Patents

Literature

54results about How to "Improve activation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

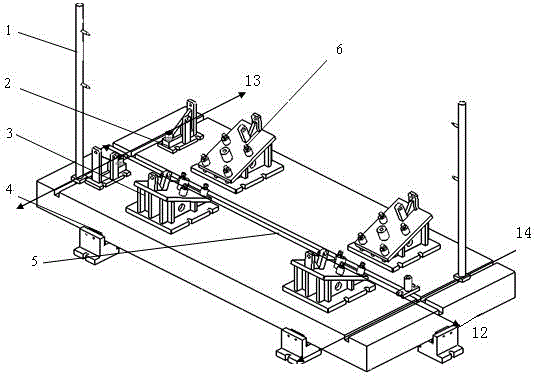

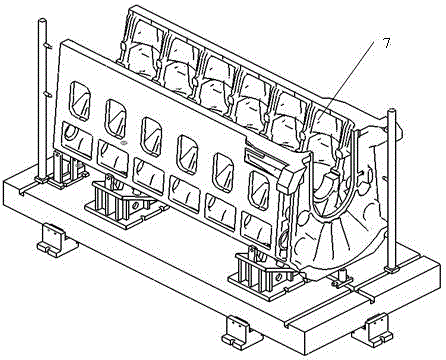

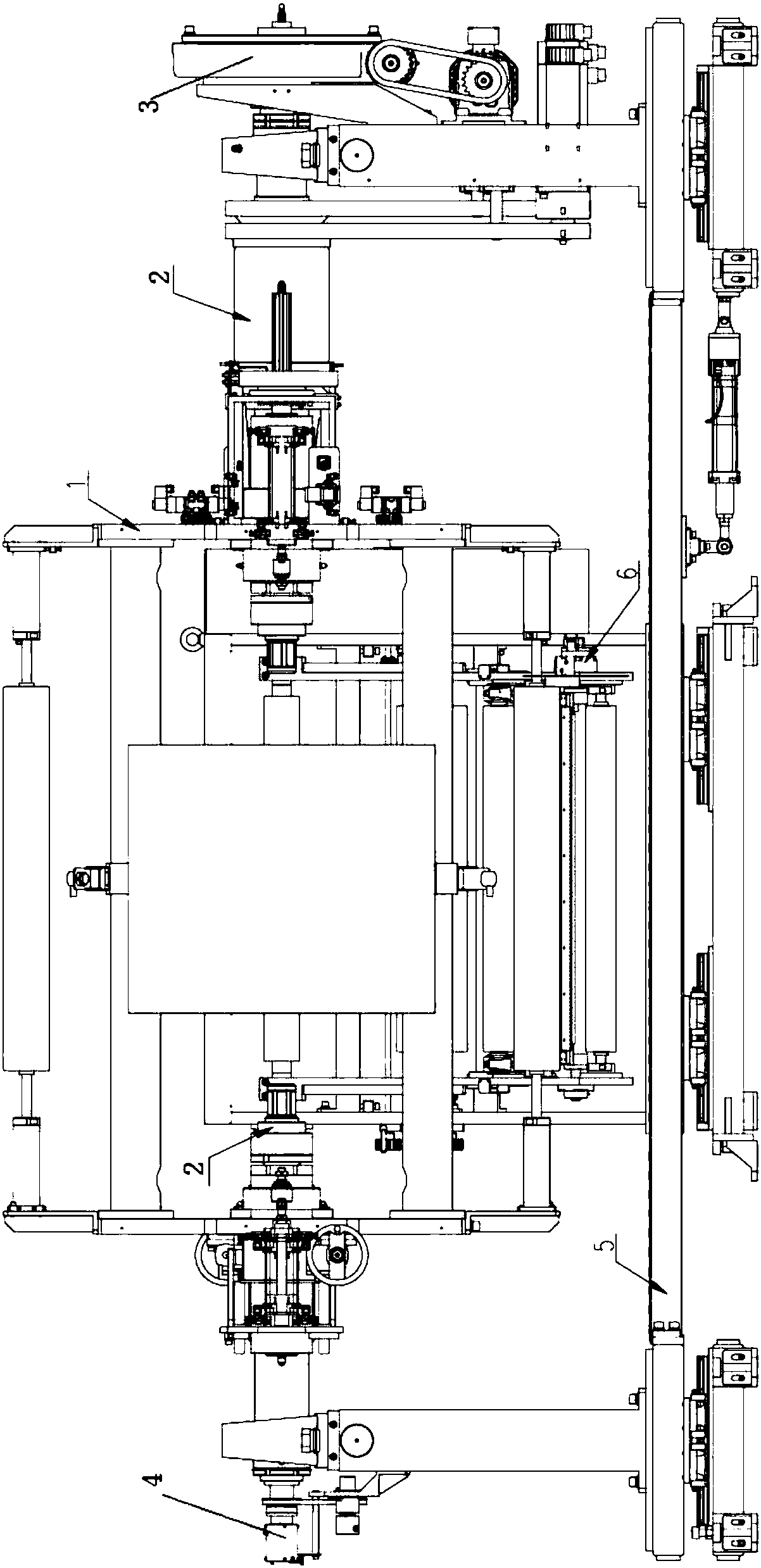

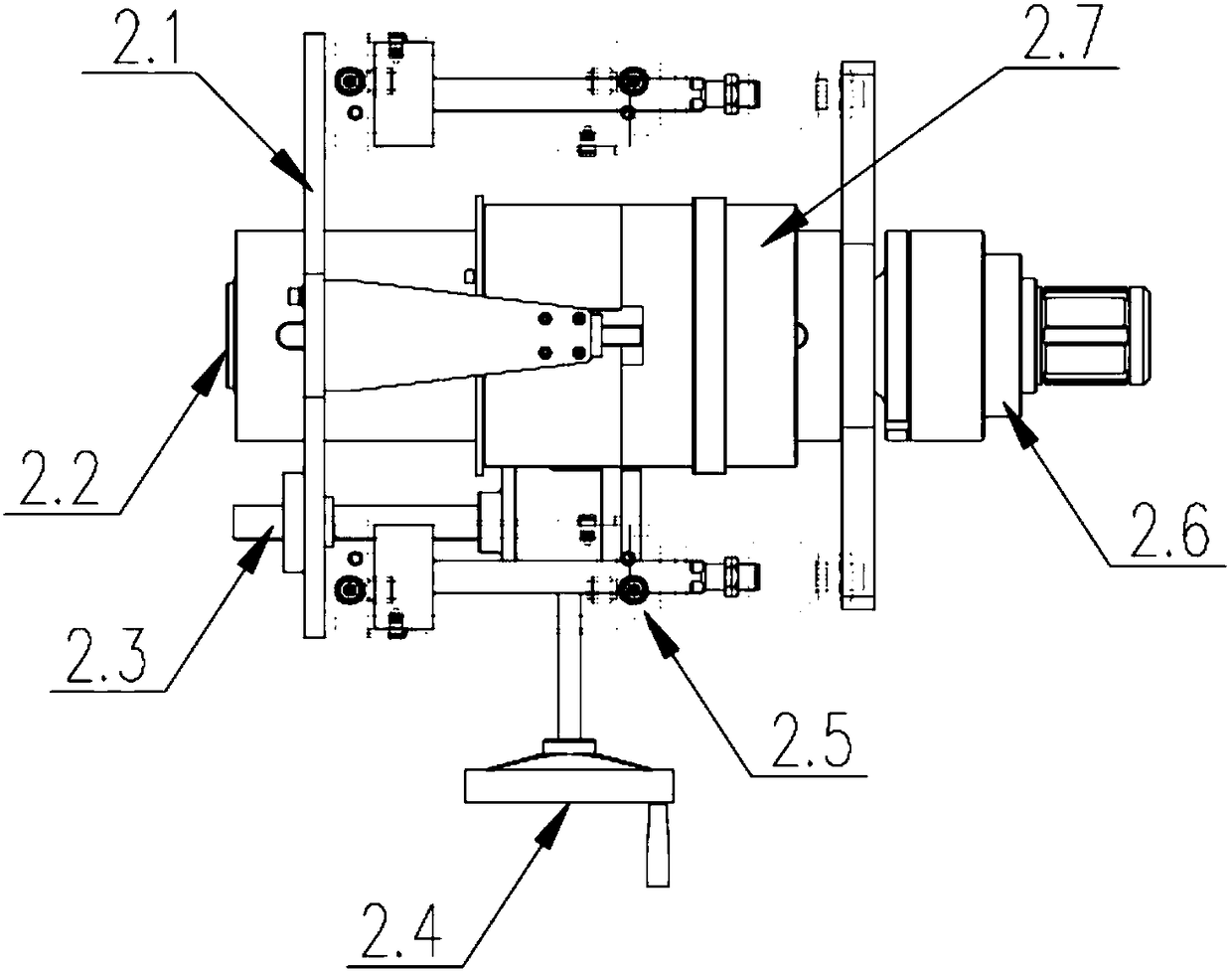

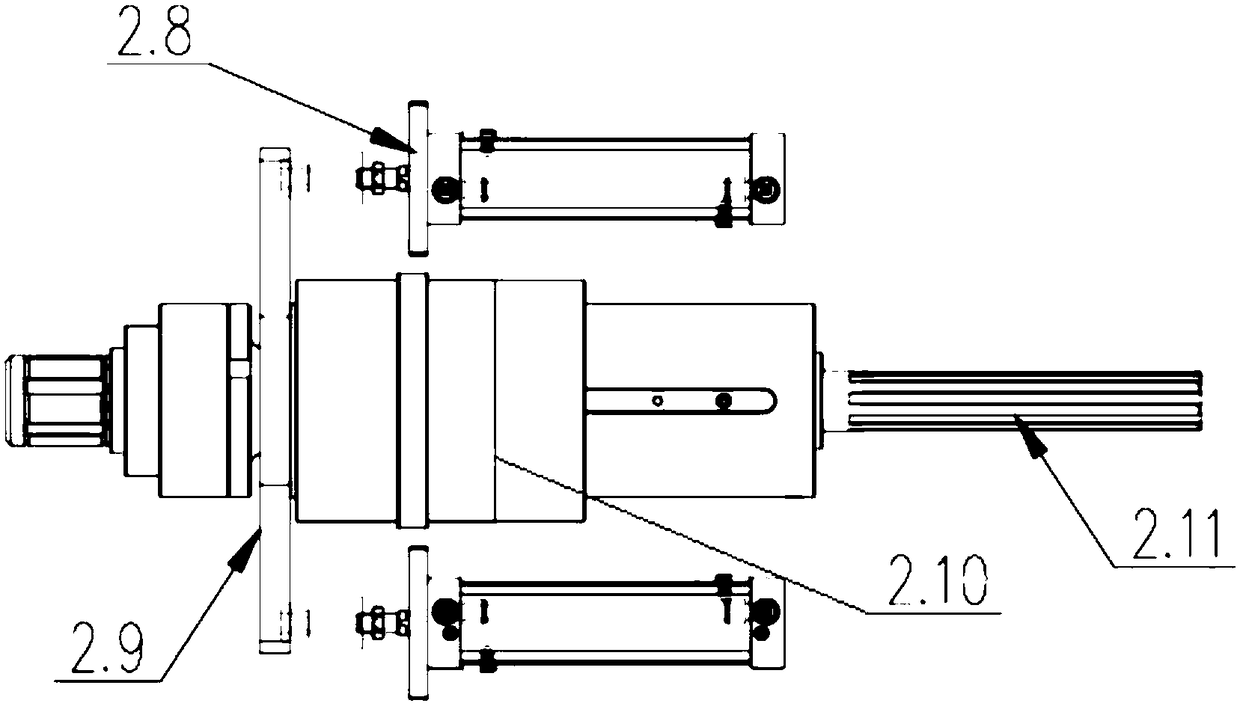

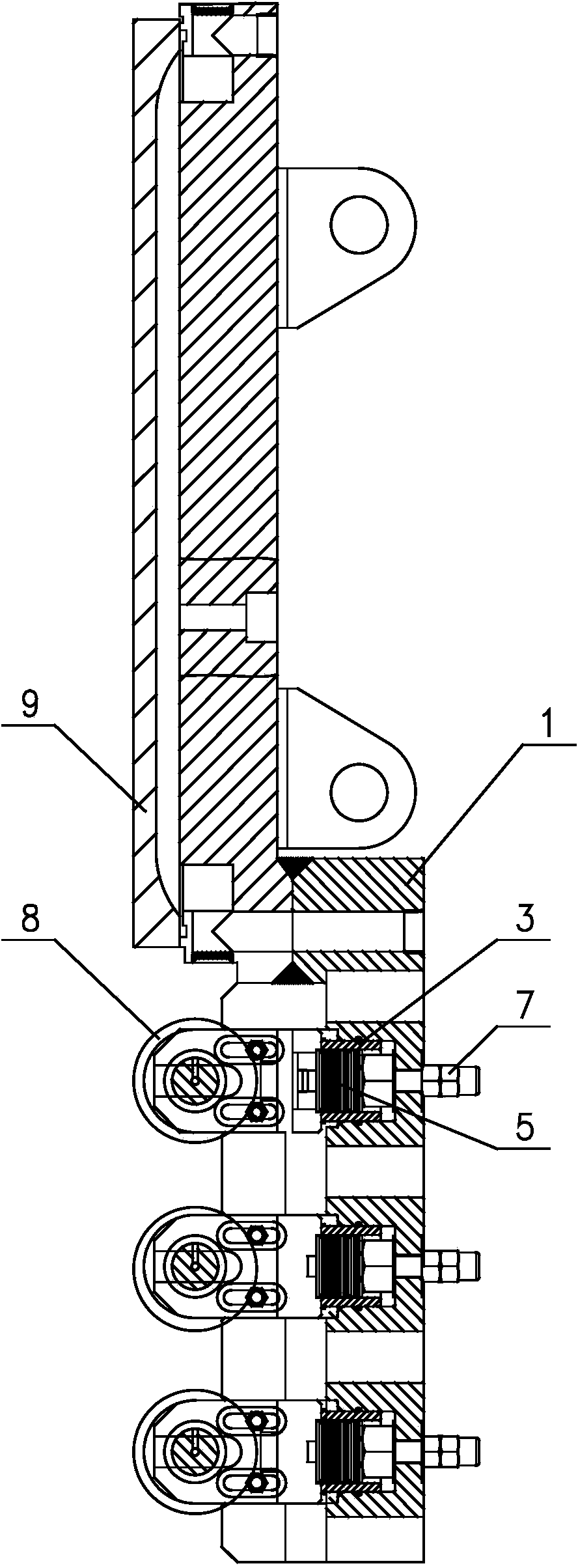

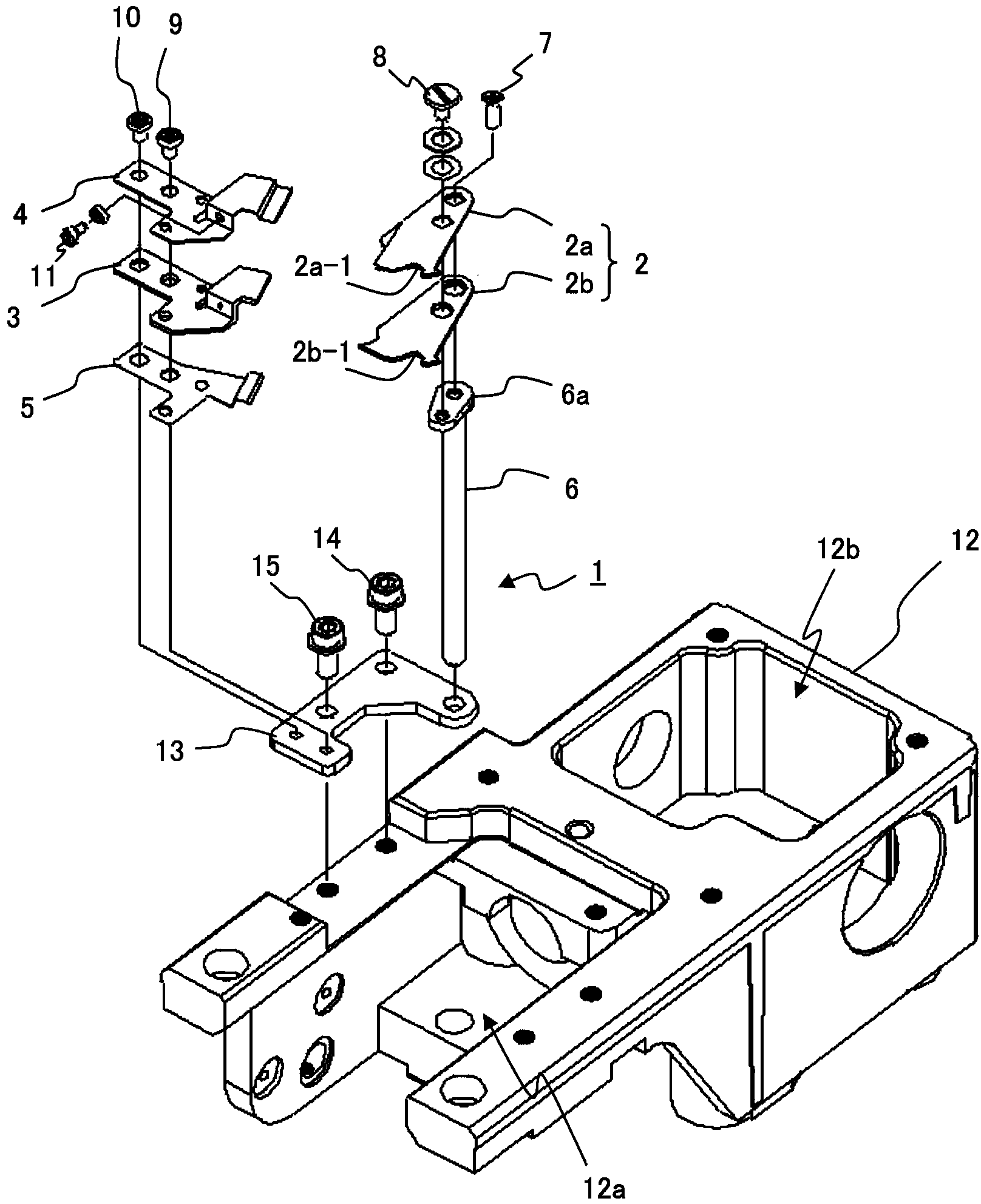

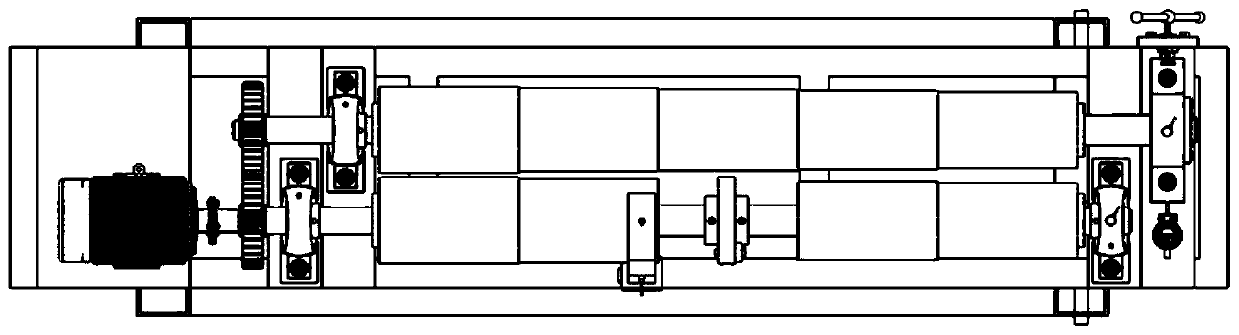

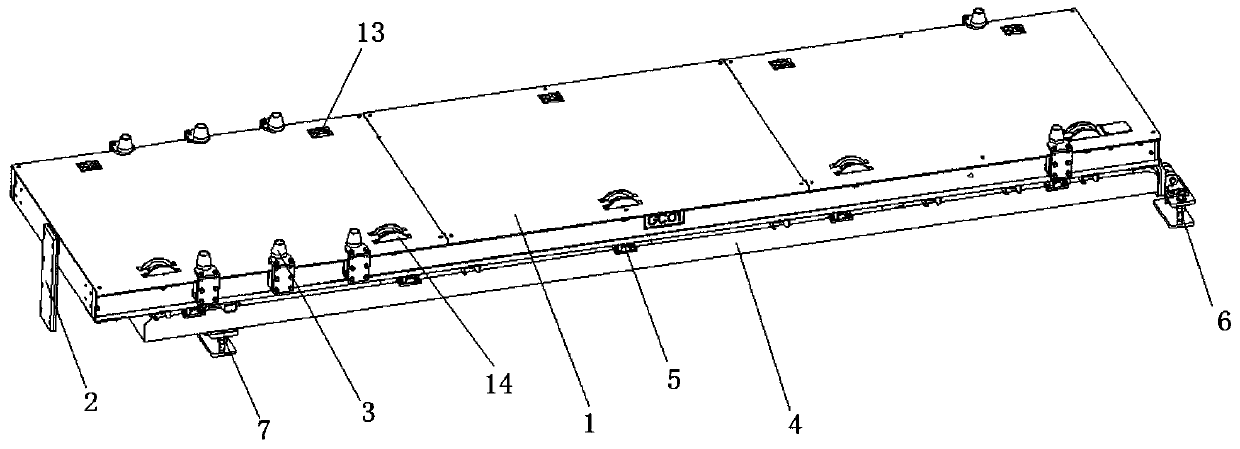

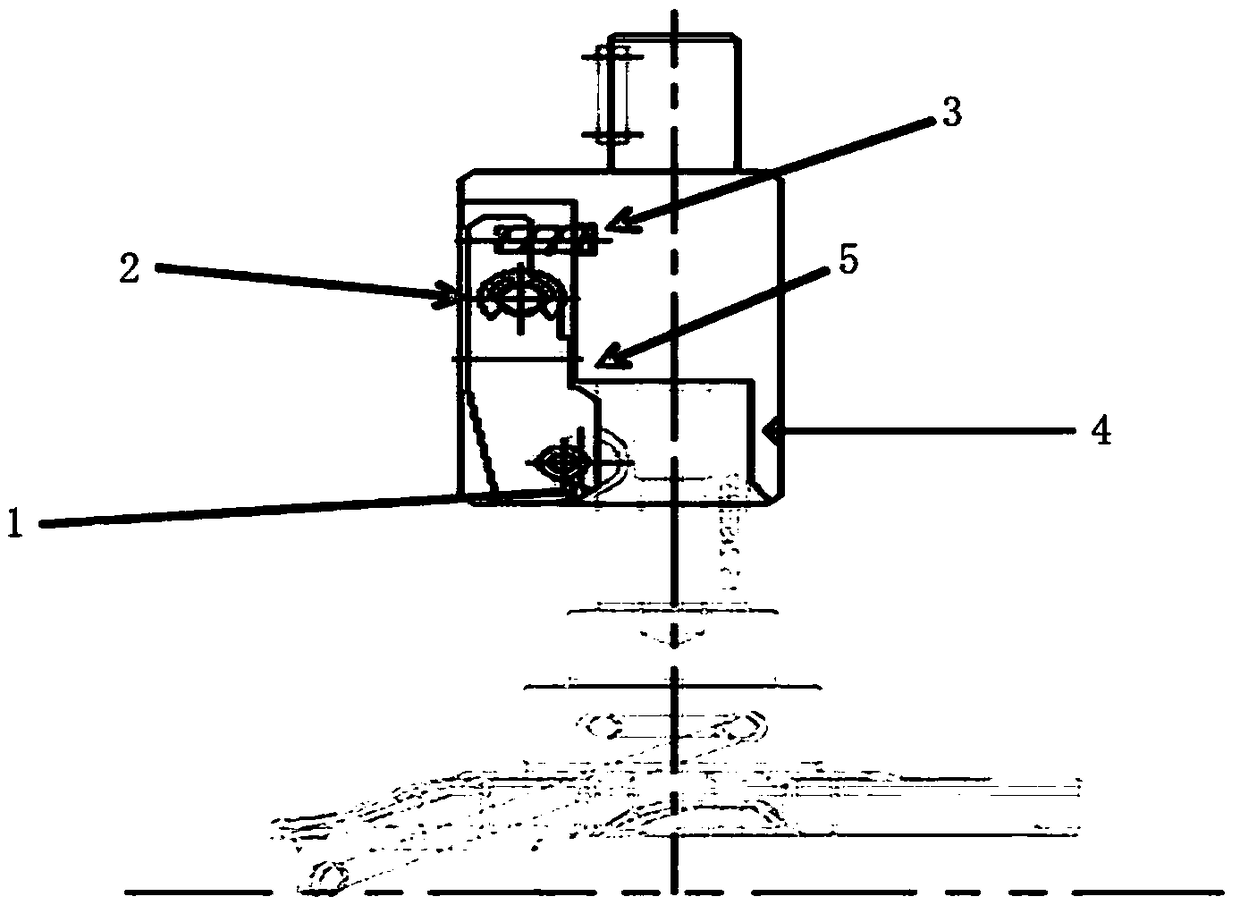

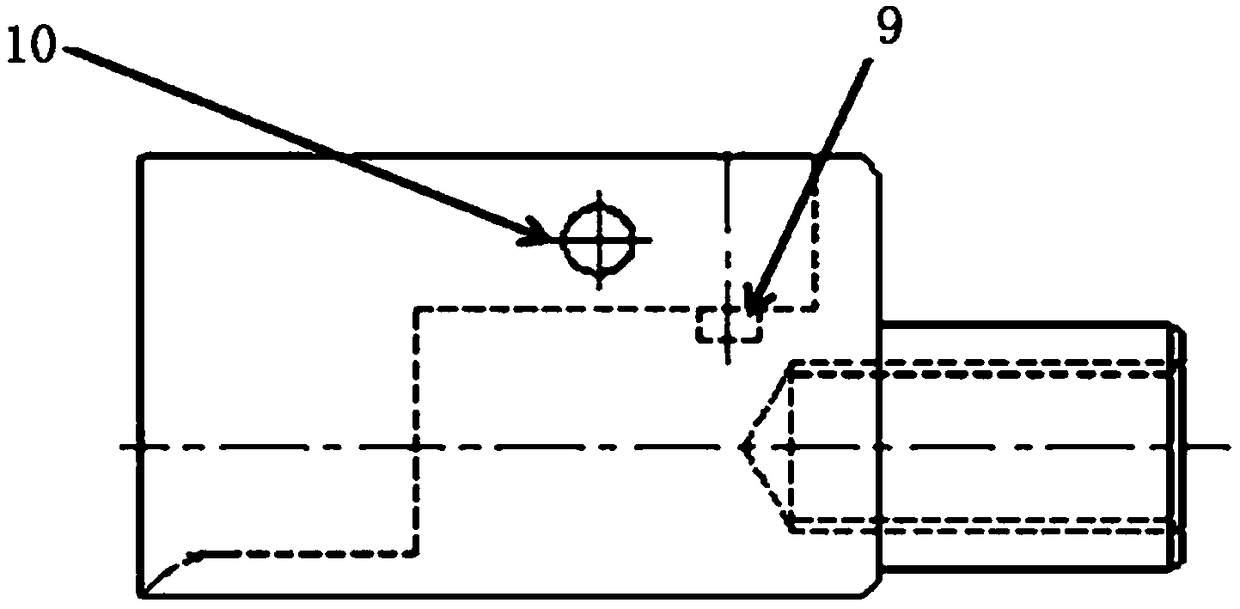

Tool suitable for machining V-shaped diesel engine rack and using method thereof

ActiveCN104924118AImprove activation rateImprove efficiencyPositioning apparatusMetal-working holdersNumerical controlJackscrew

The invention relates to a tool suitable for machining a V-shaped diesel engine rack. The tool comprises a base plate, and the base plate is provided with a datum key groove. A clamping fixture of a V-shaped diesel engine is fixedly mounted on the base plate, and the rack is placed on the fixture. The fixture comprises four angle tools used for supporting the V-shaped cylinder face of the rack, horizontal adjusting tools, adjustable jackscrews, and two equal-height scratch awls of the constant height and size. One set of adjustable jackscrews are arranged on the upper surface of each angle tool, and the equal-height scratch awls are arranged in the datum key groove of the base plate. The tool suitable for machining the V-shaped diesel engine rack has the advantages that the tool special for the V-shaped diesel engine rack in a gantry numerical control machining tool is designed, the time of the tool is not occupied in the work procedure clamping process, clamping can be achieved in an offline mode, quick positioning is achieved on the tool, the clamping time for products is shortened to the maximum degree, the actual tool operating rate is increased, and the product machining efficiency is improved.

Owner:共享智能机器(苏州)有限公司

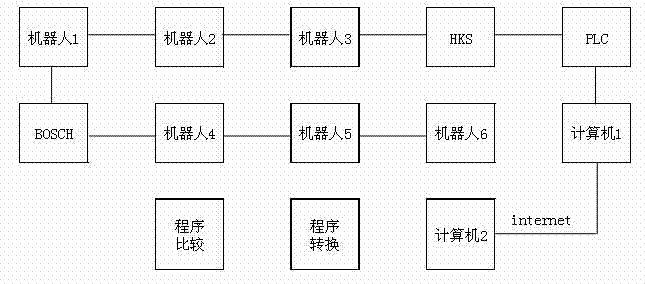

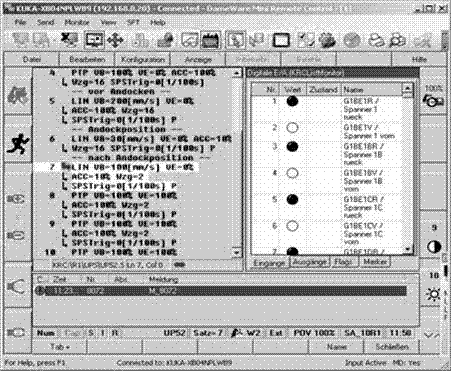

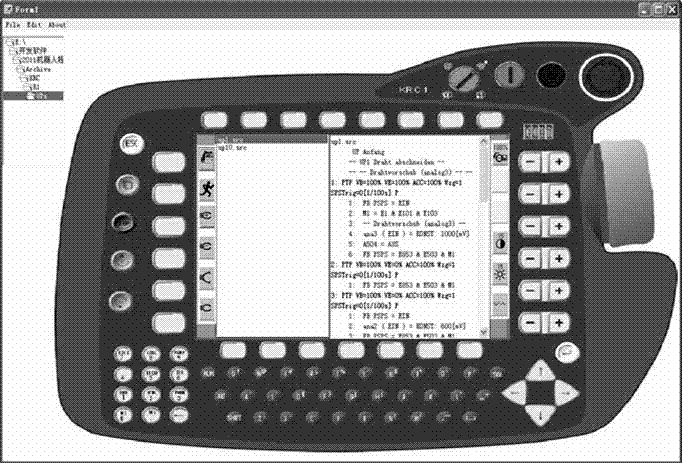

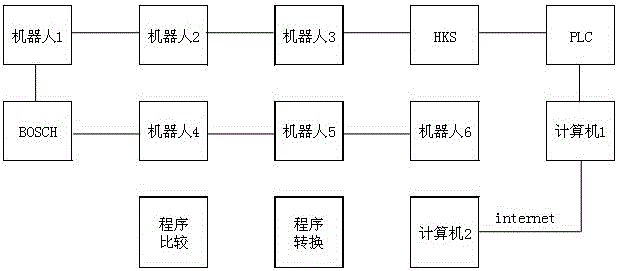

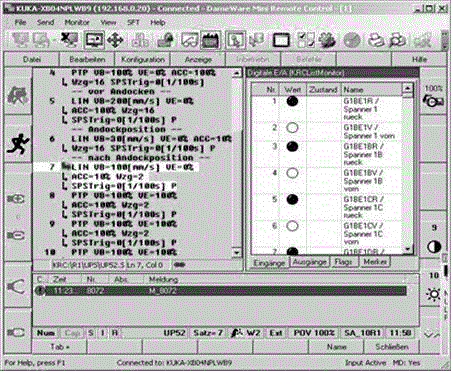

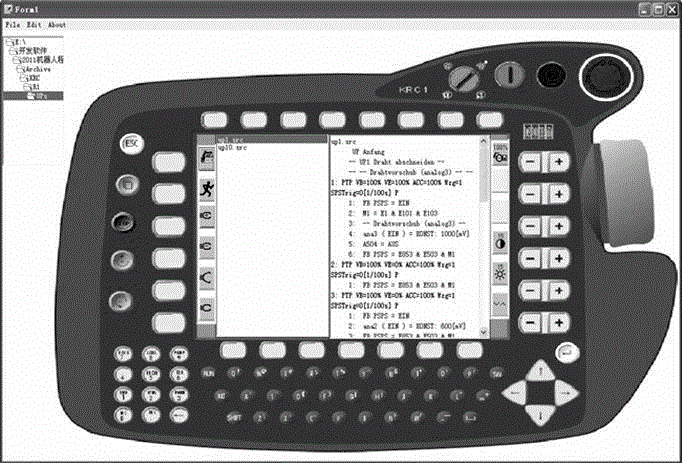

Remote control method of industrial robot

ActiveCN102830677AWith remote diagnosis functionImprove management levelTotal factory controlProgramme total factory controlSimulationField device

The invention relates to a remote control method of an industrial robot, and is characterized by comprising the following steps: all KUKA robots on a production line and a criterion for a device, which conforms to a TCP / IP (Transmission Control Protocol / Internet Protocol) are connected through network cables, an original registry of the robots is modified, and configurations of the KUKA robots are changed; a computer 1 is provided with a DameWare remote control software server, and each KUKA robot is provided with a DameWare client software, through a remote training function of the robot, the computer 1 connected with the robot and a computer 2 connected to a projector in a training room are connected to an Internet network, and the KUKA robots on the production line are subjected to remote diagnosis through Internet. According to the invention, the fault handling time is saved, and a remote control function is realized; meanwhile, dependency of the robot training on a field device is solved, a field interface of the robot is shown through the network and is connected to the projector so as to carry out large-scale targeted training and provide convenience for optimization and adjustment of a usual welding process.

Owner:CHINA FIRST AUTOMOBILE

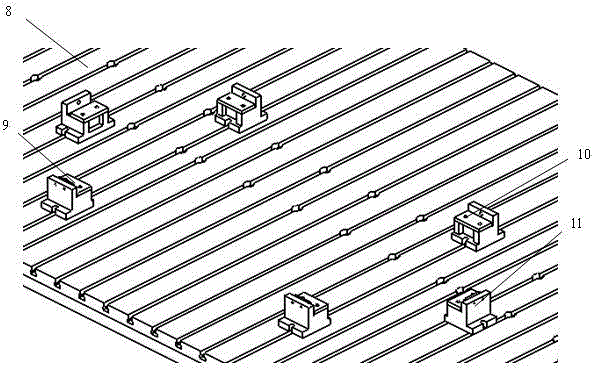

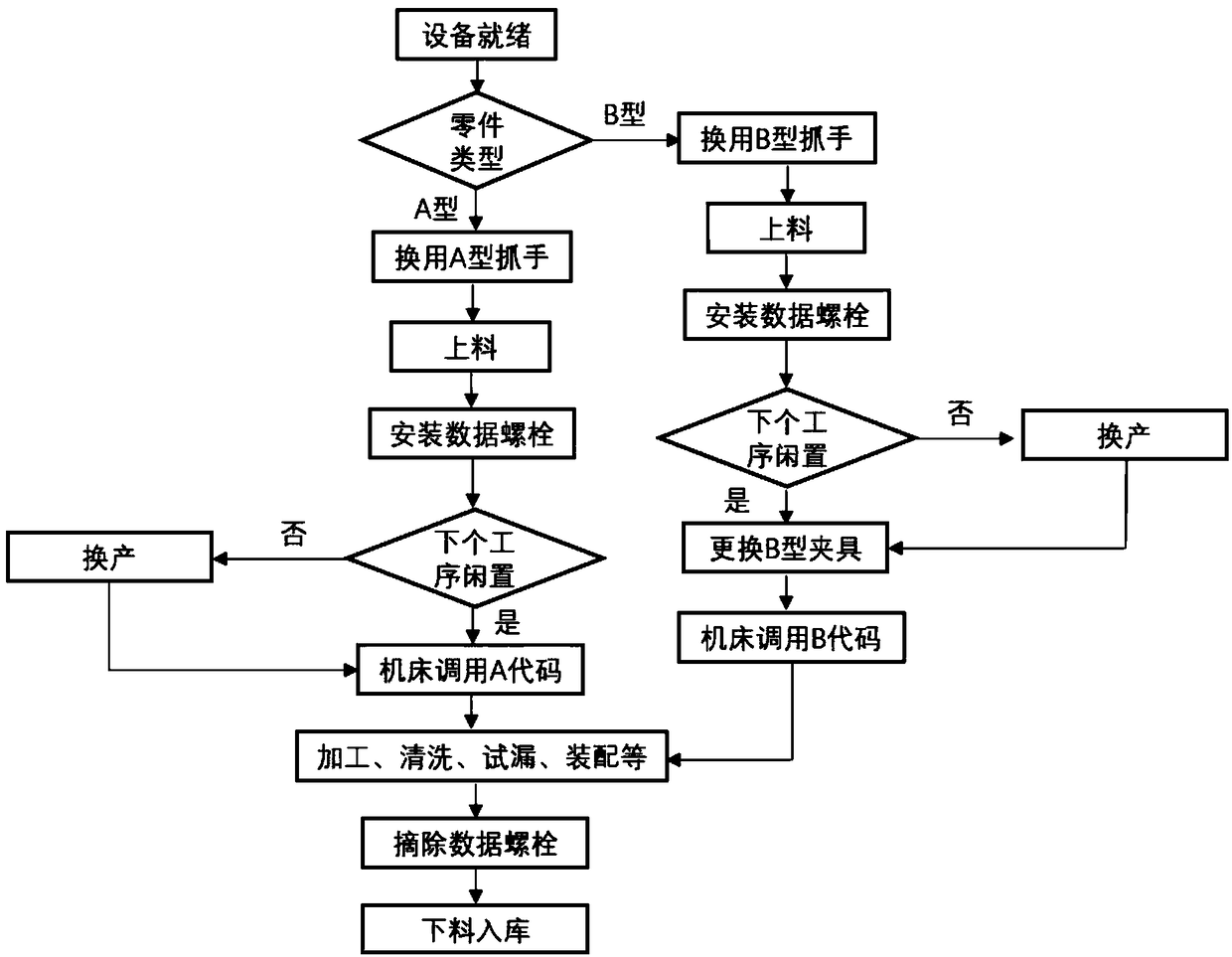

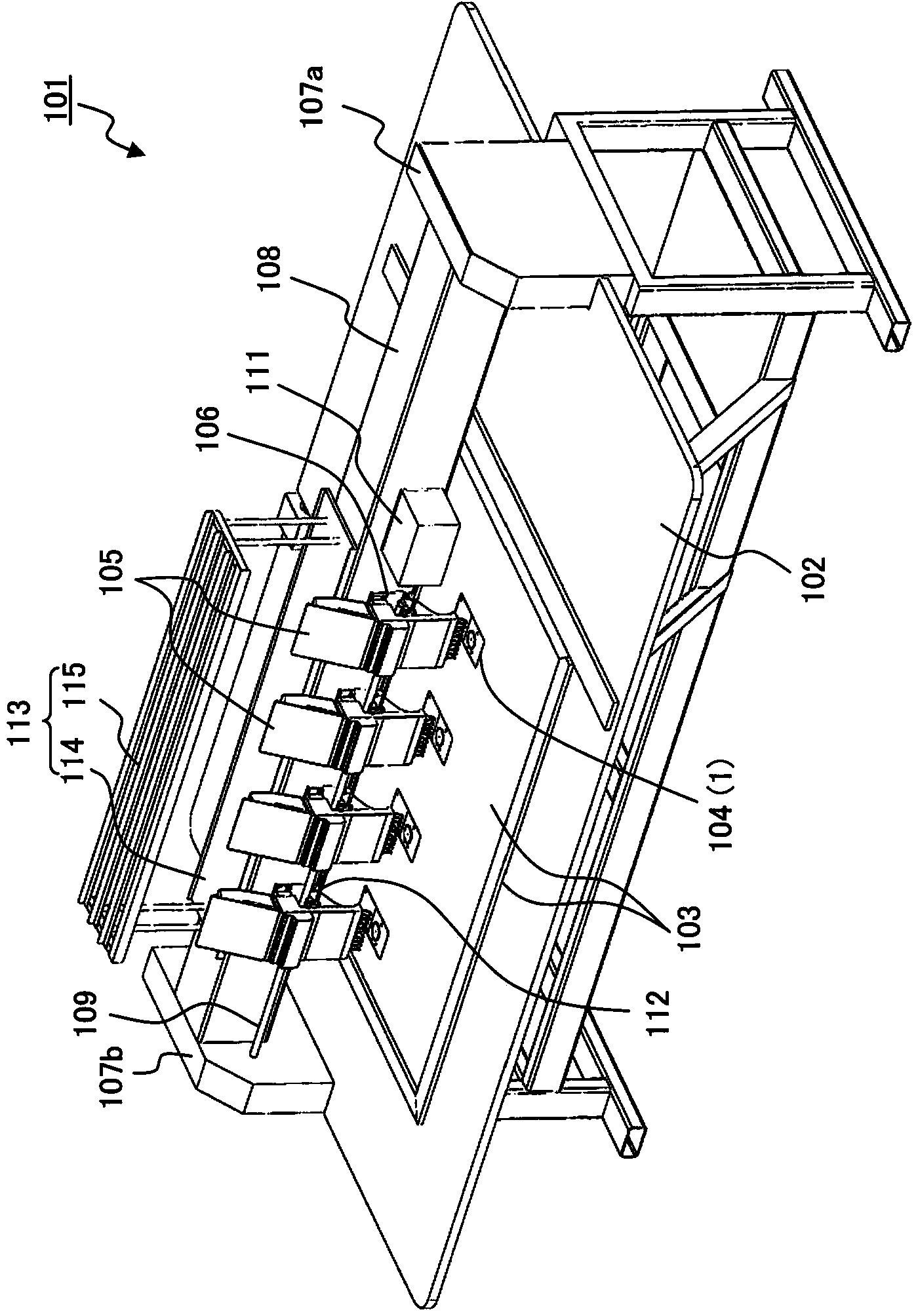

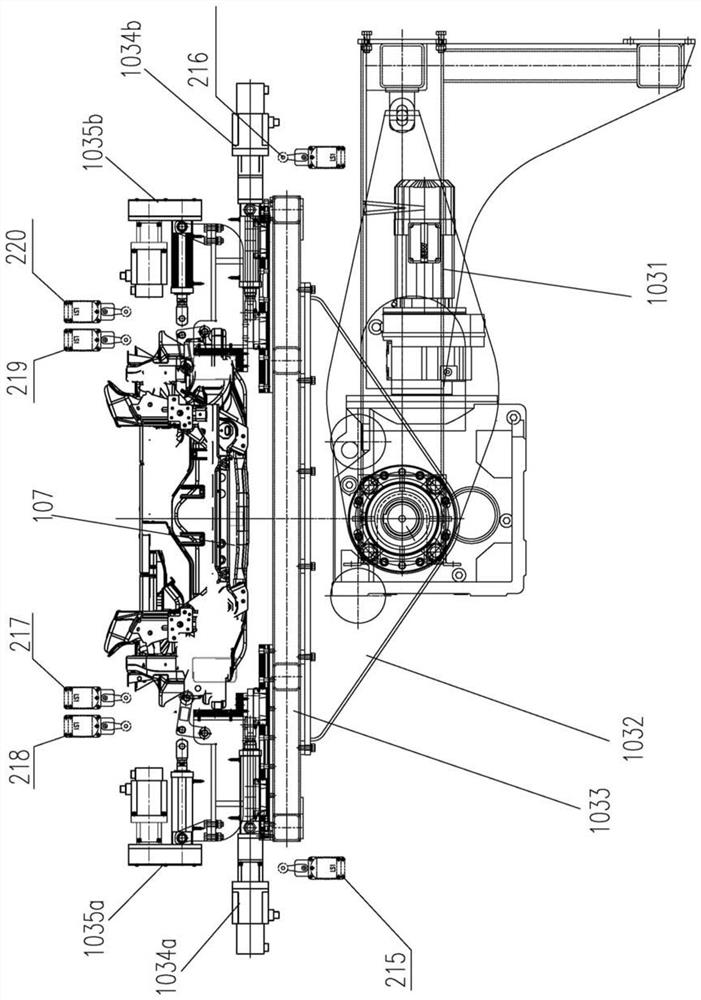

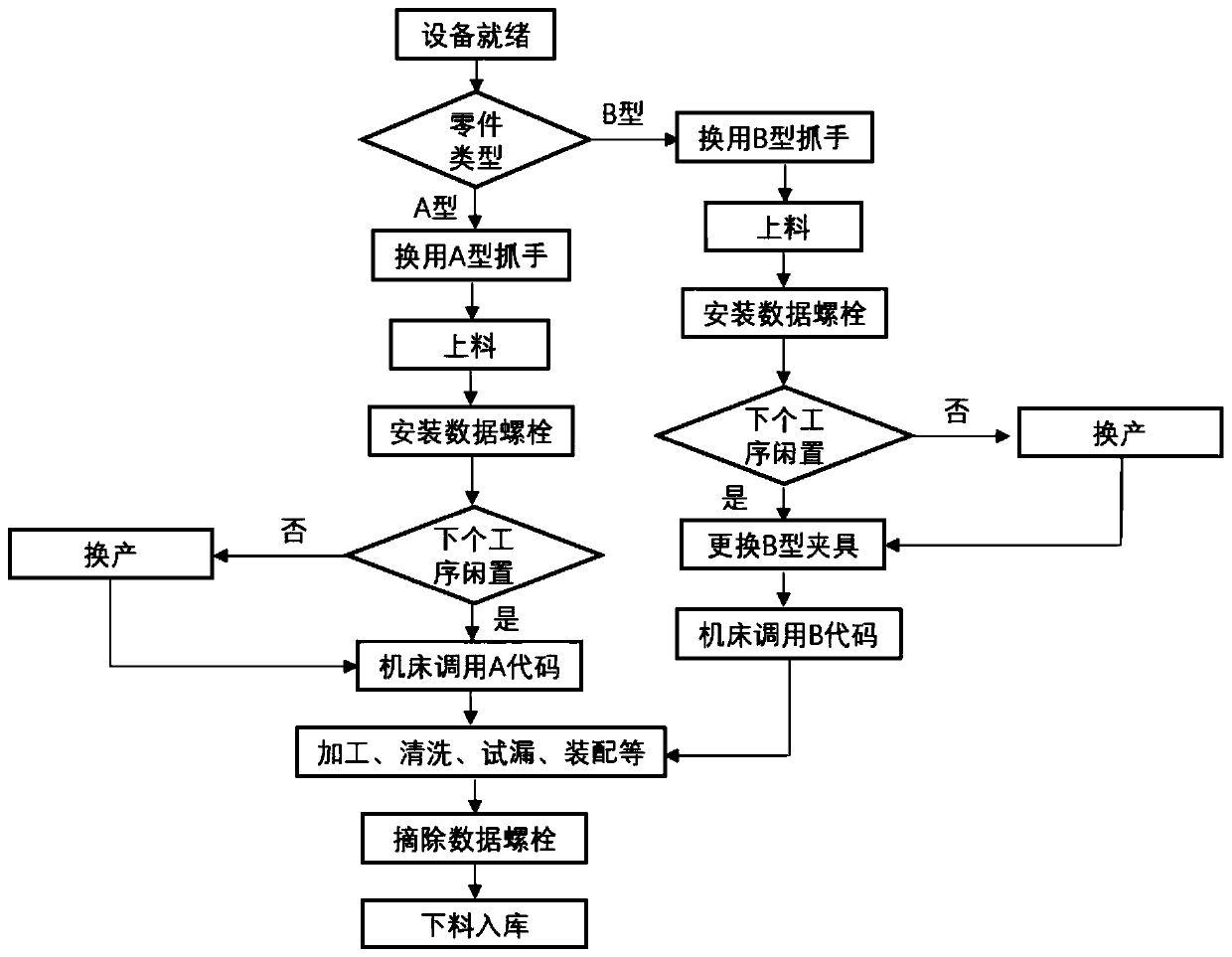

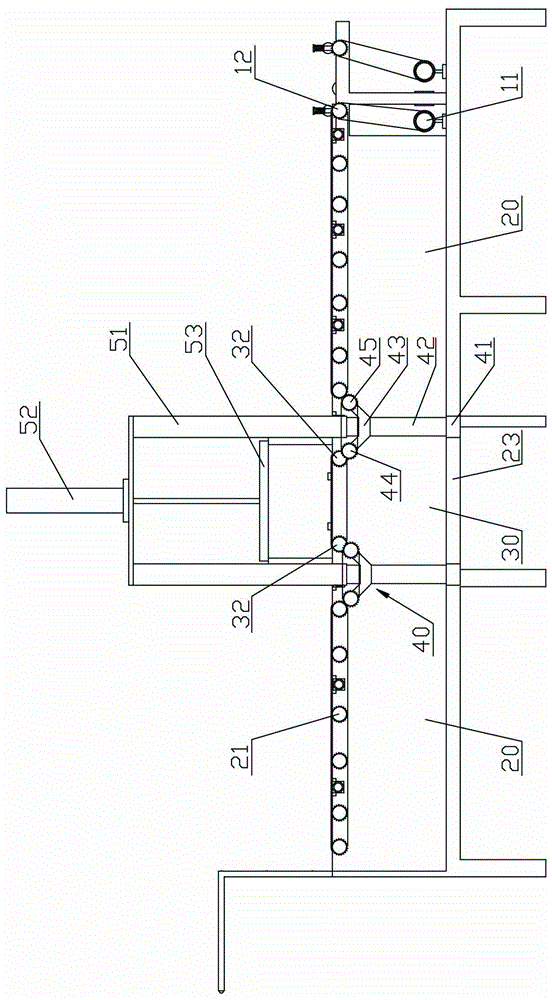

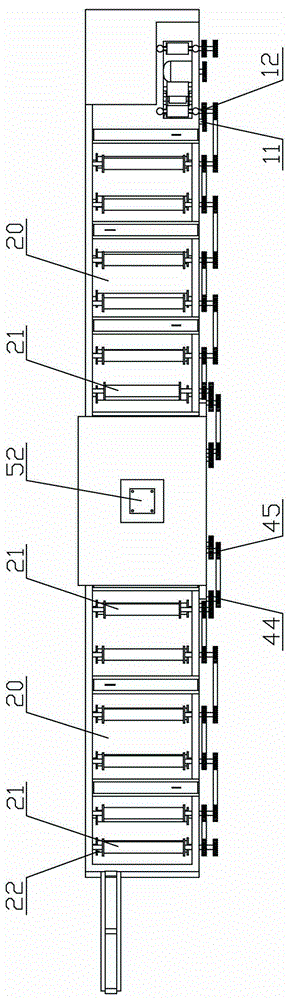

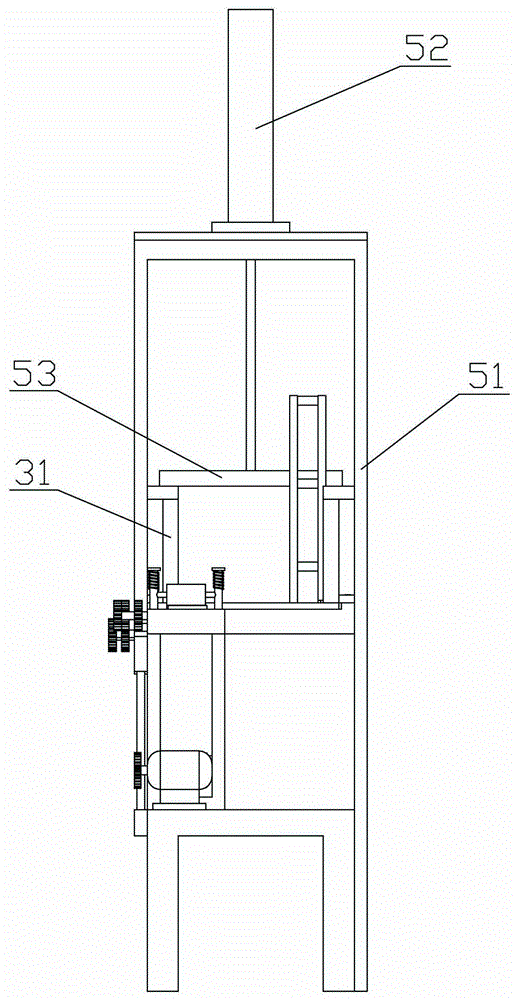

Production line dispatching system and method for mixed line production of car power assembly parts

ActiveCN109352412ASmall footprintSimple structureMetal working apparatusProduction lineMaterial resources

The invention provides a production line dispatching system and method for mixed line production of car power assembly parts. The system comprises a production line module, a control module, a transfer module and a storage module; the production line module is a mixed line module, comprises a plurality of production lines, and is used for processing workpieces to be produced into finished workpieces; and the control module can match the production process flow based on the category information of the workpieces to be produced. The structure is simple and few components are required; and by arranging an information identification part, automated, unmanned and intelligent processing is achieved in the whole process, so that space, manpower, material resources and input are greatly saved; inaddition, the dispatching system and method can effectively adjust beat and balance production capacity, and provide a verification platform for equipment, the process and the whole line; and mixed line processing can greatly shorten the waiting time and improve the comprehensive starting rate of the equipment.

Owner:SHANGHAI SMARTSTATE TECH CO LTD

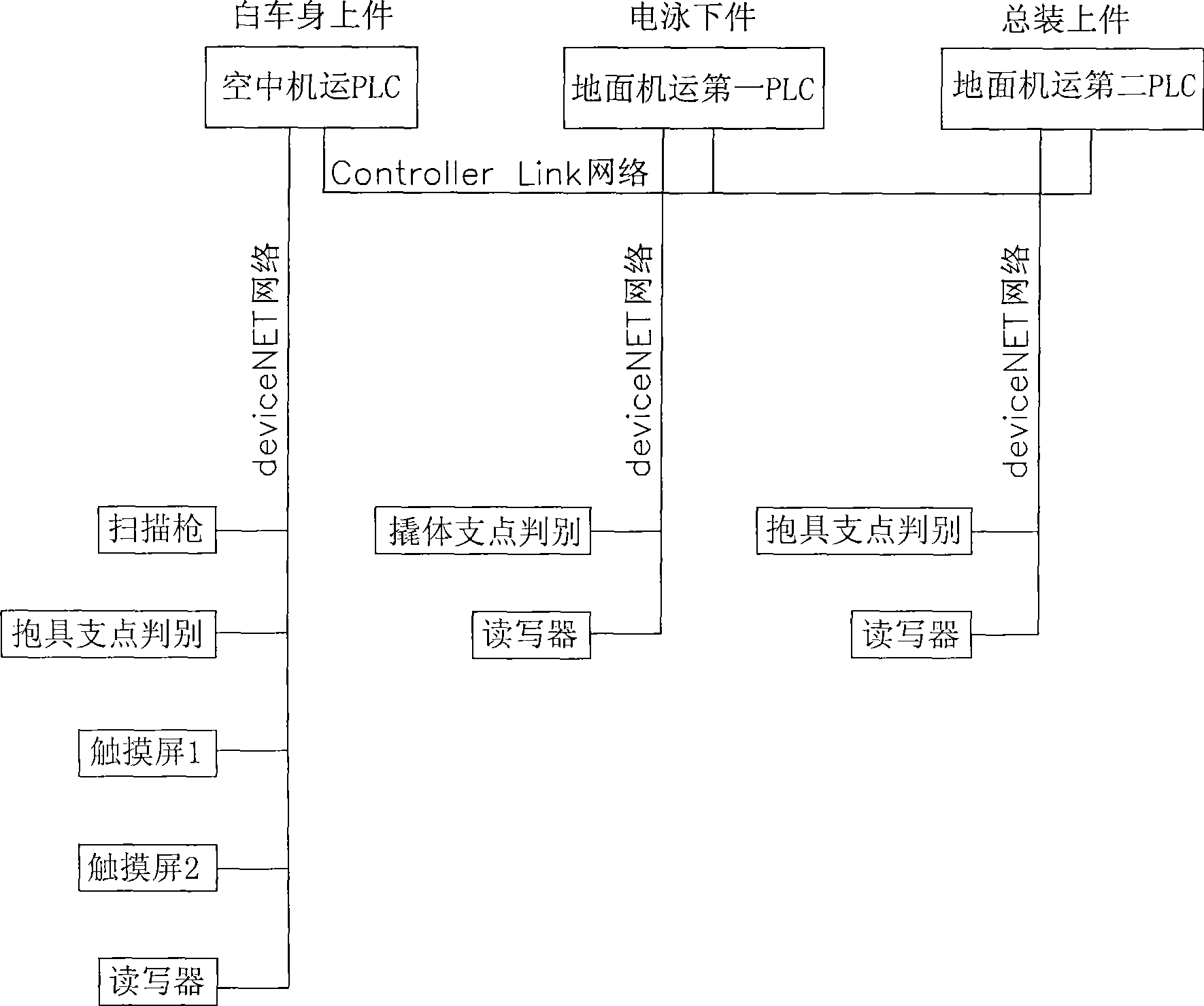

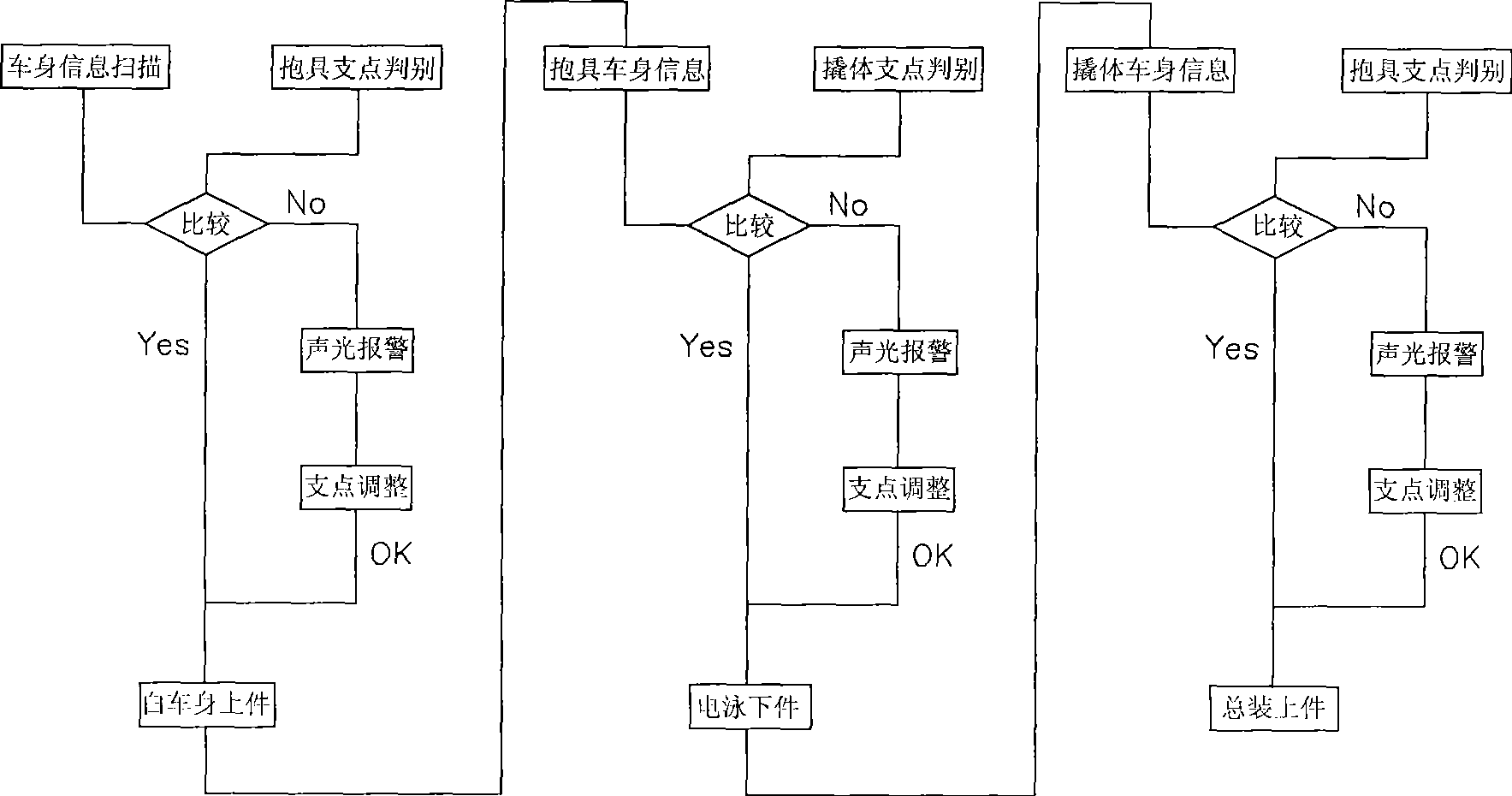

Multiple automobile mode discrimination and control method of automobile body locus line

ActiveCN101546183AReduce damage rateImprove activation rateControl devices for conveyorsTotal factory controlProduction lineEngineering

The invention relates to an automobile body painting production line, in particular to a multiple automobile mode discrimination and control method of an automobile body locus line. When a white automobile body is positioned on an overhead midline, white automobile body information is loaded to an overhead locus PLC by a scanning device, and holding tool pivot point information obtained by a holding tool pivot point discriminating system is also input to the overhead locus PLC; the overhead locus PLC compares the white automobile body information and the holding tool pivot point information, if a holding tool pivot point meets an automobile mode of the white automobile body, a holding tool enters a loading lifter of the white automobile body and automatically hangs the white automobile body into the holding tool and loads the white automobile body information into a code carrier of the holding tool, and if the holding tool pivot point can not meet the automobile mode of the white automobile body, an audible and visual alarm sends alarms; persons adjust the holding tool pivot point to enable the holding tool pivot point to be matched with the white automobile body, and the white automobile body is hung into the holding tool after being determined, and the white automobile body information is also loaded into the code carrier of the holding tool. The invention can enhance the utilization rate of the painting production line and lower the labor intensity of operating staff.

Owner:SHANGHAI ELECTROMECHANICAL DESIGN & RES INST CO LTD

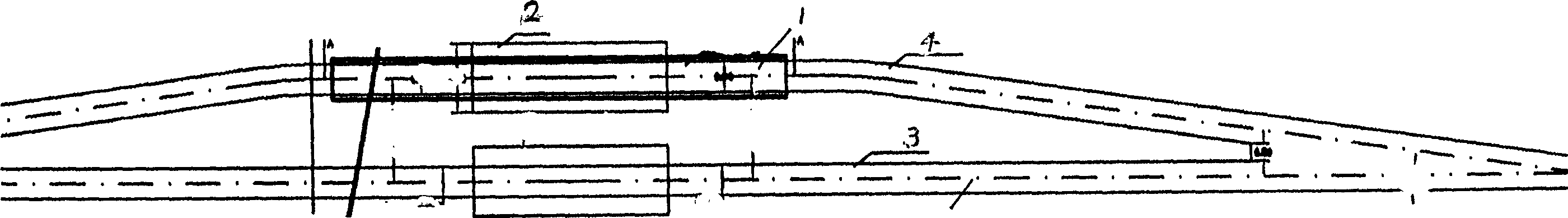

Underground ore transport train overhaul method

InactiveCN1775605AQuick exclusionTransport stableRailway stationRailway auxillary equipmentEngineering

The invention discloses a method for examining and repairing underground ore transport train, on the ore transport route, selecting a section of laneway, widening the section of laneway and laying the section of laneway into a double track route, where one track is used for ore transport, and the other track is used for train examining and repairing, a column repair channel is formed under the track used for train examining and repairing; or on the ore transport route, adding a section of parallel laneway and making the same arrangement as the above. The invention can rapidly remove the train failure, raising the operating efficiency. The invention provides a high efficiency operation environment, assuring the vehicle to be able in a normal operating state and assuring the ore transport link unblocked.

Owner:宝钢集团上海梅山有限公司

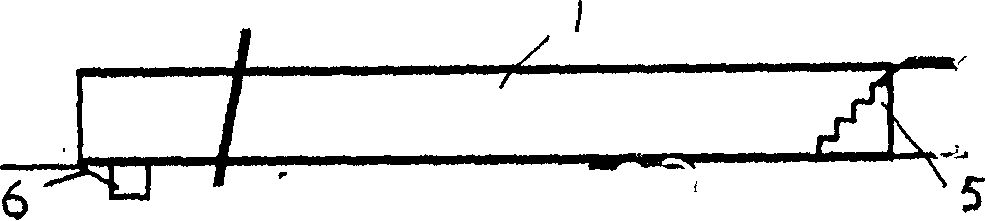

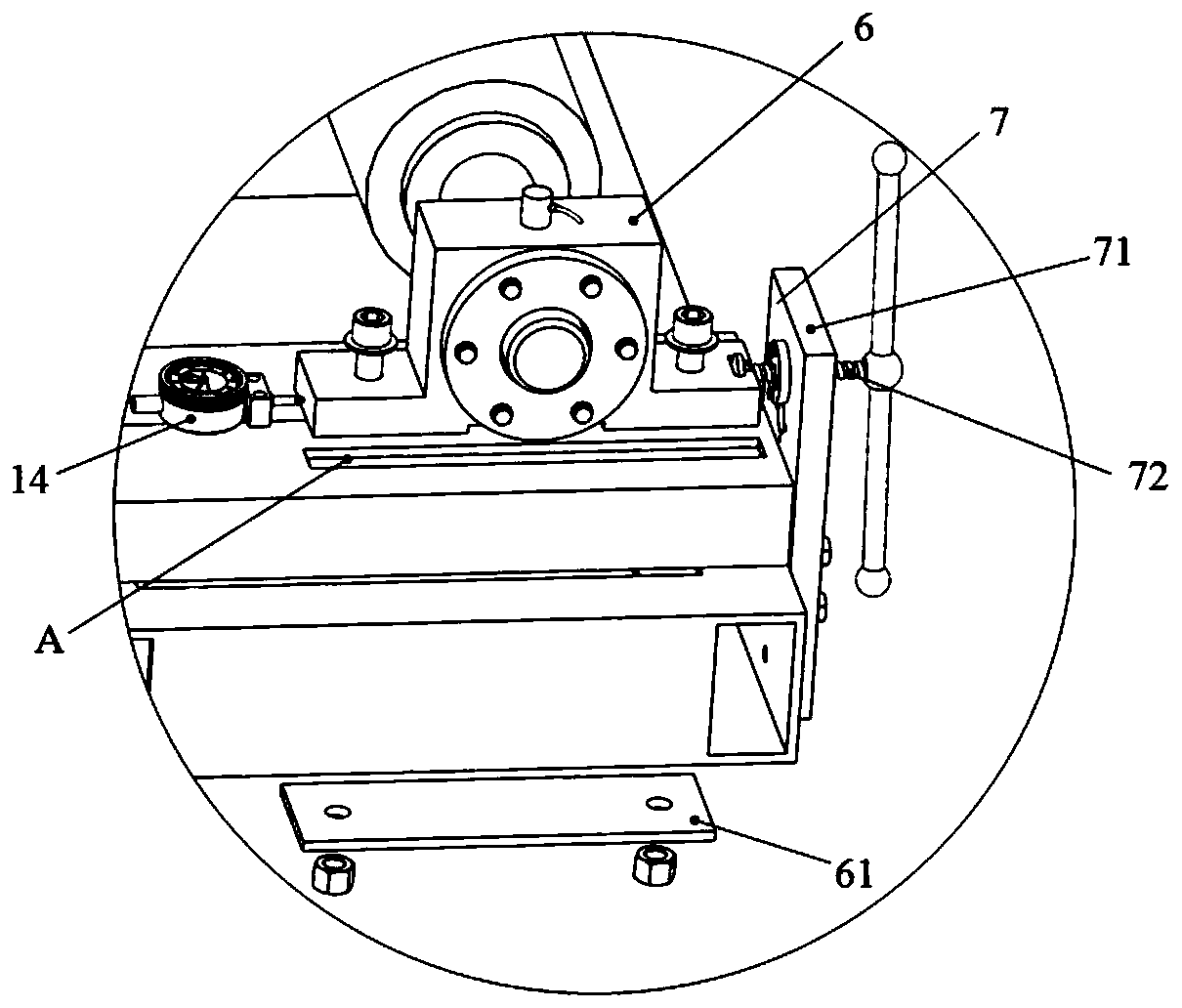

Online repairing method and tool for ring rolling mill abrasion roller

The invention discloses an online repairing method and tool for a ring rolling mill abrasion roller. The online repairing method and tool includes an online repairing method and tool for an abrasion master roller and an online repairing method and tool for an abrasion conical roller and is characterized in that the online repairing method and tool for the abrasion master roller machines an abrasion surface according to abrasion of a master roller, mainly abrasion of a cylindrical surface of the master roller, so that online repairing of the master roller can be achieved; the online repairing method and tool for the abrasion conical roller designs a proper tool fixture, and online repairing of upper and lower conical rollers can be achieved according to the condition that roller surfaces of the upper and lower conical rollers are conical and contact surfaces of the upper and lower conical rollers contacting with a rolled product are straight lines parallel to frame ground. The online repairing method and tool for the master roller and the upper and lower conical rollers includes the operation steps: designing one set of tools, and mounting cutters on the tools and then on core rollers. The online repairing method and tool has the advantages that online repairing of an abrasion rolling roller of a ring rolling mill can be achieved, and the operating rate of the ring rolling mill is increased.

Owner:MAANSHAN IRON & STEEL CO LTD

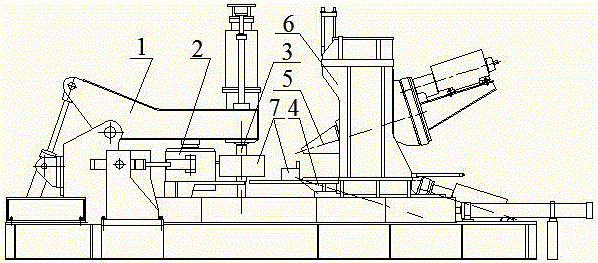

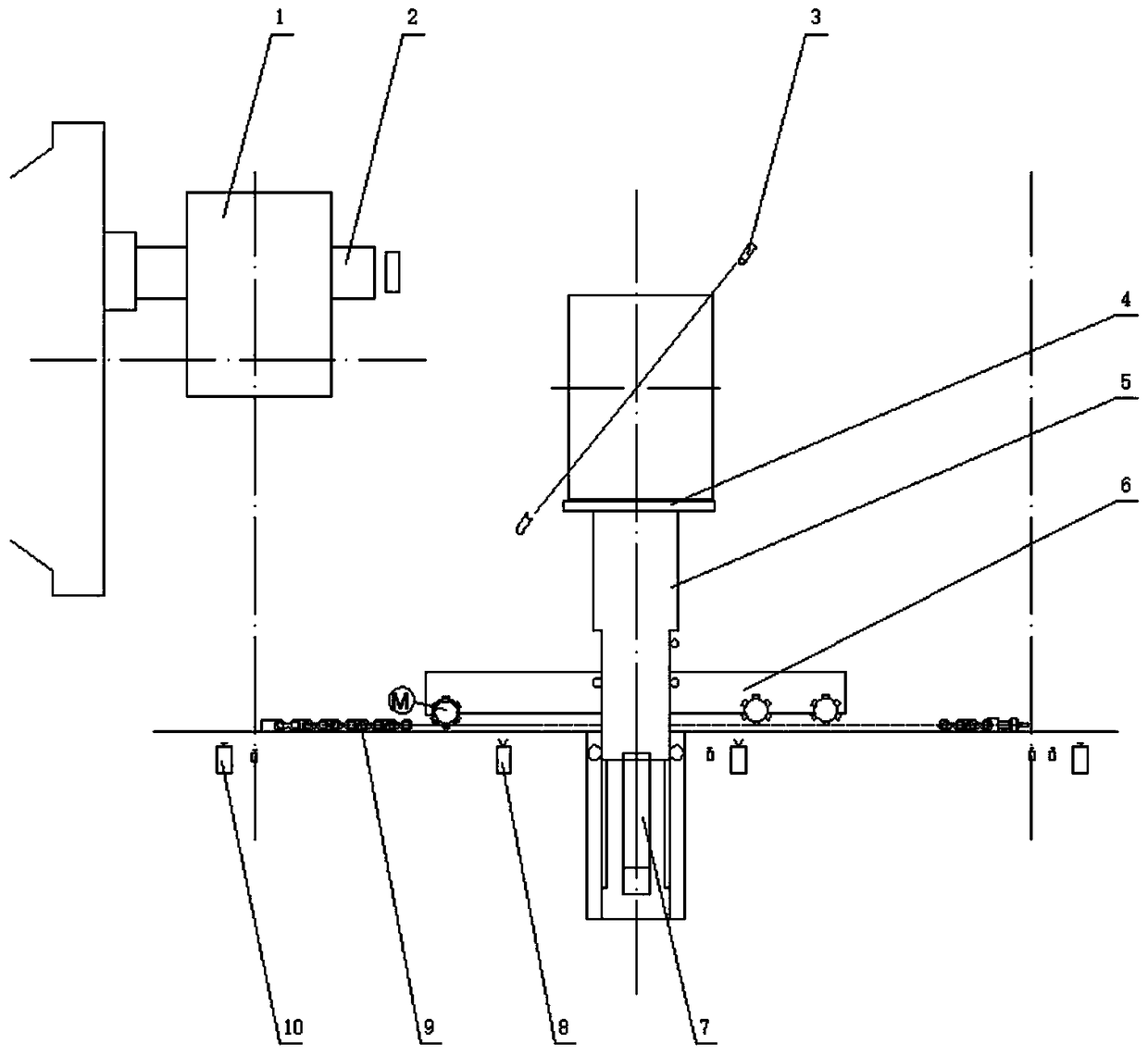

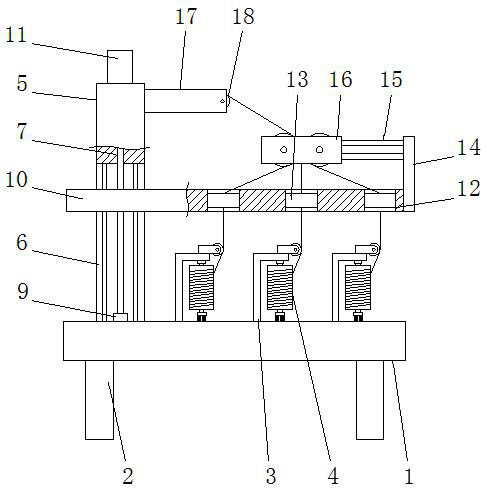

Small turret-type double-station automatic winding and unwinding device

PendingCN108438994AImprove activation rateReduce labor intensityElectrode rolling/calenderingWebs handlingEngineeringConductor Coil

The invention discloses a small turret-type double-station automatic winding and unwinding device. The small turret-type double-station automatic winding and unwinding device comprises a turret framework; the turret framework is arranged on a bottom frame; each of supporting shafts at the two ends of the turret framework is pivoted through a supporting leg; a first clamping mechanism and a secondclamping mechanism are arranged on the two sides of the turret framework correspondingly and are fixedly arranged on corresponding supports; all the supporting shafts penetrate out of the supports correspondingly; the one supporting shaft is connected with a synchronous shaft detection device; the other supporting shaft is connected with a turret transmission mechanism; the turret transmission mechanism drives the turret framework to rotate; the synchronous shaft detection device is used for detecting a rotation angle of a turret; and an unwinding automatic tape splicing device used for carrying out tape splicing on old and new material coils is arranged at a space, located below the turret framework. The automatic-driving, automatic-tape-splicing and double-station nonstop operation can be achieved, and the small turret-type double-station automatic winding and unwinding device has good automation property.

Owner:邢台纳科诺尔精轧科技股份有限公司

Rapid arc connecting method of slab caster crystallizer narrow face foot rollers

InactiveCN103433445AImprove arc connection accuracyReduce labor intensitySlab casterEconomic benefits

The invention relates to a rapid arc connecting method of slab caster crystallizer narrow face foot rollers. The method comprises the following steps: 1) firstly fixing the two sides of each foot roller on foot roller supports through L-type clamping plates, then additionally arranging 10 sets of disc spring pieces on the rear portions of the foot roller supports to be flexibly connected with foot roller billets so as to prevent casting blank bulging caused by molten steel static pressure, and finally installing the assembled foot roller device in U-type grooves in the two sides of the lower end of each Z-type supporting plate; 2) achieving foot roller arc connecting operation on copper plates by adjusting two adjusting bolts behind the foot roller supports, and locking the foot rollers through double preparation caps of studs; 3) completing one-time arc connecting through the adjustment of a speed reduction machine-a lead screw mechanism. Compared with the prior art, the method has the advantages of being small in investment, simple, scientific and practical, reducing the fault time of the device, improving the arc connecting precision of the process, reducing the labor intensity of a worker, improving the working efficiency, and creating higher economic benefits for an enterprise.

Owner:ANGANG STEEL CO LTD

Finished sheet strip roll feeding and unloading device and work method thereof

InactiveCN109500085ASolve operational problemsSolve the problem of artificial inspectionMetal rolling arrangementsHydraulic cylinderSlide plate

The invention relates to a finished sheet strip roll feeding and unloading device and a work method thereof. A reel of a coiling machine is horizontally and horizontally arranged, the reel is sleevedwith a finished roll, and horizontally and transversely arranged conveying rails are mounted below the coiling machine. A walking trolley operates on the conveying rails in a guide and driving manner,and a vertically arranged lifting sliding plate is vertically arranged in the middle of the walking trolley. A saddle is fixedly mounted at the upper end of the lifting sliding plate, and a lifting hydraulic cylinder is mounted at the lower end of the lifting sliding plate. A pressure sensor is additionally mounted on an ascending oil outlet hole of the lifting hydraulic cylinder. Wheels are symmetrically mounted at the position, on the front side and the rear side of the walking trolley, of the two sides of the lifting sliding plate, and the wheels on the two sides are embedded into the horizontal rails in a limiting and rolling manner. Chain wheels are coaxially mounted on the outer sides of the wheels, and chains capable of being matched with wheel teeth of the chain wheels are fixedlylaid on the outer sides of the horizontal rails. According to the finished sheet strip roll feeding and unloading device and the work method thereof, the human operation problems are solved, operation is safe and stable, and automatic operation is achieved; and operation personnel are saved, the equipment shutdown time is shortened, and the maintenance cost and the production cost are reduced.

Owner:天津市新宇彩板有限公司

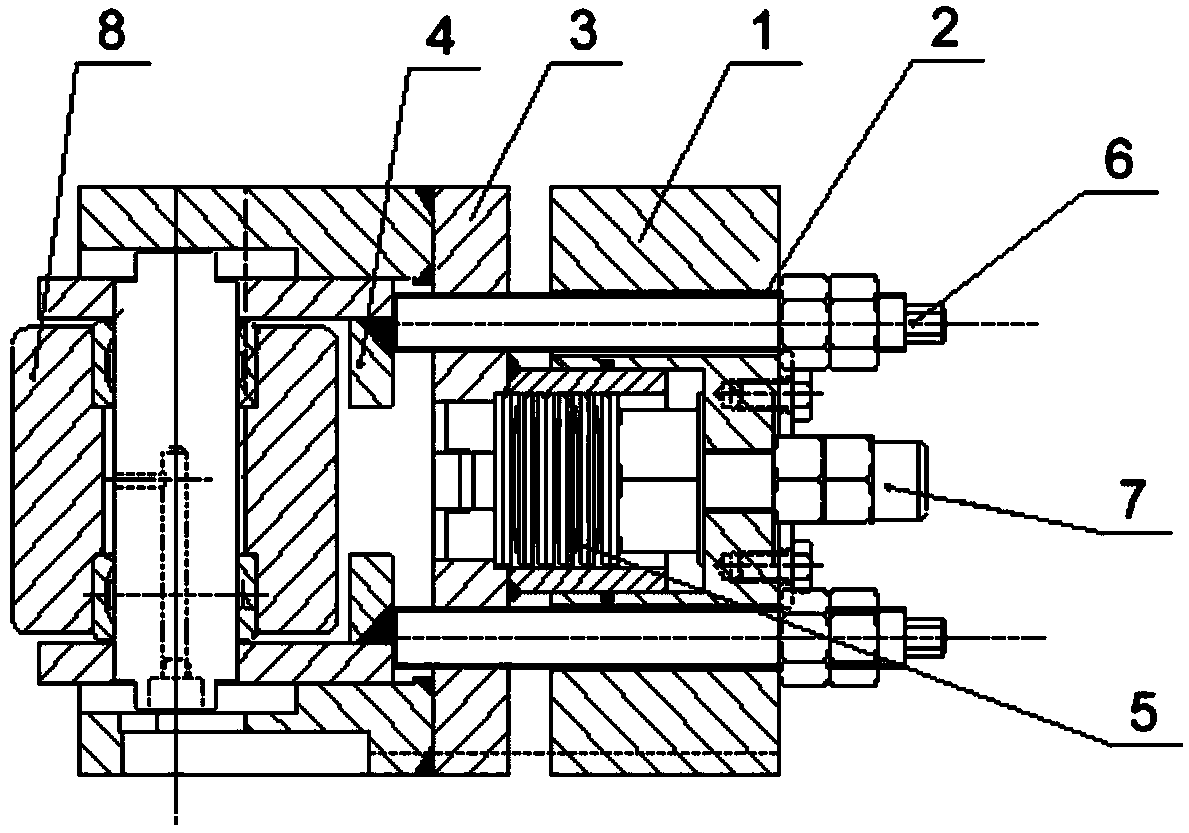

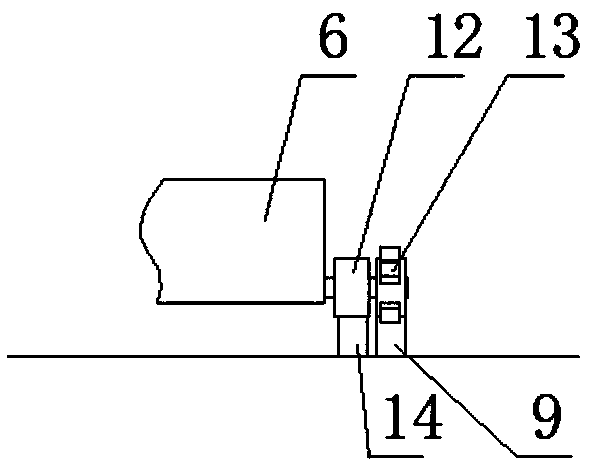

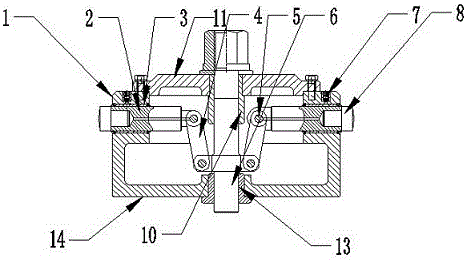

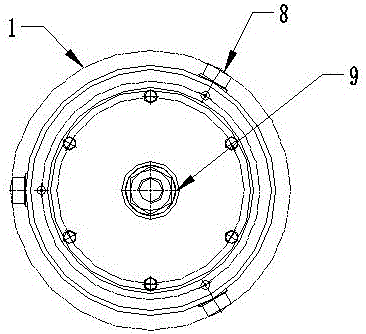

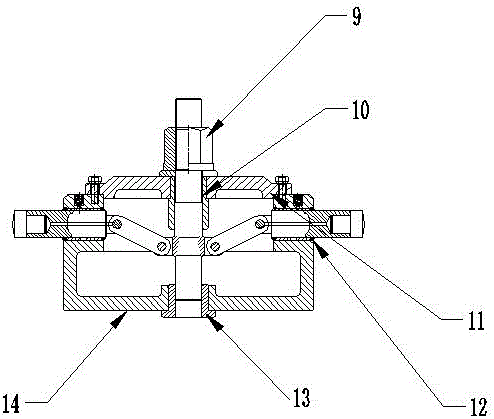

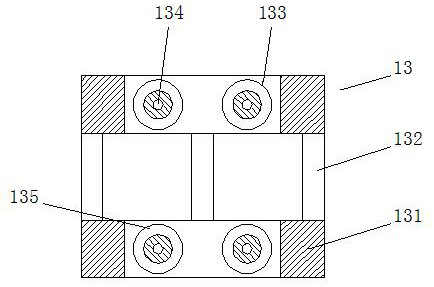

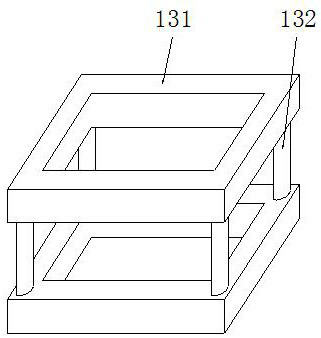

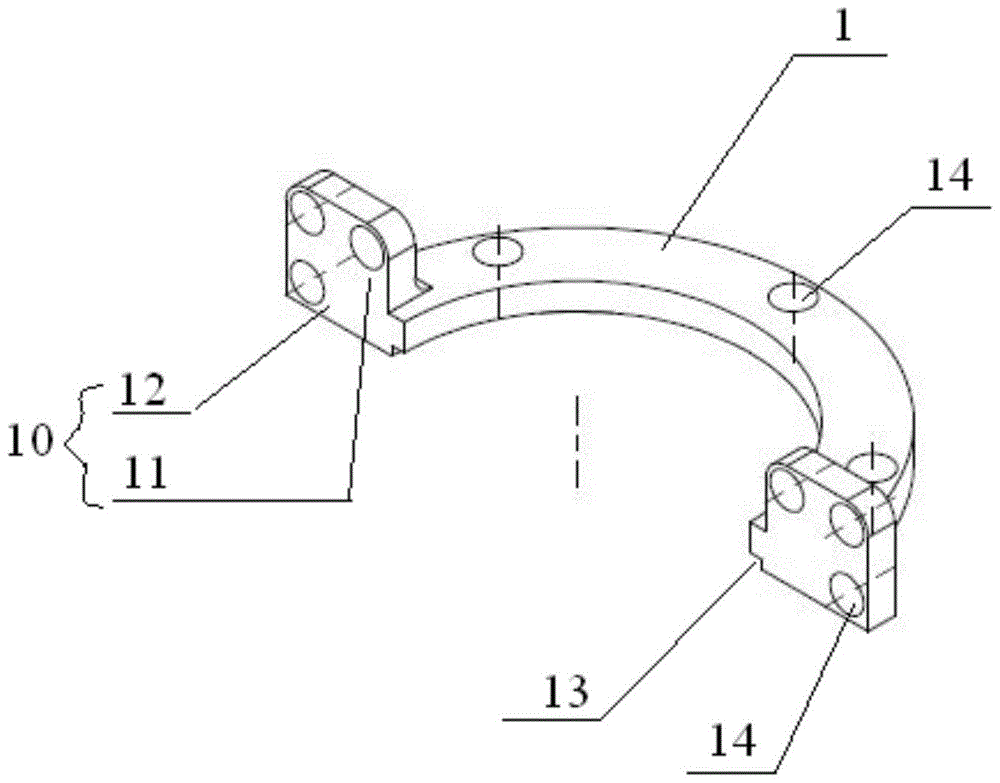

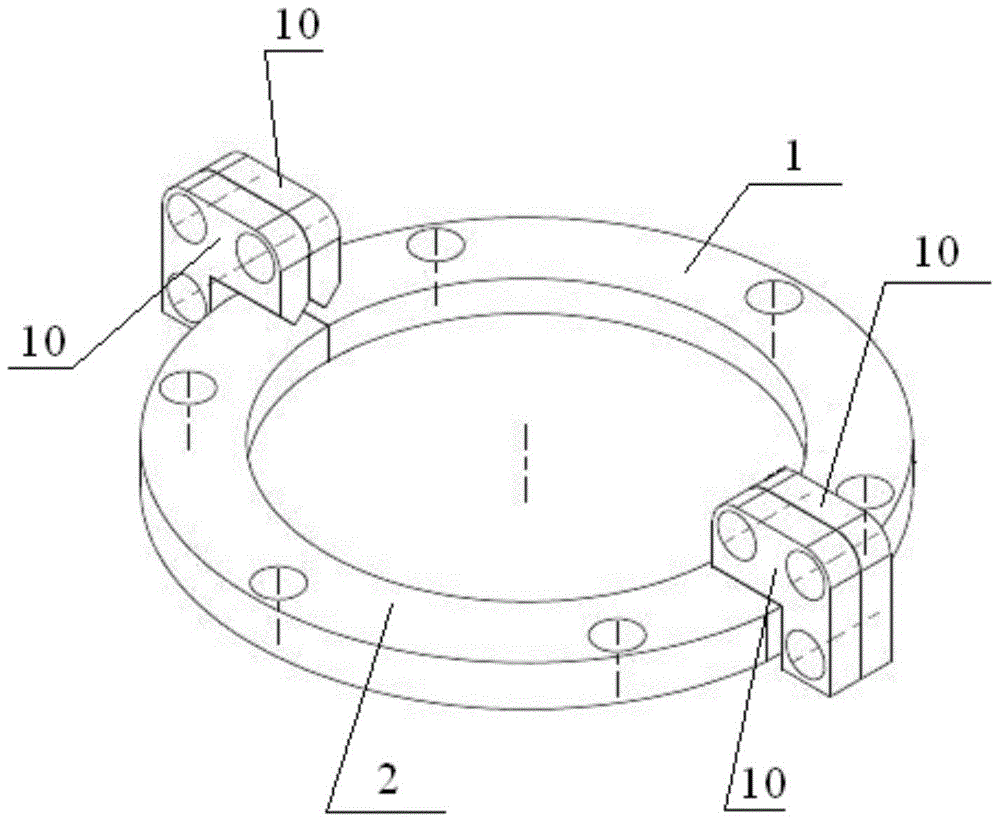

Connecting rod type self-centering universal fixture

InactiveCN106736774AHigh positioning accuracyEasy to operatePositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses a connecting rod type self-centering universal fixture. The connecting rod type self-centering universal fixture comprises a cylindrical fixture body in which a center shaft is connected in a sliding manner; a tight ejecting sliding shaft is connected to the side wall of the fixture body in a sliding manner and penetrates the side wall of the fixture body; and the center shaft is in transmission connection with the tight ejecting sliding shaft and moves to be capable of driving the tight ejecting sliding shaft to move so that a workpiece can be tightly ejected or released. The technical scheme adopted for the connecting rod type self-centering universal fixture has the following beneficial effects that the positioning precision of the fixture is improved by 1 / 2 compared with that of a universal chuck, and the precision reaches 0.03 mm; and the application range is wide, the diameter range of workpiecies to which the connecting rod type self-centering universal fixture is applicable can reach phi200-1200 mm, operation is easy, using is convenient, the production cost is reduced, and the trial effect is good.

Owner:HIMILE MECHANICAL SCI & TECH (SHANDONG) CO LTD

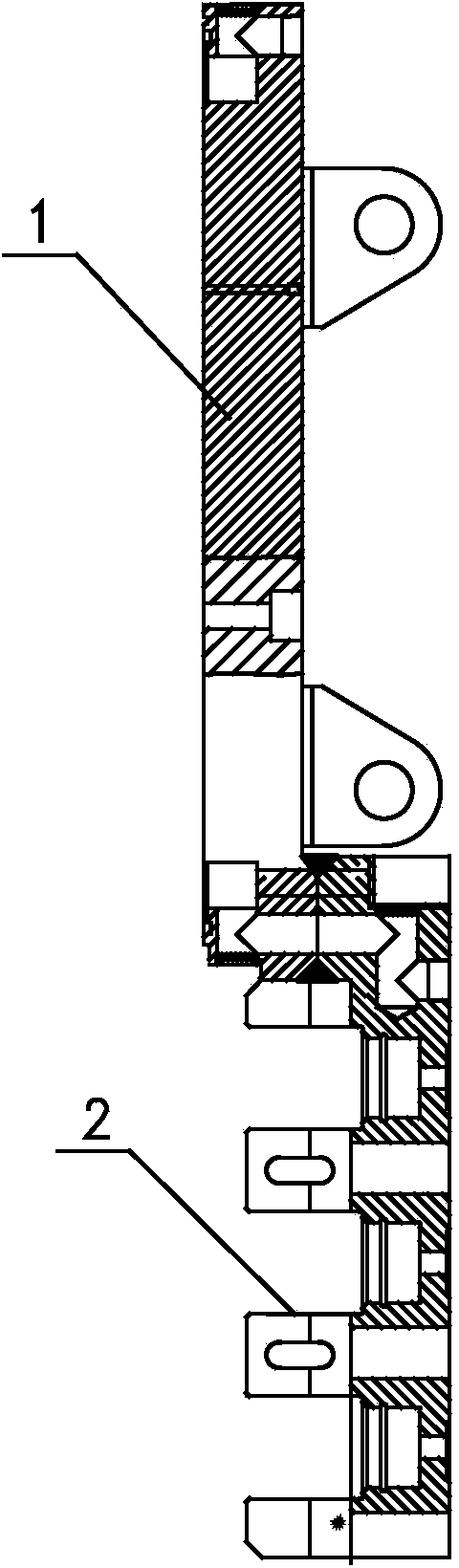

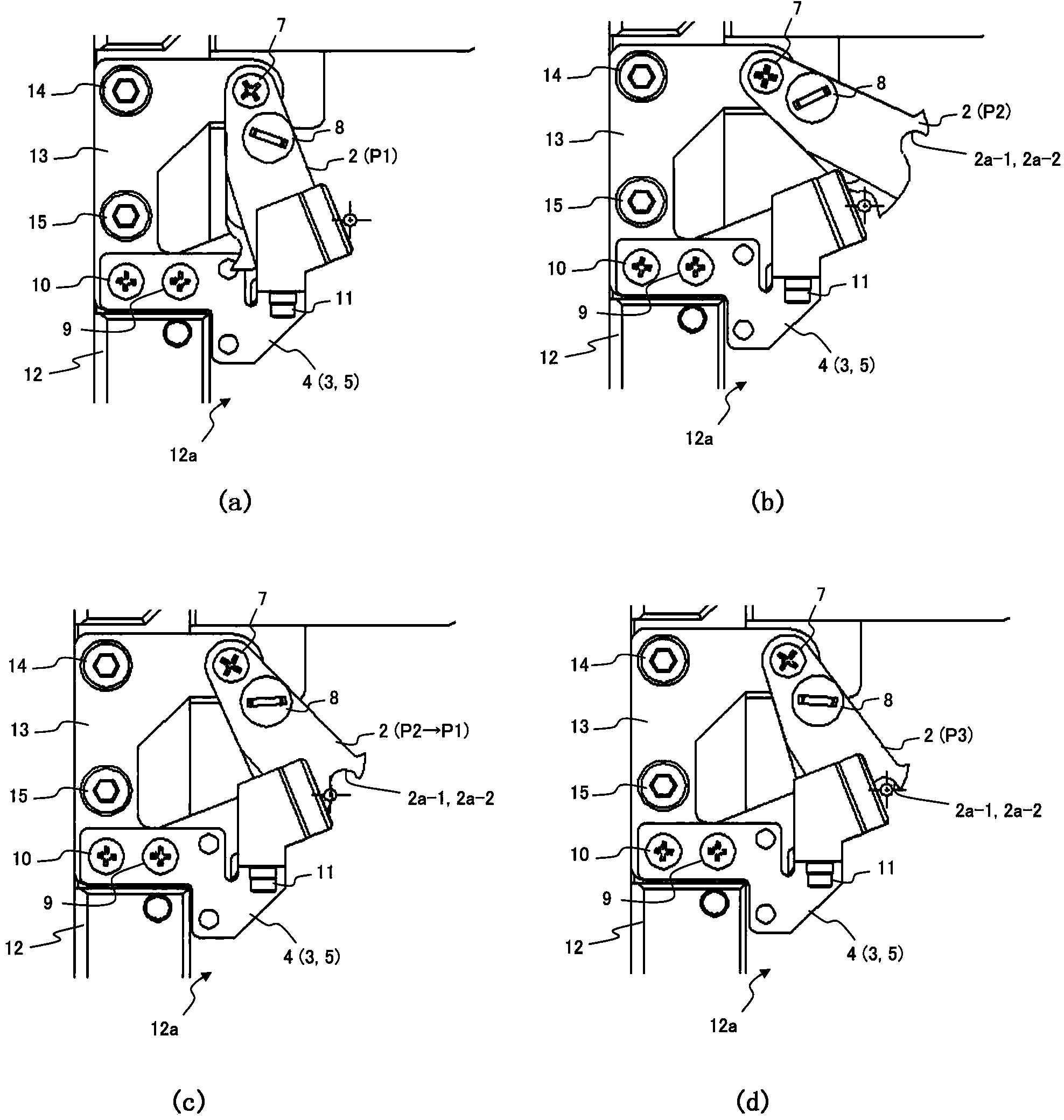

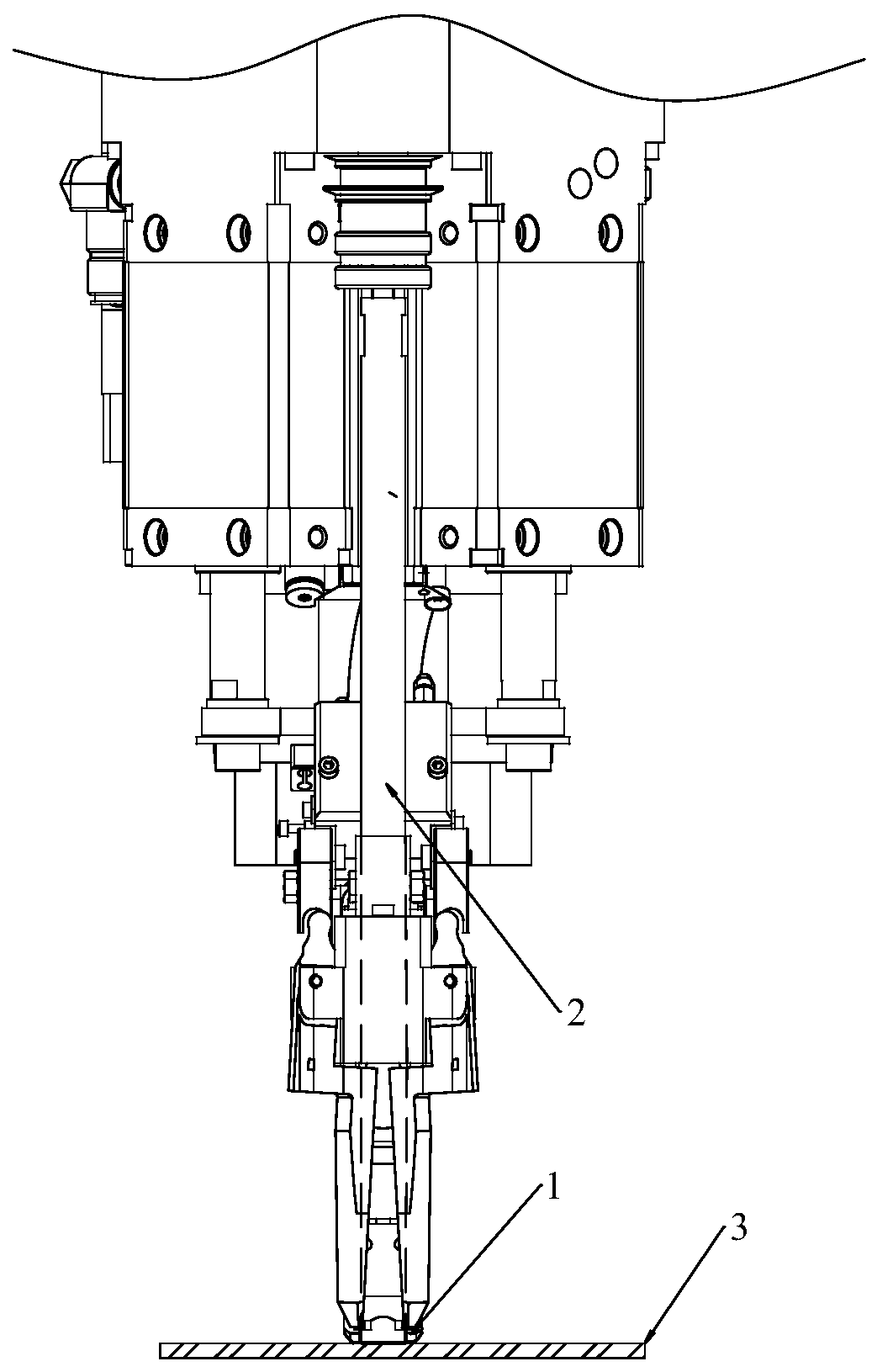

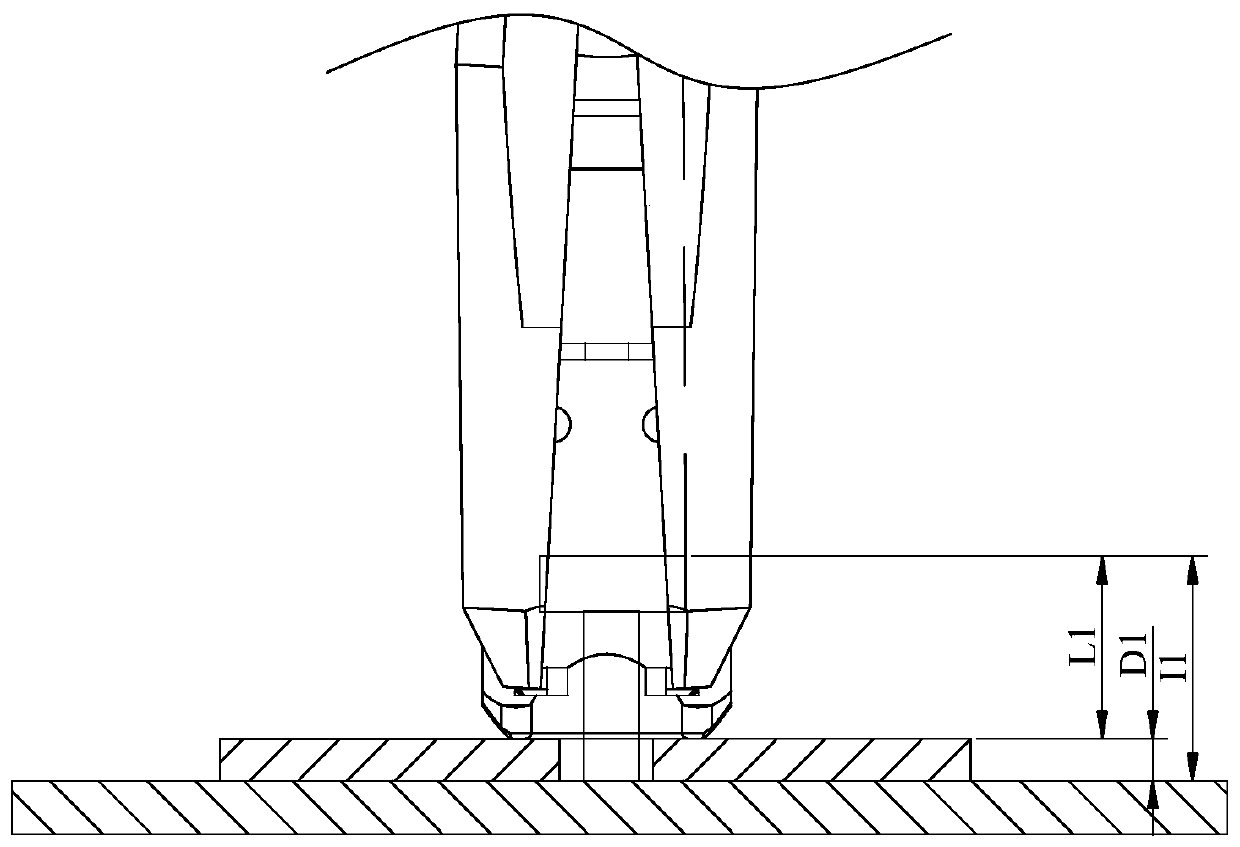

A line cutting device and a sewing machine

InactiveCN104233655AImprove activation rate and qualityImprove activation rateWorkpiece carriersNeedle severing devicesEngineeringSewing machine

The invention provides a line cutting device and a sewing machine so as to raise an equipment starting rate and quality. In the line cutting device configured to be with the sewing machine, a movable blade ( a movable knife (2) ) and a maintaining component (4) are provided; the movable blade ( the movable knife (2) ) performs reciprocating movements between a first position where the movable blade ( ( the movable knife (2) ) is accommodated and a second position (P2) where the movable blade ( ( the movable knife (2) ) starts actions of cutting an upper line (18) and a lower line (19); the movable blade ( ( the movable knife (2) ) is also provided with a third position (P3); the third position (P3) is between the first position (P1) and the second position (P2); at the third position, the movable blade ( ( the movable knife (2) ) hooks a cut new upper line (20); and the maintaining component (4) maintains the cut upper line (18) as well as the cut new upper line (20).

Owner:CANDART

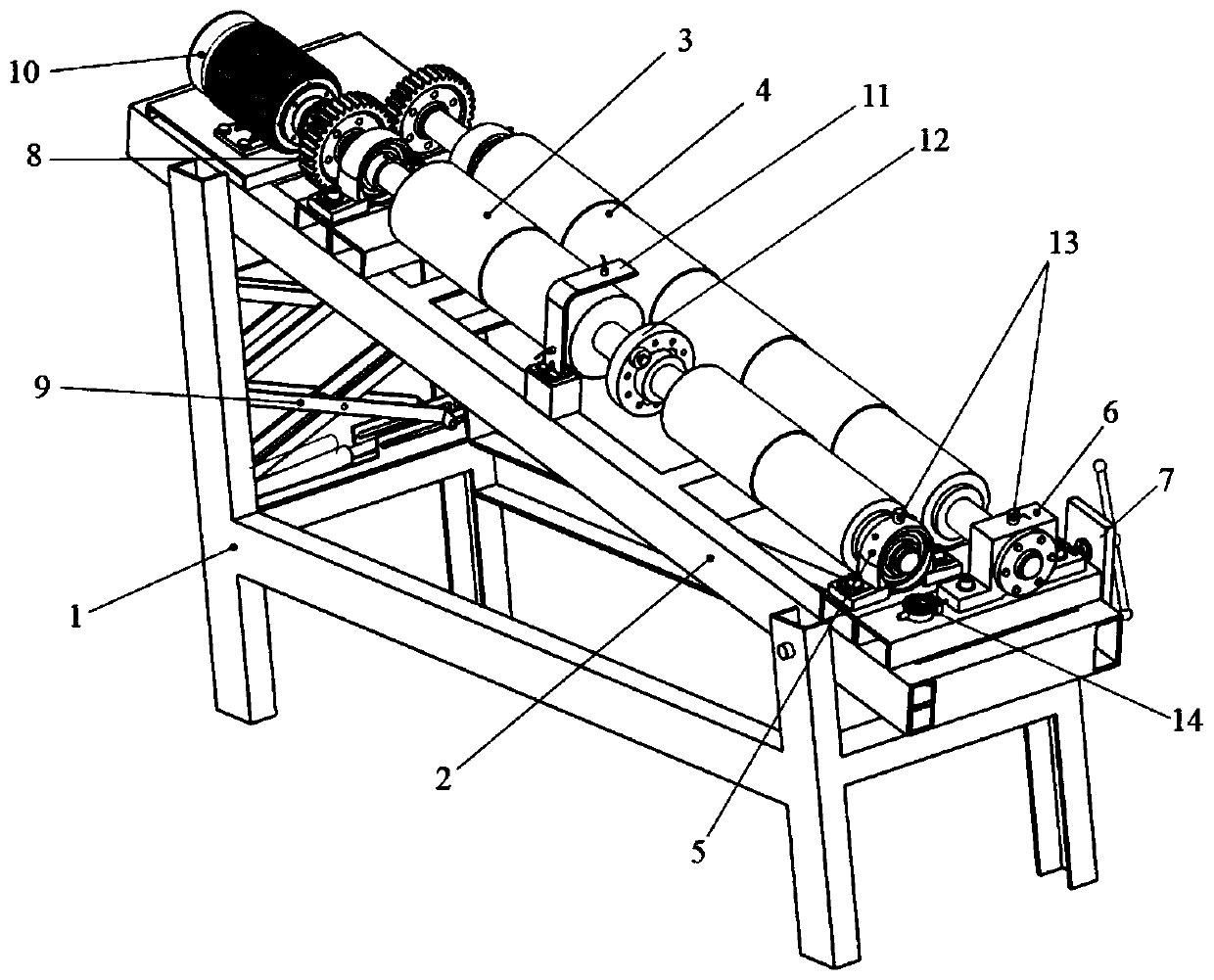

Prawn grading equipment fault simulation and detection experiment table

PendingCN110057589ACompact structureEasy to operateMachine part testingClimate change adaptationCircular discMeasurement device

The invention discloses a prawn grading equipment fault simulation and detection experiment table. According to the experiment table, a shell seat position regulation device is utilized to change theposition of an easy-to-change bearing shell seat of a movable shaft roller relative to a driving end, a non-centering fault of a bearing of the movable shaft roller of prawn grading equipment is simulated, and a vibration signal is detected through a sensor. A bearing damage fault is simulated by changing a faulty bearing in the easy-to-change bearing shell seat, and a vibration signal is detectedthrough the sensor. A bearing looseness fault is simulated by loosening a set bolt of a bearing seat at a non-driving end of a fixed shaft roller, and a vibration signal is detected through the sensor. An unbalance fault caused by shaft roller bending deformation is simulated by installing and adjusting a mass block on a big disk on the fixed shaft roller, and a vibration signal is detected through a vibration displacement measurement device. A combined fault composed of individual faults also can be simulated and detected. The experiment table is used for prawn grading equipment fault mechanism research and fault feature extraction method research and is beneficial for actively maintaining the equipment, increasing the equipment utilization rate and guaranteeing grading precision.

Owner:HEBEI AGRICULTURAL UNIV.

Rolling mill thickness gauge protecting device

InactiveCN105537279AAvoid scratchesReduce in quantityRolling safety devicesMetal rolling arrangementsBridge typeArchitectural engineering

The invention relates to a rolling mill thickness gauge protecting device which comprises a base and a C-shaped thickness gauge support. The base is provided with a mounting table for the C-shaped thickness gauge support, the mounting table is composed of two parallel bosses, and the C-shaped thickness gauge support used for mounting a thickness gauge is mounted in the middle of the mounting table. The rolling mill thickness gauge protecting device is characterized in that the two side ends of the two bosses are each fixedly provided with a bridge type frame, and the bridge type frames are transversely arranged between the two bosses. According to the protecting device for the C-shaped thickness gauge support, the elevation size is measured and the appearance is designed according to actual site environments, the C-shaped thickness gauge support is completely protected by welding the device on a thickness gauge traveling rail base, and therefore the tail of strip steel is completely prevented from scratching a thickness gauge support body; equipment failures are reduced, the equipment starting rate is increased, and the number of spare parts is reduced. The production cost and human resource expenditure are reduced, and cost decreasing and benefit increasing are achieved.

Owner:天津市新宇彩板有限公司

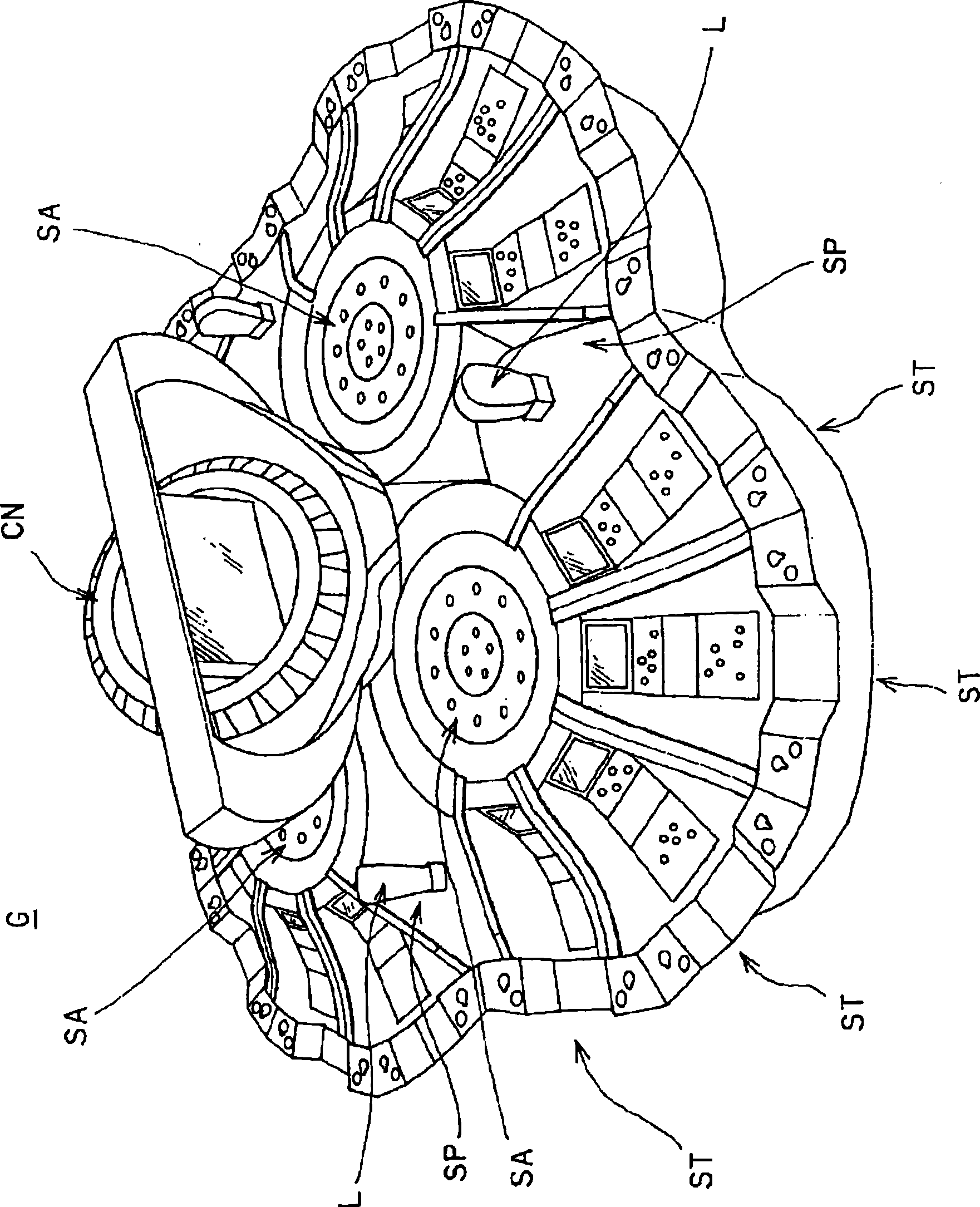

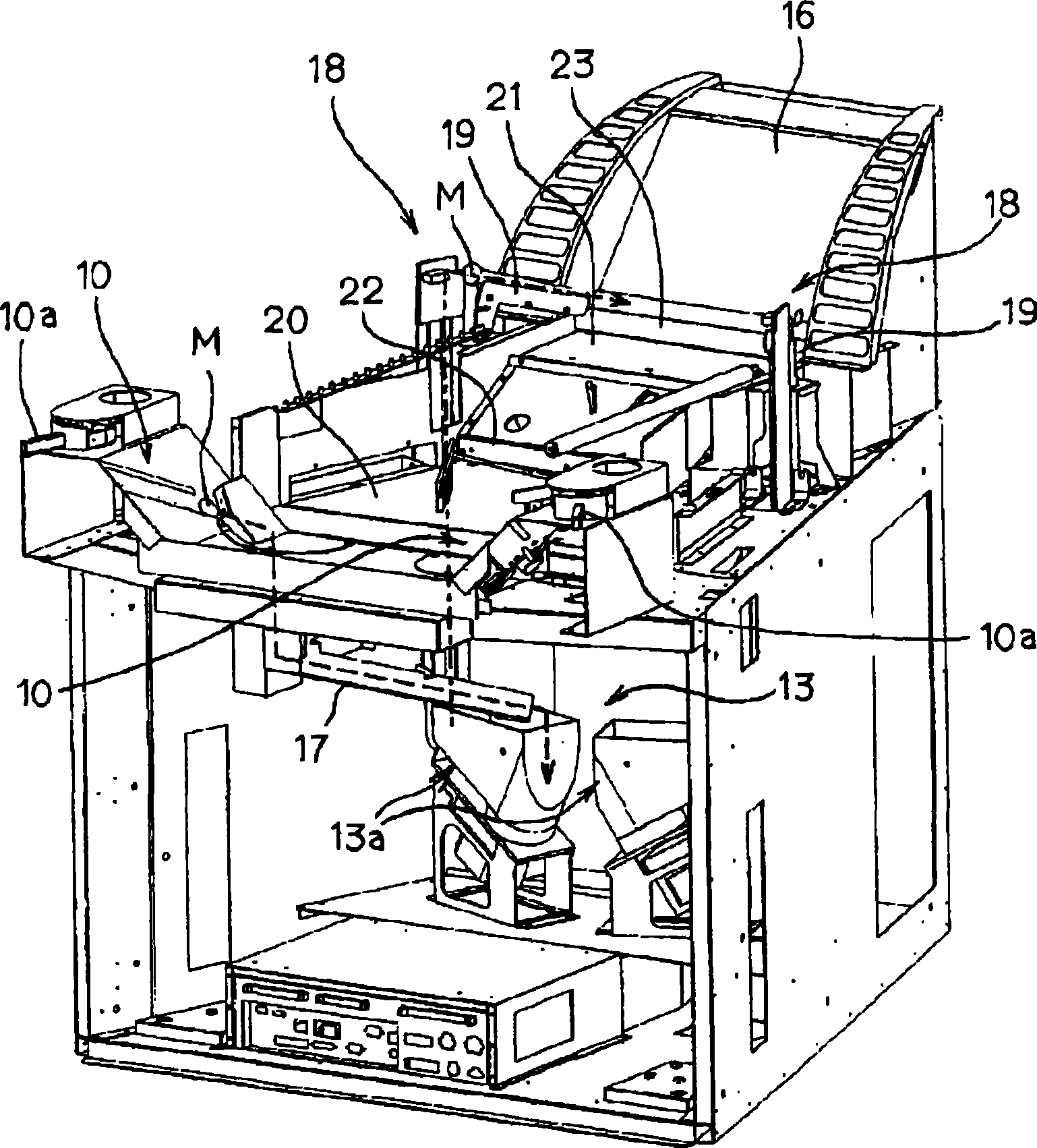

Game machine

InactiveCN101484218AImprove activation rateIncrease profitabilityIndoor gamesApparatus for meter-controlled dispensingPaymentHuman–computer interaction

Owner:KONAMI DIGITAL ENTERTAINMENT CO LTD

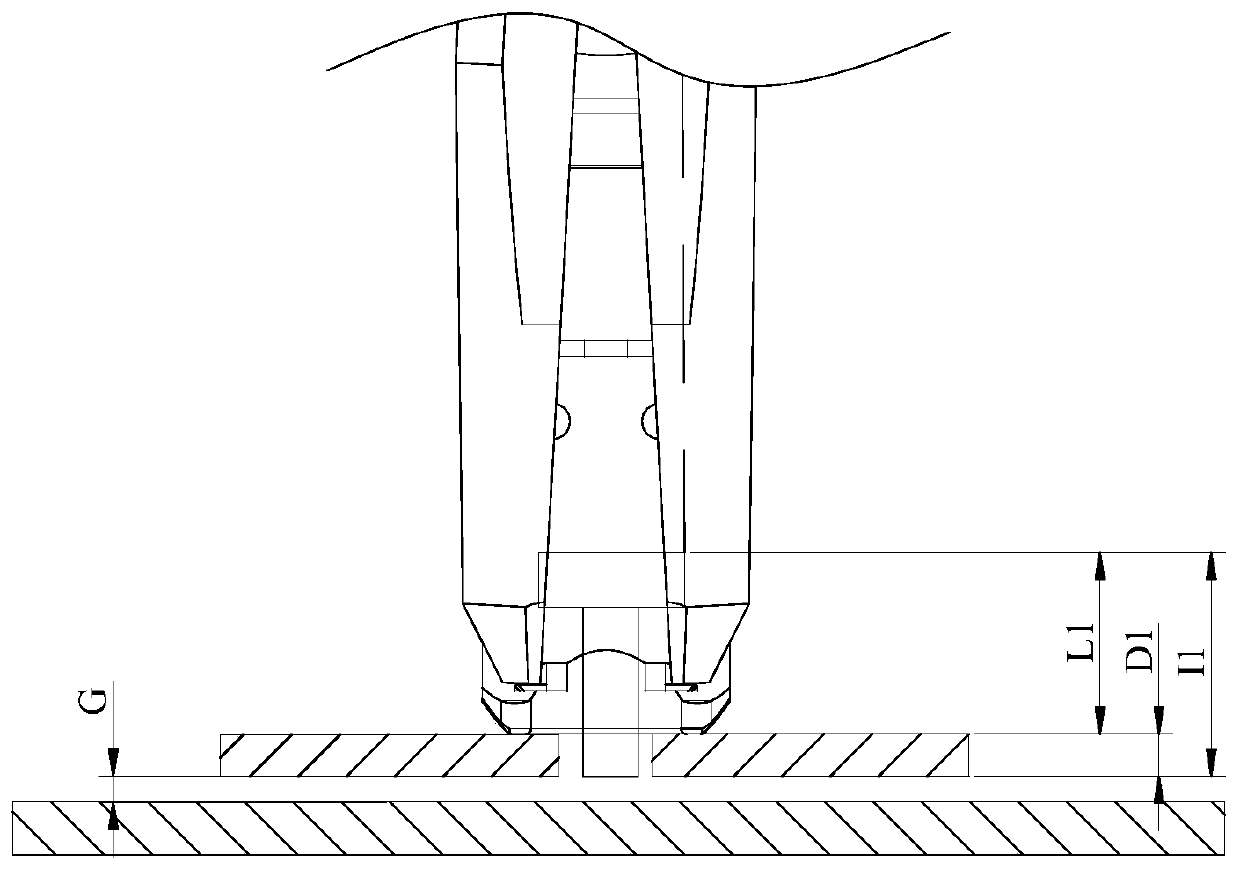

Flow drill screwing process parameter conversion key point self-adaption switching method

ActiveCN110625373AAccurate identificationThe nailing process is normal and stableMetal working apparatusEngineeringMaximum pressure

The invention discloses a flow drill screwing process parameter conversion key point self-adaption switching method. The flow drill screwing process parameter conversion key point self-adaption switching method comprises the steps of a calibration stage, specifically, a pressing block of flow drill screwing equipment is made to contact with a guide rod in the same plane, and a relative position measured by a coded ruler is taken as a null point; a cap seeking stage, specifically, after a riveting process begins, the actual pressure F3 of the guide rod is gathered, when the F3 = Faverage + a, arelative position L3 corresponding to the pressure point F3 is recorded and is taken as a cap seeking conversion point position, and then switching to puncturing stage parameters is performed; and apuncturing stage, specifically, the maximum pressure Fmax of the guide rod is monitored in the puncturing stage, then the descending pressure F4 of the guide rod is monitored, when the F4 = Fmax * b%,a relative position L4 corresponding to the pressure point F4 is recorded, and if the L4 is less than L3 - D2, the L4 is taken as a puncturing conversion point position, and a tapping stage is performed. According to the flow drill screwing process parameter conversion key point self-adaption switching method, by means of gathering of riveting force and displacement signals and in combination with a control logic, cap seeking and puncturing conversion points are accurately identified.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

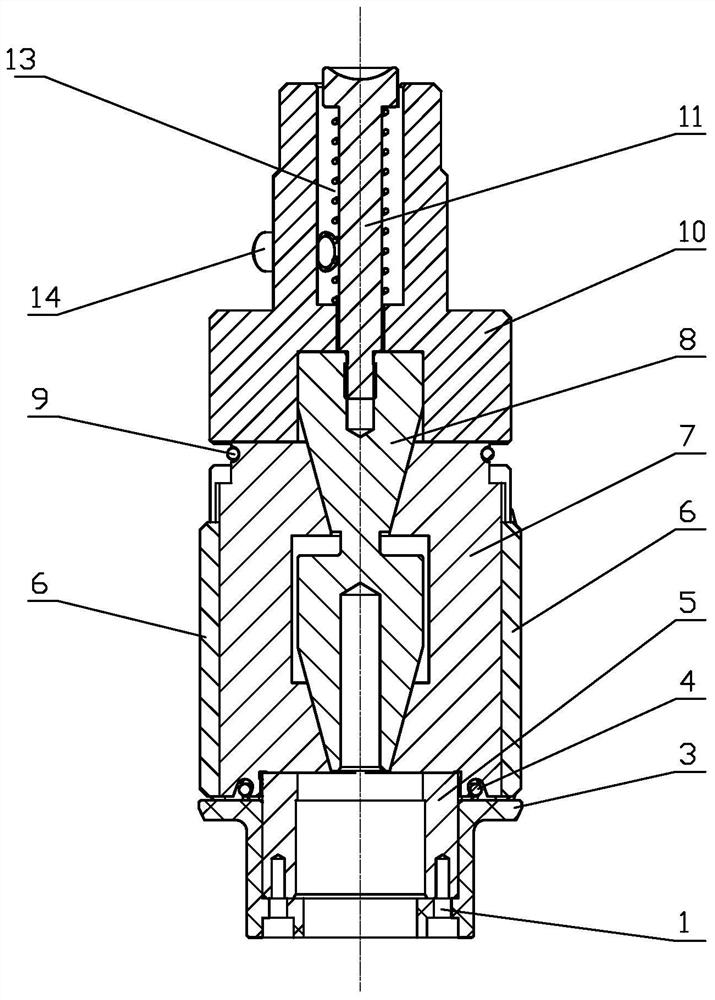

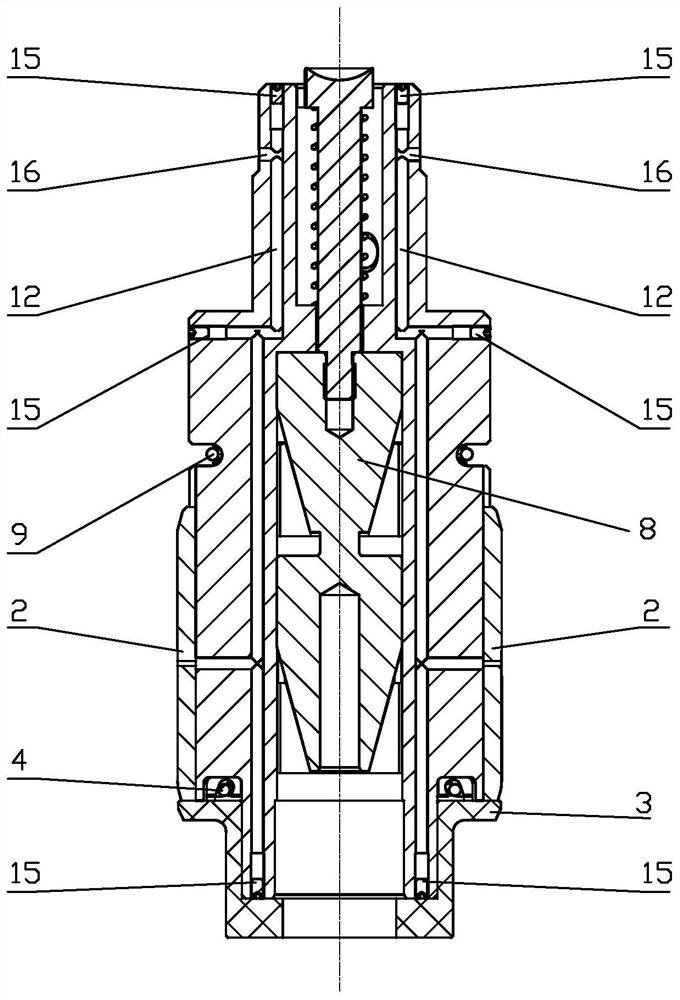

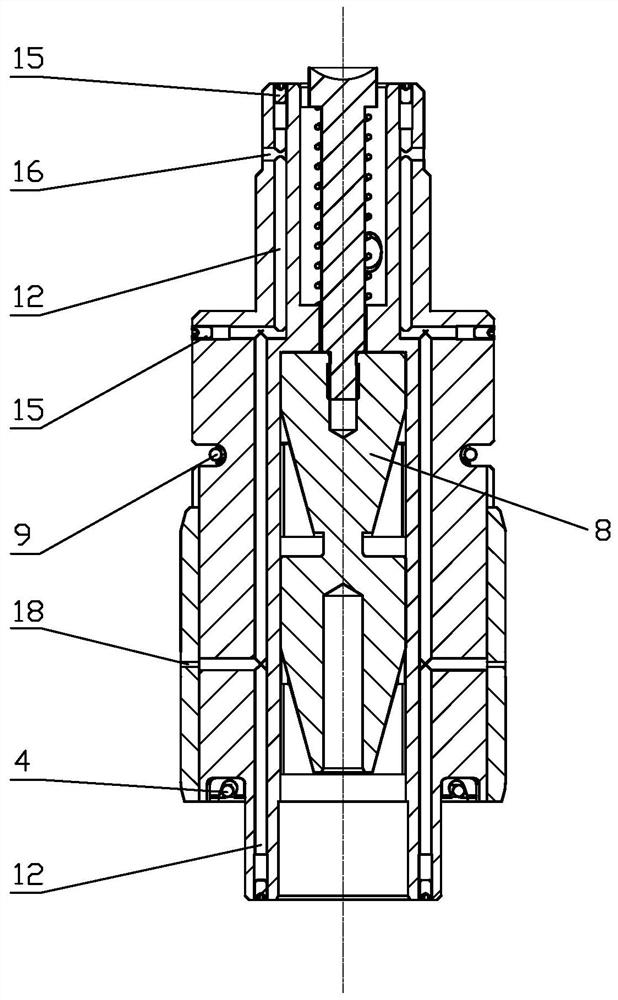

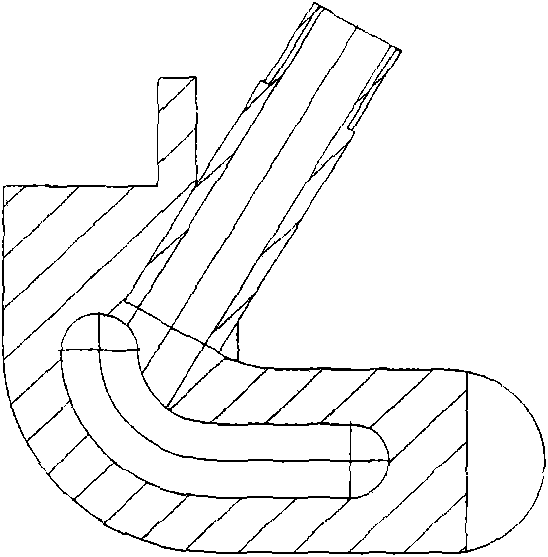

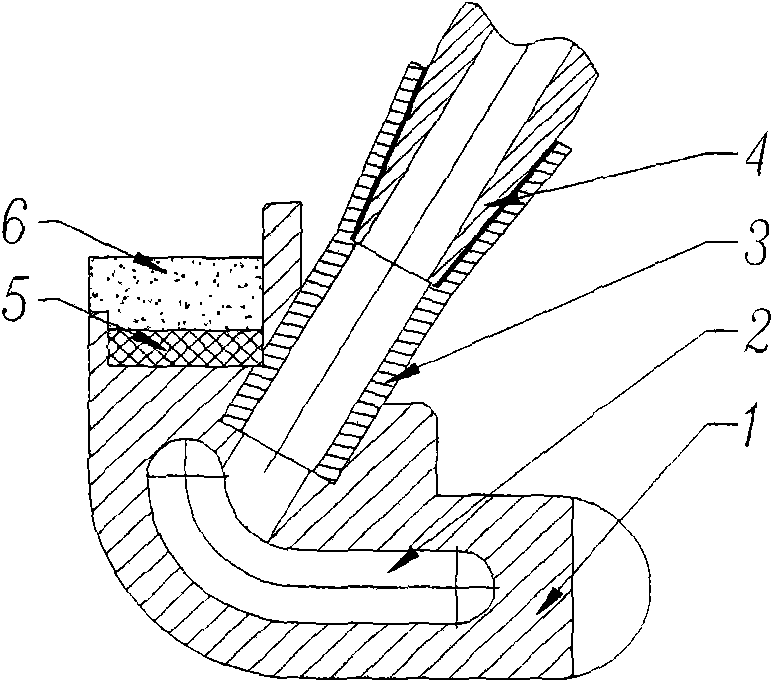

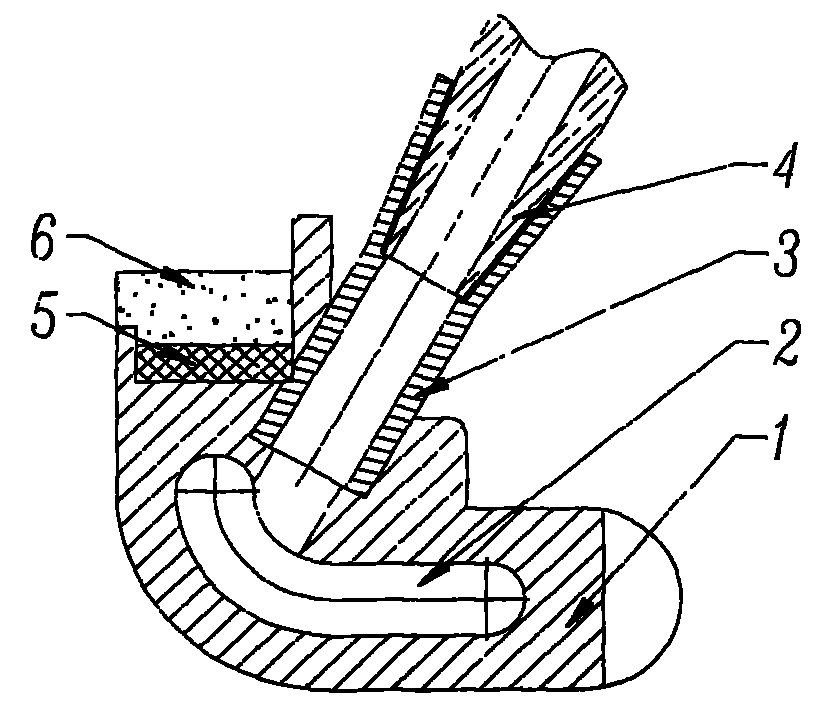

Cylinder hole honing tool

PendingCN112247824AImprove equipment start-up rateGuarantee the quality of product processingHoning toolsHoning machinesPhysicsHoning

The invention relates to a cylinder hole honing tool comprising a head body, an abrasive strip base and a support body which are connected in sequence; an expansion cone is arranged in the head body and the abrasive strip base, and abrasive strips are arranged on the abrasive strip base; a cutter expansion rod is arranged in the head body, and the lower end of the cutter expansion rod is connectedwith the expansion cone; an upper cutter retracting spring and a lower cutter retracting spring are arranged at the upper and lower ends of the abrasive strip base, so that the abrasive strip base isattached to the expansion cone; a guide alloy strip is arranged on the surface of the abrasive strip base, and chamfers are arranged at the upper and lower ends of the guide alloy strip and the abrasive strips; and anti-collision rings which can be used for blocking and protecting the bottom ends of the guide alloy strip and the abrasive strips are mounted on the support body. According to the cylinder hole honing tool, the problem that the honing abrasive strip, the honing head and the top of the cylinder hole are damaged due to swing of the honing tool is solved properly, and the equipmentstarting rate is increased; the product machining quality is guaranteed, and the tool cost and work waste are reduced; and meanwhile, damage to the honing tool and the abrasive strips is avoided.

Owner:SAIC GENERAL MOTORS +2

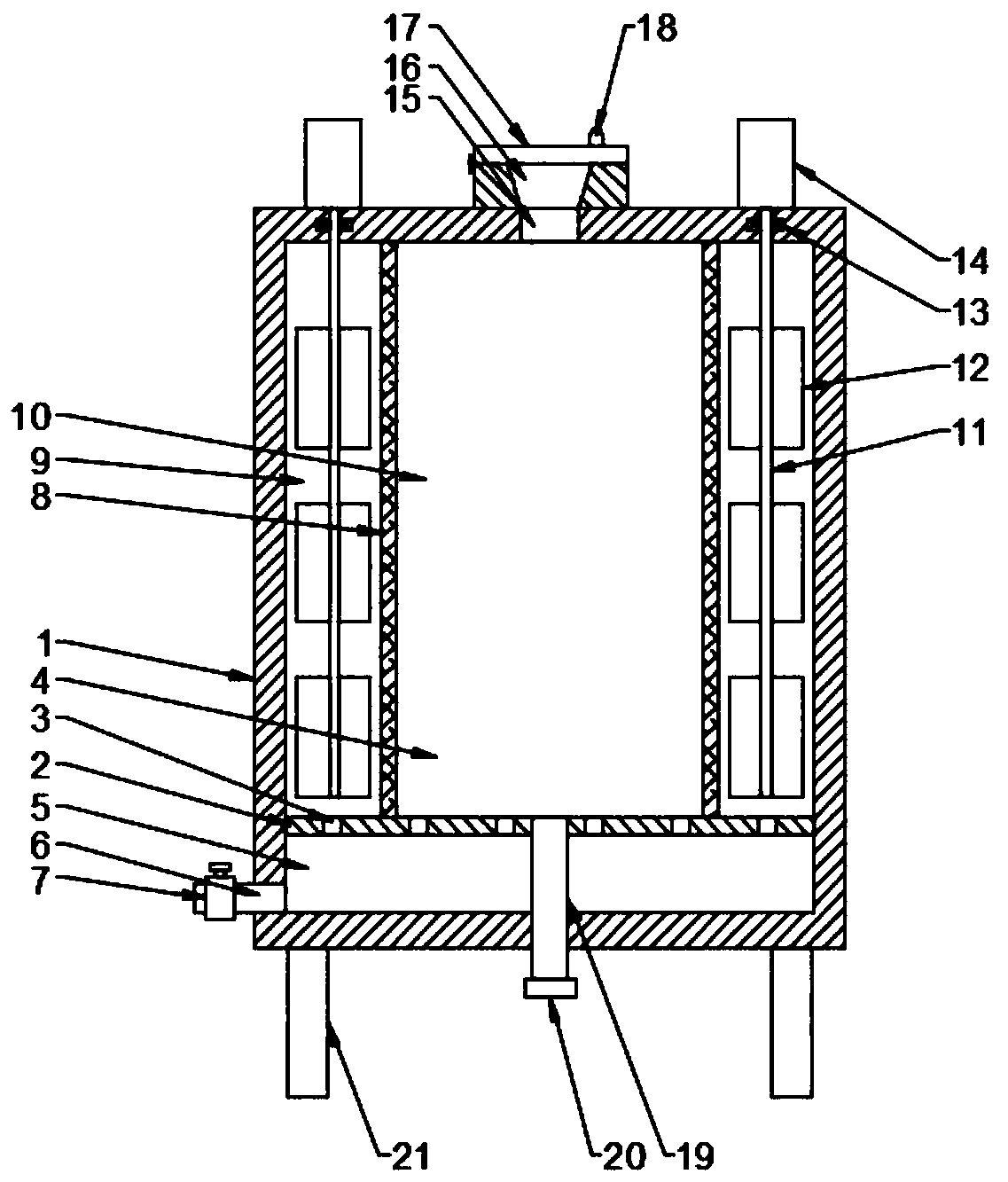

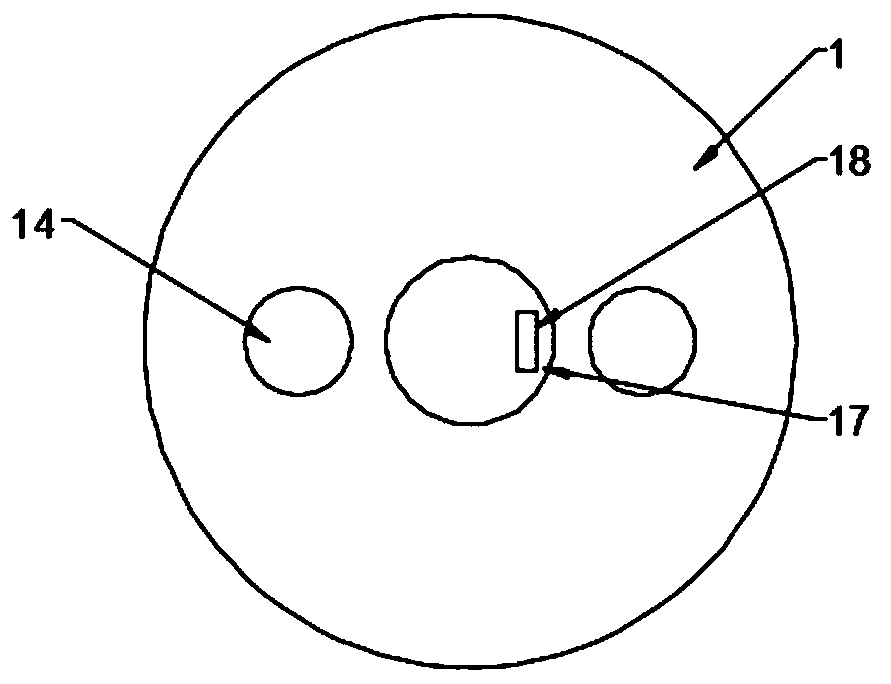

Bottom ring for combined type holder submerged-arc furnace

ActiveCN102006693ASolve the leakAvoid personal accidentsElectric discharge heatingWater channelQuenching

The invention relates to a bottom ring for a combined type holder submerged-arc furnace, belonging to a component of a submerged-arc furnace. The bottom ring comprises a body, a water channel in the body, a bottom ring water outlet pipe welded and communicated with the water channel and a water leading-out pipe communicated with the bottom ring water outlet pipe, wherein the outer side of the bottom ring is in the shape of a letter U. Thus, the invention basically solves the problems of protecting screen quenching and leakage as a result of poor high-temperature insulation and powder insulation, avoids personal injury, improves the operating rate and lowers the unit consumption.

Owner:江苏德诚冶金电炉设备有限公司

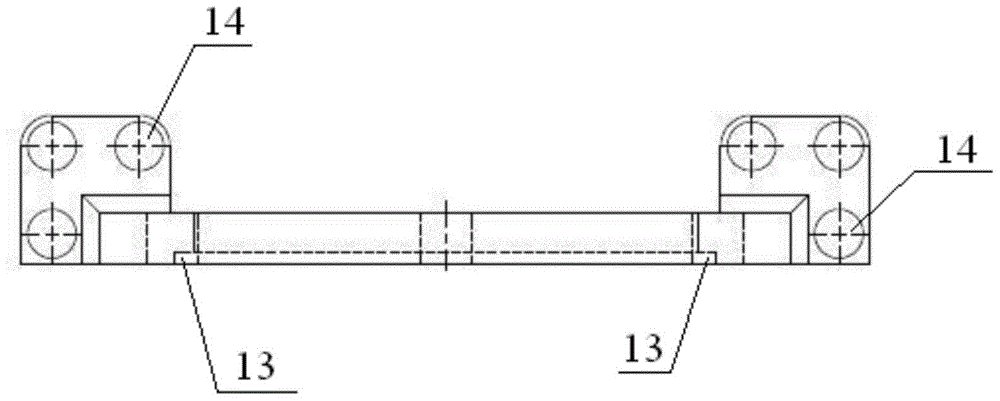

Part discharging roller machine

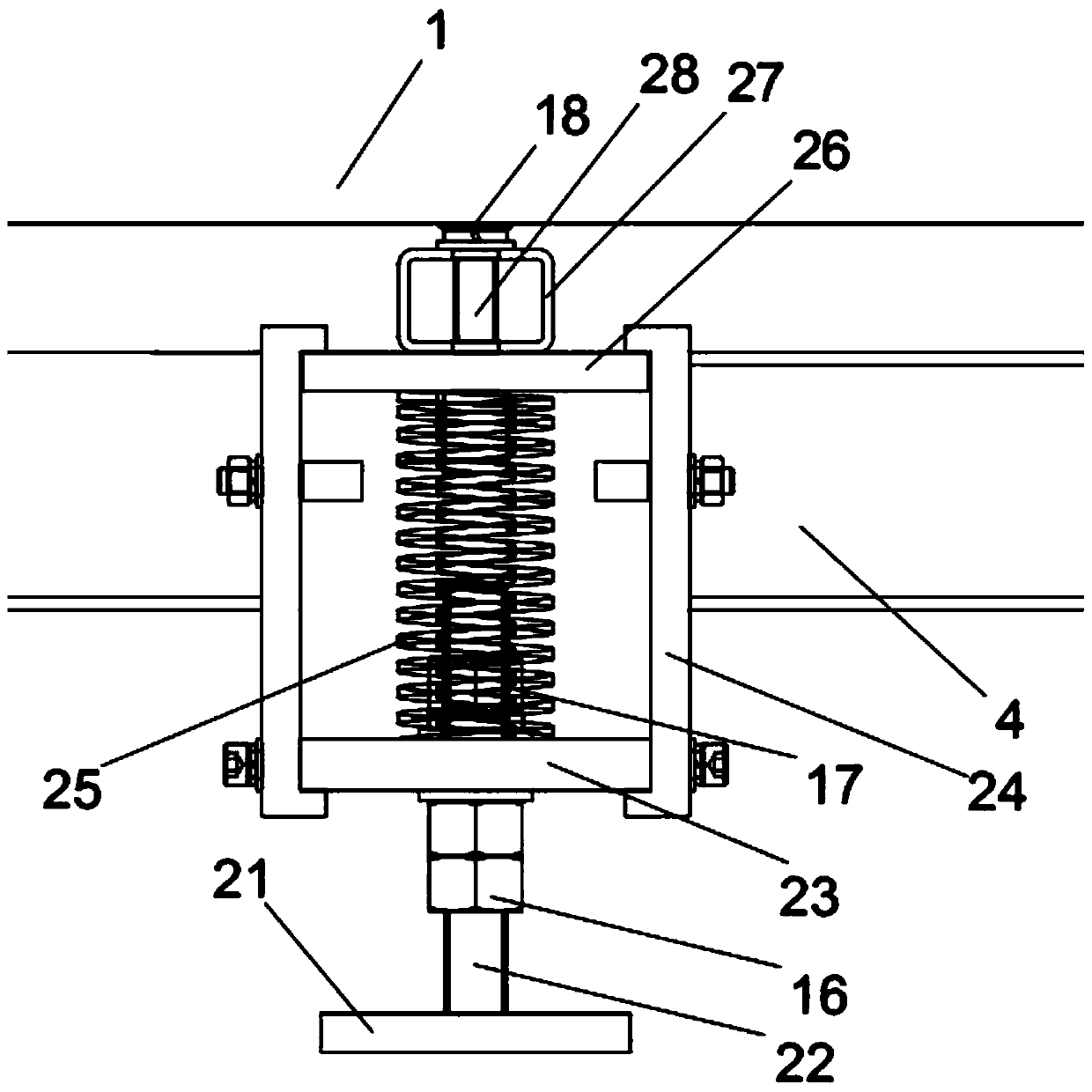

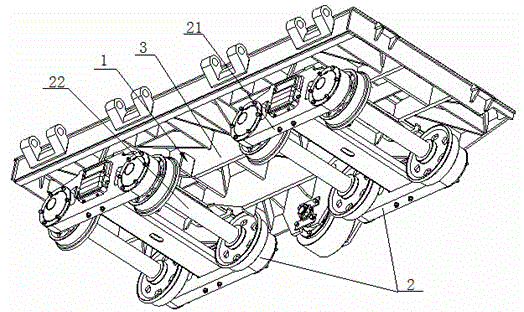

ActiveCN110316540AAvoid hard collisionImprove activation rateRollersRoller-waysDrive motorDevice failure

The invention provides a part discharging roller machine. The roller machine comprises a machine body and a frame, wherein a connecting guiding device is arranged at one end of the machine body, a plurality of guiding wheel devices are arranged on the two sides of the upper surface of the machine body, the frame is connected to the lower surface of the machine body through a plurality of connecting devices, one end of the frame is provided with a pair of supporting legs, the other end of the frame is provided with a pair of spring buffering devices, the machine body comprises a shell and a driving motor, wherein a plurality of rolling shafts arranged in parallel are arranged in the shell, a first rolling wheel and a second rolling wheel are arranged at the two ends of each rolling shaft, the first rolling wheels and the second rolling wheels protrude out of the surface of the shell, and the driving motor is in transmission connection with the rolling shafts and is arranged in the shell. According to the roller machine, through the arrangement of the spring buffering device, soft landing of a skid with a car body is realized in the transferring process, hard bumping between the skidwith the car body and a roller machine is avoided in the transferring process, therefore, the failure rate and the maintenance of the equipment are greatly reduced, the maintenance cost is saved, andthe starting rate of the whole line equipment is improved.

Owner:江苏长虹机械设计院有限公司 +1

Method for limiting and protecting wheel sets of 10m<3> underground mine cars

ActiveCN104476137AImprove activation rateEliminate hidden dangers of production lagArc welding apparatusWorkpiece edge portionsFlangeSteel plates

The invention relates to the field of technologies for limiting and protecting wheel sets of mine cars, in particular to a method for limiting and protecting wheel sets of 10m<3> underground mine cars. The method includes measuring the width-side distances from wheel flanges of the wheel sets of the mine cars to main girders at the bottoms of the mine cars to determine the widths of steel plates; abrading harmful substances by the aid of polishing machines; respectively welding the steel plates at certain positions of front groups of wheel sets and certain positions of rear groups of wheel sets. The certain positions of the front groups of wheel sets are flush with the main girders, and the certain positions of the rear groups of wheel sets are flushed with front main girders. The method has the advantages that road falling frequencies of the wheel sets of the 10m<3> mine cars at ore discharge stations can be effectively controlled after tempering heat-insulation is carried out, the flanges of the wheel sets instantly rub with the edges of the steel plates when the wheel sets are collided with steel rails and are reset, large-amplitude twisting spaces of the wheel sets can be controlled, accordingly, the mine cars can stably run, and stable and high yield purposes of enterprises can be assuredly achieved.

Owner:NANJING MEISHAN METALLURGY DEV

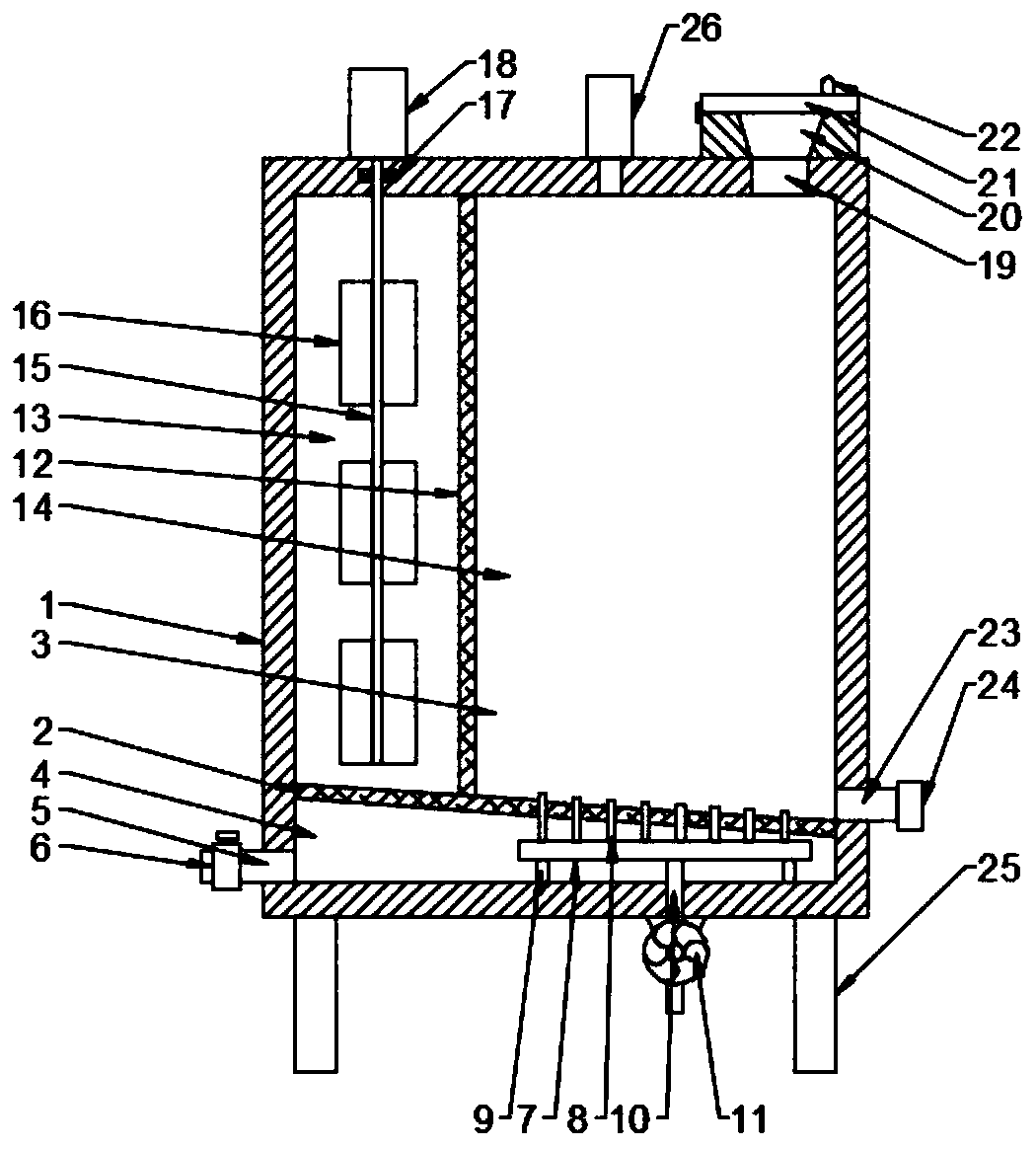

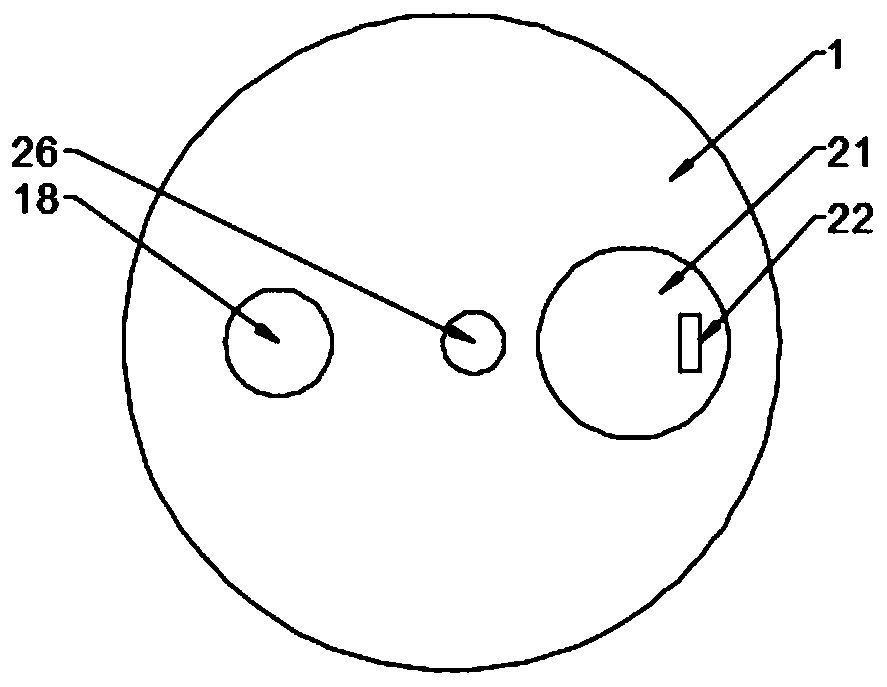

A wool cleaning device for animal husbandry based on bubble cleaning technology

ActiveCN108570714BImprove cleaning qualityEffective isolationWool fibre washing/scouringMotor driveEddy current

The invention discloses a wool washing device for animal husbandry based on a bubble washing technology. The wool washing device comprises a washing tank, wherein a first separation net is arranged atthe bottom of an inner cavity of the washing tank; the inner cavity of the washing tank is separated into a washing cavity and a draining cavity by the first separation net; an air injection device is arranged on one side of the bottom wall of the draining cavity; a plurality of air cocks are uniformly arranged at the top end of the air injection device; a second separation net is arranged on theleft side of the inner cavity of the washing cavity; the washing cavity is separated into a stirring cavity and a working cavity by the second separation net; a stirring rod is arranged in the stirring cavity; a plurality of stirring blades are uniformly arranged on the cylindrical surface of the stirring rod; a charging hole is formed in one side of the top end of the working cavity; the bottomend of one side end of the working cavity is connected with a discharging pipe in a penetrating manner; a plurality of supporting legs are uniformly arranged at the bottom end of the washing tank. According to the wool washing device disclosed by the invention, a motor drives the stirring rod to rotate at high speed for driving the stirring blades to rotate at high speed, thereby forming stirringeddy current with the stirring cavity as the center; the stirring eddy current directly acts on the working cavity by the second separation net; wood in the working cavity is stirred and impurities onthe wood are washed.

Owner:安徽省卓创信息科技服务有限公司

Industrial robot remote control method

ActiveCN102830677BWith remote diagnosis functionImprove management levelTotal factory controlProgramme total factory controlSimulationField device

The invention relates to a remote control method of an industrial robot, and is characterized by comprising the following steps: all KUKA robots on a production line and a criterion for a device, which conforms to a TCP / IP (Transmission Control Protocol / Internet Protocol) are connected through network cables, an original registry of the robots is modified, and configurations of the KUKA robots are changed; a computer 1 is provided with a DameWare remote control software server, and each KUKA robot is provided with a DameWare client software, through a remote training function of the robot, the computer 1 connected with the robot and a computer 2 connected to a projector in a training room are connected to an Internet network, and the KUKA robots on the production line are subjected to remote diagnosis through Internet. According to the invention, the fault handling time is saved, and a remote control function is realized; meanwhile, dependency of the robot training on a field device is solved, a field interface of the robot is shown through the network and is connected to the projector so as to carry out large-scale targeted training and provide convenience for optimization and adjustment of a usual welding process.

Owner:CHINA FIRST AUTOMOBILE

A wool cleaning device for animal husbandry based on vortex extrusion cleaning technology

ActiveCN108588850BAvoid entanglementEasy to cleanWool fibre washing/scouringWater flowElectric machinery

The invention discloses a wool cleaning device based on a vortex extrusion cleaning technology for the animal husbandry. The wool cleaning device comprises a cleaning box, wherein a partition is arranged at the bottom of an inner chamber of the cleaning box and divides the inner chamber of the cleaning box into a cleaning chamber and a draining chamber; a plurality of separation nets are arrangeduniformly at the edge of the cleaning chamber and divide the cleaning chamber into a working chamber and a plurality of stirring chambers; a stirring rod is arranged in each stirring chamber, and a plurality of stirring blades are uniformly arranged on the excircle surface of the stirring rod; a feeding hole is formed in the top end of the working chamber, the bottom end of the working chamber isin penetration connection with a discharging pipe, the other end of the discharging pipe penetrates the draining chamber and is sleeved with a seal cover, and a plurality of support legs are uniformlyarranged on the bottom end surface of the cleaning box. The stirring rods are driven by a motor to rotate at a high speed and then drive the stirring blades to stir water flow, stirring vortexes areformed with the stirring chambers as the center and act on inside of the working chamber under the action of the separation nets, and the multiple stirring vortexes stir and clean wool in the workingchamber jointly, so that the cleaning effect and the cleaning quality are improved substantially.

Owner:重庆市亿柘农业开发有限公司

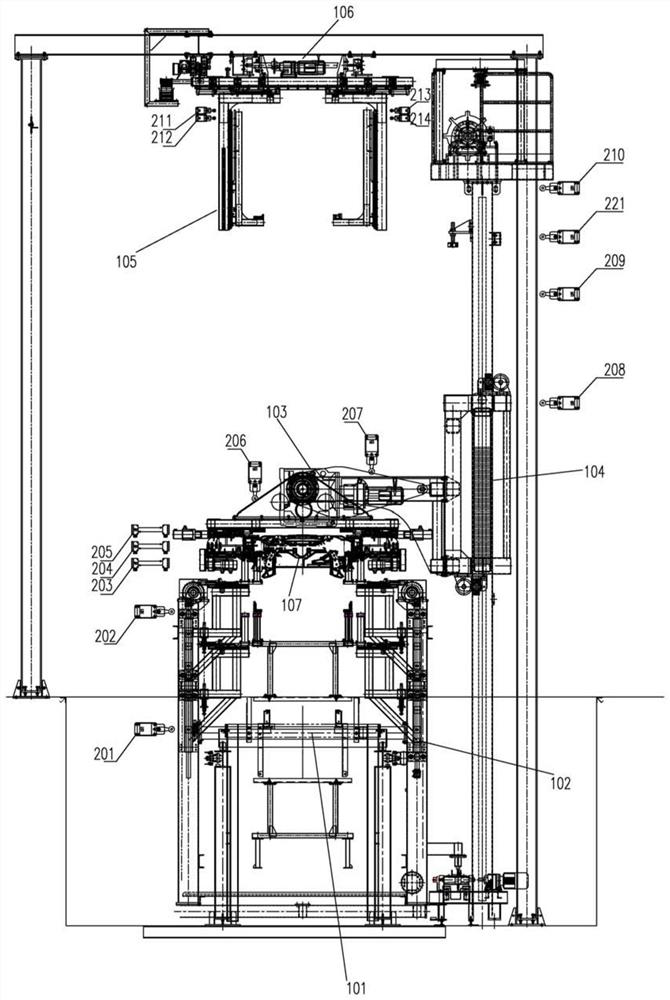

Automatic control system for vehicle frame overturning

PendingCN112125140AEasy to controlHigh degree of automationBase supporting structuresBraking devices for hoisting equipmentsVehicle frameAutomatic control

The invention provides an automatic control system for vehicle frame overturning. The system comprises a jacking mechanism descending in-place sensor, a jacking mechanism ascending in-place sensor, avehicle frame conveying equipment vehicle body detection sensor, an overturning mechanism overturning in-place sensor, an overturning mechanism in-situ detection sensor, a lifting mechanism descendingin-place sensor, a lifting mechanism overturning position sensor, a lifting mechanism ascending in-place sensor, a lifting mechanism unlocking position sensor, a left lifting appliance opening and closing mechanism opening in-place sensor, a left lifting appliance opening and closing mechanism closing in-place sensor, a right lifting appliance opening and closing mechanism opening in-place sensor, a right lifting appliance opening and closing mechanism closing in-place sensor, a left servo electric cylinder in-situ sensor, a right servo electric cylinder in-situ sensor, a left clamping air cylinder clamping in-place sensor, a left clamping air cylinder loosening in-place sensor, a right clamping air cylinder clamping in-place sensor, and a right clamping air cylinder loosening in-place sensor. The system can enable a vehicle frame overturning machine to achieve automatic overturning of vehicle frames of different vehicle models, and improve the production takt of equipment.

Owner:MIRACLE AUTOMATION ENG CO LTD

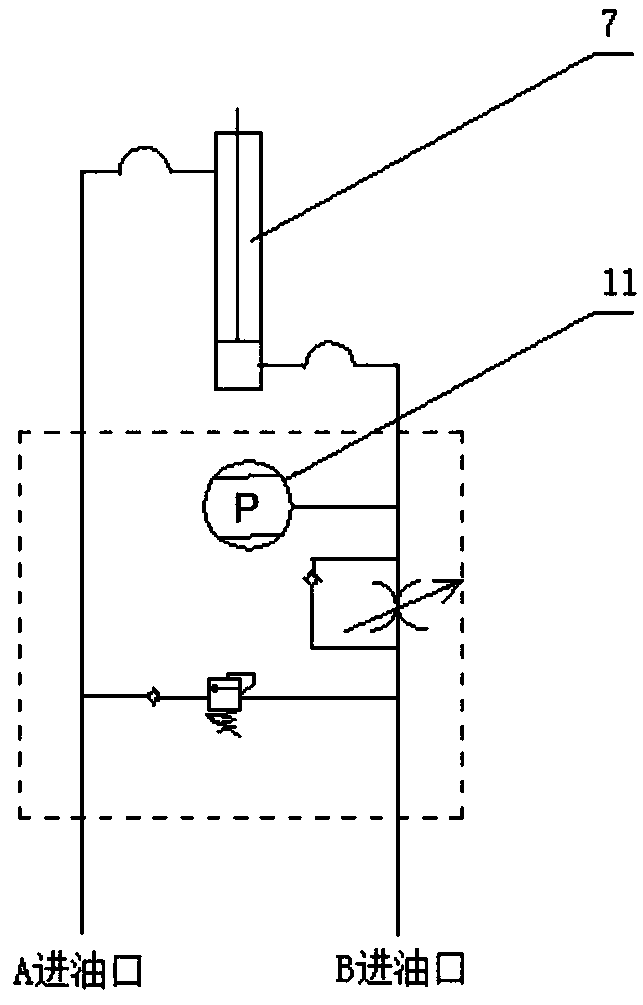

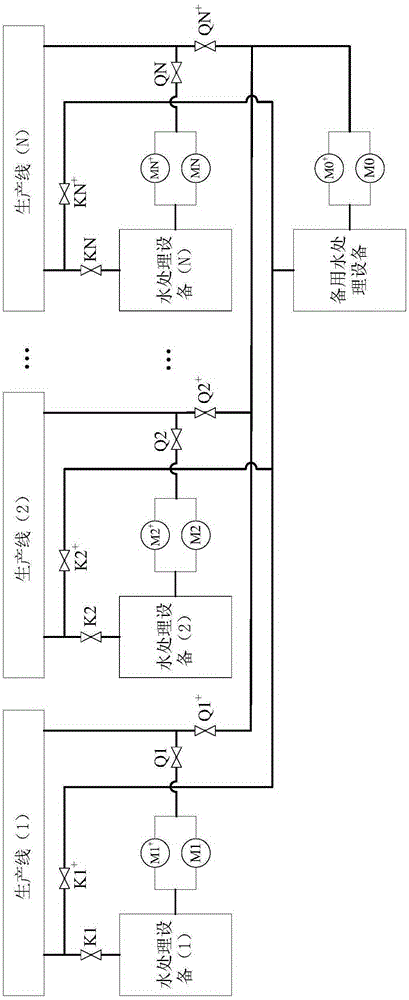

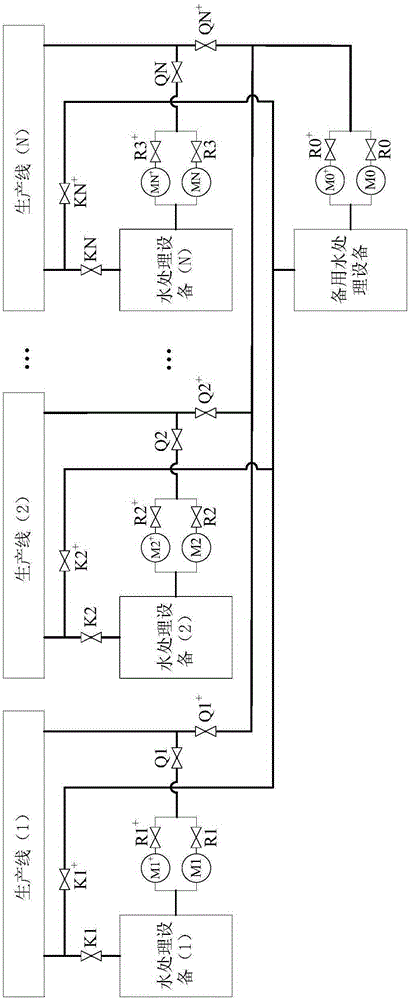

water treatment system

ActiveCN104129822BAvoid downtimeImprove activation rateWater/sewage treatmentProduction lineWater treatment system

The invention discloses a water treatment system comprising N pieces of water treatment equipment, water outlet pipelines, water return pipelines, water outlet valves, water return valves and working pumps, wherein the N pieces of water treatment equipment are applied to N production lines one to one; the water outlet pipelines are used for respectively connecting each piece of water treatment equipment with each production line; the water return pipelines are used for respectively connecting each piece of water treatment equipment with each production line; the water outlet valves are respectively arranged on each water outlet pipeline; the water return valves are respectively arranged on each water return pipeline; the working pumps are respectively arranged at the water outlet of each piece of water treatment equipment. In addition, the water treatment system comprises standby water treatment equipment, water outlet pipelines, water return pipelines, water outlet valves, water return valves and a working pump, wherein the water outlet pipelines are used for respectively connecting the standby water treatment equipment with the N production lines; the water return pipelines are used for respectively connecting the standby water treatment equipment with the N production lines; the water outlet valves are respectively arranged on each water outlet pipeline; the water return valves are respectively arranged on each water return pipeline; the working pump is arranged at the water outlet of the standby water treatment equipment; N is larger than or equal to 1. Therefore, the condition of whole production line shutdown caused by water treatment equipment halt for changing water is avoided.

Owner:SHANDONG JINYU INDUSTRIAL CO LTD

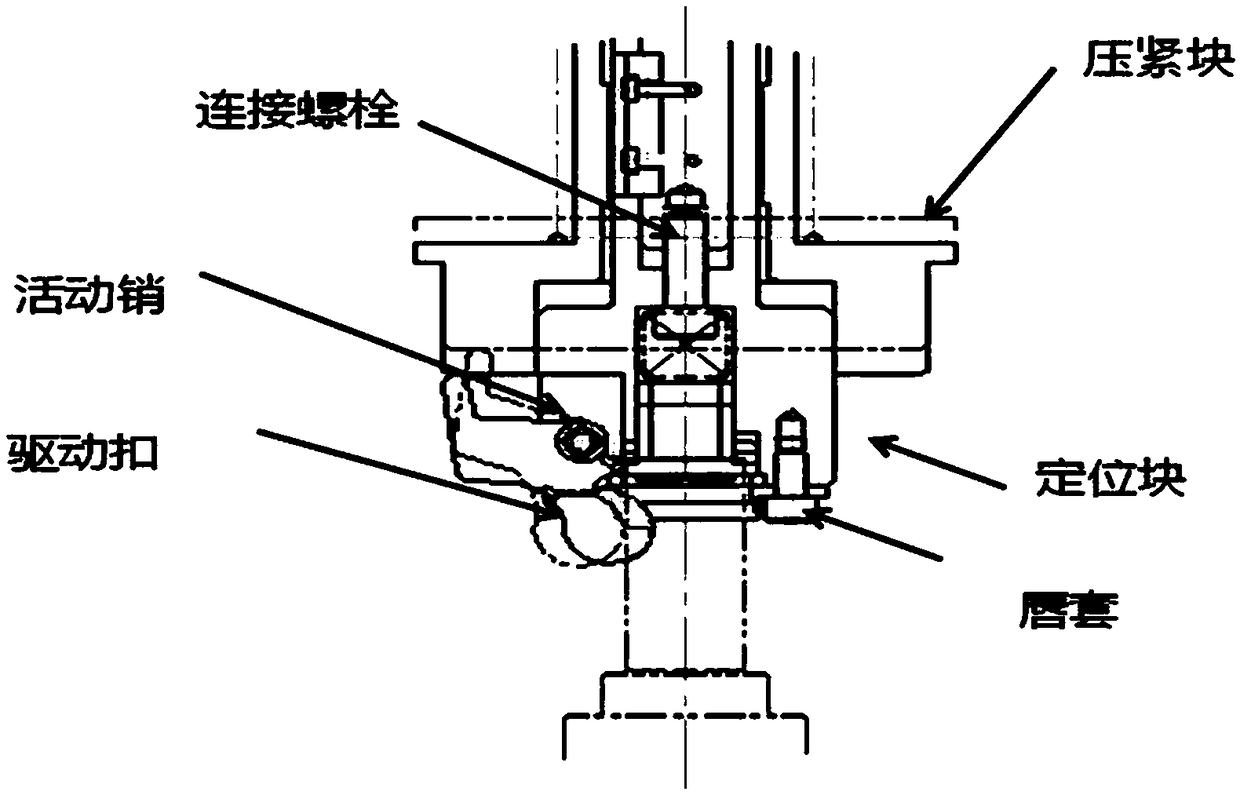

Engine assembling rotation force driving mechanism

PendingCN108340136ASimple structureEasy to processMetal working apparatusEngineeringMechanical engineering

The invention provides an engine assembling rotation force driving device. A driving buckle, a movable pin, an elastic device, a shell and a driving arm are adopted. The driving buckle, the movable pin and the elastic device are arranged on the driving arm. The driving arm is arranged in the shell. The structure that the driving arm is connected with the shell through the movable pin and the elastic device, the technical problems that in the prior art, driving mechanisms are liable to be jammed and are complex, and lateral force supporting of the two sides of driving buckles are insufficient are solved, and the technical effects that the mechanism is simple in structure and convenient to machine, the jamming phenomenon is almost avoided, the lateral force protection function is additionally achieved on a driving part, and the effect of offsetting lateral force in the rotation process is achieved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

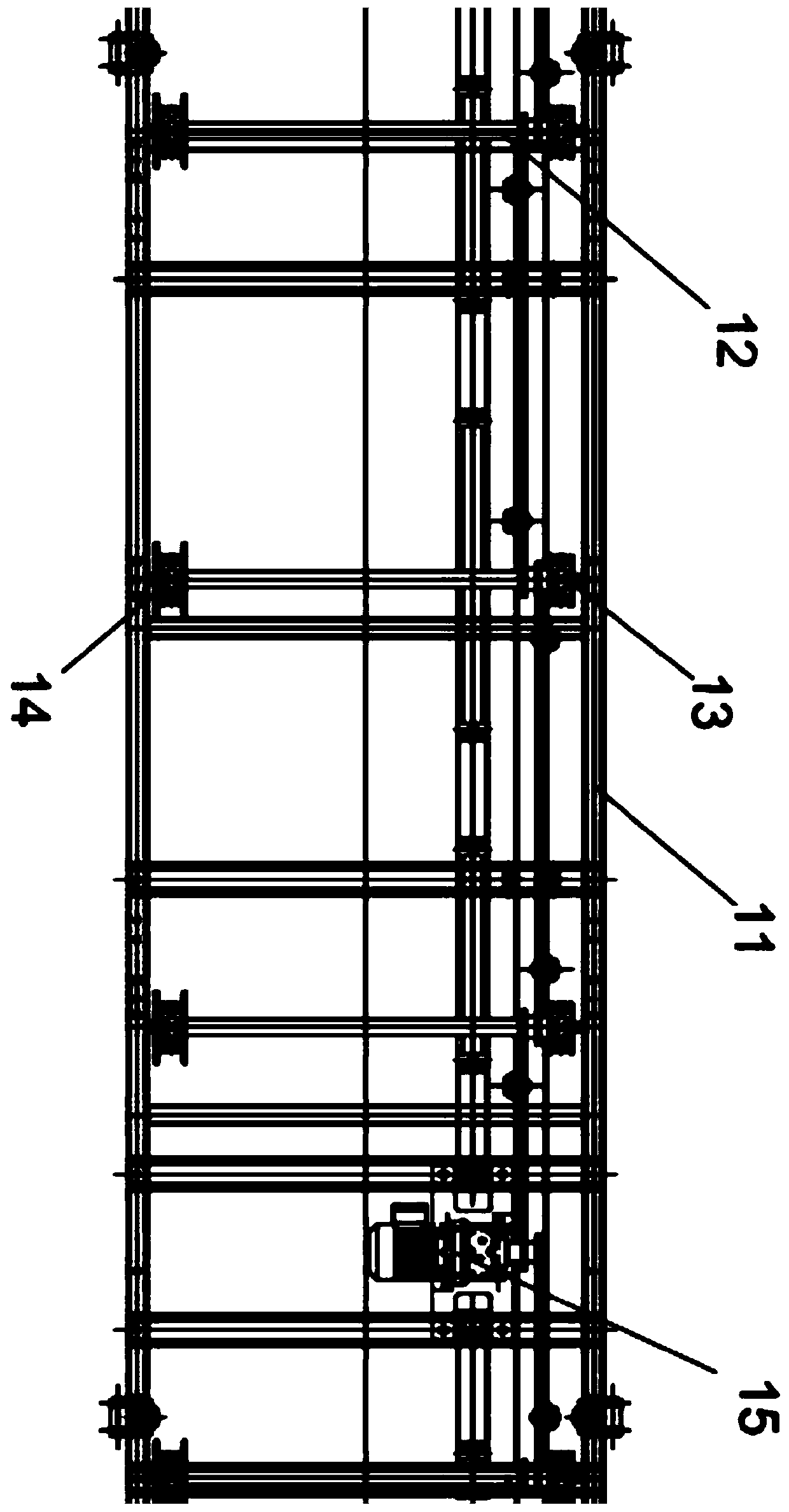

Production line scheduling system and method for hybrid production of car powertrain components

ActiveCN109352412BSmall footprintSimple structureMetal working apparatusMaterial resourcesPowertrain

The invention provides a production line dispatching system and method for mixed line production of car power assembly parts. The system comprises a production line module, a control module, a transfer module and a storage module; the production line module is a mixed line module, comprises a plurality of production lines, and is used for processing workpieces to be produced into finished workpieces; and the control module can match the production process flow based on the category information of the workpieces to be produced. The structure is simple and few components are required; and by arranging an information identification part, automated, unmanned and intelligent processing is achieved in the whole process, so that space, manpower, material resources and input are greatly saved; inaddition, the dispatching system and method can effectively adjust beat and balance production capacity, and provide a verification platform for equipment, the process and the whole line; and mixed line processing can greatly shorten the waiting time and improve the comprehensive starting rate of the equipment.

Owner:SHANGHAI SMARTSTATE TECH CO LTD

A knitting machine based on the technology of preventing knitting thread breakage

ActiveCN111979637BPrevent breakageImprove activation rateWeft knittingWarp knittingElectric machineryStructural engineering

The invention discloses a knitting machine based on the technology of preventing knitting thread breakage, which includes a machine board, a number of outrigger assemblies are uniformly arranged at the bottom end of the machine board, a stand and several wire roller frame assemblies are arranged at the top of the machine board, and the wire Wire rollers are installed on the roller frame assembly; the top of the stand is fixedly connected to the lifting motor, and the side end of the stand close to the wire roller frame assembly is fixedly connected to the knitting box. The front and rear walls of the cavity are uniformly provided with several guide rails, and a screw is provided between all the guide rails, and a lifting plate that is respectively matched with the guide rails and the thread roller frame assembly is set on the screw; the knitting thread on the center thread roller of the present invention moves The end passes through the guide hole through the first guide assembly and enters the knitting box through the wire inlet wheel for processing; by setting the first guide assembly exclusively for guiding the knitting thread, it can effectively prevent the knitting thread from breaking, thereby ensuring the stable operation of the entire device; It can greatly increase the operating rate of the entire device.

Owner:汕头市澄海区瑞胜毛织有限公司

Docking connector for four-quarter detachable Haval card

ActiveCN104078775BReduce maintenance costsShorten maintenance timeClamped/spring connectionsConnection contact member materialEngineeringMechanical engineering

The invention discloses a butt connector of a four-quarter detachable Haval card, which is used for butt-connecting the end faces of two pipes, which includes: a first clamping for clamping the side of the first pipe to be butted a second clamping piece for clamping the side of the second pipe to be butted; and for connecting the first clamping piece and the second clamping piece so that the end face of the first pipe piece and the The end face of the second pipe member is butt-connected with the locking member. The present invention realizes the direct contact of the end faces of the two pipe fittings through the above technical proposal, and the contact is firm.

Owner:DAYE SPECIAL STEEL CO LTD

A multi-purpose automatic oxidation line with replaceable tank body

ActiveCN105696044BAchieve replacementImprove oxidation efficiencySlide fastenersSurface reaction electrolytic coatingDrive shaftEngineering

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

Whole machine paint spraying process of diesel engine

ActiveCN103230863BImprove adhesionImprove activation ratePretreated surfacesCoatingsProduction lineDieseling

Owner:CHINA FIRST AUTOMOBILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com