Pipe flanging device and method applicable to fiber composite pipeline

A technology of fiber composite and pipe, which is applied in the field of pipe flanging device, and can solve the problems of high price and diameter reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

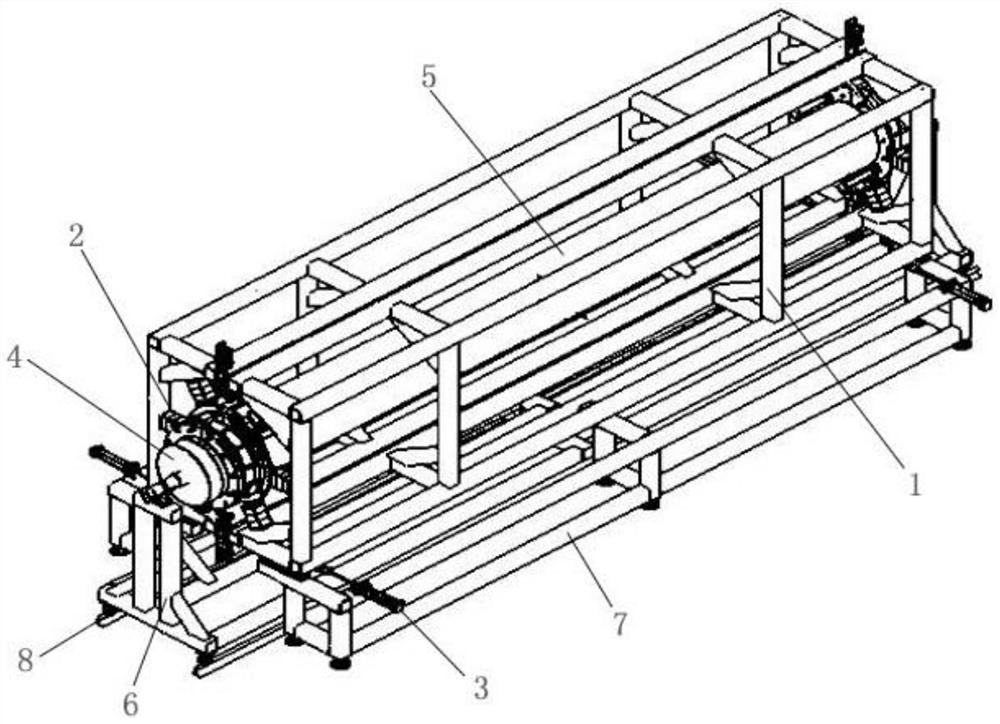

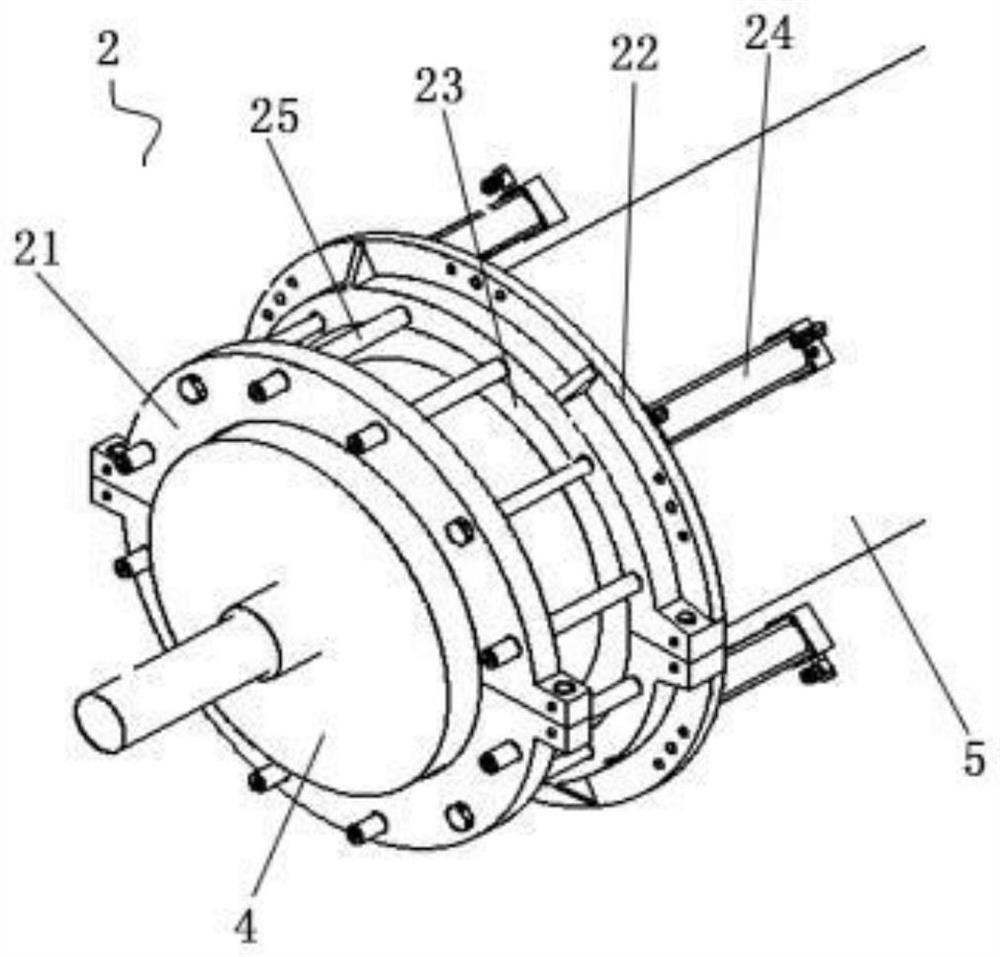

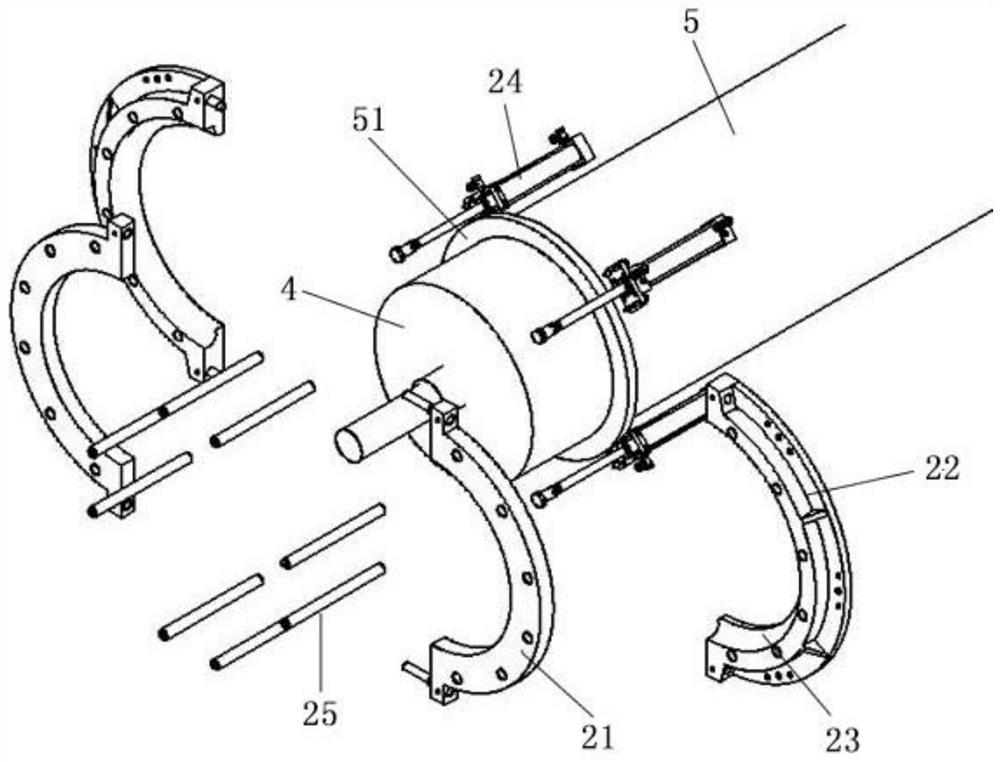

[0022] Such as Figure 1-3 As shown in one of them, the present invention is a pipe flanging device suitable for fiber composite pipes, which includes two symmetrically arranged movable frames 1, and the two movable frames 1 are respectively driven by corresponding mold clamping driving parts 3 to approach or close to each other. Move away from each other; the two movable frames 1 are respectively provided with mutually symmetrical forming molds 2, and the forming molds 2 include a semi-circular die 22 and a pressing plate 21, and the die 22 is fixed on the movable frame 1 on the corresponding side Above, the pressure plate 21 is connected to one axial end of the die 22 and is driven by the extruding driver 24 for extruding movement; the molding dies 2 on the two movable frames 1 are clamped and set on the pipe 5 to be flanged Finally, the two press plates 21 merge to form a complete ring, and the two dies 22 also merge to form a complete ring, and a complete ring-shaped flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com