A butt-type wire fixing frame for eliminating heat defects of cable heads with electricity

A thermal defect, docking technology, applied in the field of fixing frames, can solve the problems of inconvenient use of the fixing frame, no cooling and heat dissipation device, injury to operators, etc., and achieve the effect of ensuring the quality of the connection, the quality of the wiring, and the effect of the wiring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

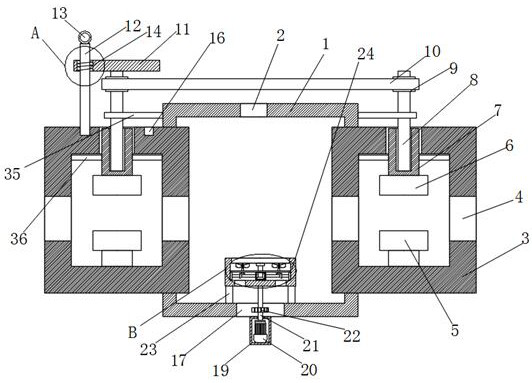

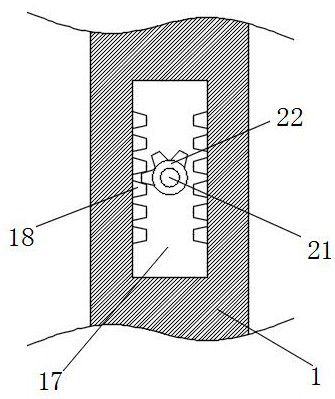

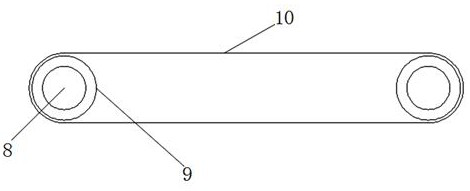

[0028] refer to Figure 1-5 , a butt-type wire fixing frame for eliminating heat defects of cable heads with electricity, including a pipe body 1, and a vent hole 2 is opened on the top of the pipe body 1 to ensure the ventilation in the pipe body 1. Both sides of the pipe body 1 Both placement tubes 3 are fixedly installed, two placement holes 4 are symmetrically opened on the two placement tubes 3, placement plates 5 are fixedly installed on the bottom inner walls of the two placement tubes 3, and sliding installations are installed inside the two placement tubes 3 There is a pressure plate 6, and the tops of the two placement tubes 3 are rotatably equipped with screw rods 8, the two screw rods 8 are adapted to the two pressure plate 6 respectively, the two screw rods 8 are connected in rotation, and the top of one screw rod 8 in the two screw rods 8 A circular plate 11 is fixedly installed, and a clamp rod 12 is slidably installed on the circular plate 11. The bottom of the...

Embodiment 2

[0039] refer to Figure 1-5 , a butt-type wire fixing frame for eliminating heat defects of cable heads with electricity, including a pipe body 1, and a vent hole 2 is opened on the top of the pipe body 1 to ensure the ventilation in the pipe body 1. Both sides of the pipe body 1 Both place tubes 3 are fixedly installed by welding, and two place holes 4 are symmetrically opened on the two place tubes 3, and place plates 5 are fixedly installed on the bottom inner walls of the two place tubes 3 by welding, and the two place tubes 3 A pressure plate 6 is slidingly installed inside, and a screw 8 is installed on the top of the two placement tubes 3. The two screw rods 8 are respectively adapted to the two pressure plates 6. The two screw rods 8 are rotationally connected, and one of the two screw rods 8 The top of the screw rod 8 is fixedly installed with a circular plate 11 by welding, and a clamp rod 12 is slidably installed on the circular plate 11. The bottom of the clamp rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com