A method of manufacturing a large-diameter pile foundation reinforcement cage

A pile foundation reinforcement cage and manufacturing method technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of poor control of welding quality of connection points, poor butt joint accuracy of reinforcement cages, and high processing costs of tire molds, etc. To achieve the effect of facilitating collaborative operation, ensuring accuracy, and low cost investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This example is 55m with making pile length, and the reinforcement cage that pile diameter is required for 2.6m is embodiment that the present invention is further explained and illustrated. The manufacture of the large-diameter pile foundation reinforcement cage is carried out according to the following steps:

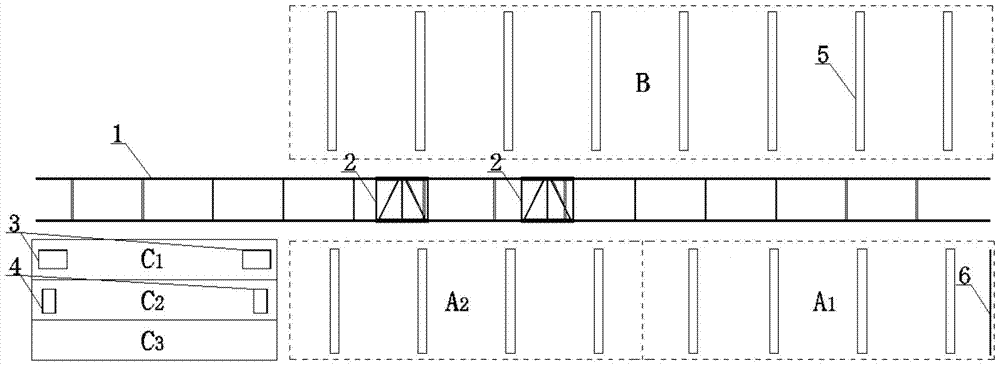

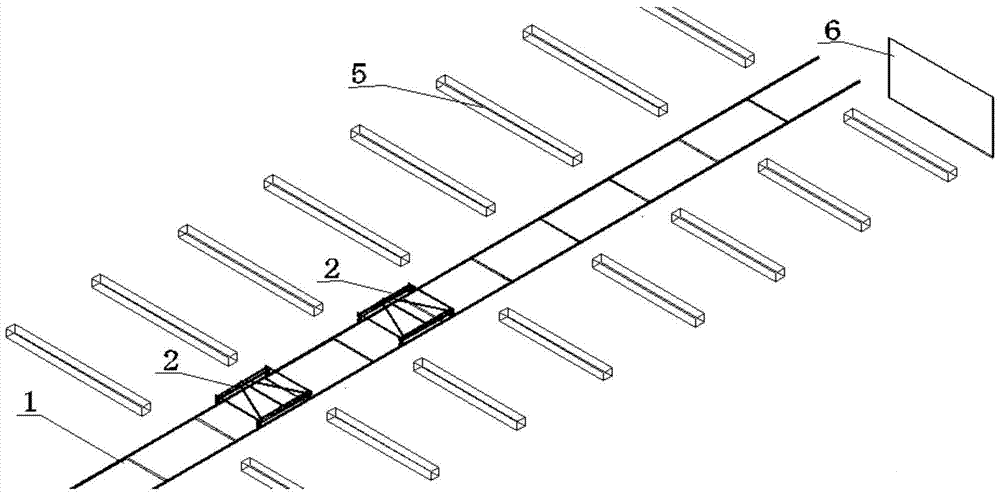

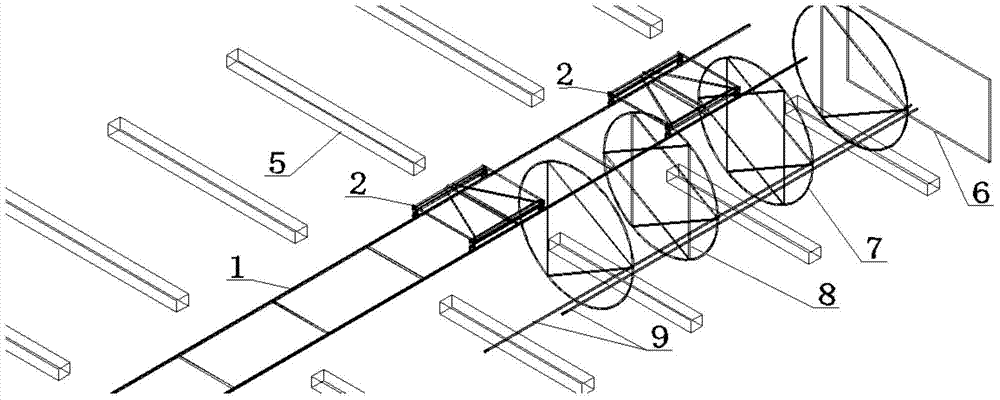

[0039] (1) Set up the production area of large-diameter pile foundation reinforcement cage; the production area of reinforcement cage is as follows: figure 1 As shown, it includes a parallel track 1 on which two railcars 2 for transporting steel bars and reinforcement cages are installed, and a reinforcement cage storage area B is respectively arranged on the left and right sides of the parallel track 1 And reinforcement cage production area, described reinforcement cage production area comprises the first production platform A 1 and the second production platform A 2 . The steel cage storage area B and the steel cage production area are respectively pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com