper side of the drying chamber 2 is provided with a sealing cover 3, which is hinged on the drying chamber 2, and the upper edge of the drying chamber 2 is equally spaced for locking and sealing. Locking device 4 for cover 3 . Such as image 3 As shown, the locking device 4 includes a screw rod 12 , a ring clip 13 and a block 14 matched with the ring clip 13 . One end of the screw 12 is hinged on the upper edge of the drying chamber 2, and the hole on one side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com