Integral pushing erection method for truss girders

A technology of truss girder and jacking, which is applied in bridge construction, erection/assembly of bridges, bridges, etc. It can solve the problems that cannot satisfy the simultaneous dragging and jacking erection of double-width main girders of inverted triangular truss beams, and reduce safety risks and assembly difficulties. Reduced, precise alignment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with test examples and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

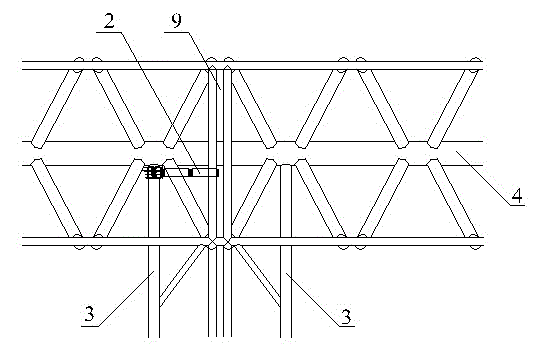

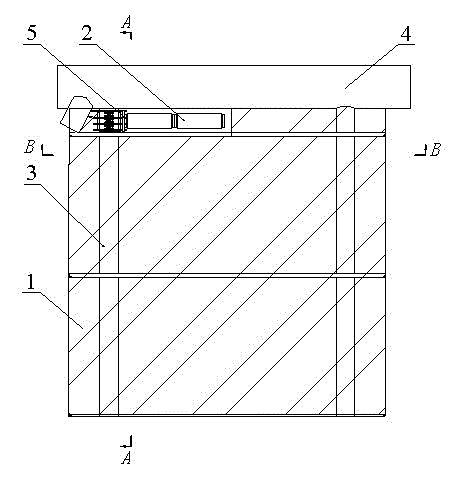

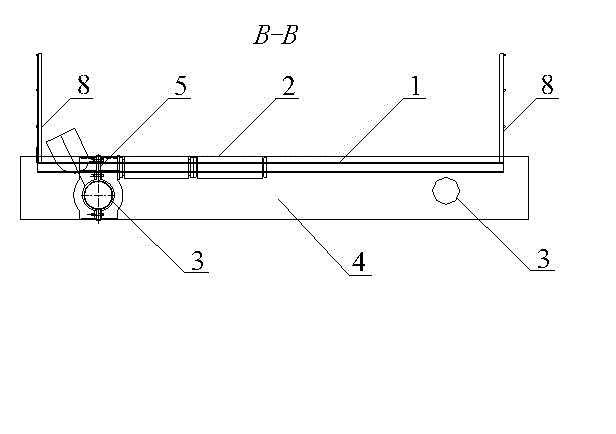

[0037] like Figure 1-7 As shown, the overall push erection method of truss girders includes the following steps:

[0038] The first step is to assemble the truss main girder, and connect the assembled two truss main girders (left main girder and right main girder) into a whole through the lower chord horizontal connecting steel pipe 3 and the upper chord horizontal connecting steel pipe 9;

[0039] The second step is to install the continuous action jack 2. Install the working platform 1 on the assembled truss beam cross-connected steel pipe. The continuous action jack 2 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com