Slab Continuous Casting Segment Positioning and Locking Device and Assembly Method

A positioning locking and slab continuous casting technology, applied in the field of metal continuous casting equipment, can solve the problems of long operation time, frequent maintenance, inconvenient installation and disassembly, etc. Stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

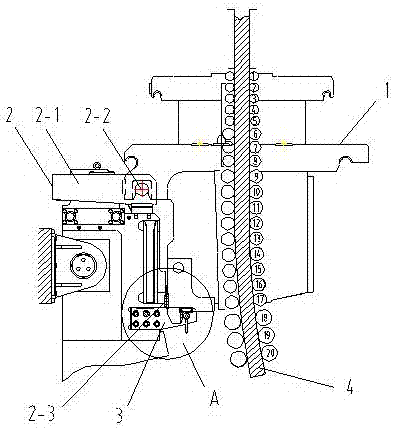

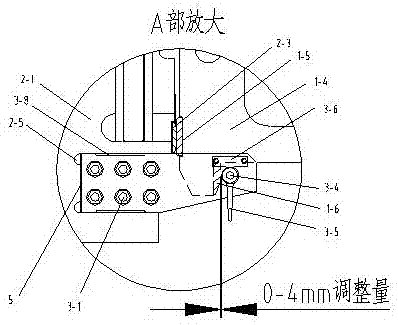

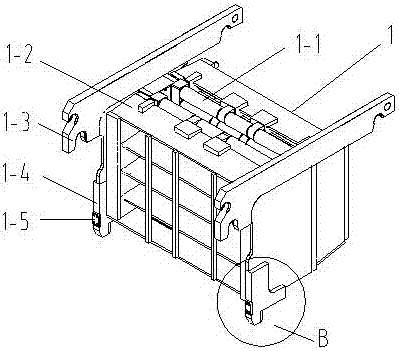

[0035] Depend on figure 1 , figure 2It can be seen that the positioning and locking device for the slab continuous casting segment is composed of segment 1, segment 2 and bearing mechanism 2, and the segment is composed of row rolls 1-1 and roll frame 1-2. The above-mentioned column rolls 1-1 are guide rolls arranged along the forward direction of the slab to guide the slab to move forward; the 2# to 17# rolls of the column rolls are fixed on the roll frame; the upper left side of the roll frame is provided with a hook 1 -3, a left adjustment block 1-5 and a corbel 1-4 are arranged at the lower end; the bearing mechanism 2 is symmetrically arranged on the foundation by two bearing frames 2-1, and a hanging pin 2-2 is arranged on the right side of the bearing frame, and is connected with the roller frame Cooperate with the hooks, set the support plate 2-3 on the lower right side, cooperate with the left adjustment block on the roller frame, the sector 1 is fixed on the sector...

PUM

| Property | Measurement | Unit |

|---|---|---|

| eccentricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com