Major diameter steel bar integral vertical hoisting apparatus in high pier construction

A technology for vertical hoisting and construction is applied in the field of integral vertical hoisting devices for large-diameter steel bars in the construction of high piers. 、Ensure the quality of steel bar butt joint and improve the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

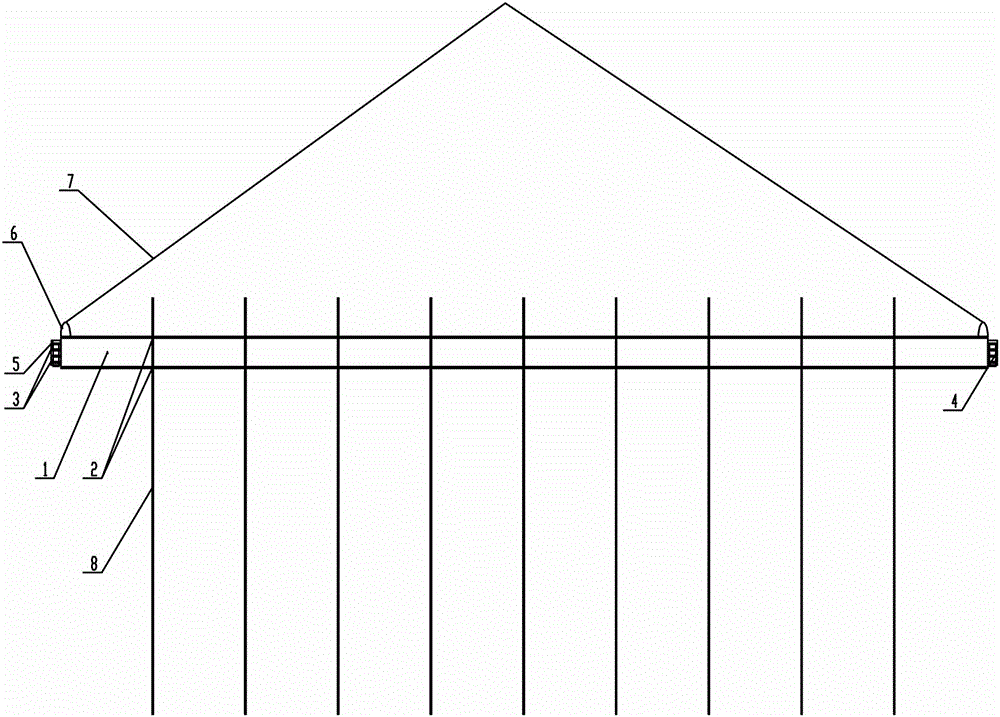

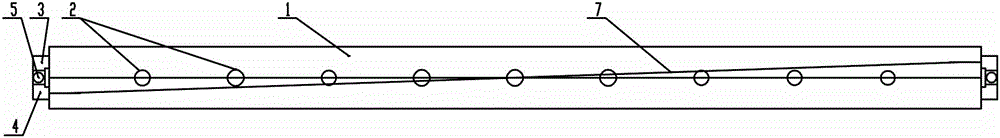

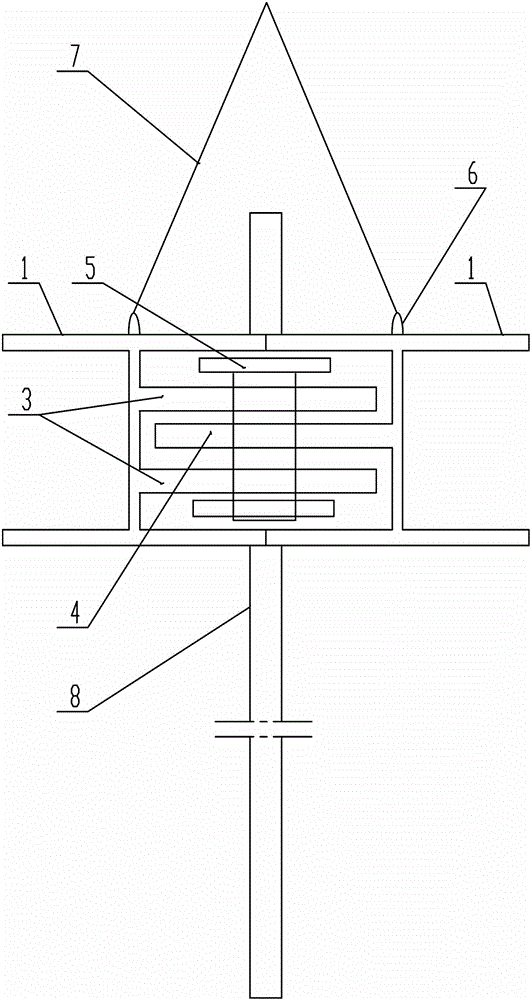

[0017] Such as Figure 1~3 Among them, an overall vertical hoisting device for large-diameter steel bars in the construction of high piers, two steel clamps 1 arranged in parallel, and a plurality of jaw grooves 2 forming an interference fit with steel bars 8 are provided on the flanges that are in contact with each other. The two ends of the two shaped steel fixtures 1 are respectively provided with a left pin orifice plate 3 and a right pin orifice plate 4, and the pin bolts 5 pass through the left pin orifice plate 3 and the right pin orifice plate 4 to connect the two shaped steel fixtures 1 together.

[0018] Both ends of the steel fixture 1 are provided with lifting lugs 6 . The set lugs 6 are used to connect the wire rope 7 for lifting.

[0019] preferred, such as image 3 Among them, the section steel fixture 1 adopts I-beam, and the flanges of I-beam are arranged oppositely. It is also feasible to use channel steel.

[0020] optimized, such as figure 2 Among the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com