Low melting point alloy phase change heat storage device applied to solar dryer

A heat storage device and alloy phase technology, applied in drying chambers/containers, heat storage equipment, local agitation dryers, etc., can solve problems such as the inability to guarantee continuous and stable operation of solar drying, and achieve safe and reliable heat transfer efficiency, feeding and discharging materials Convenience and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

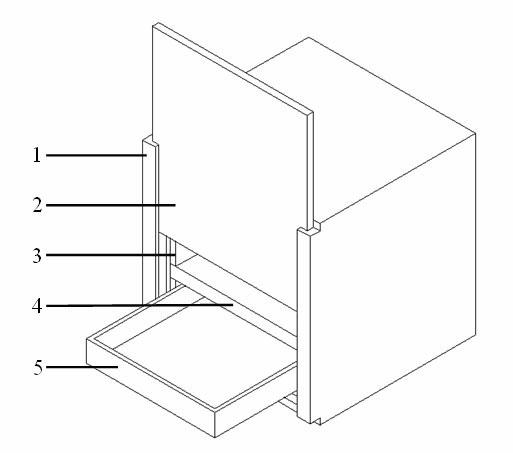

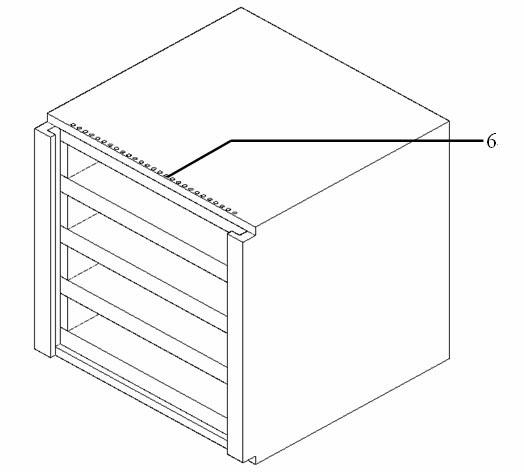

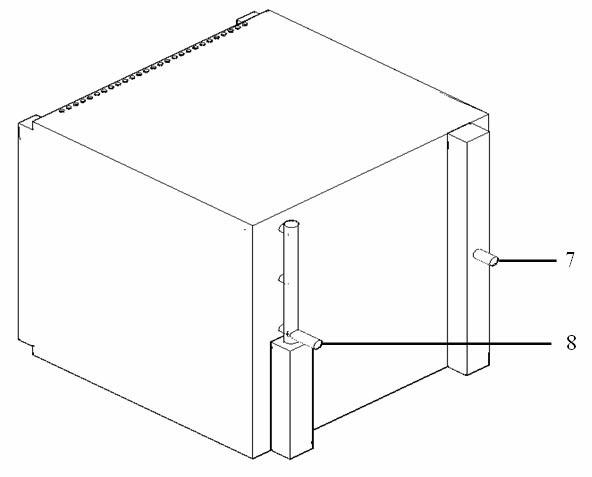

[0025] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a low-melting-point alloy phase change heat storage device applied to a solar dryer, which includes a drying chamber box 1, a pull-out material box 5, a heat storage block 4, and an up and down sliding heat preservation door 2; The box body is made of thermal insulation blocks 3, and the upper part of the drying room box body has vent holes 6, and the outside of the drying room box body is covered with thermal insulation materials; 50 heat storage blocks 4 are arranged in the drying space of the drying room box body. The edge part of the heat block is supported by the insulation block and fixed to the drying chamber box; the pull-out material box is located between the upper and lower heat storage blocks and is in contact with the lower heat storage block, and the dry sample is contained in the pull-out type material box; Insert the left and right sides of the up and down sliding heat preservation door i...

Embodiment 2

[0040] Basically the same as Example 1, the difference is:

[0041] The appearance size of the heat storage block is 2000×2000×30mm, the distance between the upper and lower heat storage blocks is 100mm, and the amount of heat storage blocks in the dry space is 30. The heat storage capacity of the device at 100-300°C is 3.305×10 6 kJ, the heat exchange process in the device is sufficient and reversible, and the heat exchange efficiency is high. It can be used as heat storage device for solar dryer.

Embodiment 3

[0043] Basically the same as Example 1, the difference is:

[0044] The appearance size of the heat storage block is 1000×1000×50mm, the distance between the upper and lower heat storage blocks is 200mm, and the amount of heat storage blocks in the dry space is 15. The heat storage capacity of the device at 100-300°C is 6.887×10 5 kJ, the heat exchange process in the device is sufficient and reversible, and the heat exchange efficiency is high. It can be used as heat storage device for solar dryer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com