A cabin rapid pose adjustment and tensioning device based on a six-axis platform

A posture adjustment and tensioning device technology, applied in the direction of offensive equipment, ammunition, weapon accessories, etc., can solve the problems of uneven tensioning force application, compartment disengagement, etc., to improve docking efficiency and reduce coaxiality Error, the effect of ensuring the quality of docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and implementation examples: this implementation example is implemented on the premise of the technical solution of the present invention, and is adapted in conjunction with the docking of a certain product cabin, but the scope of protection of the present invention is not limited to the following examples .

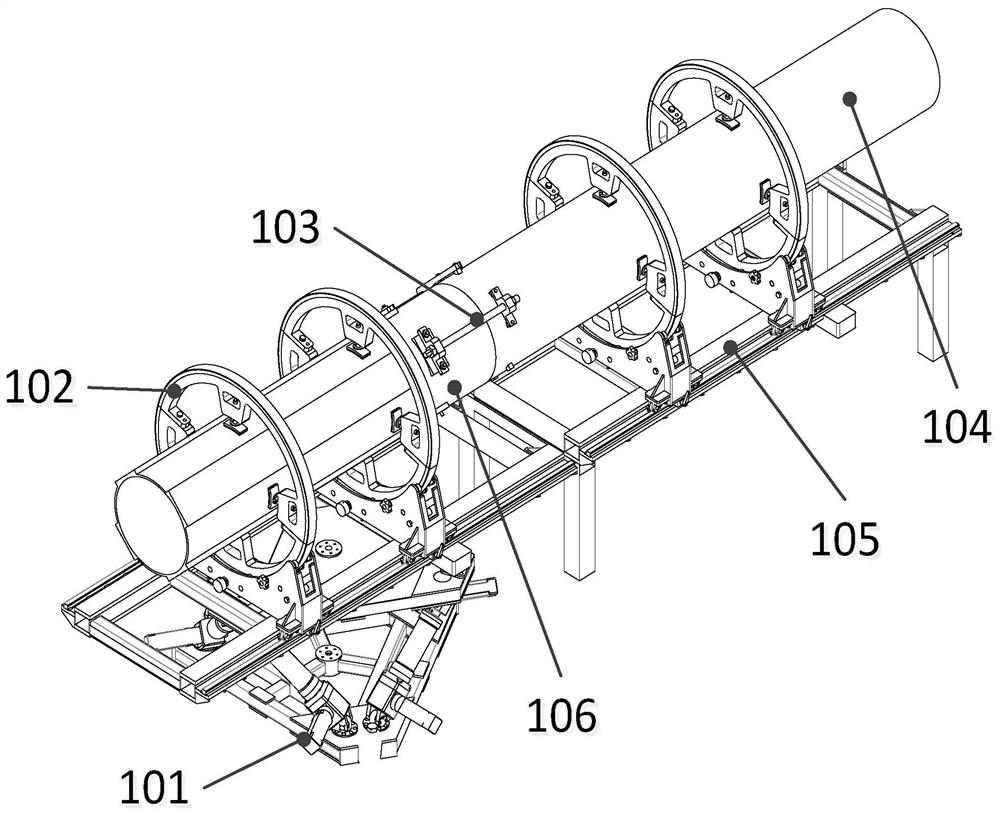

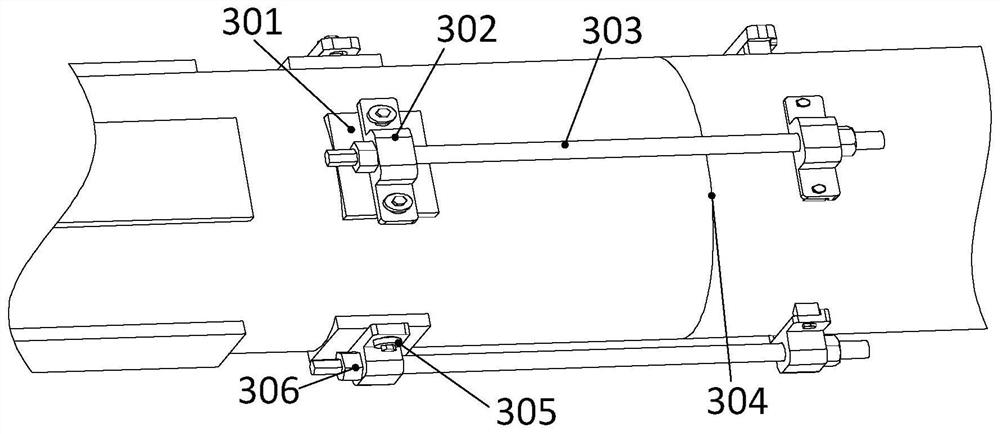

[0025] A cabin section rapid pose adjustment and tensioning device based on a six-axis platform of the present invention includes a rotary clasp module and a tensioning module.

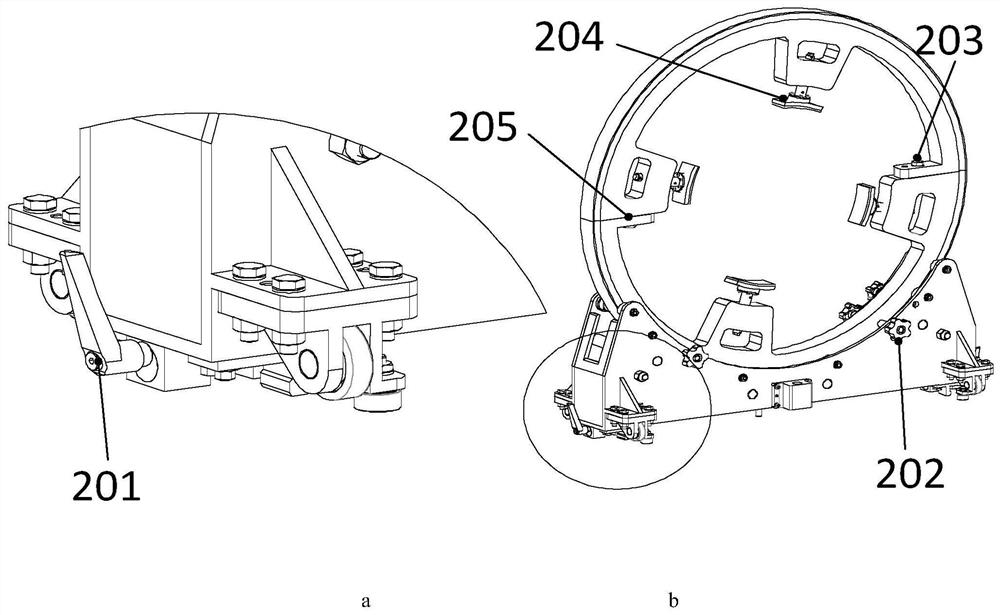

[0026] Swivel snap ring module includes 5 snap rings and base. The snap ring is split and detachable, including a set of identical half snap rings. The half snap rings are positioned by two sets of positioning pins, and connected and fixed by two sets of bolts. The snap ring is installed in the base, and an annular groove is formed on the outer periphery of the snap ring to form a slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com