Locking disc assembling prepositioning device and assembling method

A technology of pre-positioning device and locking disc, which is applied in the direction of hand-held tools and manufacturing tools, can solve the problems of poor assembly effect, complicated assembly process, waste of manpower and time, etc., to save installation time, avoid complicated operations, Labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

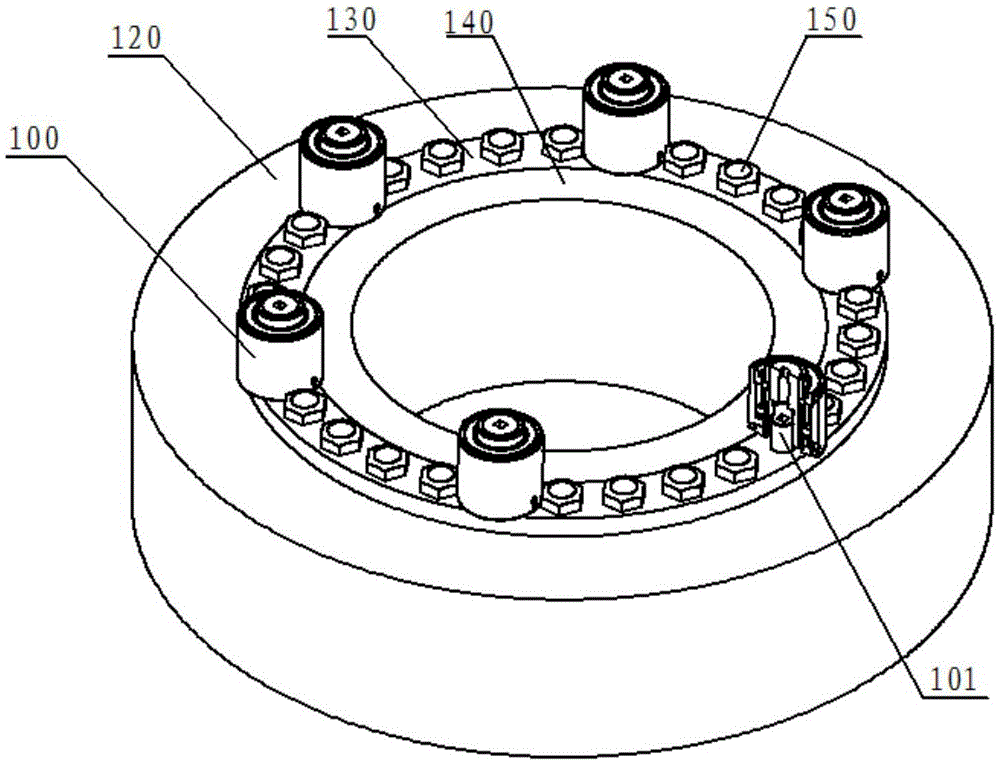

[0045]In this embodiment, the assembly of the wind power shrink disc is specifically described.

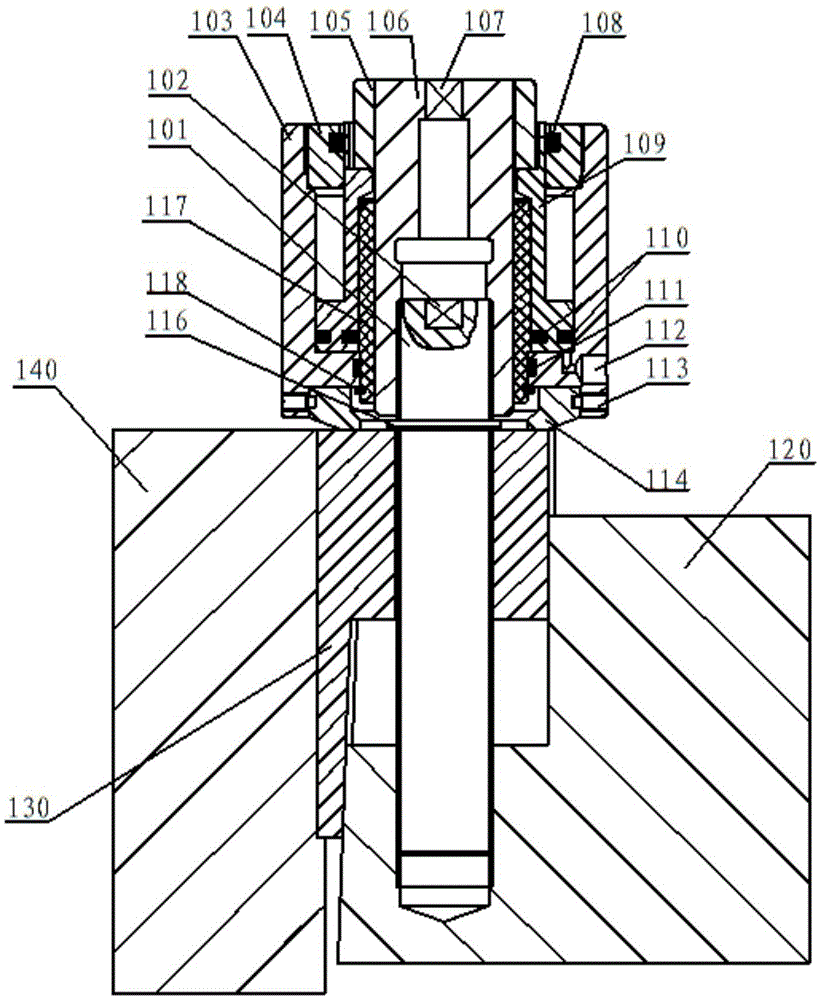

[0046] Such as figure 1 As shown, a wind power shrink disk assembly pre-positioning device includes a screw 101, a cylinder 103 and a piston 109 arranged in the cylinder 103, the upper end of the screw 101 is provided with a first connection hole 102, the first connection hole 102 is for example It can be a square hole, and it is convenient to use a wrench or other tools to quickly screw the screw into the assembly hole of the inner ring and the outer ring of the wind power locking disc. The upper side is provided with a limit shaft shoulder 116; 106 upper end is provided with push ring 105, and push ring 105 is threadedly connected with connecting shaft 106 upper ends, and push ring 105 is in contact with piston 109 upper end; Between cylinder body 103, piston 109 upper end, push ring 105, be provided with upper end cover 104, upper end cover 104 An end cap seal 108 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com