Optical module capable of being quickly aligned and assembled

An optical module and fast technology, applied in the field of optical modules, can solve the problems of increasing optical energy loss in the transmission process, high technical difficulty, and low processing efficiency, so as to omit the packaging glue and packaging process, simplify the fixed alignment relationship, and improve the docking The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

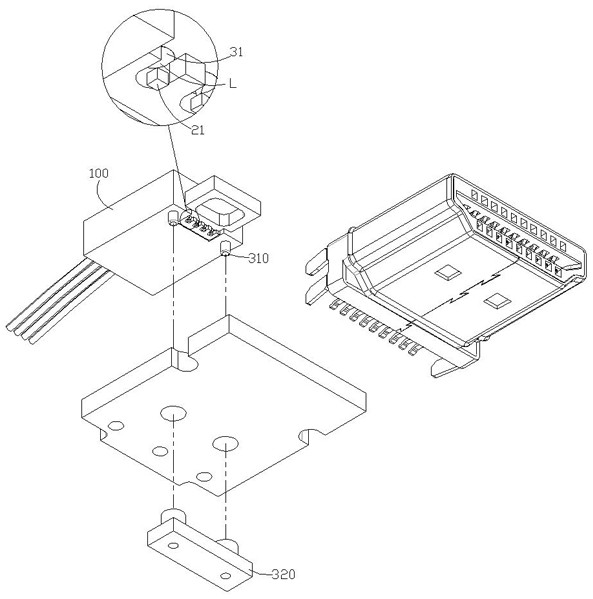

[0064] Example 1: L=150μm, D1 / D2=0.8 (D2 / D1=1 / 0.8), D2=750μm, the total length of the plastic optical fiber 30 is less than 0.016 meters, (2mm / 150μm)*(1 / 0.8)*10 -750μm / 250μm m = 0.016 m.

example 2

[0065]Example 2: When L=50 μm, D1 / D2=0.9 (D2 / D1=1 / 0.9), D2=500 μm, the total length of the plastic optical fiber 30 is less than 0.44 meters, (2mm / 50 μm) *(1 / 0.9)*10 -500μm / 250μm m = 0.44 m.

example 3

[0066] Example 3: (the most typical application parameters) when L=100μm, D1 / D2=0.95 (D2 / D1=1 / 0.95), D2=250μm, the total length of the plastic optical fiber 30 is less than 2.11 meters, (2mm / 100μm) * (1 / 0.95)*10 -250μm / 250μm m = 2.11 m.

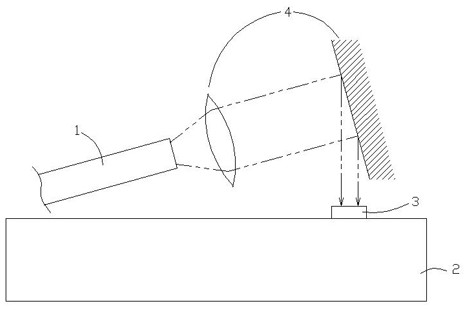

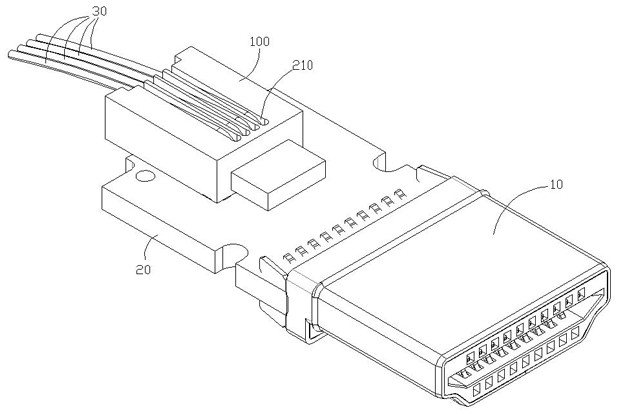

[0067] The design idea of the plastic optical fiber 30 in the present invention is as follows: First, the functional optical modules 21 on the control circuit board 20 are all placed horizontally, and the glass optical fiber (GOF) 1 will break when bent, so in order to realize the transmission of optical signals, Then it is necessary to increase the optical converter 4, and the addition of the optical converter 4 will inevitably increase the cost of the product, and will also greatly increase the volume of the product. The biggest advantage of using glass optical fiber (GOF) 1 for optical transmission lies in long-distance optical transmission. The signal attenuation is weak, but in practical applications, most signal transmissions are com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com