Rapid arc connecting method of slab caster crystallizer narrow face foot rollers

A technology of slab continuous casting machine and narrow-faced foot roll, which is applied in the field of metallurgical machinery, can solve problems such as the influence of production rhythm, screw nut grinding, and reducer failure, so as to improve work efficiency and arc connection accuracy , The effect of reducing downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

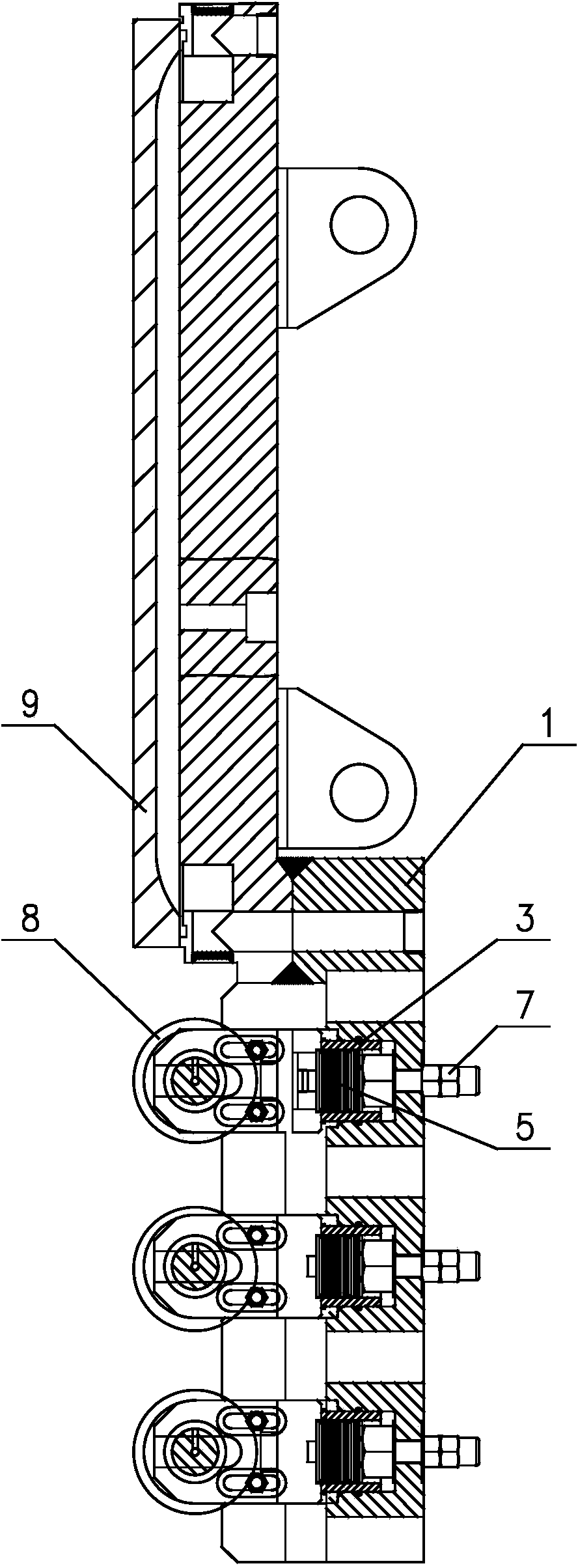

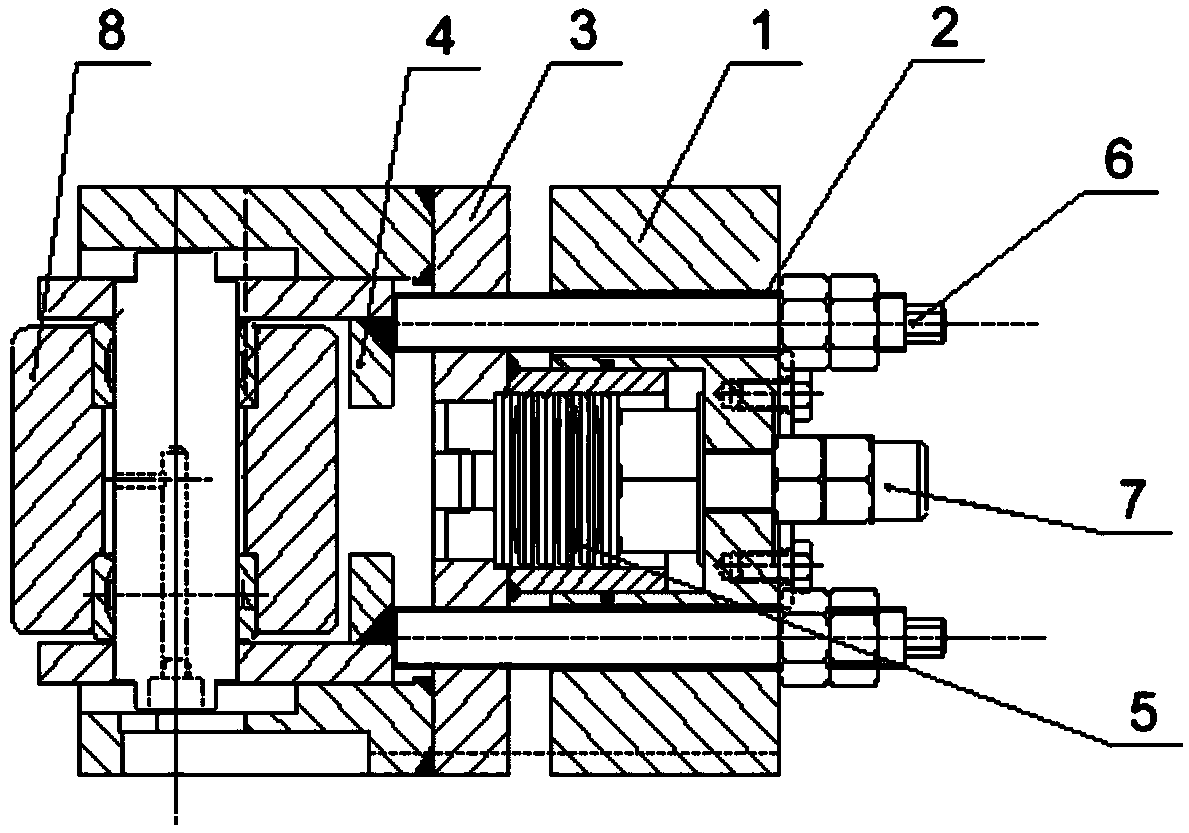

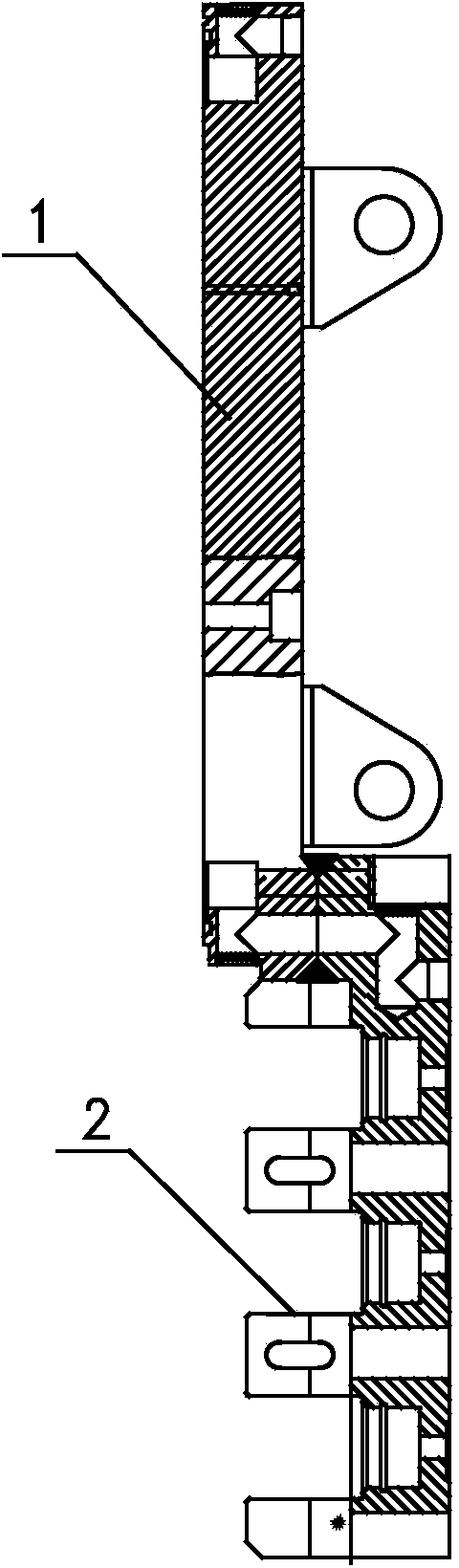

[0017] Such as Figure 1 ~ Figure 3 Said, a method for quickly arc-connecting the narrow face foot roll of the crystallizer of a slab continuous casting machine, comprising the following steps:

[0018] 1) First, fix the two sides of the foot roller 8 on the foot roller bracket 3 through the L-shaped clamp plate 4, and then add 10 sets of disc springs 5 at the rear of the foot roller bracket 3 for flexible connection with the foot roller billet to prevent hydrostatic pressure The bulge of the billet is caused, and then the wear-resistant layer is electroplated on both sides of the foot roll bracket 3 to achieve good lubrication, and finally the assembled foot roll device is installed in the U-shaped groove 2 on both sides of the lower end of the Z-shaped support plate 1;

[0019] 2) The arc connection operation of the foot roller is achieved by adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com